Autonomous heating systems in a private house can be open or closed, with gravitational and forced circulation of coolant. Closed-type schemes with forced water movement are considered optimal and more practical. Volatile heating lines ensure uniform supply of coolant to all devices without reducing the water heating temperature. But for the circuit to work uninterruptedly, you need automation for the heating circulation pump - what this is and why, you should understand in more detail.

Scheme and principles of operation of heat pumps

Structurally, the device is a complex of main and auxiliary elements:

- Impeller or impeller. Parts with blades that capture liquid and direct it to the heating system devices.

- Electrical engine. The element is needed to put the equipment into operation.

- Pumping chamber. The compartment is equipped with coolant supply and pressure pipes, which are connected to the system pipelines.

- Frame. Serves to protect the device from damage due to mechanical impact; it can be made of cast iron or heat-resistant plastic.

- Terminals. A box with terminals is needed to connect the unit to the electrical network, to receive power for all elements and control parts.

How the pump works: coolant flows through the supply pipe into the pumping chamber of the equipment, then the electric motor starts the impeller, the blades of which capture the liquid. After this, the pressure on the coolant increases, it is directed to the outlet pipe, which is connected to the main pipeline.

A simple circuit for a heating pump does not require any special skills during installation, and there will also be no problems in finding out the reason for the equipment stopping - there is no power, the impeller is clogged. The supercharger does not provide any additional functional features; it does not increase the pressure in the system; it is only needed to ensure normal fluid circulation in the devices.

Harness

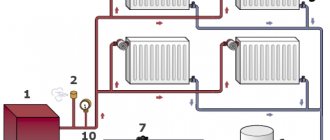

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump; systems with natural circulation work, but in this mode they have lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is installed into it. This gives high heating efficiency and reliability. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with heated floors are forced - without a pump, the coolant will not pass through such large circuits

Forced circulation

Since a forced circulation heating system without a pump is inoperative, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They can jam the impeller and stop the motor. Therefore, a mesh dirt filter must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also advisable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps and remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not working. One ball shut-off valve is installed on the bypass, which is closed the entire time the pumping is running. In this mode, the system operates as forced.

Installation diagram of a circulation pump in a system with natural circulation

When the electricity goes out or the unit fails, the valve on the jumper is opened, the valve leading to the pump is closed, and the system operates as a gravity system.

Installation features

There is one important point, without which the installation of the circulation pump will require rework: it is necessary to rotate the rotor so that it is directed horizontally. The second point is the direction of flow. There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, just when selecting a model, make sure that it can work in both positions. And one more thing: with a vertical arrangement, the power (pressure created) drops by about 30%. This must be taken into account when choosing a model.

Automation devices for pumps

The complex includes several separate units - a thermostat, a relay, and an uninterruptible power supply (UPS). The equipment is required to maintain the uninterrupted operation of heat pumps, as well as to determine the heating mode of the coolant that is transported along the main line.

Advice! A thermostat for a heating circulation pump is useful not only in an autonomous system, but also in a centralized one (in apartments). The device is installed on the radiator and serves to correct the intensity of coolant transportation in the radiator.

Features and purpose of thermostats

Choosing a heat circulation pump for home heating

The device is designed to control the heating of the coolant and combines the functions of a shut-off valve and a thermoelement.

Operating principle of the temperature sensor:

- reading information from the temperature sensor, which is needed to determine the heating mode;

- comparison of sensor readings with preset heating settings that the user enters into the device menu, determining the temperature at which the pump turns on and off;

- putting the equipment into operation or turning off the pump.

The main point in determining the mode is hysteresis. This is the delay interval for the temperature indicator when starting and stopping the device. As soon as the process of heating the coolant begins, the hysteresis is added to the temperature indicators that determine the start of the pump, and when the liquid cools, the set hysteresis is subtracted.

Hysteresis is set manually; the owner himself can set the interval to 5 degrees or more. For example, in the mode settings there is a set temperature level of +50 C, a hysteresis of +7 C, then first the coolant warms up to +57 C, then the automation unit that controls the circulation pump starts the unit into operation. But to turn off the supercharger, the coolant needs to cool to +43 C (50-7).

Advice! The hysteresis should be set from +5 C so that the device does not start and turns off every minute, maintaining a heating accuracy of 1 degree. When selecting a pump, you need to look at the hysteresis settings in the firmware; it is more convenient to work with +/-1 degree minimum and +/-10 degrees maximum.

The temperature sensor is installed next to the boiler, and if the thermostat is set taking into account the temperature data in the room, then the boiler control devices must provide for changes in the heating temperature of the coolant.

Capabilities and principle of operation of an uninterruptible power supply

The circulation pump is a volatile equipment, so if the power supply is turned off, the device will not work. In order not to be left without heat, the owner needs to take care of an additional power source, which can be an uninterruptible power supply (UPS) or a generator. But the generator is noisy, but the support unit guarantees silence, while not being inferior to generators in functionality. The main thing is to choose the right source of direct current, taking into account the individual characteristics of the system.

Operating principle, design and repair of a heat pump

You can do without an additional source of energy if you create a heating scheme with the pipelines sloping towards the boiler - this way the coolant will circulate by gravity, that is, if the power goes out, the house will not be left without heat. However, gravity flow schemes are not suitable for buildings with more than 1 floor and an area of more than 25 m2. The water will not rise to a height by gravity, and while the coolant by gravity reaches the outer radiator, the temperature will drop and the rooms will be cold. Therefore, it is impossible to do without a pump, and, accordingly, a source of additional power in such heat mains.

Installing a UPS is not difficult; the equipment is equipped with an automatic control system and a battery for the blower - such a complex provides energy to the control unit for the heating circulation pump and other elements of the system that operate on electricity.

On a note! The technical data sheet of the uninterruptible power supply specifies the battery capacity and the standard operating time of the device. When choosing a UPS, the power of the circulation pump is taken into account. And in order to provide energy to all elements of the circuit, the power source must be taken with a reserve.

How to choose a circuit breaker and wire for an electric boiler

admin Date: 02/04/2019

To protect electric boilers from overload, circuit breakers are used. How to correctly calculate the parameters and choose a circuit breaker for an electric boiler.

The circuit breaker for the electric boiler protects the power cable from thermal overload. The cause of insulation melting is prolonged overheating of the wires caused by excess current. This may cause a short circuit.

As a rule, the fuse is installed on the meter, on the wire leading to the protected equipment.

To correctly select a pass-through switch with an automatic circuit breaker, you need to select the wire cross-section, calculate the rated current of the electric boiler and take into account the nature of use of the connected equipment.

The wire

To connect an electric boiler, you need to lay a dedicated cable. Even if the boiler has a power of up to 3 kW at 220 V, you should not plug it into the network through a regular outlet - you will load the internal wires of the electrical wiring unnecessarily.

It is recommended to connect electrical equipment and partitions with a power of over 1.5 kW via a copper wire. Copper wires are more durable than aluminum, and for the same load you will need a smaller cross-sectional diameter.

The cross-section of the current-carrying wire is selected based on the rated power of the connected equipment and the network voltage.

The power section of the wire for 220 V will be thicker than for a voltage of 380 V with the same power of an electric boiler.

You can calculate the wire cross-section yourself. To simplify the task, we offer a final table of cross-sections of aluminum and copper conductors.

Wire cross-section table

Table of wire cross-sections for connecting electrical equipment

| Core cross-sectional area, mm2 | Copper wire | Aluminum wire | ||||||

| Single-phase network 220 V | Three-phase network 380 V | Single-phase network 220 V | Three-phase network 380 V | |||||

| Rated current, A | power, kWt | Rated current, A | power, kWt | Rated current, A | power, kWt | Rated current, A | power, kWt | |

| 1,5 | 19 | 4,3 | 16 | 10,0 | — | — | — | — |

| 2,5 | 27 | 6,0 | 25 | 16,6 | 20 | 4,5 | 19 | 11,9 |

| 4 | 38 | 8,5 | 30 | 18,7 | 28 | 6,3 | 23 | 14,6 |

| 6 | 46 | 10,3 | 40 | 25,0 | 36 | 8,1 | 30 | 18,7 |

| 10 | 70 | 15,7 | 50 | 31,2 | 50 | 11,2 | 39 | 24,3 |

| 16 | 85 | 19,0 | 75 | 46,8 | 60 | 13,4 | 55 | 34,3 |

| 25 | 115 | 25,8 | 90 | 56,2 | 85 | 19,0 | 70 | 43,7 |

| 35 | 135 | 30,2 | 115 | 71,8 | 100 | 22,4 | 85 | 53,0 |

| 50 | 175 | 39,2 | 145 | 90,5 | 135 | 30,2 | 110 | 68,6 |

| 70 | 215 | 48,2 | 180 | 112,3 | 165 | 37,0 | 140 | 87,4 |

| 95 | 260 | 58,2 | 220 | 13,7 | 200 | 48,0 | 170 | 106,1 |

Electronic type models

They are also briefly referred to as ET. These are automatic devices that help maintain a given temperature. If necessary, they can be used with any type of pump.

An electronic thermostat can automatically control system actuators such as valves and pumps, mixers, and boilers.

How does it all work?

The presence of a remote or built-in temperature sensor in the design becomes mandatory. It is installed in a place free from direct influence of other heating devices. This part is used to adjust the device.

The temperature sensor gives the ET information about what temperature is maintained in the environment. Currently, digital and analog versions of ET are produced.

The former have greater functionality, due to which they have become widespread.

In turn, digital type models are divided into two types:

- with open;

- or closed logic.

Circulation pump automation

Automation for the circulation pump includes several devices:

- Uninterruptible power supply with rechargeable battery.

- Temperature controllers.

- Pressure switch with remote pressure gauge.

- Dry running relay.

These devices make it possible for the heating system to function after being adjusted to the specified parameters. After this, the constant presence of a person in the house is not required. The owner can leave for the whole day to work or take a few days off. Automatic control of the circulation pump will monitor the level of pressure or temperature in the system, emergency shutting off if the values exceed the permissible values.

About installation and its features

A thermostatic type valve is installed on the supply part of the regulator pipeline. It is important to maintain a horizontal position for the heating device head. Exposure to direct sunlight and heat in large quantities is unacceptable.

Radiators cannot perform their functions properly if they are covered with curtains or crowded with furniture. In such a situation, a zone with an almost complete lack of sensitivity appears. This means that there is no contact with the environment.

Otherwise

If it is impossible to install the heating system in any other way, you will have to use remote control sensors that have a sensitive overlay element. So-called mini heating regulators are also designed for installation in niches.

Experts recommend installing a special shut-off valve on the return line of the heating radiator. Then you will not have to disconnect the entire heating system from the riser if you need to clean the battery or dismantle it.

The pump thermostat must be fully opened when the heating season ends. After this, no excess sediment will form on the valve seat; the device itself simply turns counterclockwise.

There are several thermal modes with which different types of pump devices can operate.

- summer - 28 °C;

- bathroom - 24 °C;

- living room - 20 °C;

- bedroom - 16 °C;

- internal corridor - 11 °C;

- frost protection - 7 °C.

It is necessary to adjust the thermostat for the pump before starting active operation. At this stage, additional hydraulic resistance is created. It is necessary to smoothly adjust the throttle mechanism to achieve the desired result of the pump.

The battery check valve and the battery inlet valve are equally good at accomplishing this same task.

Selecting the location for inserting the device into the system

The installation of the circulation pump is supposed to be in the area immediately after the heat generator, not reaching the first branch line. The chosen pipeline does not matter - it can be either a supply or a return line.

Where can I put the pump?

Modern models of household heating units, made of high-quality materials, can withstand temperatures of a maximum of 100 °C. However, most systems are not designed for higher heating of the coolant.

The temperature of the coolant in the personal heating network rarely even reaches 70 °C. The boiler also does not heat the water above 90 degrees

Its performance will be equally effective on both the supply and return branches.

And that's why:

- The density of water when heated to 50 °C is 987 kg/m3, and at 70 degrees – 977.9 kg/m3;

- The heating unit is capable of generating hydrostatic pressure of 4-6 m of water column and pumping almost 1 ton of coolant per hour.

From this we can conclude: the insignificant difference of 9 kg/m3 between the statistical pressure of the moving coolant and the return does not affect the quality of space heating.

Are there exceptions to the rules?

As an exception, inexpensive solid fuel boilers with a direct combustion type can serve. Their device does not provide automation, so at the moment of overheating, the coolant begins to boil.

Installation of collector wiring in a heating system using a solid fuel boiler is considered the most effective. However, this type of heating of a private house is one of the most difficult to perform.

Problems begin to arise if the electric pump installed in the supply line begins to fill with hot water and steam.

The coolant penetrates through the housing with the impeller and the following occurs:

- Due to the action of gases on the impeller of the pumping device, the efficiency of the unit decreases. As a result, the coolant circulation rate coefficient is significantly reduced.

- An insufficient amount of cold liquid enters the expansion tank located near the suction pipe. The overheating of the mechanism increases and even more steam is formed.

- A large amount of steam entering the impeller completely stops the movement of warm water along the line. Due to the increase in pressure, the safety valve is triggered. Steam is released directly into the boiler room. An emergency situation is being created.

- If the firewood is not extinguished at this moment, the valve will not be able to cope with the load and an explosion will occur.

In practice, no more than 5 minutes pass from the initial moment of overheating to the activation of the safety valve. If you install the circulation mechanism on the return branch, then the period of time during which steam enters the device increases to 30 minutes. This gap will be enough to eliminate the heat supply.

In inexpensive heat generators made of low-quality metal, the response pressure of the safety valve corresponds to 2 Bar. In high-quality solid fuel boilers - this indicator is 3 Bar

From this we can conclude that it is impractical and even dangerous to install a circulation device on the supply line. Pumps for solid fuel heat generators are best installed in the return pipeline. However, this requirement does not apply to automated systems.

Heating with a group of separate lines

If the heating system is divided into two separate lines, heating the right and left sides of the cottage or several floors, it would be more practical to install an individual pump for each of the branches.

When installing a separate device for the heating line on the second floor, it becomes possible to save money by adjusting the required operating mode. Due to the fact that heat has the property of rising, it will always be warmer on the second floor. This will reduce the coolant circulation rate.

The pump is inserted in the same way - in the area located immediately after the heat generator before the first branch in this heating circuit. Typically, when installing two units in a two-story house, fuel consumption for servicing the upper floor will be significantly less.

What is a circulation pump

This is a small unit that is installed in the heating pipeline system and distils the coolant through all branches of the heating system, that is, it ensures the circulation of hot water. There is a wide variety of circulation pumps for heating systems. but for private houses, units with the so-called “wet rotor” are usually used. What is the design feature of this model?

The thing is that the moving parts of the pump, and this is mainly the rotor and impeller, are cooled and at the same time lubricated by the liquid flowing inside the pump, that is, the coolant. Hence the quiet operation, high reliability, and small dimensions of the unit itself. Let's add durability, efficiency and cost-effectiveness here.

Mechanical models

The valve and thermal head are the main elements, without which it is impossible to imagine almost any thermostat. In this case, the latter performs the function of a sensitive element. These parts do not require external energy in order to function properly.

In turn, the thermal head also has several components. This is a regulator and drive, a liquid element, sometimes elastic or gas parts are found as an alternative.

Internal organization

When choosing a temperature controller, it is necessary to take into account all factors that may affect the operation of the device in the future. Its main parts are as follows:

- adjustable scale;

- ring that fixes the set temperature;

- mechanism of compensatory action;

- union nut;

- stock;

- spool;

- detachable connection;

- sensing element;

- thermostatic element;

- thermostatic valve.

Rules for connecting to power supply

The circulation pump is powered. The connection is standard. It is recommended to install a separate power supply line with a surge protector.

To connect, you need to prepare 3 wires - phase, neutral and ground.

You can choose any of the connection methods:

- through a differential machine device;

- connection to the network together with an uninterruptible power supply;

- power supply to the pump from the boiler automation system;

- with thermostat regulation.

Many people wonder why complicate things, because connecting the pump can be done by connecting a plug to a wire. This is how the pumping device is plugged into a regular outlet.

However, experts do not recommend using this method due to the risk of unforeseen situations: there is no grounding and a safety device.

A circuit with a differential machine is used for so-called wet groups. A heating system constructed in this way ensures a high degree of safety for wiring, equipment and people.

The first option is not difficult to assemble yourself. It is necessary to install an 8 A differential circuit breaker. The wire cross-section is selected based on the device rating.

In the standard scheme, the power supply is carried out to the upper sockets - they are marked with odd numbers, the load - to the lower ones (even numbers). Both phase and neutral will be connected to the machine, so the connectors for the latter are designated by the letter N.

To automate the process of stopping the circulation of the coolant when cooling to a certain temperature, an electrical circuit is used to connect the pump and thermostat. The second is mounted in the supply line.

At the moment when the water temperature drops to the specified value, the device disconnects the electrical supply circuit.

In order for the thermostat to turn off the circulation process at the right time, it is installed on a metal section of the pipeline line. Due to poor heat conductivity of polymers, installation on a plastic pipe will result in incorrect operation of the device

There are no difficulties in supplying electricity through an uninterruptible power supply; it has special connectors for this. A heat generator is also connected to them when there is a need to provide electricity.

If you choose the method of connecting the pump to the boiler control panel or automation, you will need good knowledge of the power supply system or the help of a professional.

Open logic

There are also freely programmable types of devices with open logic. They are also often found in circulation-type pumping products. Such devices can be easily adjusted to any environmental conditions and temperature conditions.

But managing them is quite difficult; special qualifications are required. That is why they are not widely used; in circulation-type devices, closed logic is most often found.

You should not save on purchasing a thermostat for your heating system, because this product significantly increases productivity and efficiency.

Source