When the question of which heating radiators is best to choose for a private home appears on the agenda, there are many who nostalgically recall Soviet cast-iron “accordions” - although bulky, they are hot and warm the room well. Indeed, at one time such batteries worked “excellently,” but now they are deteriorating and are considered obsolete. They have already been replaced by new, more efficient, convenient and cost-effective models.

But the main problem is that there are many diametrically opposed opinions regarding new radiators. And in practice it’s the same: you go to neighbors who have installed modern radiators at home - some are warm, while others are cold. At the same time, both places have almost identical heating batteries - that is, which of them is better for a private home does not always depend on the specific model.

Heating a house with radiators

Classes of heating radiators and their types and features

The principle of operation of a radiator is to transfer heat to the surrounding space from the coolant fluid circulating in this heating device.

The autonomous heating system (AHS) consists of:

- boiler;

- pipelines;

- thermal elements.

The table shows the main types of thermal appliances:

| Device | Operating principle | Example |

| Radiator | Heat is radiated | ceiling radiant panels, sectional cast iron, tubular radiators |

| Battery | Heat is radiated and also transferred by convection | sectional aluminum, sectional steel, bimetallic, tubular |

| Convector | Heat is mainly transferred by convection | plate, tubular convectors, finned tubes |

Heating a house with radiators

In addition, heating devices are divided into the following classes, let's consider a unique rating of heating radiators from this side:

Sectional

They consist of heating sections that are connected to each other. The more sections, the more heat they will transfer to the surrounding space. To prevent the room from overheating, special thermostats are installed on the radiators to regulate the temperature.

Standard cast iron radiators are also sectional: heat from them is transferred in the form of infrared radiation, evenly distributed throughout the room - top, bottom and middle. Such batteries have large dimensions and thick walls, which accumulate enough heat so that it is emitted in the infrared spectrum. It is this method of heating that is considered optimal for human health, although it must be borne in mind that part of the heating also occurs through convection.

Thanks to the thick walls, such batteries have high thermal inertia - therefore, after turning off the AOS, the radiators remain hot for a long time. Cast iron is not very susceptible to corrosion and is not afraid of harmful impurities in the coolant - the service life of such devices reaches 50 years. One of the disadvantages is the heavy weight.

Aluminum radiators have good heat transfer (1/2 radiation + 1/2 convection) and quickly warm up the room. Compared to cast iron, they are more lightweight, and in general, the ability to transfer heat into the room is several times higher than that of cast iron and steel.

An additional advantage of modern models is the ability to regulate the temperature using a valve with a thermal head. The metal surface is coated with a protective coating, which increases its service life. The cost of aluminum radiators is low, and therefore the prices are more affordable.

Aluminum radiators cannot withstand high overloads, so they are not used in central heating systems (CHS). They break due to pressure surges, the presence of rust or sand particles in the coolant. Chemical additives are not allowed in liquids.

Bimetallic heating radiators consist of external aluminum plates and steel pipes located inside the sections. They are valued for their reliability and durability, but are not cheap. Equally well suited for centralized and autonomous heating systems.

Radiators are also produced that have only steel-reinforced vertical pipes. These are no longer completely bimetallic devices; they are less corrosion resistant. Among their advantages, it is worth noting their high thermal conductivity, which is higher than that of real bimetallic radiators.

Tubular

Steel tubular heating devices give off heat well, are economical in terms of energy consumption, and heat up quickly. Their disadvantage is that they are sensitive to oxidative processes. If the coolant fluid does not fill the steel radiator reservoirs, it will begin to corrode. Another weakness of a steel radiator is its hypersensitivity to water quality. Even if the water is considered good by usual standards and can be drunk, it is recommended to install filters to minimize the formation of scale.

The sizes of steel tubular radiators are from 30 cm to 3 m. The number of rows of tubes is 1–9. They are considered very reliable - the permissible operating pressure for devices from a number of Russian manufacturers reaches 15 atm. Radiator reservoirs are designed to hold a large volume of liquid, so they quickly reach the required temperature levels when it is necessary to increase or decrease power. The method of heat transfer is radiation and convection.

Steel radiators are also used as heated towel rails, which, in addition to drying clothes, provide additional heating in bathrooms

Floor radiators-benches with support legs are steel tubular heating devices with a seat in the form of a wooden board on top. They are connected to the heating system in the same way as conventional radiators. They can also serve as the main heating device in rooms such as the kitchen, bathroom, hallway.

Panel

These steel radiators are a rectangular panel that acts as a heating device. The panel consists of 2 ribbed sheets welded to each other; plates with a U-shaped relief are placed inside.

Operating pressure is 6–8 atm, high sensitivity to pressure changes, therefore they are used only in autonomous heating systems for residential and commercial premises. Such radiators can consist of 1, 2, 3 heating plates. React quickly to temperature changes. The main method of heat transfer is convection. The choice of sizes of such devices is wide enough so that they can be selected for a room of any size.

Ceiling thermal panels consist of steel plates to which pipes intended for coolant are welded. Their use is advisable in rooms with high ceilings from 3 to 20 m. Heat transfer is carried out by radiation.

Lamellar

Plate heating devices consist of horizontally arranged pipes to which metal plates are welded, thereby increasing the surface area for heat transfer. Heat transferrs can additionally be covered with protective covers. The advantage of such radiators is their reliability - they can be used for centralized and autonomous heating. The main method of heat transfer is convective, so the space is heated unevenly: it is much warmer on top. They are mainly used for offices, corridors, garages and utility rooms, but there are also models for residential premises.

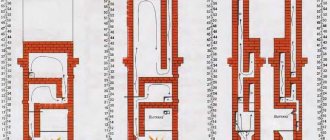

Operating principles of automation for solid fuel boilers

The intensity of combustion of any fuel depends on the flow of oxygen into the firebox: the more air, the hotter it burns and the faster the coolant heats up. Therefore, the first option for boiler automation is draft control. Traction is controlled by:

- turning or sliding the damper in the chimney;

- opening the ash pan door;

- pumping air with fans.

Accordingly, the damper is moved manually, a mechanical draft regulator can be attached to the door (see photo below) and the blower fan is connected to the electronic unit.

The second control mechanism is the movement of the coolant. In this case, the circulation of water through the pipes is started or stopped; for this, the system must have a circulation pump connected to the control electronics:

And the third option is the automatic supply of fuel from the bunker to the firebox. By decreasing or increasing the speed of transport units (screws, belts, etc.), active or economical combustion and heating modes are set. The following photo shows just such a boiler with automatic feeding:

Rules for the location of batteries in the house

In order for the system to work properly, installation rules must be strictly followed. Although the installation technology is not complicated, it has its own nuances, so the work must be carried out by specialists.

Important! If radiators are installed incorrectly, they are not covered by the warranty.

In order to avoid heat loss and uneven heating of the room, when installing devices it is necessary to observe indentations and choose the correct location:

- The most suitable option for the battery is considered to be a place under the window, i.e. where the heat loss is the most significant. The radiator width must be at least 70% of the window width. Mounted clearly in the middle.

- Leave at least 10 cm from the battery to the windowsill, as well as to the floor. The optimal distance between the floor and the radiator is 12 cm. It is not recommended to leave more than 15 cm.

- The battery is fixed at a distance of 5 cm from the wall.

- You can stick heat-reflecting material behind the radiator - then some of the heat will not go into the wall, but will return to the room.

- If the radiator is planned to be placed not under the window sill, but on the wall, then the distance between them should be at least 20 mm.

Calculation of the number of sections

It is not necessary to look for the most expensive heating devices to make the room comfortable. The main thing is to correctly calculate the number of sections. If the rooms are standard, then this greatly simplifies the calculations.

Often they resort to calculations based on the volume of space because they are simple, but at the same time give fairly accurate results.

- 1 m³ requires 41 W of power. If good double-glazed windows are installed and heat loss is minimal, then the indicator drops to 34 W.

- Room volume (m³) = area (m²) × height (m).

- Required heating power for the entire room (W) = room volume (m³) × 41 W (or 34 W).

- In the technical data sheets of devices, manufacturers indicate the heat transfer of one section.

- The total power (the value calculated in point 3) must be divided by the heat transfer of one section. The resulting number is the number of sections.

For example, the required thermal power is 2890 W, and the heat output of one section is 170 W. Then for this room you need to purchase 17 sections.

If the room is non-standard, the calculations become more complicated. To calculate the total power, the features of double-glazed windows (double or triple), thermal insulation parameters of the walls, the ratio of the sizes of windows and floors, ceiling heights and other parameters are taken into account. Designers calculate all this using specialized software.

Automation equipment for boiler rooms

Automation technical means:

- sensors of technological process parameters;

- actuators that move regulatory bodies according to commands in the desired direction;

- control equipment that processes information from sensors in accordance with the algorithms and programs embedded in it and generates commands for actuators;

- devices for selecting control modes and for remote control of actuators;

- means of displaying and presenting information to operational personnel;

- devices for documenting and archiving technological information;

- means of collective presentation of information.

All this technology has undergone revolutionary changes over the second half of the last century, not least thanks to the achievements of Soviet science. For example, pressure gauge instruments, widely used in measuring pressure, flow, speed and level of liquids and gases, as well as in measuring force and mass, have changed the physical principle of the sensing element.

Instead of a membrane that bends under the influence of force and moves the rod of an electromechanical transducer, they began to use a strain gauge method. Its essence is that some materials, when subjected to mechanical action, change their electrical parameters. A sensitive measuring circuit detects these changes, and a computing device built into the device converts them into a process parameter value.

Devices have become more compact, more reliable, and more accurate. And more technologically advanced in production. Modern actuators don't just accept "on" and "off" commands, as they did for many years. They can accept commands in digital code, independently decipher them, execute them and report on their actions and their condition. Control technology has evolved from tube regulators and relay-contact circuits to microprocessor-based control, logic and demonstration controllers.

Abroad, the use of such controllers in automation systems for various objects began a little earlier. A microprocessor controller is a computing device designed specifically to control a technological object located in its immediate vicinity.

The controller consists of the following blocks and devices:

- power unit;

- calculator;

- block for input of analog signals of different ratings with galvanic separation;

- device for inputting discrete active (in the form of voltage) and passive (in the form of a dry contact) signals;

- block for outputting analog signals of different ratings with galvanic separation;

- device for outputting discrete active and passive signals;

- an interface communication device for connecting the controller to the system information field.

Signal input and output blocks - blocks of the ICD group (communication devices with the object) - are all multi-channel, have from 8 to 16 channels. The controller is assembled for a specific task using the design layout method. The composition and number of USO blocks is selected based on the number of corresponding signals in the system. The computer block contains a processor, random access memory (RAM) and read-only memory (ROM). A library of algorithms is stored in ROM. Its composition covers almost all control tasks used in such systems - regulation, arithmetic calculations, dynamic transformations, logical actions.

Programming of controllers is carried out using the technological programming method. For modern controller models, this method is an assembly of a functional diagram of a control task on the monitor screen.

After a simple check for errors, the program circuit is loaded into the controller’s RAM. The intuitive accessibility of the method for traditional machine gunners contributed to the rapid and widespread spread of RemiKonts.

Which radiators to choose for a wooden house

Heating a wooden house (we are talking primarily about log houses) indeed has its own characteristics, since the thermal conductivity of wood is low and depends on its species. In addition, it is necessary to ensure maximum fire safety. But in general, the issue of providing heat, as well as safety, rests primarily on the correct installation of the heating system, the choice of boiler and the number of radiators. There are no restrictions on the type of radiators here: steel, cast iron, bimetallic, aluminum - all of them can be used in a wooden frame.

By material and type of heat exchanger

Heat exchangers can be:

- cast iron;

- copper;

- aluminum-silicon;

- made of carbon or stainless steel.

The design of the heat exchanger may also vary.

The most popular are separate heat exchangers. Heating water flows separately, and water for residents’ household needs passes separately. They are a little more expensive, but more reliable.

A bithermic heat exchanger looks like a pipe within a pipe. In the inner pipe there is DHW water, which needs to be heated, and in the outer pipe the heating coolant circulates.

The third type is a heat exchanger in which a coil is built in. The container with water is heated by the coolant flowing in the coil. An indirect heating system is good for everyone, but in the summer you will either have to heat the boiler or live without hot water.

The bithermic option is not recommended for use where there is hard water. And be prepared that every time scalding water will flow out of the tap first, and only then at the temperature you need.

Which heating batteries to choose for a private home and cottage

It is not difficult to select batteries for a private home, because the autonomous heating system operates without significant overloads, which a centralized system experiences. Here you can connect any radiators, focusing on the required power, quality, efficiency, and cost of the device.

Many owners of private houses prefer aluminum radiators. They are cheaper than cast iron, more economical to operate and have higher heat transfer rates, and the sensitivity of aluminum devices to water hammer in an autonomous heating system can be neglected.

If you want to choose batteries based on the brand name, then you can take into account the unspoken rating of aluminum heating radiators for a private home. The top positions here belong to the brands Calidor, Global, Rifar, STI, which are well suited for operation in Russian climatic conditions.

Steel radiators are no less common, which is not surprising, because they are reliable, affordable, able to warm up quickly and have good heat dissipation. Here, in the ranking of steel heating radiators for a private home, the leading places are occupied by Kermi, Purmo, Zehnder, Sunerzha.

Among the worthy brands producing bimetallic radiators are the Russian Rifar and the Italian Global. Those who decide to purchase cast iron heaters should pay attention to Konner (Russia), Guratec (Germany), Retro Style (Russia).

As a result, all radiators are universal, which means posing the question of which heating radiators are best for a private house with a gas boiler is not entirely correct, because when choosing, they are mainly guided by the required power, the features of the room and the possibilities of the budget.

Automated system functions and effective technical solutions

Energy consumption modes and thermal energy production are significantly influenced by many factors, such as climatic conditions, thermal properties of the facility or characteristics of the utility network. In addition, the correlation with other life support systems is also taken into account: gas, electricity, and water supply.

Automation of hot water supply (DHW) and heating (HC) systems not only helps to improve the technical level of their operation, but also provides significant energy savings. That is why automated heating units that provide control and automatic regulation of coolant parameters are effective sources of energy saving and provide comfortable conditions in heated rooms.

Automation of heating points, carried out taking into account the wishes of the customer and the level of complexity of the facility, makes it possible to solve the following tasks:

- Maintaining optimal heat supply parameters;

- Diagnostics of the operation of the system as a whole and individual engineering equipment;

- Minimizing the consequences of emergency situations by timely notification of their occurrence;

- Improving the functioning of the entire heat supply system;

- Improving the quality of DHW services by maintaining a constant coolant temperature;

- Reduced thermal energy consumption;

- Reducing the load on maintenance personnel, all of whose duties in the presence of automated heating points are reduced to monitoring parameters, controlling technological processes and making competent decisions in the event of emergency situations;

- Obtaining average total thermal energy savings of up to 30% of the volume of heat consumption for the residential sector and up to 50% for administrative and industrial facilities;

- Reducing costs for maintenance, replacement and repair of equipment. And an increase in its service life, thanks to constant automatic monitoring of the parameters of the DHW and CO systems.

The key to their solution is competent integrated solutions, high quality control of all technological processes implemented in heating and hot water systems, and the use of variable frequency electric drives, the use of which is effective both from a technological and energy point of view.

Automated heating systems based on frequency regulation, developed by TekhStroyServis LLC, will allow you to configure the optimal heat supply mode and provide cost savings by controlling its intensity according to an individual schedule.

Radiator prices

The cost of heating devices varies significantly depending on the following factors:

- brand and country of origin;

- material and production technology;

- design.

Italian, German, Finnish, and Czech batteries are more expensive than Russian ones, but in terms of their technical and operational characteristics, products from domestic manufacturers are not much inferior and even superior to many foreign analogues.

Buying heating radiators for a private home is quite expensive. But if you make the right calculations and select cost-effective devices, then costs can be significantly reduced.

The average cost of aluminum radiators per section is in the range of 1227–8200 rubles, bimetallic devices – 3000–11900 rubles. The cheapest of them can be purchased at a price of 1100 rubles. The range of prices for steel radiators is also quite wide: from 830 to 60,000 rubles. Steel models costing from 3,500 to 26,000 rubles are popular. Inexpensive cast iron batteries can be purchased for 500–1000 rubles. Cast iron appliances are in demand for RUR 3,000–8,000.

Retro-style batteries can be found from 8,000 rubles.

If batteries are needed for an entire house, then even inexpensive devices cost a pretty penny. In addition, costs will be added for related products: valves, thermostat heads, brackets and other parts.