One of the publications on our website has already discussed various types of electric heated floors, as well as their advantages over similar water systems. Returning to this topic, we want to talk in more detail about infrared (hereinafter referred to as IR) heating, its structure, features, advantages and disadvantages, as well as methods of installation on the floor, walls and ceiling. The information collected will be useful to those who have decided to insulate a house or room with film electric heaters and want to do it themselves.

Operating principle and design of IR heating film

The main element in this design is a carbon coating; modern nanotechnology is used to apply it, allowing printing on a film base. The result is a unique atomic structure in the form of a hexagonal lattice, which is so small that to describe its dimensions it is necessary to use a nanometer scale (this order is expressed in 10-9 m). Thanks to this, the material acquires the ability to emit waves with a length of 5.0-20.0 microns, that is, those in the IR range (not to be confused with ultraviolet and infrared radiation).

Let us recall that the peculiarity of this radiation is that upon contact with matter, wave energy turns into heat. That is why such designs are also called PLEN heaters. This abbreviation stands for as follows:

- P – film.

- L – radial (radiant).

- E – electric.

- H – heating.

Film film can be produced in rolls or mats, their design is presented below.

Design of film electric heaters

Designations:

- A – Carbon (carbon) coating plays the role of the main heating element.

- B – Dense film base.

- C – Silver plating (used as an electrical conductor).

- D – Power bus, made of flexible copper tape.

- E – Film, used as a protective coating.

Benefits or harms of infrared radiation

Most of those who are thinking about installing infrared equipment in their home have questions about the safety of such a system.

First, let's figure out what infrared radiation is. These are electromagnetic waves of a certain length. Their natural source is the Sun, which emits a large number of waves of different spectrums. The longest ones are the so-called red ones, because the human eye sees them as red.

However, scientists have proven that there are also infrared waves, the length of which is slightly longer. They belong to the waves of the spectrum invisible to humans. They get on the skin and are felt as a thermal effect. But not all infrared radiation is created equal.

Physicists distinguish three groups of such waves:

- Short , emitted by bodies with temperatures above 800 °C.

- Average _ They are emitted by objects heated to 600 °C.

- Long . Emitted by bodies with temperatures up to 300 °C.

Depending on the wavelength, infrared radiation affects living organisms differently. Short waves penetrate deep enough into the human body and can warm up the internal organs.

In areas of the skin that have been exposed to short infrared waves, redness, blisters and even burns form. Medium-length waves have a milder effect, but are still undesirable for the body.

Film heaters heat up to a temperature of 50C, accordingly they emit only long infrared waves, useful for humans

Long-wave infrared radiation is perceived by humans as pleasant warmth. It penetrates the upper layers of the skin and gently warms up the moisture in them. This is why all living organisms love to bask in the sun.

Long-wave infrared radiation not only warms, but also activates the immune system, triggers restoration and regeneration mechanisms for many systems and organs.

Considering that film equipment heats up to 45-50C, you can be sure that it emits long infrared waves. In the operating mode of maintaining the set temperature, the system operates on average from 6 to 10 minutes per hour.

Thus, it has a short-term effect on humans. The safety of PLEN is confirmed by many certificates. It is recommended for installation in medical and children's institutions.

Detailed information about the dangers of infrared heaters is discussed in our other article.

Pros and cons of film heating

Let's start with the main advantages:

- Relatively simple installation of film systems. This is an absolute plus; PLEN heaters are not filled with screed, which makes it possible to install these elements without starting a major overhaul.

- The film is also easy to install on the ceiling, floor or walls.

- There are no restrictions on finishing coatings; the film heater can be installed under linoleum, laminate, parquet, tiles, etc.

- Taking into account the fact that the thickness of the IR coating does not exceed 0.40 mm, the warm floor will not rise significantly. Therefore, if you organize heating of only one room, there will not be a significant difference.

- The material has low inertia, which allows you to quickly influence the thermal conditions in the room.

- Uniform heating of the room than other floor heating systems, not to mention central heating, where radiators are installed.

Temperature changes in a room with central heating (A) and the PLEN system (B) - High efficiency and, accordingly, energy consumption of IR film is significantly lower than that of other types of electric floors. Moreover, this difference is quite noticeable, we are talking about 20-25%.

- Easy integration into the Smart Home system.

- There is practically no EMI, unlike electric floors, especially with one heating wire.

- If one of the heating elements is damaged, heating will still occur (except for the damaged area).

- The heating system can be quickly and easily dismantled without causing damage to the finishing of the room. This allows you to reconfigure or completely remove the film if necessary, for example when moving.

As for the disadvantages, these include the high cost of the equipment compared to other types of electric floors. In addition, you should take into account the features of IR heating panels, namely:

- The PLEN must be installed on a flat (smooth) surface, otherwise there is a high probability of damage to the heating element.

- Installation should be carried out only in free space, that is, furniture should not be located in the area where the IR film is installed. This limitation does not allow the entire floor area to be used. As practice shows, the PLEN system is installed, at best, on 70% of the total area.

- Without the skills to connect the PLEN the first time, it is almost impossible, this is due to the installation features.

- Installing an electric floor in wet rooms (bathroom or bathhouse) is undesirable, since an installation error can lead to dangerous consequences for humans.

Ceiling heaters

When installing infrared heating in this case, it is necessary to take into account the height of the suspension, most often it is 2.2-3.5 meters from the floor, it depends on the height of the ceilings. But it is not advisable to point such devices at a person’s area, especially where the head is located.

Ceiling infrared heater

You cannot hang the heater above the bed so that it is directed at the head; it is best to point it at the torso and legs. It is not advisable to install them near windows, as heat will be lost. It is also not recommended to install infrared heaters on PVC ceilings.

Scope of application

Despite the fact that some PLEN manufacturers position their products as an alternative to central heating, independent use of that system for heating a summer house, house, store, warehouse or other type of building in winter is not economically profitable. To do this, it is better to use a water boiler and a tubular floor heater, despite the fact that the installation of such equipment is much more complicated. As for industrial and production premises, gas emitters are more suitable for them.

Gas-radiant heating of the workshop is most efficient when installed on the ceiling

The ideal application area for IR films is an auxiliary heating system, which is used to heat a nursery, loggia, French balcony or floors of a private house.

This system can also be used to heat small auxiliary spaces, such as a garage, poultry or chicken coop, basement, etc. PLEN is often used as a soil heater in a polycarbonate greenhouse.

Taking into account the facts stated above, it can be stated that the efficiency of PLEN decreases with increasing heating area.

Main technical characteristics

Despite the large number of PLEN manufacturers, the main parameters of their products are quite similar, here are the main ones:

- Power specifications: 220-240 VAC, 50 Hz.

- Maximum power ≈ 200 W/m2.

- Average daily power is 25-65 W/m2.

- Permissible heating temperature 150°C, melting point 250°C.

- The temperature of the heating elements is 45-50°C.

- Width 0.50-1.0 m.

- Roll length – up to 50 m.

- The maximum laying length is 8 m.

- Thickness – up to 0.4 mm.

- Heating inertness – no more than 3 minutes.

- Efficiency up to 90%.

System components

If you decide to choose PLEN as the main heating system, then you need to take into account the level of air exchange: more than 80% of the area of the room that will be heated must be covered with film. These are walls, floor, ceiling. When applying isolon to the ceiling, you need to make overlaps on the walls of up to 3 cm. This will prevent heat leakage from your room.

Before connecting the PLEN, you need to find out its technical characteristics. They include the efficiency level, protection class, voltage used, current consumed, electrical power, radiation wave. It is advisable to read user reviews.

Installation on floor, ceiling, walls

Now that we have a general idea of PLEN, we can move on to a description of the installation. Before starting the process, it is necessary to plan the placement of the film on the floor surface. As we remember, the film should be placed only on free areas. We recommend making a floor plan, indicating on it the location of furniture and IR coverage.

An example of a plan for laying IR film, taking into account the interior of the room

Based on the result, it is easy to calculate the area of the film, and knowing its width, the length of the tape. After this, we calculate the power, this will allow us not only to select a circuit breaker, but also to evaluate the profitability of such heating.

Power calculation

Knowing the total area of the PLEN heater, we calculate the maximum power. For example, if 100 m2 is needed to heat a house, then the maximum load will be 20 kW, and the current will be slightly more than 90 A (I=P/U), which is quite a lot for a household electrical network. Average daily consumption will be about 2.5-6.5 kW. That is, with 10 hours of operation, such a system will consume from 250 to 650 kW/h per day, and this is a very expensive pleasure. As you can see, the simplest calculation once again suggests that using infrared flooring as the main heating is unprofitable.

On the Internet you can find resources with an online calculator that can significantly simplify the calculation process.

Algorithm of actions when laying infrared warm floors

Having made the calculations and made sure that the results are satisfactory, we proceed directly to installation. Below is a typical installation diagram.

PLEN laying diagram

We will assume that the floor surface is leveled and cleared of debris and dust, and all necessary materials have already been purchased. In this case, the algorithm of actions will be as follows:

- We install the thermostat in a pre-selected location (in fact, this step can be done later, before connecting the laid film).

- The primary base is laid with a heat insulator, preferably with a reflective layer. If installation is carried out on a concrete surface, it is recommended to first lay down waterproofing, which can be a plastic film. To fix the thermal and waterproofing we use mounting tape.

- We cut and lay out the PLEN according to the previously drawn up plan. We do not lay the film close to the wall; we leave a gap of 10.0-15.0 cm so that the plinth can be installed. We remember that the maximum length of the segment should not exceed 8 meters. Incisions should only be made in the indicated locations; they may be marked with a dotted line or a scissors symbol.

The film is cut only in the places marked for this purpose. - We lay the cut fragments in such a way that the copper conductive bars are located at the bottom. We make sure there are no overlaps. Laying end-to-end or with a gap between fragments is allowed.

Example of correct installation

Like thermal insulation, fragments can be fixed with mounting tape.

- We make a connection. This process requires a more detailed description. The sequence of actions is as follows:

- First of all, we measure the length of the mounting wires and strip their ends to a length of 10-12 mm.

- We take the contact clip that comes with the film and insert the stripped end of the wire into the shank.

Contact clamps for connecting IR film - We install the clamp on the copper tape and crimp it, after which we insulate it.

Clamp installation and insulation - We connect the fragments together so that they are connected in parallel.

Schematic illustration of connecting fragments - Install the temperature sensor (included in the kit). It should be on a coal surface. It is advisable to place it in a place that will be least exposed to load.

- We connect the sensor and PLEN to the thermostat. The connection diagram should be given in the manual for the device.

- We test the assembled system. Turn on the heating and set the required temperature. If there is no sparking, the contacts do not heat up, and the system turns off when the set temperature is reached, then we can state that the innovative floor heater has been connected correctly.

- After connection, the finishing coating is installed. After this, installation of the system can be considered complete.

Using the described method, you can install both strip PLEN and IR panels for heating.

Question: How fireproof are the systems, and can they be used in a wooden house?

Answer: Film heaters are completely safe against fires and are equipped with automatic power shutoff devices when the required temperature is reached, not exceeding 50 degrees. They can be used in a home made of any building materials. The safety of heater materials is confirmed by a fire safety certificate.

How is infrared heating installed on ceilings?

The only difference from the method described above is that it is necessary to install a wooden sheathing on the ceiling. The substrate will be attached to it, and thermal modular elements or PLEN will be attached to it. They are fastened using a construction stapler. In this case, care must be taken not to pierce the carbon coating and current-carrying structural elements with staples. Otherwise, the installation principle does not differ from that described above.

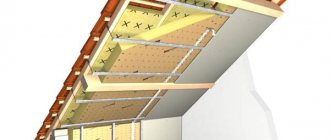

Installation diagram of PLEN ceilings

Designations:

- A – Main ceiling.

- B – sheathing beam.

- C – Vapor barrier layer.

- D – Thermal insulation coating.

- E – IR elements.

- F – Ceiling finishing.

It is noteworthy that a properly installed heating ceiling can be used in conjunction with stretch ceilings. We also note that infrared heaters can be installed not only on concrete floors in an apartment, but also on the wooden ceilings of a country house, but using them as the main heating system is unprofitable, even if there is no gas. When heating a large area, infrared heating consumes a lot of electricity. In such situations, it is better to use heating convectors.

As for wall mounting, it is performed in the same way as IR film ceilings. If the wall bases are plasterboard or wooden, then lathing is not required in this case.

Self-installation of heating PLEN. Reviews from real owners

Film infrared heating of the house, prices for the material were discussed above, you can install it yourself. To do this, prepare the surface to which you will attach, and then do the following.

| Work stage | Photo example |

| After cleaning the surface, it is necessary to create conditions so that the IR radiation goes in the desired direction. Cover the surface with foil or insulation with such material on one side. This should be done with an overlap of 2-3 cm. | |

| It is recommended to secure PLEN strips with a stapler. Leave a gap between the strips with a distance of up to 20 cm. Make sure the system is tight. | |

| The cable to which you will attach the heaters should be routed directly next to the panels. In this case, the wiring must run parallel to the main cable. | |

| Choose a suitable location for the thermostat, which is usually placed at a height of no more than 1.7 m in an open access area. | |

| Before carrying out finishing work, check whether the PLEN heating system is functioning correctly. |

Whether it is worth buying PLEN heating, the price of which is quite high, is up to you to decide. To make it easier to carry out installation work yourself, watch the video on the topic.

Installation of PLEN under suspended ceilings (video)

Consumer Reviews

When choosing heating systems, PLEN heating is also considered. The technical characteristics and price were discussed earlier, but the last aspect remains - reviews from the owners of such heat.

Dmitry, Ryazan: “I have a small one-story private house. A gas boiler, according to my calculations, was too expensive, and PLEN was recommended. I installed it myself a year ago. I did it quickly, but at first I didn’t get the finishing right and lost half the heat along the way. I remade it after 2 months, greatly regretting that I got involved with film heating. But after the correct selection of finishing material for the ceiling, all the problems went away, it was easy to set the temperature in the rooms and it was very convenient to use the equipment.”

Example in a wooden structure

Maria, Tula: “I ordered the finishing along with the installation of a heating system from one company in our city. The employees annoyingly advertised PLEN, and I gave up. Honestly, when I first saw the ceilings, I was shocked. Office type and nothing what I wanted. But with the arrival of winter, I felt all the delights of this type of heating and now I myself recommend it to my friends.”

Related article:

Infrared heaters for heating rooms. IR heaters are very common today. Let's consider the features of their designs, as well as areas of application.

Manufacturer's choice

The characteristics of PLEN are approximately the same, since the same production technology is used, so statements about the advantages of a particular brand are not always reliable. PLEN has proven itself well, in particular EVO 300; you can buy this film in almost any large city, even Khabarovsk or Irkutsk. There are also many good reviews about Fracarro and Orient heating plates.

However, it should be taken into account that energy-saving technologies do not stand still, so new products regularly appear on the market that make it possible to reduce heat loss, and, accordingly, electricity consumption. Therefore, when designing alternative heating systems, this issue should be carefully studied.