An electric boiler with a pump and expansion tank is the most convenient heater. A potential buyer needs to know how to select the power of the unit and connect it correctly. A little trick will help reduce energy costs.

Design features of an electric boiler with a pump and expansion tank

The device has everything necessary for the operation of the heating system. The user only has to connect the pipes to it.

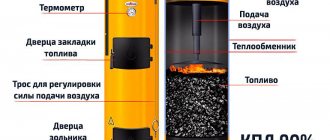

In addition to the pump and expansion tank, the thermally insulated housing contains:

- heat exchanger;

- heating elements - heating elements, electrodes or coil (induction boiler);

- automation system, including a controller with a display and temperature sensors;

- safety group - pressure gauge, safety valve and air vent;

- mud collector for rough cleaning of coolant.

Some models do not have filters. It is recommended to install them additionally, especially if the heating circuit has been in operation for many years.

Advantages

The popularity of electric boilers with a heating pump is explained by the following positive characteristics:

- Rich assortment

. Models of various capacities are available for sale, which makes it possible to acquire exactly the brand that best suits the operating conditions. In this way, you can choose a heating device for both a country house and an industrial premises: there are always options with suitable parameters in stock. - Economical

. Due to the high energy efficiency of modern electric heating boilers (their efficiency is close to 99%), their use allows you to save significant finances. An additional economic effect is facilitated by the use of a circulation pump, which is part of the structure itself. Having low energy consumption, it nevertheless significantly increases the rate of coolant passage through all pipes. As a result, rooms warm up many times faster. - Environmental friendliness

. Such a heating system does not emit combustion products during operation. Therefore, there is no need to spend money on organizing a chimney and providing additional air flow. For this reason, electric boilers are widely used in city apartments and office premises. It is important to remember that the absence of smoke does not mean that the ventilation in the house may be poor. - Ease of management

. This is facilitated by maximum optimization of monitoring and control devices. As a result, even an amateur can monitor the operation of heating equipment. Most of the models on the market are equipped with automatic control units: this allows you to resort to adjusting the operation of the system in very rare cases.

Equipment of this type is able not only to heat rooms, but also to cover the need for hot water. To optimize the water supply system, you will need to install an expansion boiler and a tank with a volume of 80 liters or more.

How does it work

The working medium passing through the heat exchanger gains temperature in one of the following ways:

- heating elements. The heater is a sand-filled tube with a nichrome spiral inside. When current flows through it, the filament becomes hot due to its high electrical resistance. Boilers of this type are the most common.

- Electrodes. Voltage is supplied to metal rods built into the heat exchanger. Current flows through the working medium, increasing its temperature.

- With a coil. An alternating electromagnetic field is created, inducing eddy currents (induction) in the walls of the heat exchanger and the core located inside it. They cause heating of the material and the working environment in contact with it.

Electrode boilers are superior to heating element boilers in the following parameters:

- cost - a tubular element is more expensive to manufacture than an electrode (a piece of wire);

- safety - dry operation is impossible, since the coolant is a conductor, and in its absence, current does not flow.

But they are less convenient to use for the following reasons:

- it is necessary to ensure the exact concentration of salts in the coolant so that its resistance is within the limits specified in the instructions;

- It is necessary to periodically change the electrodes - they dissolve in the working environment.

The advantages of induction boilers compared to heating elements are as follows:

- the integrity of the heat exchanger is not compromised, which means there is no risk of leaks;

- large heating area.

A significant drawback is the high cost, several times more than that of its heating element counterpart.

Thus, in terms of the combination of price and practicality, boilers with tubular elements are superior to all others, which explains their popularity.

Heater performance is regulated automatically.

It is also available in three varieties:

- With sensor immersed in coolant. The simplest option is to support a user-specified temperature regime, for example 90/80 (flow/return).

- With remote thermostat. A more practical type - the user sets the desired temperature in the room, and the boiler itself selects the optimal mode - 90/80, 70/60 or some other.

- Weather-compensated automation. The best option is that the sensor is installed outdoors and the heater learns to select performance in accordance with the outside temperature, promptly responding to colder temperatures and warmer temperatures.

The movement of the working medium in the circuit is ensured by a built-in circulation pump. The expansion tank prevents pipes from bursting when the coolant heats up.

Frost protection is provided: when the working environment cools down to +5 ˚С, the boiler turns on automatically in order to maintain the temperature at this level.

What does it mean to heat with air?

This kind of heating method has been known to ordinary people for a long time. Previously, ordinary houses were warmed by heated air, which from the stoves that were heated went through channels specially made for these purposes. And these days, many owners of country houses are thinking about how to make air heating for their homes with their own hands, since this heating method has many advantages over others.

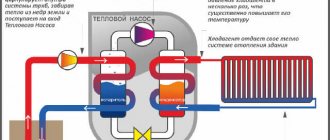

To heat rooms, both internal and external air masses are used. If air is taken only from the street, then this kind of system will be called a supply air system. For this purpose, supply-type fans are used; they drive air directly to the heating unit.

The complete recirculation scheme looks like this: the internal air is in motion all the time, moving from a hot state to a cold state, after which it goes to the heating device, where it heats up again and moves into the room to release heat and a new cooling stage.

Air heating is a type of heating that you need to pay attention to if the choice is made first in order to save money. The most economical method is designed for the air to be heated in a heater or heat exchanger and distributed throughout the rooms through special channels

In each room, several holes can be placed near the floor, through which the air will fill the room with heat.

The most economical method is designed for the air to be heated in a heater or heat exchanger and distributed to rooms through special channels. In each room, several holes can be placed near the floor, through which the air will fill the room with heat.

Description of heating type

First, you need to stock up on three main ingredients.

- Heat generator. For this purpose, a heating boiler or furnace is most often chosen. The boiler will operate on any known type of fuel or be powered from the home electrical network.

- A network of air ducts that are usually made of galvanized steel. They may look unsightly, but are often decorated with all sorts of finishing materials to match the design of the room.

- Supply fan.

This heating design, equipped with your own hands, will heat any room well and fairly quickly. Climate control devices can be built into such a system, which in the summer will serve as air conditioning and air purification. The location of air conditioning devices is carried out both at the top of the room and at the bottom - this depends on the selected air heating scheme.

The supply fan forces warm air into the ducts. It is installed immediately under the combustion chamber of the boiler and, using a filter, cleans the air from all kinds of impurities and dust in order to supply it to the heating site - the heat exchanger. After it passes through the duct network, the cooled air is returned to the heat exchanger.

Advantages and disadvantages

Advantages of an electric boiler:

- Environmentally friendly - no exhaust.

- Easy installation - no chimney required.

- Quiet operation.

- Safety – no open flame, and therefore no risk of fire; no explosive fuel is used; poisoning of residents by carbon or natural monoxide is excluded.

- The ability to change heat output over a wide range without reducing efficiency. Several heating elements are installed, each corresponding to one heating stage. In the case of a gas boiler, this is only possible with an expensive modulated burner.

- There are no special requirements for boiler room ventilation.

Flaws:

- High energy costs.

- Difficulty connecting. Electricity is distributed at the rate of 7-10 kW per household. To power a boiler with more power, you will have to seek permission and change the wire laid from the power line. Sometimes this is not physically possible. Thus, one of the users had to pay for the replacement of a transformer at the substation to connect a 15 kW heater.

- Dependence on the operation of a centralized network.

To reduce costs, they follow the following scheme:

- equip the heating system with a heat accumulator - a container in a mineral wool “coat” containing a supply of heated working fluid;

- switch to a multi-rate electricity payment tariff, providing a discount at night up to 70% (depending on the region).

The boiler operates only during the grace period, heating the coolant in the battery to +95 ˚C. During the day, boiling water is added to the heating circuit through a mixing unit as it cools.

What are the recommended criteria for choosing?

Focus on the main parameters of the boiler:

- Power, i.e. heat output per unit of time. Different models vary from 3 kW to 70.

- Expansion tank volume.

- Pressure at the outlet of the circulation pump.

The capacity of the working part of the membrane expansion tank (the other is filled with air) should not be less than 4% of the volume of coolant in the heating system. It expands by this amount when heated. Thus, for a circuit containing 150 liters of working medium, a boiler with a tank of 150 x 0.04 = 6 liters is suitable.

The pump pressure must be sufficient to overcome the hydraulic resistance of pipes and radiators. The height of the coolant rise does not need to be taken into account, since the circuit is closed. Those. calculated using one formula, regardless of the number of floors:

P = L / 100, where

- P – required pressure, atm (bar);

- L – contour length, m.

Example. For a heating system with a length of 80 m, a pump with a flow of 80 / 100 = 0.86 atm will be required. (bar). For example, Wilo-Star-RS is suitable.

Installation of a wall-mounted boiler

Installation of gas heating boilers of this type requires care when installing fastening units that are fixed on one of the walls of the room. This boiler is very popular among owners of private or country houses, as it is light in weight and compact in size.

If the house is built from a material such as wood, then the wall on which the boiler will be installed must be covered with a sheet of non-combustible material, such as metal. Often in private homes, a wall-mounted gas boiler is installed in the kitchen. Modern devices have an attractive appearance, so they will fit into any interior and will be combined with kitchen furniture.

A wall-mounted gas boiler does not require a separate boiler room, since it includes all units and components, such as a circulation pump, shut-off equipment, automation, and others. You will need to carry out such a step as installing heating from a gas boiler.

This will help avoid mistakes that could affect the efficiency of the heating system.

If you do the installation yourself, you must have certain skills and knowledge, and also take as a basis all the requirements specified by SNiP. Otherwise, the system simply will not be approved by government services and will require repair of gas heating boilers. Date: September 25, 2022

How to calculate power

The nominal performance should be equal to the heat loss of the heated object in the coldest period of the year. The calculation is carried out according to the methodology set out in SNiP “Heating, ventilation and air conditioning”, taking into account the temperatures given in “Building Climatology”.

The following factors are taken into account:

- thermal resistance of enclosing structures;

- difference between indoor and outdoor temperatures;

- air exchange rate, i.e. ventilation performance;

- illumination by the sun (insolation) - depends on the orientation of the object to the cardinal points.

In-depth knowledge of this issue is required, so it is recommended to entrust the calculation to an engineer from a construction or design organization.

This parameter can be approximately estimated using the following formula:

W = (S / 10) * K, where

- W – required power, kW;

- S – heated area, sq. m;

- K – specific value of heat loss, kW / 10 sq. m.

The last indicator depends on the region:

- southern part of Russia - K = 0.7-0.8;

- middle band – K = 1;

- northern regions - K = 1.2-2.

The approximate calculation is suitable for a house of standard architecture with a ceiling height of up to 3 m, well insulated and without panoramic glazing.

Power determines how you connect to the electrical network. For boilers up to 7 kW, a single-phase line with a voltage of 220 volts is suitable. For more powerful ones this is not enough. In such cases, you need an electric boiler for heating the house 380V.

Rules for installing an electric boiler

When installing and connecting, take into account the following requirements of regulatory documents:

- The suspended model must be placed on a non-combustible solid wall that can support the weight of the unit.

- It is prohibited to install the heater next to a sink or in other places where even a small amount of water may come into contact with it.

- Room temperature – +5 ˚С… +40 ˚С, maximum permissible relative humidity – 85%.

- It is not recommended to lay the power cable under water supply or heating pipes. If this is the only possible option, it is placed in a protective box or sleeve.

- The minimum distance from the top surface of the heater to the ceiling is 200 mm, to the floor for suspended models is 1.5 m.

- A switch with open contacts is installed on the supply line. The gap between them is at least 3 mm.

- The boiler is connected via an RCD.

- It is necessary to ensure grounding of the housing and heating system.

- Copper wire is used. The cross-section of the cores is determined in accordance with the rated current and the method of installation (PUE 7, table 1.3.4).

- When connecting a 3-phase model, the circuit breaker is placed on the wall next to it.

Permission from Energy Supervision or other services is not required for installation.

Pipes

What kind of pipes can be used for installation of filling and connections to the boiler and heating devices?

Low operating temperatures and moderate operating pressure allow the use of all types of metal, high-temperature plastic and metal-plastic pipes. The only thing that needs to be mentioned separately is the use of polypropylene:

Pipes must be reinforced with aluminum foil. It will reduce the elongation of the pipeline when heating water in the circuit;

The use of polypropylene pipes without reinforcement for heating needs. The heated spills lengthened and went in waves.

On long straight sections of pipes, expansion joints are needed - U-shaped, ring or bellows. They will not allow the bottling or riser to bend when heating water in the pipes;

Ring and bellows expansion joints for polypropylene pipelines.

- Straight sections are fastened movably with sliding clamps;

- When pipes are laid hidden, gaps remain at the ends of the grooves. They will allow the pipe to lengthen without destroying the groove seal.