Fireplaces, despite the fact that they are among the most ancient heating devices, still remain in demand and never go out of fashion. Indeed, a fireplace is the only interior accessory that will definitely create an atmosphere of comfort in the room, conducive to rest and relaxation.

Fireplace insert with glass

The open fireboxes of these heating structures, although they allow you to observe the beauty of the play of flames without any interference, are not safe. You cannot leave an open fire unattended for even a minute - at any moment the fireplace will “shoot” burning coals into the room. In addition, building a truly correct brick firebox for a fireplace is a very difficult task.

Everything will be much simpler and safer if the brick hearth is replaced by a ready-made metal fireplace insert with glass. This block is built into the heating structure during its construction. A metal glazed firebox allows you not only to easily observe the fire, but also to increase the duration of the fireplace operation on one wood stack, and also to retain the generated heat longer.

In order for the fireplace to operate effectively and its appearance to be attractive with its aesthetics, you need to know how to choose the right product. It also makes sense to conduct a short review of the models of metal fireboxes on sale.

Advantages of metal fireboxes

The traditional fireplace, which has been around for centuries, has an open combustion chamber lined with refractory bricks. Heat into the room from such a heating device is supplied only by direct thermal radiation from the hearth, since the brick walls of the fireplace do not have time to warm up properly to become a significant source of heating the room.

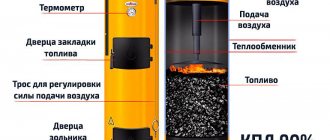

The metal firebox built into the brick structure retains heat well inside the fireplace, and also provides a number of advantages that can be determined by studying this diagram:

One example of the structure of a metal fireplace insert with an air flow circulation diagram

- It is possible to regulate the burning intensity of the wood stash.

- The smoke does not enter the room, but goes into a metal chimney connected to the firebox.

- Between the outer walls of the metal chimney and the outer casing in which it is enclosed, a space is formed that works on the principle of a convector. Heated air enters the room through windows provided in the casing, equipped with metal grilles, sometimes with controllable blinds.

- The glass of the firebox also heats up and releases heat into the room.

- If desired, you can always open the fire door and sit by the open fire.

- When the firebox is closed, you can also observe the burning of wood, since the glass is not covered with smoke due to the provided airflow.

- Safety. A closed firebox eliminates the risk of coals accidentally entering the room, which often happens when wood burns intensely in a traditional fireplace.

Prices for a fireplace with glass

fireplace with glass

Rules for arranging a fireplace with your own hands

Before assembling the fireplace correctly so that it is as reliable and durable as possible, you need to take into account a number of rules aimed at achieving these goals:

- When installing a brick fireplace, you need to create a separate foundation for it;

- The working part of the firebox can only be made of fireclay bricks, which should not be in contact with ordinary bricks;

- When installing the door and ash pan, you need to lay an asbestos cord and leave a small gap necessary for the thermal expansion of the metal elements;

- The interior of the firebox does not require plaster;

- It is advisable to place the rear wall of the fireboxes at a slight angle.

A separate point is the fire safety rules, compliance with which reduces the risk of fire to a minimum:

- Along the entire length of the smoke exhaust duct, special cuttings must be installed to increase the degree of fire safety;

- When placing a fireplace in close proximity to a wall, it is imperative to lay a layer of refractory material between them with a thickness of at least 20-25 mm;

- When installing a fireplace on a wooden floor, it is necessary to lay a metal sheet or ceramic coating under the structure so that it protrudes beyond the perimeter of the fireplace by at least 30-35 mm;

- At the point where the pipe passes through the interfloor floor or ceiling, a 15-cm layer of heat-insulating, heat-resistant material must be installed;

- A fireplace can only have one of its own chimneys.

The operation of the fireplace is also carried out according to certain rules:

- It is strongly not recommended to heat the fireplace to extreme temperatures;

- For normal operation, the fireplace must be regularly cleaned of soot deposits and ash;

- All flammable objects must be kept at least 70 cm away from the fireplace;

- You can only use the type of fuel in the fireplace for which the design was designed.

Design features of metal fireboxes

The design of the firebox and the chimney installed on it includes a number of elements that help retain heat:

One of the designs of metal fireboxes

- The reflective rear wall of the firebox ensures the correct direction of thermal radiation into the room.

- A damper (view) in the chimney helps regulate the draft in the fireplace, preventing heat from directly escaping into the chimney.

- Under the firebox there is a ash chamber through which air flows, promoting normal combustion and maintaining draft. We can say that the blower and the view work in tandem.

- The door, equipped with heat-resistant glass, hermetically closes the combustion chamber. As a rule, it is also equipped with a non-heating handle.

Some models are equipped with additional functions that increase the efficiency of the device:

Combustion chamber with secondary combustion system

- Secondary combustion system. Such fireboxes are divided into two chambers by a horizontal lintel. The firewood burns in the lower chamber, and the pyrolysis gases released during its combustion are burned in the upper chamber. The design allows the fireplace to be operated from one load of fuel for 5–12 hours, depending on the volume of the combustion chamber.

- Afterburning of gases released during smoldering occurs due to the supply of secondary air.

- The long burn system also includes additional thermoregulation and convection capabilities.

- The efficiency in fireplaces of this design can reach 80-85%, which is a very high figure for wood-burning heating structures.

By lighting a long-burning fireplace with a closed firebox in the evening, you can be sure that the next morning the room will have a comfortable temperature. After which you can make the next stack of firewood, which will heat the room until the evening.

Fireplace insert with heat exchanger

In addition to long-burning fireboxes, manufacturers sell products equipped with a water heat exchanger, which makes it possible to provide heat to not one, but several rooms. A heating circuit with radiators built into it is connected to such a fireplace.

One of the diagrams for connecting a metal fireplace insert to a heating circuit

Some models are equipped with a convection casing or have additional holes in the body itself for connecting corrugated metal pipes. The pipes are routed to different rooms, through which air heated in the space between the casing and the outer walls of the fireplace will flow into the rooms.

A special convection distribution casing that allows you to organize air heating in several rooms

If the housing has double walls, then convection openings can also be provided in its outer part.

How to install correctly?

Fireplace inserts must be installed using the following rules:

Installation of a fireplace insert

- For fireplace inserts, only non-combustible materials should be used;

- when installing fireplace inserts, you need to make a level base;

- if you install the unit in a wooden house, you need to additionally install insulation for the wall that is located near the device;

- for fireplace inserts, it is necessary to provide reliable sealing when connecting to the chimney;

- the combustion chamber should be at a height of 15-20 cm from the floor.

If you use high-quality non-combustible materials for fireplace inserts, it will last for many years without major repairs.

[ads-pc-2][ads-mob-2]

Types of closed fireplace inserts

In addition to the features mentioned above, metal fireplace inserts are also divided according to other criteria - the material of manufacture, the type of product, the specific design of the doors.

Material of manufacture

Based on the material used, fireplace inserts can be divided into two groups: cast iron and steel. Steel models are usually lined on the inside with fireproof materials (fireclay or vermiculite boards).

To make a choice based on this criterion, you need to familiarize yourself with the characteristics of each variety.

Fireplace insert “Tarnava Professional Prestige II” 21 kW

- The traditional material for the production of fireboxes is cast iron, as it is characterized by durability and high heat capacity. Cast iron is resistant to high temperatures, so it does not require additional protection from open fire. A firebox made from this material does not deform or collapse at normal operating temperatures for a fireplace.

The disadvantages of cast iron models include:

- their weight is quite large, so the installation of such a fireplace will require a very reliable foundation;

— not a particularly large range of models of cast iron fireboxes, unlike steel options, narrows down the choice options;

— fragility of the material, which must be taken into account during transportation and installation;

— instability to sudden temperature changes;

- significantly higher cost compared to steel products.

Steel firebox "ELBA 609".

- Steel fireboxes are made from heat-resistant steel alloys. The inside of the housing must be protected from the effects of open flames with slabs of fireclay or vermiculite. However, such functional elements as flame dividers, smoke collector, and grate are still made of cast iron.

The advantages of steel options include the following:

— a wide range of models with different design solutions;

— the possibility, if necessary, of replacing the fire retardant lining;

— high thermal conductivity coefficient;

- more affordable price.

However, the service life of steel fireboxes is significantly shorter than that of cast iron products. Steel is subject to deformation processes at too high temperatures and when there are temperature changes.

Fireboxes with a built-in water circuit can be made of either cast iron or steel.

Prices for heating stoves

heating stove

Combustion chamber configuration

Another criterion for choosing a firebox is the design features of the product, selected depending on the design of the fireplace itself. There are several options - built-in fireboxes, double-sided, three-sided, round and through.

- Built-in fireboxes. This type of firebox is also called inserts. Their body is completely integrated into the design of the fireplace portal during its construction.

Built-in firebox installed in a corner fireplace

Most models of built-in fireboxes are long-burning heating devices, that is, they operate using a system of secondary combustion of pyrolysis gases. In addition, the fireboxes are equipped with temperature control, an air glass cleaning system and other functions that simplify the operation of the fireplace.

- Double-sided fireboxes have corner glazing. This option is suitable for fireplace designs with an external corner.

Double-sided firebox in a wall-mounted fireplace

Thanks to this location of the fireplace itself, the panoramic view increases, that is, the fire can be observed from both sides of the room. These types of fireboxes can be installed in island, wall-mounted or corner fireplace models.

- The through version of the firebox can also be called double-sided, since it has two facades located opposite each other.

Island fireplace with a through firebox

This firebox is suitable for a wall-mounted fireplace adjacent to the wall at the end, as well as for an island design. This fireplace model will help to zone the room, for example, into a living room and an area for personal relaxation.

- Three-sided combustion chambers are a firebox glassed on three sides. They can have different configurations:

One of the options for a three-sided firebox

is narrow side walls and a wide façade;

— narrow facade wall and wide sides;

— U-shaped firebox.

Three-sided models are installed against walls or in an island version of the fireplace.

- Round and semicircular fireboxes. The first ones have glazing along the entire circumference. The base and the upper part connected to the chimney are made of metal. Round fireboxes are best suited for island fireplaces, but they can also be installed near a wall, although this does not seem rational.

Island fireplace with a round combustion chamber

The round island version of the fireplace is used for rooms with a large area, since in a small room it will simply look ridiculous.

Semicircular fireboxes, as well as three-sided chambers, are most often installed near the wall.

- Fireboxes for biofireplaces can have different shapes and glazing. Their main difference is that they do not need to be connected to a chimney, since ethanol with special additives is used as fuel in this fireplace. These substances burn completely without releasing fumes.

A bio-fireplace in an interior is beautiful, but usually nothing more...

However, this type of fireplace is only a decorative element of the interior, unable to heat the room. True, some models have a built-in electric heater that can create either a flow of warm air or infrared warming radiation.

Fire door design

When choosing a fireplace insert, you need to pay attention to the shape of its glazed doors and the material from which they are made, as they are designed to ensure the safe operation of the device. In the production of these structural elements, tempered fire-resistant glass is used, which is adapted for operation in conditions of extremely high temperatures, reaching up to 800 degrees. The metal door frame for glass installation is equipped with a gasket made of non-flammable sealant.

Doors on a closed firebox can be attached and opened in different ways - vertically, traditionally wide open and in combination.

Firebox with guillotine door

- The vertically opening firebox door, “guillotine” type, is equipped with a special elevator. The glass, framed by a metal frame, rises upward into a niche provided in the firebox body. The movement of the door is carried out due to special cables or chains, on which a counterweight is attached to the rear side of the frame, balancing the forces of gravity on both sides.

Design of a guillotine door on suspensions

Such models of fireboxes can have a mechanism not only for vertical opening, but also for the traditional horizontal one. Thanks to these options, it is possible to enjoy an open or closed flame, while simultaneously monitoring the safety of the fuel combustion process.

Guillotine-type combustion chambers can only have a front view or have a through design.

Fireplace prices

fireplace

- The traditional version of the doors opens similarly to window frames - wide open. There may be one or two doors. Which model to choose will directly depend on the preferences of the fireplace owner.

Fireplace insert with hinged doors

Doors can have frames with a different number of lintels, but if there are too many of them, the viewing function of glass doors is reduced. The double or single classic door provides a view of the combustion chamber only from the front. These fireboxes are designed for wall-mounted fireplaces.

Types of glass in firebox doors

Various heat-resistant glasses can be installed in the combustion door, and their type affects the viewing capabilities of the door:

- Regular straight glass is a standard option that is installed in doors of any size and design.

- Prismatic glass can refract the appearance of a hot flame. Thanks to this effect, the flame visually appears closer and larger in size. Such glass is perfect for wall-mounted and corner fireplace models.

- Spherical glass is installed in round or semicircular fireplace models. This glazing option does not refract the view of the fire, but the view is increased due to the openness of the combustion chamber. These fireplace options can be installed either near a wall or as an island design element in a room.

Chimney in a private house

The most traditional material used for chimney installation is brick. However, steel can also be used for these purposes - this item has virtually no effect on the efficiency of the fireplace. There are solid ceramic chimneys on the market, but they are very difficult to work with, so you won’t be able to build a fireplace with your own hands if you choose this option.

When designing fireplaces with your own hands with a detailed description of their parameters, it is necessary to consider fire safety measures, which are largely related to the design and location of the chimney:

- When installing a chimney, care must be taken to protect the interfloor ceilings from high temperatures. Typically, asbestos material is used for protection, which is also suitable for insulating walls in close proximity to the fireplace.

- Thermal insulation material (asbestos or sheet metal) must be installed under the base of the fireplace. To reliably protect the floor from flying sparks or firewood falling out of the firebox, the material must extend beyond the fireplace by at least half a meter.

- The foundation itself must be strong and powerful enough. If the fireplace is made of brick, then its weight may well exceed 1 ton, so the structure will require a separate foundation. This is due not only to the total weight of the fireplace, but also to the shrinkage of the building, during which the fireplace should not move so that the tightness of the chimney pipe is not compromised.

What are the principles for choosing a fireplace insert?

Fireplace insert power

If the fireplace being created is seriously considered as a heat source, and not just as a “decoration”, then power can be called one of the main parameters. The right choice determines how effectively the fireplace will heat the rooms of the house.

In order to choose the right power of the heating device, it is necessary to take into account a number of factors:

- The dimensions of the room (or rooms, if the fireplace will need to supply heat to more than one room).

- The presence of windows and doors, their number and sizes.

- Quality of home insulation.

- Other features of both the entire house and a specific room.

For such devices, three power categories are usually indicated - maximum, rated and minimum. When choosing a specific model, you need to focus on the nominal value, since if the device constantly operates at maximum power, its service life will be significantly reduced. At maximum capacity, the fireplace should operate very rarely, only in some completely abnormal cold weather for the region of residence.

Operating the device at minimum power will not provide effective heating of rooms. Typically this mode is used when the fireplace serves mainly a decorative function.

How to determine the power required for a particular room in order to focus on it when choosing.

You can do it simply - calculate from the ratio of 100 W per 1 square meter of area. But the likelihood of making a very serious mistake is very high.

The second way, more accurate, is to carry out a calculation taking into account the main features of the room. Our online calculator will help. And some explanations for working with the program are located under the calculator.

Calculator for calculating the required thermal power

Go to calculations

Explanations for working with the program

The calculation is simple - you just need to specify the requested data - and the program will do the rest itself.

The calculation is carried out for the specific room where the fireplace will be installed. If the fireplace insert model involves supplying heat to several rooms, then the calculation is carried out for each of them, and then the results are summed up.

- First, indicate the area of the room and the height of the ceiling.

- Next, you should indicate the number of external walls, that is, those in contact with the street. It is through them that heat loss occurs, and a lot depends on the number of such walls. In my mind, the area of these walls should also be taken into account, but the calculation is somewhat simplified without much loss of accuracy of the final result.

- It also matters whether the wall receives a “charge” of solar energy, or is located on the side of the house where there is no sun (north, northeast).

- If the house is located in an open area, then winter winds can have a significant impact. If their predominant direction (wind rose) is known, then this can also be taken into account in the calculations. If the owners do not have such data, then you can leave it as default - the calculation will be made as for the most unfavorable conditions. If the house is well protected from the wind by natural or artificial barriers (trees, dense urban development, etc.), then the calculation can be carried out as for the leeward side.

- The next point is the level of minimum temperatures in the coldest decade of winter. Important - normal temperatures for the region of residence must be indicated.

- The degree of insulation of external walls. By and large, walls in a residential building should not be uninsulated at all. The average degree of insulation can be conventionally understood as brick walls with two bricks (about 500 mm thick) or a wooden frame with a wall thickness (log or timber) of at least 200 mm. Full thermal insulation is one that has been completed in full according to preliminary thermal calculations.

- The next two data entry fields are, so to speak, “vertical neighborhood,” that is, an assessment of what is located below and above the calculated room.

- A whole group of fields evaluates the quality, quantity and size of windows in a room. Based on the entered data, the program will compare the glazing area with the area of the room and add the necessary correction factor to the calculation result.

- Finally, if the room has a door to the street or to any cold, unheated room, and this door is regularly used during the day, then there is a path of considerable heat loss. This means that adjustments need to be made in this regard as well. By the way, there may be several such doors.

After entering all the data, all that remains is to click on the “CALCULATE...” button. The result obtained will become a guideline when choosing a fireplace insert model based on its rated power.

Other criteria for choosing a combustion chamber

To make the right choice of fireplace insert, you need to highlight the main points that you should pay attention to. The cost of a particular product will depend on these same characteristics. Some points have already been mentioned, but it would be worth repeating.

- The linear dimensions of the combustion chamber depend on the planned fireplace model.

- Application of innovative technologies in the design of the firebox.

- Parameters of panoramic glass and its type (regular, prismatic, spherical).

- Method of opening doors (hinged, guillotine or combined design).

Distribution of air heating ducts from the fireplace to adjacent rooms

- The presence of convection channels in the fireplace body, making it possible to connect corrugated pipes that will supply heated air to other rooms of the house.

- Availability of a water circuit.

- Equipping the structure with a long-term combustion system.

- Combustion chamber power.

- Design features of the product that affect its performance. For example, corner versions of fireboxes have compact parameters and a neat aesthetic appearance, but they are not capable of heating a large room. Such models are best suited for a small room; they will not take up much space, and their power will be enough to heat a small area.

- Type of fuel used. Almost all fireplaces are designed for wood heating, but there are models that use alternative types of solid fuel. The efficiency of home heating depends not only on the type, but also on the quality of the fuel used.

- The design of the firebox doors is purely at the discretion of the owners.

Find out how to make a decorative fireplace with your own hands, as well as how to finish it by studying the step-by-step report in a special article on our portal.

Example of fireplace arrangement

There are a lot of different orders that allow you to lay out fireplaces of very different configurations. However, the technology for carrying out work always includes the same steps, which will be discussed below.

As an example, we will consider making fireplaces with our own hands with the following parameters:

- Portal width – 62 cm;

- Height – 49 cm;

- Firebox depth – 32 cm;

- A square pipe with a side of 26 cm is used as a chimney;

- To lay the back side of the fireplace, half bricks are used, and the side walls are laid out of solid bricks.

A short overview of fireplace insert models

To make it easier to choose a suitable firebox, a brief overview of several popular models will be presented below, indicating their advantages and performance characteristics. Let us note one more nuance - some manufacturers, without indicating the power of the product, name the area for which the model is designed to heat. Apparently - based on the average indicators mentioned above.

Laudel Prismatic 850

The first to be considered is the model produced by the French company, “Laudel Prismatic 850”.

External view of the Laudel Prismatic 850 fireplace insert

The combustion chamber is made of high quality cast iron, which is the best option for storing and releasing thermal energy. The firebox door frame is made of brass and has fire-resistant prismatic glass, resistant to temperatures up to 750 degrees.

Prismatic glass not only enhances the visual effect of a hot fire, but also enhances the thermal radiation emanating from it.

The firebox is equipped with a “clean glass” system, which prevents burning from settling on the inner glass surface when burning wood.

The door has two opening mechanisms - vertical and side. The door is lifted vertically by a counterweight attached to metal chains.

The firebox also has a standard heat radiation distributor, as well as a high smoke collection section of the body, which promotes good removal of combustion products and heating.

The smoke collector has four convection pipes for connecting pipes that distribute heated air throughout the rooms. They are located around a pipe designed for installing a chimney pipe, which has a top connection.

The back wall, grate, firewood limiter, and deflector are removable structural elements, which makes it possible to replace them without completely disassembling the fireplace structure. This need may arise due to accidental mechanical damage to parts.

The firebox is equipped with a long-burning system, which allows for economical use of fuel.

The product is manufactured using innovative technologies, meets European NF environmental standards, and also has the French “Green Flame” certificate.

The main characteristics of the Laudel Prismatic 850 model are presented in this table:

| Name of parameters | Indicators and characteristics |

| Manufacturer country | France, Invicta |

| Material of manufacture | Cast iron, brass, glass. |

| Type of fuel | Firewood |

| Volume of heated room, m³ | 240 |

| Functionality | Long-term combustion (afterburning of released gases), convection distribution of heated air throughout the rooms. |

| Standard heated air distributor | Eat |

| Equipped with a “clean glass” system | Eat |

| Smoke collector | High |

| Glass type | Prismatic |

| Door opening type | Swing and guillotine |

| Vertical door lift system | Counterweight, chains |

| Availability of gate | No |

| Ash pan and grate | Eat |

| Facade shape | Unilateral |

| Chimney diameter, mm | 200 |

| Firebox weight, kg | 230 |

| Device power, kW | 12 |

| Linear parameters, mm (depth, width, height) | 530×825×1095 |

| Efficiency, % | 70 |

Fireplace insert “Tarnava Professional Premium 18 kW”

Polskaya constantly uses innovative developments in the production of its products. Thanks to this, fireplace inserts from this manufacturer are highly energy efficient and economical to operate.

The products are made of high-quality cast iron and are intended for air heating of premises. The body of the combustion chamber quickly warms up and releases heat into the room for a long time, and the presence of horizontal and vertical fins minimizes heat loss.

The firebox is equipped with a long-burning system, that is, it has a double combustion function.

According to European standards, Tarnava fireboxes are equipped with a cast iron deflector, which replaced the damper. The deflector is a plate that is designed to cut the flow of unburned fuel particles, directing them to secondary combustion.

Prices for the Tarnava Professional fireplace

fireplace “Tarnava Professional”

External view of the fireplace insert “Tarnava Professional Premium 18 kW”

The advantages of fireplace insert products from this manufacturer include the following:

- The combustion chamber is made by injection molding, that is, there are no welds or bolted connections in the design.

- Fireplace doors are adjusted to each product manually, so they are completely sealed and do not require additional sealing gaskets.

- The efficiency of Tarnava products is one of the highest on the fireplace insert market. This quality is achieved through innovative secondary air supply solutions.

- Economical use of firewood.

- The “clean glass” system provides internal protection to the glazing from contamination during the operation of the fireplace.

- The presence of cast fins on the body increases the useful heat transfer area from the walls of the firebox, which contributes to the greatest heat retention in the room.

- Tarnava combustion chambers are designed for continuous combustion over a long period of time.

Speaking specifically about the “Professional” line of fireplace inserts, the following features should be highlighted:

- "Tarnava Professional" are monolithic products that can have different design options.

- Fireplace inserts of this series are characterized by stable operation and endurance under constant loads.

- The quality of the products is confirmed by a ten-year guarantee; it has average linear parameters and is equipped with flat fire-resistant glass, enclosed in a wide frame.

- The fireplace insert is suitable for different fireplace portals that have a straight shape.

- In models of this line, handles for regulating the intensity of fuel combustion are located on the front side of the firebox. Thanks to this, adjustment can be made without using the throttle valve.

- The ash drawer is almost invisible - it is hidden behind the door of the structure. And to remove it, you just need to open the door.

The characteristics of the fireplace insert “Tarnava Professional Premium 18 kW” are summarized in the table:

| Name of parameters | Indicators and characteristics |

| Manufacturer country | Poland, Tarnava |

| Material of manufacture | Cast iron, glass. |

| Type of fuel | Firewood |

| Volume of heated room, m³ | 300 |

| Functionality | Prolonged combustion (afterburning of released gases). |

| Equipped with a “clean glass” system | Eat |

| Smoke collector | High |

| The presence of a deflector | Eat |

| Glass type | Direct, fire resistant. |

| Door opening type | Swing (side) |

| Ash pan and grate | Eat |

| Facade shape | Unilateral |

| Chimney diameter, mm | 160 |

| Firebox weight, kg | 185 |

| Device power, kW | 18 |

| Linear parameters, mm (depth, width, height) | 495×625×755 |

| Efficiency, % | 78 |

Fireplace insert “KRATKI MB100G”

Another version of a wood-burning fireplace insert from a Polish manufacturer, made from high-quality boiler steel 5 mm thick. A distinctive feature of this model is the ability to use it both for embedding into a brick portal, and for installation separately. That is, for this design it is not necessary to build a fireplace portal.

The fireplace door is equipped with glass, on which a special tinting is applied, which can visually increase the space of the fuel chamber, and make the flame from burning wood more spectacular.

Heat-resistant glazing is designed to operate at temperatures up to 800 degrees.

The model is equipped with a “clean glass” system, the function of which is to supply cold air flows to the inner glass surface. The air pushes flue gases away from the door, preventing soot from settling on it.

The “KRATKI MB100G” model has a design that makes it possible to use the firebox even without building a fireplace portal

The door “KRATKI MB100G” is made according to the guillotine principle and opens vertically with the help of counterweights. The movement of the door panel is silent and smooth. It is possible to fix the door in the required position at any height. In addition, the door design also allows for side opening, which simplifies cleaning of the combustion chamber.

For safe operation of the device, a locking system is built into the doors, which is especially important if small children live in the house.

The door frame is made of a heat-resistant profile that can withstand high temperature loads. The tightness of the door closure is ensured by a special heat-resistant seal fixed along its perimeter.

The internal walls of the combustion chamber are lined with gray refractory ceramic material “Acumotte”, capable of accumulating and then releasing heat into the room.

The firebox is equipped with a gas afterburning system, which occurs when secondary air is supplied.

A deflector made of vermiculite and installed in the fuel chamber increases the high heat transfer of the device.

The intensity of fuel combustion in the combustion chamber is regulated using a special handle located on the bottom of the door.

The firebox is equipped with height-adjustable legs, which allows you to position it correctly even on an uneven surface.

The ash pan is not provided in the design - its function is taken over by the secondary combustion chamber.

The manufacturer's warranty is five years.

Characteristic features of the fireplace insert “KRATKI MB100G”:

| Name of parameters | Indicators and characteristics |

| Manufacturer country | Poland |

| Material of manufacture | Steel, glass. |

| Type of fuel | Firewood |

| Volume of heated room, m³ | 280÷300 |

| Functionality | Prolonged combustion (afterburning of released gases). |

| Equipped with a “clean glass” system | Eat |

| Smoke collector | High |

| Glass type | Direct, fire resistant. |

| Door opening type | Swing (side) and lifting |

| Facade shape | Unilateral |

| Chimney diameter, mm | 200 |

| Firebox weight, kg | 327 |

| Device power, kW | 14 |

| Linear parameters, mm (depth, width, height) | 548×1203×1293 |

| Efficiency, % | 82 |

Fireplace insert “Single Face AX-F 1400 PC”

The firebox of the French “Single Face AX-F 1400 PC” is made of steel, and can have four different options for facade finishing - gray cast iron, mirror brass, black or stainless steel. The cost of the device will also depend on the facing material of manufacture.

All products from this manufacturer are tested and have environmental safety certificates NFD 35-376.

The device is equipped with a draft regulator, which automatically opens when the door is opened.

The housing has openings for air supply with rotating and removable valves.

The combustion chamber comes with removable legs, 180 mm high.

The firebox is lined with fireclay bricks, which perfectly accumulates heat and protects the steel walls of the housing from overheating and deformation.

Appearance of the “Single Face AX-F 1400 PC” firebox

The characteristics of the fireplace insert model “Single Face AX-F 1400 PC” are collected in the table:

| Name of parameters | Indicators and characteristics |

| Manufacturer country | France "Axis" |

| Material of manufacture | Steel and fireclay, the facade can be lined with different materials. |

| Type of fuel | Firewood |

| Volume of heated room, m³ | 350÷400 |

| Functionality | Long-term combustion (afterburning of gases released during pyrolysis). |

| Equipped with a “clean glass” system | Eat |

| Heated air distributor | Eat |

| Smoke collector | High |

| Availability of gate | Eat |

| Glass type | Direct, fire resistant. |

| Door opening type | Swing (side) and lifting using counterweight |

| Ash pan and grate | Eat |

| Facade shape | Unilateral |

| Chimney diameter, mm | 300 |

| Firebox weight, kg | 500 |

| Device power, kW | 19 |

| Linear parameters, mm (depth, width, height) | 690×1352×1780 (+180 legs) |

| Efficiency, % | 0.725 |

Fireplace insert "Radiante 600/57 Rk Ecoplus"

An interesting model from a German manufacturer, which can be built into a fireplace portal or installed as an independent heating device. Moreover, this firebox option is suitable for both straight and corner, round or semicircular fireplaces. For heating a small room, “Radiante 600/57 Rk Ecoplus” is the optimal model, as it can be built into a compact fireplace portal.

"Radiante 600/57 Rk Ecoplus" has an elegant facade design that fits perfectly into any interior design

Spherical or semicircular glass significantly expands viewing capabilities. The glazing is cleaned by air flows entering its internal surface, so that it always remains clean.

The presence of a secondary afterburning system allows for economical use of fuel. In addition, the firebox is equipped with adjustment of the burning intensity of wood or coal. All these functions allow you to operate the fireplace for 24 hours, so the firebox is quite suitable for heating a small room, even as the only source of thermal energy.

The manufacturer's warranty on the product is five years, but provided that all operating requirements are met, the combustion chamber can last much longer.

The characteristics of the combustion chamber "Radiante 600/57 Rk Ecoplus" are shown in the table:

| Name of parameters | Indicators and characteristics |

| Manufacturer country | Germany "Hark" |

| Material of manufacture | Cast iron, fireclay lining |

| Type of fuel | Firewood, coal. |

| Volume of heated room, m³ | 170÷175 |

| Functionality | Long-term combustion (afterburning of gases released during pyrolysis). |

| Equipped with a “clean glass” system | Eat |

| Smoke collector | High |

| Availability of gate | No |

| Glass type | Spherical, fire resistant. |

| Door opening type | Swing (side) |

| Ash pan and grate | Eat |

| Chimney diameter, mm | 180 |

| Firebox weight, kg | 158 |

| Device power, kW | 8 |

| Linear parameters, mm (depth, width, height) | 509×585×1465 |

| Efficiency, % | 0.75 |

* * * * * * *

Having received information about which combustion chambers for installation in a fireplace can be found on sale, as well as what you need to pay attention to when purchasing a product, it will be much easier to decide on the choice of the required model.

It should be noted that the range of fireplace inserts in specialized stores, as well as online offers, is so large that in this variety it is quite possible to find the only option that is suitable for a particular portal and will satisfy the needs of the most demanding consumer. As proof of this, there is an interesting review of Kaw-Met fireplace inserts.

Fireplace design

When we build brick fireplaces, the first thing we need to do is create a project that displays all the necessary dimensions of the structure and its parameters:

- Creating a drawing . At this stage, a place to install the fireplace is usually selected and its dimensions are calculated. When these parameters are known, fireplaces with a detailed description must be depicted on paper, observing the scale and putting down all dimensions. Of course, the drawing must also take into account the proper passage of the chimney through all the ceilings, as well as the location of the blower and the design of the firebox.

- Preparation of tools and materials . Serious variability in materials is only possible when selecting them for cladding. Thus, finishing can be done using red ceramic bricks or decorative tiles. In this example, the first option will be considered.

The set of materials for laying a fireplace with the specified parameters is as follows:

- Fireclay brick of a grade not lower than M200 for forming a firebox;

- Red ceramic brick in the amount of 250 pieces (it is advisable to take with a margin of about 10%);

- Materials for pouring the foundation and laying bricks (cement, sifted sand, gravel and water);

- Waterproofing material for laying the foundation;

- Smooth boards for formwork;

- Grate;

- Metal door;

- flap;

- Blower;

- Metal wire and rods necessary for reinforcing the structure;

- Wire 0.8 mm thick for dressings;

- Asbestos cord.

Before you make a fireplace in your house with your own hands, you need to prepare the following set of tools:

- Master OK;

- Tape measure and marker;

- Smooth rule;

- Bulgarian;

- Level, plumb and square;

- Construction stapler;

- Bayonet and shovel;

- Construction mixer or drill with an appropriate attachment;

- Rubber hammer for leveling brickwork;

- A regular hammer for installing formwork.

Preparatory work

The first step is to build the foundation, on which the durability and reliability of the fireplace depends. The foundation for the fireplace must be separate - the building shrinks to some extent, so the installed heating unit may become deformed. When creating a foundation in a house that is already in use, it is necessary to take into account all roofing elements that may interfere with the future structure or affect the installation process.

It is much easier to equip the foundation before building the house - all work will be reduced to the following sequence of operations:

- First you need to dig a pit, the depth of which is equal to or greater than the freezing depth of the soil;

- Next, the formwork is installed, and the bottom of the pit is filled with a mixture of crushed stone and sand;

- The next step is laying the selected waterproofing material;

- The foundation is reinforced with metal rods and filled with mortar to a mark located at a height of two bricks below the floor level;

- The poured foundation must be left until it hardens completely (usually this takes about three weeks).

If the foundation is poured from scratch, then there will be no special problems with it. A completely different matter is creating a foundation in an already built house, which will require dismantling part of the floor in the place where the fireplace will be installed.

The work process looks like this: first you need to mark the base of the fireplace on the floor and make indentations of about 20 cm in each direction. Using a grinder, the floor covering is cut along the marked lines. When this operation is completed, you can begin to extract the bare soil and perform the algorithm described above.

When the base of the fireplace is brought to the floor level, the gap between the stone and the floor covering must be decorated. In addition, after each stage of work, it is advisable to carry out cleaning, and immediately before building a fireplace in the house, the room should be covered with plastic film to minimize the amount of contamination of the floor and furniture.

After creating the foundation, you can begin work to ensure fire safety. If we make a fireplace with our own hands, located near the walls, it is necessary to protect each of them from exposure to high temperatures. Asbestos sheets are usually used for these purposes, but ceramic tiles are also a good option.

The last stage of preparatory work is to bring the purchased bricks into working condition. The bricks used need to be collected, sorted by size, and a small number of bricks that will be used in the near future need to be moistened - this way they will not take moisture from the mortar.

Before you build a fireplace in your house with your own hands, it is advisable to lay out a brick structure without mortar. This operation serves two purposes: firstly, preliminary installation will allow you to localize all difficult areas of the work and understand how to create them later during final installation, and secondly, this will prevent some installation errors. If during the dry laying process you number all the bricks in order, then further creation of the fireplace will be much easier.