Do you want to get cozy and warm housing, the temperature in which does not depend on the vagaries of the weather? Then you should insulate the walls outside with polystyrene foam. Don't know where to start and how to get started with this work? In this case, study this article - it will give you answers to your questions.

Insulation of external walls with foam plastic

Features of foam

The structure of the foam is a foamed mass, where the bulk of the mass of the slab is air. Due to this, the density of this material is much lower than the density of the raw materials from which it is produced. The huge amount of air in the structure of the material is its undoubted advantage, in addition:

- foam-based panels are lightweight;

- the material has excellent sound insulation properties;

- good thermal insulation properties.

The material has different densities depending on the raw material, and this also affects the level of mechanical strength. The greater the density of the structure, the less air inside the material; accordingly, the thermal insulation properties will be worse , but at the same time the material will withstand more mechanical loads.

When insulating, foam plastic boards, depending on the strength level, are used in the following way:

- slabs with a minimum strength indicator must be combined with insulation with a maximum level of protection from mechanical damage;

- slabs with low strength are best installed for insulation with the frame method of installing load-bearing structures;

- if the slabs have greater strength, protection from mechanical damage will be provided without a frame, but it must still be installed in addition to the insulation.

Myth No. 2. Mineral wool is cheaper

At this point there is a substitution of witnesses. Which mineral wool is cheaper? The answer is - in rolls. To make the house as warm as if you covered it with foam plastic, you will have to use a huge amount of rolled mineral wool, which will be much more expensive than in the case of foam plastic. Often facades are insulated with mineral wool boards, which are much more expensive than foam boards.

Also, mineral wool boards are more difficult to install, which indicates the cost-effectiveness of foam insulation.

Advantages and disadvantages

Polystyrene foam has both strengths and weaknesses. The advantages are obvious:

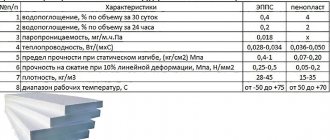

- low thermal conductivity - 0.037-0.041 W/(m K), comparable to mineral wool, which makes it possible to effectively insulate building structures made of brick, concrete, expanded clay concrete, gas silicate blocks, etc.;

- ability to maintain performance properties over a wide temperature range: from -50oC to +75oC (if there is no contact with an open flame, it begins to deteriorate at +160oC);

- low cost - refers to the budget type of materials;

- simple installation - there is no need to install the sheathing, as it is fixed with adhesive;

- does not require work experience or special tools when carrying out thermal insulation;

- low specific gravity - does not create a load on the structural elements of the building;

- does not serve as a base for the proliferation of mold and mildew;

- exhibits inertness to the components of cement-sand mortar, gypsum, and weak acids.

disadvantages , but consumers pay little attention to them. Among the disadvantages:

- flammability - class G3 (normally flammable). Clarification is necessary here: manufacturers claim that the insulation is self-extinguishing due to special additives - fire retardants, as indicated by the marking with the letter “C” (see photo above). However, this property is demonstrated during experiments only by products of well-known brands: Nova Chemicals, BASF, Polimeri Europa and Styrochem. Russian manufacturers also introduce fire retardants into the composition, but do not achieve a self-extinguishing effect: the products burn well;

The foam with the cladding is burning.

- release of toxic substances during combustion (hydrocyanic acid, phosgene, hydrogen bromide, etc.), as a result of which a person quickly loses consciousness and dies during a fire;

- transition to a fluid phase during the combustion process - spreads across the floor, increasing the area of the fire;

- release of styrene, which is harmful to health, when the temperature rises above +30oC;

Attention: is polystyrene foam harmful as insulation indoors? In the absence of extreme (high temperature) or force majeure circumstances (fire), foam insulation is absolutely harmless to humans, which cannot be said in the event of an emergency situation.

- short service life - 5-7 years, during which the original thermal conductivity values are maintained, although manufacturers claim the opposite, talking about 30 years or more. Laboratory tests, during which a foam plastic slab that had served for 9 years was removed from the wall, showed that due to destructive processes (the appearance of shells, cavities, increased density and decreased volume), the thermal conductivity coefficient increased almost 8 times;

- amplifies (resonates) indoor noise. Explanations are also needed here, since on the Internet, including Wikipedia, it is stated that polystyrene foam has good soundproofing properties. But this is a myth. The insulation has a closed cell structure and is light weight. Therefore, it cannot reflect sound waves - there is no mass and absorb noise - the material does not allow air to pass through. On the contrary, the high rigidity of the plate and low mass lead to the occurrence of resonance in the region of 500 Hz, i.e. in the very center of household noise;

- instability to most paint solvents - melts instantly;

- ages intensively under ultraviolet radiation (sun rays), which is intensely hushed up by manufacturers and sellers;

- lack of vapor permeability, although all reference books provide digital values that refute this statement. The problem is solved either by the correct choice of material thickness, which requires complex calculations, or by installing a ventilated facade and roof;

- low mechanical strength - easily damaged during transportation, installation and operation.

The foam was damaged by a falling branch.

Particular attention should be paid to the relationship between the insulation and mice - if they are found in the house, then first of all the damage will be caused to the foam plastic.

The mice did their best.

Where and how can foam plastic be used for insulation?

The areas of application of polystyrene foam for insulation are:

- external wall insulation;

- internal insulation;

- ceiling fittings;

- installation in attics;

- on the floor;

- insulation for the foundation.

However, it is worth noting that one of the disadvantages of such insulation is that even if it has a high level of density, it is not strong enough. That is why it is not recommended to use it for internal insulation of walls that face the street, unless they are also insulated from the outside.

Myth No. 3. It doesn’t matter what you use for insulation.

The most wrong opinion that could ever be thought up or expressed. Your comfort will depend on the quality of the material in the future. Therefore, before choosing it, remember a few important rules:

- choose material from trusted, well-known manufacturers;

- the polystyrene foam you choose must be produced in a factory that provides certification for its products. This way you will receive quality material;

- the reinforcing mesh should not have low density, be fragile or too cheap;

- facade dowels (fungi) must be made of good plastic, flexible, frost-resistant, elastic, and also be at least 50 mm longer than the foam;

- decorative plaster and paint applied to it must be of high quality.