Insulating a wooden house from the outside with polystyrene foam is a very common occurrence. This thermal insulation material has both many advantages and some disadvantages that limit its use as insulation. Among professional builders, debates about the possibility of using polystyrene foam in a wooden house continue. Due to the high flammability of this material, many experts do not recommend using it for thermal insulation of wooden structures. In this article we will take a detailed look at the characteristics of the material and try to figure out how safe it is to use it as insulation. You will also learn how to properly cover a wooden house with foam plastic.

What is this building material?

First, let's figure out what polystyrene foam is? Knowledgeable people sometimes call it expanded polystyrene. This material, which is often used in construction for insulating houses, is a plastic mass.

These masses are usually filled with gas or air. The most common type is foamed polystyrene. The dimensions of the foam do not exceed 15 millimeters. Polystyrene foam contains 2% polymer, the rest of the space is filled with air.

The material is made from polymer under high pressure and using a gas generator, due to which it has a high density. High sound and thermal insulation are the distinctive features of this material, which is why it is so popular in construction.

Foam plastic or mineral wool: what is better for insulation?

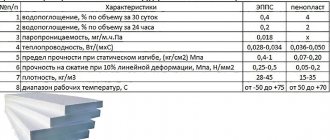

Developers and installers argue about how to cover the outside of a house - foam plastic or mineral wool. Mineral wool has a vapor permeability rate that is 10 times higher. According to practice, walls are insulated in several layers using different materials, on which the final vapor permeability depends.

With a polymer structure of the insulation system, mineral wool is not recommended. This is explained by the fact that the outer layer is made of a polymer that does not allow moisture to pass through well. If condensation gets inside, the mineral wool becomes saturated with it, which will lead to loss of thermal insulation properties. Polystyrene foam is not capable of transmitting or accumulating steam.

Mineral wool is not capable of ignition when exposed to high temperatures, therefore, from a fire safety point of view, it is recommended to give preference to it. When using expanded polystyrene, it is treated with fire retardants, which reduces the possibility of fire spreading. During the operation of the building after insulation with polystyrene foam, it is recommended to follow fire safety precautions. Expanded polystyrene ideally resists heat loss, and mineral wool allows it to pass out. From an environmental point of view, polystyrene foam for heating the outside of a house is a safe material.

Mineral wool and polystyrene foam have their advantages and disadvantages, so the choice is made based on the operating characteristics of the building and the financial capabilities of the user.

Polystyrene foam is a material with insulating properties that is used indoors and outdoors. When using the material, it is recommended to take into account its features and technical characteristics, which will extend its service life.

The advantages of this insulation

What are the main advantages of insulation with this particular material? Several points can be highlighted here.

The first is, as mentioned above, high thermal insulation. Polystyrene foam is made using gas, which allows it to maintain the optimal temperature in the house.

The second is environmental friendliness. The material does not contain toxic substances, but only if the manufacturer did not use heat treatment during production.

The next advantage is high moisture resistance. This material does not retain moisture or accumulate it, that is, when insulating, dampness or the possibility of mold appearing is completely eliminated.

The fourth advantage is ease. The lightness of foam plastic greatly simplifies the insulation process, since the material can be easily cut or sawn.

And the last thing I would like to note is accessibility. The cost of this material is not high, absolutely anyone can afford it.

How to deal with slopes

Thermal insulation of house slopes is also important for comprehensive insulation. In some situations, it’s even worth starting with the windows, and only then insulating the walls. When choosing insulation for windows, do not forget that there will still be a layer of finishing on it, and all this thickness should not interfere with the operation of the window. Where the slope insulation connects to the wall insulation, you just need to cut off the first one.

When everything is ready, the walls and slopes are insulated, you can choose whether to line the wall with clapboard, more modern siding, or simply plaster the house.

Both lining and siding require the installation of additional slats, which are nailed to the ends of the sheathing slats directly onto the membrane. The strips of siding or lining themselves are attached to these mounting rails.

To plaster the walls, an adhesive composition should be applied to the insulation, a reinforcing mesh should be placed in it, and then the entire structure should be allowed to dry. We level and clean the surface, apply the finishing touch.

Now you know how to insulate a house with polystyrene foam. Remember that each case has its own optimal solution, and you will definitely have your own opinion and answer to the question whether it is possible to insulate a wooden house with foam plastic from the outside. Considering that thousands of home owners in our country have insulated and will continue to insulate their homes with polystyrene foam, we can conclude that this method has the right to life. Don't forget to install good ventilation and don't freeze in your wooden house in winter!

Designation of foam plastic and types existing on the market

Many beginners come across different letters when comparing this material and do not know what they mean. These letters are a type of foam. Usually, it is marked as “PS”, then other letters and numbers are added depending on the type. There are several types of foam on sale.

The first type is non-press, it is manufactured without pressure. The granules are dried and foamed, and the process is repeated several times. The output of this material is more voluminous, airy, and the cost is much cheaper than the others.

The next type is extruded. It is made using a forming hole and the material is passed through it. This foam is completely waterproof.

The third type of foam is pressed foam, it is made by pressing. The material turns out to be more dense, but this does not make its thermal insulation higher. Pressed foam is not popular, since the market price for it is higher than that of non-pressed foam, but at the same time it is almost no different.

The last type found on sale is autoclave. It is produced by one American company, there is no additional information about it.

Advantages and disadvantages

Each method has advantages and disadvantages.

Frameless method

The frameless installation method involves finishing the wall with plaster. This is due to the need:

- To “ennoble” the appearance of the building - white sheets of foam plastic with visible dowel heads and foamed joints create the impression of unfinished construction.

- Expanded polystyrene of any brand is susceptible to destruction under the influence of ultraviolet radiation; an opaque “covering” material is used for protection.

- The structure of polystyrene foam does not allow it to effectively withstand destructive mechanical influences.

Advantages of the method:

- Minimum number of technological operations.

- Short lead times.

- Long service life.

The advantages are slightly offset by the difficulties that may arise for a master who does not have plastering skills:

- Additional costs for skilled labor.

- Finishing must begin immediately after installing the insulation and finish as quickly as possible, minimizing the time the foam is exposed to the sun.

Frame insulation option

The method involves preliminary installation of a frame on the walls of the building, with insulation installed between the joists. The finishing trim is attached to the sheathing.

Wireframe method:

- Suitable for using foam with a density of 15 kg/m3.

- Saves building materials for fastening the sheathing.

- Available for beginners and inexperienced craftsmen.

- External finishing and a layer of waterproofing reliably protects thermal insulation from mechanical damage and weather conditions.

Drawing. Insulation using frame method.

Foam depending on density

When insulating a wooden house with polystyrene foam, it is important to choose it wisely. The material is also distinguished by density.

- PSB-15 is the lowest density. It is used when strength is not required. This type of foam is used in insulating carriages, attics and attics.

- The most popular type is PSB-12, it is found most often on the market. This material is universal and is used for insulating walls, floors and facades. A big advantage of this type is also its high sound insulation.

- The third type is PSB-35. You can guess that this is high-density foam. This type is used for insulating foundations or, for example, underground structures.

- The final look is PSB-50. This material has the highest density and is used, for example, in road construction or in industry.

Which polystyrene foam should I choose?

Experts say that it is better to insulate a wooden house from the outside with polystyrene foam, which has a low density. This does not affect thermal conductivity. This material is light in weight. Its compressive strength when deformed is up to 10 percent, which guarantees its resistance to fractures. It is recommended to use insulation that has a thermal conductivity of up to 0.042 W/mK.

Recommendations for selecting polystyrene foam

Thickness is the main and most important criterion when choosing polystyrene foam, and here you cannot be guided by the rule that the thicker the insulation, the longer it will last. After all, if the material is thick, there is a possibility that the material inside will begin to bulge when the temperature changes.

Indeed, it is important to take into account the density of the material, as well as manufacturing standards (when purchasing, look carefully at the fault line, it must be correct), it is worth choosing well-known manufacturers.

Disadvantages of polystyrene foam

Expanded polystyrene is a fire hazardous material. It is damaged by rodents that make moves, which speeds up the process of its disintegration.

Fragility or service life

The average service life of insulation is 10-15 years, subject to proper installation and processing.

Mold and mildew

When heated to more than 70 degrees, a loss of the structural properties of the material is observed. Polystyrene foam has low vapor permeability, which leads to dampness and rotting of the wood. Over time, mold and mildew spread on the tree.

Release of harmful impurities

The disadvantages of the heater include instability to combustion, during which toxins dangerous to humans are released. Therefore, when choosing expanded polystyrene, pre-fire retardant treatment is carried out and fire safety rules are observed during the operation of the building.

Preparing walls for insulation

You can’t just go ahead and start attaching polystyrene foam to the walls. A special insulation technology was invented a long time ago; it is quite simple. For insulation with this material, a special construction adhesive is used.

It can be purchased in “build. materials." Just like tile adhesive, it is sold in powder form, which must be diluted with water. This glue provides excellent “adhesion” of the foam to the wall.

If the surface is perfectly flat, then you should apply the adhesive mass as thinly as possible. Thin application should be both on the foam and on the wall.

In order not to “accidentally” waste all the glue at the very beginning of work, you can run a comb over these layers. After this, lean the foam against the wall, press and hold until it “sticks” completely.

If the surface is not smooth, then the application principle is different. The glue should be applied to the surface in small sheets, as well as along the boundaries of the wall and the material. For optimal fixation, you also need to apply glue to the existing recesses.

The insulation is glued onto the wall in a strict order, like on a chessboard, and after installation it is secured with special mushrooms. Here you will need a hammer drill to make holes and install the mushrooms. They are also attached in several ways: along the edges and at the joints.

It's all about vapor permeability

To prevent the wood of the walls from rotting after insulation, it is required that the “dew point” - the point where water vapor turns into water - does not fall on the surface or body of the wooden wall. If this happens, the tree will rot. That is, having made a calculation using a calculator, the walls of a house in the Moscow region have the following structure:

- Beam made of pine or spruce wood, across the grain - 250 mm.

- Insulation – polystyrene concrete slab PPS FG15–80 mm.

- Moisture-windproof membrane – 0.1 mm.

- The air gap is 40 mm.

- Plank cladding (similar to a ventilated façade).

We find that the wall satisfies all thermal requirements, and there are no conditions for the formation of condensation. No condensation means no rotting, which means insulation with polystyrene foam followed by finishing with plank or clapboard, walls of this design are possible.

Second option: we have a house in the Moscow region made of Ø 250 mm logs, insulated using a plaster system:

- Pine or spruce log working thickness – 150 mm.

- Closed air gap (due to rounding of the log) -50 mm.

- Insulation – polystyrene concrete PPS F 20–50 mm.

- Finishing layer – mineral plaster – 8 mm.

In this case, there is 100% humidity inside the structure and rotting of the wall is inevitable. This can only be prevented by increasing the thickness of the insulation.

As can be seen from these calculation examples, external insulation of a wooden house with polystyrene foam is possible, but requires a balanced approach, and a thermal insulation thickness of 50 mm for a log frame Ø 250 mm with a working thickness of 150 mm is clearly not enough if you want your house to last longer after insulation. 5-8 years. A person who claims otherwise is a mythmaker.

From a functionality point of view, foam insulation works better when subsequently facing using a ventilated façade system rather than using plaster systems. This is due to the fact that layers of materials, as they approach the outside air, must have greater vapor permeability.

The vapor permeability of moisture and windproof membranes is higher than that of adhesive and finishing layers of plaster materials, and the air layer and cladding provide a 100% release of water vapor.

Frameless and frame methods of insulation

There are several methods of insulation - frameless and frame. What is their difference? The first one differs in that when insulating, the foam is mounted close to the wall.

All surfaces are treated in a certain sequence so that the insulation adheres better. The frame method of insulation differs in that processing is required only where the guide bars will be installed.

Stages of do-it-yourself foam insulation work

Before starting work, the walls of a timber house must be treated with antiseptic compounds.

- To install a ventilated facade, it is necessary to make a vertical sheathing. To do this, wooden boards are nailed to the walls so that the insulation fits as tightly as possible, the distance between them is 5-8 mm less than the width of the boards.

- A vapor barrier film is stapled onto the top of the sheathing.

- Counter-lattice slats are placed on the vapor barrier, which serves to create a ventilation gap between the wall and the insulation.

- Foam plastic is placed between the racks, which should fit tightly to the slats. The gaps between the plates must be filled with foam.

- A diffuse membrane is laid on top of the insulation. The smooth side of the material should face the wall. The membrane ensures good air circulation and removal of excess moisture from the house.

- The joints between the sheets are taped with adhesive tape.

- The last stage is cladding with decorative material. Siding, facade panels, lining, etc. can be used as finishing.

When externally insulating a log house with polystyrene foam, which due to the natural roundness of the logs has uneven walls, a two-layer sheathing is made. To do this, first install vertical posts, and then, after laying thermal insulation boards in them, they are additionally secured with horizontal guides. This fastening ensures a tighter fit of the insulation and makes the structure even more reliable.

When thermally insulating a log house, there is no need to install a counter-lattice, since a natural air gap is created between the logs and the insulation.

Technological difference between internal and external wall decoration

Most often, interior wall finishing is done using wet technology, that is, using glue. To save space inside the house, you should not use an additional frame or anything else. The stages of work are as follows:

- Surface preparation and adhesive application.

- Installation of foam plastic boards and blowing out the joints between them.

- Applying the base layer of plaster.

- Applying the final layer of plaster.

Exterior finishing is also done using wet technology in most cases. There is almost no difference between them. External installation differs only in some details and the number of work processes. An insulating film is used here, since external factors act on the foam from the outside. Stages of work:

- Cleaning the base and priming it.

- Installation of the base profile.

- Layout of insulation placement and “fitting” on glue.

- Eliminate gaps with foam and fix them with dowels.

- Attaching the waterproofing film.

- Applying the first layer of plaster.

- Reapplying a layer of plaster.

- Final application of the third layer of plaster.

- Decorative finishing upon request.

Preparatory work

For high-quality results, it is recommended to carry out work in the warm season. Dry, hot weather would be ideal. At higher temperatures, the walls dry deeply, which prevents moisture from penetrating inside.

Before starting work, you need to prepare the necessary materials and tools:

- antifungal primer;

- polyurethane foam;

- wooden slats;

- vapor barrier film;

- stapler;

- mushroom dowels;

- diffusion membrane;

- duct tape;

- glue;

- reinforcing mesh;

- finishing materials.

Necessary materials for insulating a wooden house

When preparing walls for insulation with foam plastic, the surfaces are thoroughly cleaned from the outside of dirt, paint and varnish, and any gaps found in the cracks of the logs are eliminated using polyurethane foam. It is advisable to coat the walls with an antifungal primer. Window drains are attached to wooden or plastic windows prior to the installation process. To do this, they are foamed from below and pressed down with a small weight for several hours.

Technology of insulating the facade of a house with polystyrene foam

Insulation of the house must be carried out in strict accordance with technology. It can be divided into several stages. If you insulate a house using polystyrene foam and strictly follow the instructions, you can ensure the durability of the material and maintain the desired properties.

Initial stage: preparation for insulation

Prepare everything you need for free access to the walls of the house. You will need a stepladder and scaffolding if the house is high. Check that you have all the necessary tools and building materials. Make sure the wall is clean and free of mechanical damage. Remove dirt and dust. Also check the evenness of the insulated surface. Differences in plane level should not be more than 50 mm.

Padding

You will need a deep penetration mixture. Priming can be done using a brush, roller or spray. The mixture is chosen at your discretion; you can consult a hardware store. Do not prime if the wall is wet.

Installation of beacons

Beacons are important to eliminate the slightest deviations during installation. Stretch the beating cords from one corner of the wall to the other. Take into account the distance from the surface to be finished (thickness of insulation, adhesive material). The sheets will have to be laid alternately in rows in accordance with the markings.

Preparing the adhesive

The adhesive solution is prepared in a very simple way. Add the adhesive to the water and mix thoroughly. Do this in a small container. Mix until you get a homogeneous mass of creamy consistency. A solution that is too liquid will not adhere well to the foam, which may move away from the surface, and the insulation will be ineffective.

Installing sheets

We warn you: do insulation and install foam only in dry weather, preferably without wind. Otherwise, the adhesive will lose its properties. Installation will be completed correctly if you follow these recommendations:

- Apply adhesive to the surface of the foam board. This is done over the entire surface with small tubercles. This provides a better joint, especially if the wall surface is uneven.

- We remind you about beacons: lay out the slabs in strict accordance with the markings.

- If gaps form, use polyurethane foam.

- The slabs of the second row are laid offset relative to the first.

- For a better joint between adjacent panels, make overlaps in the corners of the structure and in the places of slopes.

- Install thinner sheets on the south side of the house, thicker ones on the north.

After carrying out these procedures, wait until the glue hardens. After 1–3 days, you can begin further, no less important actions.

Fixing foam

The durability of the insulation will be ensured with additional mechanical fastening. This is done with the help of fungi. Their length is calculated as follows: thickness of the foam layer + thickness of the adhesive layer + 40 mm. This is done like this:

- We make a recess using a hammer drill in the places where the fungus is installed.

- We install the fungi until the cap touches the surface of the foam.

- We hammer a nail into the technological hole.

Wherein:

- Use fungi with metal nails.

- Each sheet is fixed in 5 places (along the perimeter, in the center).

- It is advisable to recess the cap into the foam by 1–2 mm.

We rub the seams

To grout the joints you will need a special trowel. All protrusions must be removed to ensure a smooth surface for subsequent finishing.

Reinforcement

This procedure is performed using a painting mesh. First, the surface of the insulation is coated with a primer. After complete drying, we begin to reinforce.

- You need to start from the corners of the building and the junction line of the slopes.

- The finishing solution is evenly applied to the foam plastic (layer 1–2 mm).

- The mesh is laid and pressed to the base surface with a spatula.

- The solution should cover the entire mesh.

- Laying is done in small sections.

- Protrusion of material is not allowed.

- Adjacent sections are laid overlapping (1–2 mm).

Final finishing

A day after reinforcement, the grout is grouted. Next, the surface is coated with a primer. Use a wide spatula to finish with a leveling mixture. We try to achieve ideal surface quality for subsequent cladding with stone, mosaic, and decorative plaster. If we are talking about finishing with siding or corrugated board, an intermediate procedure may not be required. The panels will be attached using fungi.

Thus, we examined in detail how to insulate wooden houses with foam plastic from the outside. The effect can be achieved if you follow all the recommendations. We wish you good luck in insulating the facade.

Insulating the house from the inside

This type is rarely used due to the fact that improperly performed work can lead to increased humidity in the room.

In addition, the footage of the room is significantly reduced. However, this method allows you to preserve the natural appearance of the building’s facade, can be carried out at any time of the year and in any weather, and is much cheaper.

Just as in the case of exterior finishing, work begins with cleaning the walls. Next, they are caulked and a vapor barrier is performed.

In the case of interior finishing, it is advisable to attach the insulation to the sheathing, after which the ventilation system is installed and finishing is carried out.

Is it possible to insulate a wooden house with polystyrene foam from the outside?

- 1 Penoplex - what is it? 1.1 Advantages of external wall insulation

- 2.1 Preparing the base

A wooden house, no matter whether it is old or recently built, very rarely meets modern standards for heat conservation - too thick logs would have to be used. In addition, it is very difficult to get rid of cold bridges between them, and only after complex and expensive wood processing. In this regard, very often economical owners use additional insulation of the house with penoplex, which allows them to reduce the load on the heating system in winter and reduce the cost of heating the premises by 1.5–2 times.

Penoplex - what is it?

Penoplex is a manufacturer’s trademark and at the same time a common name for extruded polystyrene foam as a type of insulation that relatively recently appeared on the Russian market, and they began to produce it under this brand. Penoplex is hydrophobic, has a low volumetric weight and practically zero vapor permeability, which allows it to be used without the use of hydro- and vapor barriers. We can say that this is the best insulation of all existing ones in terms of thermal conductivity, it is easily processed and mounted on all types of surfaces - vertical, horizontal and inclined.

Among the negative characteristics is that penoplex does not support combustion, but when exposed to fire, it melts, emitting caustic toxic smoke. In addition, it loses its properties and becomes unusable under the influence of prolonged exposure to the sun.

Advantages of insulating walls outside

The owner of a house always has a question: should he insulate his home with penoplex from the inside, or mount it from the outside? The option of placing the insulation on the facade side is more preferable - it allows you to transfer the dew point into the insulation (provided the thickness is calculated correctly) and thereby protect the walls from excessive moisture. It should also be remembered that the internal location of penoplex significantly reduces the area of the house, and also leads to the need to finish the walls, which is not entirely advisable - well-treated wood looks good in the interior of a home without any finishing. Therefore, it is better to insulate the surface of the walls with penoplex from the outside.

Stages of insulation of a wooden house

How to insulate a wooden house from the outside with penoplex yourself? It is important for the owner to remember some of the features of just such insulation, so that, on the one hand, he does not pay extra money, and on the other, he does everything taking into account the characteristics of the wooden facade as a base.

Important! Before you start decorating your wooden house with foam plastic, it is important to know that many experts do not recommend this method of insulation, since due to the lack of vapor permeability, wooden walls stop “breathing”.

It is recommended to use vapor-permeable mineral wool, but such material is usually more expensive. Despite this circumstance, many homeowners continue to insulate with foam plastic, and claim that the performance characteristics of the house have not been affected.

Preparing the base

Insulation with penoplex from the outside can only begin after careful preparation of the walls, otherwise all further efforts may be in vain and the costs will not bring the expected effect. Wood is a specific, living material, even in a sawn and processed state, which, under the influence of changes in humidity at different times of the day and time of year, will remain unstable. In addition, if a wooden house was recently built from logs, it must stand for at least a year to settle.

- We carefully examine the surface of the walls and, if there are even small cracks, we seal them with tow or dry moss;

- We check the flatness of the facade surface; if there are significant protrusions, it is better to remove them;

- We impregnate the logs with fire retardants and antiseptics, which will protect against rotting and make possible combustion more difficult.

After completing these procedures, the wall surface is ready for further DIY work.

Sheathing device

Many builders neglect this stage of work, and indeed, the sheathing of the walls on the outside can be omitted, but only if they are made of rounded logs, not beams, and not using frame technology. The fact is that between the penoplex and the wall of the house there must be space for air circulation, and logs, but only even ones and laid strictly vertically, make it possible to do this.

The lathing is usually made from timber 25 x 50 or 50 x 50, but it can also be made from a metal mounting profile. It must be mounted on the walls with high quality, making sure that an absolutely flat surface is formed for installation - the foam boards are very rigid and in case of unevenness, they will not fit tightly. Considering the dimensions of the insulation boards - 1200 x 600 mm, vertical and horizontal guides must be positioned in such a way that squares of 600 x 600 mm are formed - for better reliability, or 1200 x 600 mm - this is also allowed.

Many people then install a vapor barrier membrane on the sheathing, but this is unnecessary - extruded polystyrene foam itself is an excellent vapor barrier and is not afraid of moisture.

Attaching the insulation

After installing the guides, you can begin installing the penoplex yourself. This is done using self-tapping screws and a special two-component adhesive composition. Conventional inexpensive glue is not suitable for a wooden facade - it is an unstable base, the slightest movement of which towards expansion or contraction will lead to deformation and peeling of the insulation. That is why they use an adhesive composition with special polymer additives, which allow it to maintain elasticity after drying.

It is better to insulate walls with penoplex in two layers - if the required insulation thickness is 100 mm, it is better to take 50 mm slabs and fasten them with offset seams. This will add increased rigidity to the structure and prevent the appearance of cold bridges. Installing the slabs with your own hands is quick - they are light and, if necessary, easy to cut. We simply coat the surface of the beams with elastic glue, apply foam plastic to them, additionally fasten it on the outside with self-tapping screws, not forgetting to get into the sheathing and coat the joints of the plates with the same adhesive. The second layer of slabs can be mounted only with glue, applying it with your own hands to the first evenly over the entire surface or in strips, making sure that the seams of the layers do not coincide. This is easy to do - if the first layer of slabs was laid horizontally, we install the second one vertically with a horizontal and vertical offset of 300 mm.

After the owner has attached the insulation to the outside of the facade, you can begin finishing the walls.

Penoplex cladding

There are quite a lot of options for what the owner should do next to make his home beautiful. All that remains is to choose the one that is suitable in terms of cost and labor intensity - and finish insulating the house from the outside. Since after installing the foam boards in two layers, the surface of the facade became very hard, you can decorate it with plaster yourself. Briefly about the stages of plastering walls outside:

- We apply the first layer of the same elastic adhesive solution to the insulation boards;

- We embed a reinforcing mesh made of durable fiberglass into it;

- Apply a second layer of glue, making sure that the mesh is completely recessed;

- After the surface has dried, apply a leveling plaster composition - smooth or textured, white or colored.

Description of insulation processes

Each of the above insulation methods is carried out according to an individual technique.

Thermal insulation algorithm using the frameless method

The method involves attaching the insulation directly to the wall of the house and subsequent finishing.

Sequencing:

- Calculation and purchase of foam plastic and fasteners. It is easy to calculate the amount of insulation required. The perimeter of the task is multiplied by the height of the walls and the area of window and door openings is subtracted. Dividing 100 by the selected sheet thickness in cm, you get the area that 1 m3 of material can cover. 5-10% is added to the result obtained in case of unforeseen situations. To fasten the foam, dowels with disc-shaped caps are purchased. To attach one sheet measuring 1x1 m you will need 5-6 hardware.

- To seal the seams, buy adhesive foam or polyurethane foam. You will need a special gun for application. It should be noted that foam adhesive is more expensive, but is better suited for sealing seams, since it expands less after application, without deforming the insulation sheets.

Excess foam that needs to be removed

Important! Be sure to purchase a foam cleaner - you won’t be able to wash your tools, hands and clothes with any other means.

*

- Prepare the surface of the walls for insulation. It is best to carry out work in the summer, when the walls are best dry. Timber, logs, boards are cleaned of dirt and old paint is scraped off. Gaps in walls made of logs and timber are sealed with tow or caulked. The surface is treated with an antiseptic to prevent the appearance of fungus, mold, and destroy wood pests. Damaged areas of the walls are restored by removing the damage. Finish the work by applying fire retardant (fire retardant impregnation) twice. The walls are drying.

- Using a building level and a plumb line, apply horizontal and vertical markings for the first row of insulation. If the first row is suspended, a support bar is attached to the wall.

Installation of the first row of insulation

- Using a drill, the insulation is attached using dowels. The second and subsequent rows are installed offset relative to the first. It is important to install the first row strictly in a horizontal position - this will prevent gaps from occurring in subsequent rows.

- Seal the seams with foam. Removal of excess sealant is carried out after it has completely cured; the process usually takes from 12 hours to 24 hours.

- Using a toothed roller or improvised means, perforations (punctures up to 1 cm deep) are applied to the surface of the insulation. Perforation promotes better adhesion of the plaster to the foam.

- A layer (1-2 mm) of polystyrene foam glue is applied to the surface of the foam and leveled.

- I apply and lightly “sink” a fiberglass plaster mesh onto the surface coated with glue. The joints of the canvases overlap by 10 cm. The seams between the foam plates and the edges of the mesh should not coincide.

Laying reinforcing mesh

Important! When purchasing a mesh, check its compatibility with the composition of the plaster adhesive that they plan to use - some meshes can be destroyed by the cement included in the adhesive composition.

- The reinforcing mesh is leveled with a spatula from the center to the edges, embedded in the adhesive composition. Having leveled the mesh, apply a second layer of glue, leveling the surface.

- The dried surface is treated with a deep penetration primer; it is advisable to apply a second coat after the first has dried.

- The surface is plastered with compounds for external use. As a finishing option for experienced builders, we can recommend bark beetle plaster. A simplified option is to paint the surface with facade paint.

*

Frame thermal insulation method

The frame method differs from the method described above. Here is his step-by-step algorithm:

- Geometric measurements of the walls of the house are taken, including the perimeters of windows and doors. Having calculated the area to be insulated, purchase polystyrene foam; you can buy material with a density of 15 kg/m3.

- Calculate and purchase wooden bars and a galvanized profile for the frame. The amount of material depends on the finishing material used. Usually I make vertical logs at a distance of 50 cm so that the siding can be securely fastened and foam sheets can be used without waste. In cases where extruded polystyrene foam is used, they are guided by the geometric dimensions of the insulation plates.

- Similarly, with the method of frameless insulation, the walls are prepared - cleaned, treated with impregnations.

- Fix the sheathing on the wall. For wooden blocks, use self-tapping screws and nails of suitable length. Wide products are secured using corners. The metal profile is mounted on pre-installed brackets. It is important to maintain the exact distance between the frame guides so that the foam “lays down” as tightly as possible. For example, if foam plastic with a width of 50 cm is used, then the distance between the edges of the joists should be 49.5 cm.

Ready-made sheathing for foam insulation

- Install the insulation between the sheathing joists, securing the polystyrene foam additionally with dowels with disc-shaped caps.

- Gaps between the insulation and the frame larger than 1.5 mm are foamed - this will prevent the appearance of cold bridges in winter.

- A waterproofing membrane is attached on top of the foam to protect the house from moisture penetration, and the foam from destruction.

- If the house is finished with siding, thin slats are attached on top of the waterproofing membrane, which will provide a gap for ventilation.

- Install the finishing material using self-tapping screws.