Beretta gas boilers have proven themselves as a source of thermal energy in autonomous heating systems. The units are equipped with a self-monitoring function for the processes occurring in units and parts during boiler operation. Equipment malfunctions can be identified by light signals.

We will analyze the typical malfunctions of the Beretta gas boiler and their elimination. Let's consider in what cases it will be possible to solve the problem on our own. Let's find out when you will have to call a gas service technician for repair operations.

We will talk about how to identify an error in the operation of the equipment, about which it independently warns the owner. We'll tell you what the combinations of letters and numbers that appear in the event of a problem with the built-in display or indicators mean. With this information, you can decide how best to proceed.

Design and principle of operation of Beretta boilers

Floor models

The Bereta company produces floor-mounted, wall-mounted and condensation wall-mounted models of gas boilers. Floor standing units are presented in the Novella and Fabula series.

The control panel is located at the top of the case, the buttons are covered with a hinged lid. On the left are the power buttons, burner lock reset buttons, temperature regulator and thermometer. To the right is a limit thermostat for flue gases and a draft sensor with manual reset. There are LED network and lock indicators at the bottom.

In the upper right part of the body there is a sleeve for installing sensors. Below the base is an atmospheric two-stage gas burner with two gas valves. A sectional cast iron heat exchanger is installed above it.

Novella models from 174 RAI to 279 RAI have two heat exchangers of equal power, connected together and having one flue. The circulation pump is mounted on top of the burner. To the left is the gas fittings. In the lower left corner there is a tap for draining the heat exchanger from the boiler.

Wall models

The wall-mounted Beretta City 24 CSI has a control panel in the lower right corner of the case. It has a switch for the “Summer” and “Winter” modes. The Beretta Ciao 24 CSI model has a backlit screen that shows the temperature of the coolant and hot water, and also displays error codes in case of problems.

The Beretta Super Exclusive device has a separate pressure gauge for monitoring the water pressure level in the system. A secondary plate heat exchanger is installed separately to provide hot water supply. A thin expansion tank is attached to the right wall.

The combustion chamber is a closed type, completely isolated from the room. The fan for removing combustion products is located in the upper part and is connected to the flue gas flange. Under the pump there is a three-way valve with an electric drive.

Boiler Beretta City 24 CSI

To the right of it is a hydraulic pressure switch, which will prevent the system from igniting if there is insufficient pressure and will display an error message on the display. If desired, you can separately connect a remote control and a room temperature sensor to the boiler.

Condensing apparatus

Bereta condensing boilers are available in the Minute Green, Exclusive Green and Power Plus series. They allow you to use the energy of gas combustion more efficiently, due to the fact that they additionally use the heat of its combustion products. Both single-circuit and double-circuit configurations are available. Power Plus devices are available with one and two combustion chambers.

The fan-driven gas burner is modulating, has a pre-mixing system and can be configured to operate with liquid gas. All Beretta boilers have the ability to cascade to achieve greater total power.

Let's look at the main error codes for Beretta gas boilers and other common faults.

Repair the board or replace it with a new one?

The electronic board of any boiler is an expensive device and replacing it with a new one in case of any malfunction is not advisable, especially since Beretta boards do not have the most complex circuit diagram.

We offer our clients board repair because it is, first of all, profitable, since the cost in most cases does not exceed 30% of the price of a new board. To carry out repairs, we have professional equipment, diagrams, original spare parts and experience.

To carry out diagnostics, special stands have been organized that simulate a real unit, on which the boards are checked after repair.

We don’t just repair boards, but we provide a significant warranty period for the work, because we have already repaired more than one such board and are confident in the result.

Other faults

Other damage may also occur. If you smell gas in the room where the boiler is located, you need to turn off the boiler and all electrical devices. Open the window and call emergency services. If you smell combustion products, there is most likely a problem with your draft. Inspect the chimney for blockages and its connections for leaks.

Delayed ignition may be caused by incorrect settings of the gas valve. If the coolant does not heat up to the required temperature, the problem may be a clogged burner or incorrect settings on the control panel.

Gas fittings for Beretta boilers

When the required temperature is reached on the boiler screen and the heating radiators are cold, this may indicate the following:

Basic error codes

a01

Error a01 (01) means that there have been 5 failed attempts to ignite the burner flame. It is necessary to check whether the gas valve is open, whether a spark appears between the ignition electrodes and inspect the cable of the ignition system. The slave electronic board may also fail.

Beretta City boiler electronic board

a03

Error a03 (03) occurs when the flue gas thermostat is triggered. It is necessary to inspect the smoke removal and air supply system, as well as the functionality of the fan.

a04

Error a04 (04) indicates that the ignition valve relay has opened and the limit thermostat has tripped. You should look for faults in the slave electronic board.

a07

Error a07 (07) is triggered when the safety relay is not open. In this case, the slave electronic board must be checked.

10

Error 10 appears when there is no flame in the burner.

Errors in Beretta gas boilers - meaning and methods of elimination

The occurrence of a malfunction in Beretta gas boilers is reported by the self-diagnosis system. It has monitoring sensors that detect problems in various components and signal this to the control module. As a result, the unit is blocked and an error code appears on the display. Some of them can be eliminated yourself. And if it doesn’t work, then they call a specialist.

How does the self-diagnosis system work?

In Beretta boilers, the self-diagnosis system consists of a network of monitoring sensors located on the main working units of the units.

After turning on the boiler, the sensors begin to function in continuous mode; they do not require an additional special start. Using the same principle, it is impossible to disable the sensors without stopping or blocking the gas boiler.

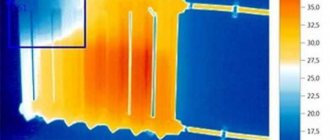

All main components of the Beretta gas boiler contain sensors that send signals to the display with an error code when problems are detected

When the monitored parameters change or the operation of a particular unit is disrupted, signals from the sensors are sent to the control module, which blocks the equipment. At the same time, an error code is displayed on the display, allowing the boiler owner to determine the type of problem and take measures to eliminate it.

In addition to the display, malfunctions in Beretta boilers are signaled by special indicators located depending on the design features of different models of heating equipment.

Error codes for Beretta gas boilers and their meaning

The manufacturer of Beretta gas boilers has made sure that the buyer has plenty to choose from - floor-mounted, wall-mounted, as well as condensing units are available for sale. The following models are popular among consumers: Super Exclusive, City, Novella, Fabula.

The control of various Beretta gas boilers can be mechanical or electronic with an information display. Condensation models are represented by the Green, Exclusive Green, Minute lines. They use fuel more economically and efficiently.

It happens that while the unit is operating, a fault code appears on the screen. In this case, you can try rebooting the device, and if this does not help, you should read the instructions about malfunctions of the Beretta gas boiler and their elimination. Let's look at the most common errors. Code A01 indicates problems in the ignition system of the gas boiler. There may be a problem with the control board or there is no light. The reasons are usually as follows:

- the flame detection electrical wire is clogged - this can be corrected by cleaning it;

- there is no fuel supply - the gas supply to the mains is interrupted or the gas valve is closed;

- malfunction of the gas valve - only a specialist can adjust it;

- the connection of the contacts on the ignition unit is broken - the contacts should be cleaned and connected;

- The ignition unit relay is broken - it needs to be fixed by a specialist.

Error A02 shows temperature violations. Often appears when there is a sharp decrease in coolant circulation pressure. The reasons may be:

- problems with the circulation pump due to blockages - only a specialist can correct the situation;

- problem with the temperature sensor - you will have to replace the part;

- violation of the supply of wires to the sensor - it is necessary to check the integrity of the wiring and contacts.

Code A03 indicates problems with smoke removal . Perhaps the reasons are as follows:

- pipe blockage, icing, strong wind - can be eliminated by cleaning the chimney;

- insufficient air supply due to a breakdown of the fan, which performs forced smoke removal - the part needs to be replaced.

Error A04 on the screen of a Beretta gas boiler indicates a lack of normal pressure in the heating system. This code appears as a result:

- pressure sensor failure - replacement required;

- problems in the operation of the pump - you will have to replace the element;

- clogging of the heat exchanger - it is necessary to remove scale using special means;

- leakage in the circuit - repair of the heat exchanger;

- poor contact of the wiring with the pressure sensor - clean the edges and connect.

Code A05 indicates a failure of the NTC DHW temperature sensor - it is necessary to inspect the contacts or replace the broken part.

Error A06 indicates a breakdown of the NTC heating thermistor - the faulty part will need to be replaced.

Code A07 indicates that the relay has not opened - it is necessary to diagnose the module.

A11 simulates the presence of a flame - you need to contact a specialist.

Error A24 appears when the fan is not operating correctly.

ADJ - it is necessary to adjust the power of the gas boiler.

Code E33 means a violation of the phase and neutral connections - this can be eliminated by reconnecting the boiler.

Error E34 appears when you press the Reset key frequently. If the reading does not disappear after 45 minutes, you need to contact a specialist. E35 indicates a problem with the pressure switch. It is recommended to check the fluid flow in the heat exchangers as indicated in the instructions.

E37 means false detection of fire. You should check the connection of the smoke exhaust sensor.

Code E38 indicates a short circuit in the combustion products sensor. In this case, you will have to replace it. E39 indicates that the sensor contacts have opened; the wiring needs to be replaced.

E40 means voltage drops - you need to install a stabilizer.

Error E42 indicates a short circuit of the sensor on the supply line, E43 - the sensor contacts are open, E44 - a short circuit of the return sensor. To eliminate E42, E43 and E44, you should diagnose the connectors or replace the broken element.

Code E45 is the sensor opening, and E46 the thermistor indicates an increase in temperature. To troubleshoot the problem, make sure that the coolant flow is correct. The normal rate is 2 m³ per hour.

Error E48 indicates that the fan speed is too high or the temperature of the combustion products is high. It is necessary to check the water flow or clean the circuit of deposits.

Flashing 88ºC indicates ignition standby mode.

If the letter P is lit, this means DHW preheating. Flashing P – a request for preheating has been received.

Each model of Beretta units comes with instructions that clearly indicate possible error codes and how to eliminate them. But in any gas boiler, malfunctions may appear that are not indicated by codes. These include:

- there is a smell of gas in the boiler room - immediately turn off the boiler, ventilate the room and call the gas workers;

- smell of smoke - check the quality of draft in the chimney and the functionality of the coaxial pipe fan;

- ignition of the burner is late - you should check the gas valve, clean the burner and nozzles from soot, adjust the flame modulation;

- the unit works, but the radiators do not heat up - release excess air using the Mayevsky tap.

You can independently troubleshoot a floor- or wall-mounted Beretta gas boiler only in accordance with the described recommendations. In other cases, you should call a Beretta service center specialist. You cannot disassemble the components yourself - this can subsequently lead to damage to the elements and increase the cost of repairs.

Error A01 Beretta boiler

In beret boilers, error A01 (or A01 in Russian) indicates problems with the ignition system (lack of flame, faults in the control board). This may be due to the following reasons:

- 1. The flame detection electrode is dirty. You can clean the electrode from any deposits that have appeared on your own.

- 2. Lack of gas supply. There is a disruption in the supply in the main gas pipeline or the gas valve is simply closed (open).

- 3. Malfunction of the gas valve. Only a qualified specialist can adjust the operation of the valve.

- 4. The reliability of the connecting contacts on the ignition unit is compromised. Corrects itself. Disconnect, clean, connect.

- 5. Failure of the relay included in the control system for the operation of the ignition unit, gas valve, fan. This problem can only be resolved by a specialist. The reason may be either in the relay itself or in the electronic board.

Error A02 Beretta boiler

If the boiler display shows error A02 (A03), then in this case there is a problem with a violation of the temperature regime. Usually occurs in the event of a sharp drop in pressure in the coolant circulation system. The reasons may be the following:

- 1. Circulation pump malfunction. Pump operation may be impaired due to contamination. After several starts it can work normally. It is not recommended to disassemble it yourself. This should be done by a specialist. Only he will determine the cause of the malfunction and repair the pump or replace it.

- 2. Temperature sensor malfunction. This malfunction can only be eliminated by replacing the part.

- 3. Violation of the integrity of the electrical connections by the sensor. It is necessary to check the integrity of the wiring insulation and check the reliability of the contacts.

Error A03 Beretta boiler

The boiler display shows error A03, problems with removing combustion products. This may be due to:

- 1. Clogging of the combustion products exhaust channel. This situation rarely occurs; there are practically no gas combustion residues. But the cause may be the appearance of ice at the outlet of the pipeline system due to condensate freezing. Strong wind can also cause difficulty in removing combustion products, which results in the thermostat triggering, shutting down and blocking the boiler.

- 2. Lack of air supply, in case of forced smoke removal. The main problem is a broken fan. Will need replacement.

Error A04 Beretta boiler

On the display of the Beretta boiler, error a04 indicates a lack of optimal pressure in the heat exchange system. The error is similar to error a02. The only difference is that this code primarily indicates problems within the system of the boiler itself. The following error may appear on the display:

- 1. Clogged heat exchanger circuit inside the boiler. Long-term operation using hard water leads to the formation of scale on the internal surfaces of the heat exchanger. Adding chemicals to the heating circulation system helps remove it.

- 2. A leak has appeared. Sometimes a technician will be able to repair the heat exchanger on site (solder it). Otherwise you will have to make a replacement.

- 3. Violation of the tightness of the heating system circuit. Such problems can be eliminated yourself using tools and sealing materials.

- 4. Malfunction of the circulation pump. The pump needs to be replaced.

- 5. Poor contact of electrical wiring with pressure sensor. Removable by yourself (clean and connect).

- 6. Pressure sensor failure. Will need replacement.

The instructions attached to all models of BERETTA boilers indicate most of the errors of Beretta boilers with a description of possible problem situations that arise during operation. In addition, the operating parameters of the boilers are displayed on the display. For example, by comparing the error code of the Beret City boiler and the parameters of the operating functions, the technician is able to identify the problematic unit or component on the spot or eliminate the cause, which does not require complex repair work. Problems associated with the described errors should be resolved by qualified technicians. Only a technician who has practical experience in servicing gas boilers of various brands and models can carry out comprehensive diagnostics and determine the specific cause of errors on the display.

| Navien boiler repair | Baxi boiler errors |

| Installation of a heating system in a house | Gas boiler errors |

| Gas boilers with installation | Replacing heating radiators |

By contacting us, you agree to the terms of the “User Agreement” - Offer Agreement!

Remember - we are ALWAYS HERE!!!

Probable errors and causes of occurrence

This article contains all possible malfunctions and options for eliminating them, as well as error codes for Beretta boilers. All information is read in the following order: code - name - possible malfunction. If you have any additional questions, please leave them in the comments to this article.

p, blockquote 1,0,0,0,0 —>

- Beretta Ciao

- Error code A01 - Flame error

- Error code A02 - Limit thermostat error

- Error code A03 - Flue gas thermostat error

- Error code A04 - Hydraulic pressure switch error

- Error code A05 - DHW NTC sensor error

- Error code A06 - Heating NTC sensor error

- Error code E011 - False flame appears

- Error code ADJ - Electronic settings error for minimum and maximum power

- Beretta City

- The green light blinks once every 3.5 seconds

- The light bulb blinks once every half second

- The green light blinks quickly, once every 0.1 seconds

- The green lamp is on continuously

- Red LED lights up continuously

- The red light is flashing

- The green light and red LED flash simultaneously

- Yellow indicator is on

Most Common Error Codes and Troubleshooting Methods

Let's try to figure out what the error codes for the Immergaz gas boiler mean. The most common error is 01, it is the ignition is blocked. Let's look at each error in more detail.

01

Ignition blocking. The boiler is designed so that it switches on automatically. If the burner has not ignited after ten seconds, a lockout occurs. To remove it, click on reset.

If the boiler turns on after a long period of inactivity, you will need to remove the blockage because air has accumulated in the gas line. If the unit turns on quite often, seek qualified assistance from a specialist.

02

Error 02 - the safety thermostat is triggered, overheating has occurred, the flame control is faulty. If the temperature begins to rise during normal operation of the device, a protective function is activated. Wait until the temperature drops to the desired level, then press the reset key. If this problem occurs frequently, seek help from a specialist.

03

Error 03 appears on the display when the smoke thermostat is triggered. That is, the fan is malfunctioning; to solve the problem, remove the housing. Then open the chamber, it houses a motor that draws air out of the combustion chamber. Open it by unscrewing the screws, clean its blades from accumulated dirt, this can be done with a brush. Lubricate the bearings and reinstall everything.

04

Error 04 - high resistance of electromechanical contacts. The contact is blocked; the reason may be a failure of the protective thermostat or the minimum permissible water pressure sensor. Turn off the device, and after a couple of minutes try to restart it, or try closing the contact of the limit thermostat.

Water pressure sensor

If this does not work, close the minimum pressure contacts. Test the contact at the smoke exhaust pressure switch using the same method, after turning on the fan. If you find a breakdown, replace the element. If this does not work, you need repairs performed by a qualified specialist and diagnostics of the board.

06

Error 06 - the NTC sensor in the hot water supply system has broken down. To identify and repair, you must contact a service center.

10

Error 10 - low pressure in the system. Error e10 occurs when the pressure in the system drops when it is less than 0.9 bar. The first step is to try restarting; if the error remains, you need to check the following.

The cause may be a heat exchanger leak, check it, if you find a leak, fix it. To eliminate this, use the make-up lever, it looks like a screw, turn it counterclockwise, with this action water from the water supply will flow into the heating, monitor the pressure values, when the number is 1.3, close the valve.

11

Error 11. The smoke pressure thermostat is triggered. When the chimney does not work well, the boiler is blocked; after half an hour, it restarts if the draft has become sufficient. If more than three shutdowns occur in a row, the display with an error code lights up red.

Smoke pressure switch

To unlock the boiler, press reset. In the instructions, the manufacturer recommends contacting a service center, however, first you can check the chimney draft and clean it.

20

Error 20 occurs with stray flame. This indicates a gas leak or a failure of the flame control system. Restart; if the same thing happens when you turn it on again, you need to test the board at a service center.

27

Error 27. This error indicates insufficient circulation in the heating system. The boiler begins to overheat, the reasons for overheating may be the following: air in the heating pipes, taps are turned off. It is also possible that the circulation pump is blocked; unblock it. The cause may be clogged filters, check and clean. Check the heat exchanger for deposits.

Removing air from the heating system

28

Error 28 indicates a leak in the water supply circuit, that is, the device heats the heating circuit, and the temperature in the water supply also increases, at a time when it should be constant. Check all faucets in the house for leaks, and also check that the taps are closed.

Beretta Ciao

The Beretta Ciao boiler is equipped with a liquid crystal display, which displays not only operating modes, but also possible breakdowns. There is no standby mode.

p, blockquote 2,0,0,0,0 —>

Error code A01 - Flame error

This fault code appears when there is no flame. Two symbols appear on the display. Crossed out flame and bell.

p, blockquote 3,0,0,0,0 —>

Error code A02 - Limit thermostat error

The device stopped due to a malfunction of the limit thermostat. A bell appears on the display.

p, blockquote 4,0,0,0,0 —>

Error code A03 - Flue gas thermostat error

Stops according to flue gas thermostat readings. A bell appears on the display.

p, blockquote 5,0,0,0,0 —>

Error code A04 - Hydraulic pressure switch error

The unit stops according to the indications of the hydraulic pressure switch. The display shows a bell symbol.

p, blockquote 6,0,1,0,0 —>

Error code A05 - DHW NTC sensor error

It signals a breakdown of the NTC DHW sensor. The display shows a bell symbol.

p, blockquote 7,0,0,0,0 —>

Error code A06 - Heating NTC sensor error

It indicates that the heating NTC sensor is faulty. The display shows a bell symbol.

p, blockquote 8,0,0,0,0 —>

Error code E011 - False flame appears

Indicates the appearance of a false flame. The display shows a bell symbol.

p, blockquote 9,0,0,0,0 —>

Error code ADJ - Electronic settings error for minimum and maximum power

This fault code indicates problems with the electronic minimum and maximum power settings. The display shows a bell symbol.

p, blockquote 10,0,0,0,0 —>

Turning on the ignition standby mode 88 degrees. The bell symbol blinks. A breakdown associated with the boiler being blocked by a signal from the smoke exhaust pressure switch. The bell symbol blinks. Failure associated with stopping the device due to a hydraulic pressure switch. The bell symbol blinks.

p, blockquote 11,0,0,0,0 —>

Operating mode showing the presence of sensors that measure the temperature outside. The thermometer icon lights up on the display.

p, blockquote 12,0,0,0,0 —>

Operating mode indicating that the unit supplies water to the domestic hot water supply. The display shows the value 60 degrees and the faucet sign.

p, blockquote 13,1,0,0,0 —>

Operating mode indicating that the device operates on the heating system. The display shows a temperature value of 80 degrees and a “radiator” sign.

p, blockquote 14,0,0,0,0 —>

A mode in which the operation of the device is aimed at preventing the system from freezing. A snowflake lights up on the display.

p, blockquote 15,0,0,0,0 —>

Boiler mode indicating that flame is present. The flame symbol lights up on the display.

p, blockquote 16,0,0,0,0 —>

If you are not 100% sure what exactly the problem is and that you can solve it, immediately contact the service center to diagnose and fix the problem.

p, blockquote 17,0,0,0,0 —>

Beretta CIAO 24 CSI

The Beretta brand is the property of one of the leaders in the European heating industry - the Italian company Riello, which is approaching its 100th anniversary.

Beretta boilers are manufactured using modern technologies and fully comply with European requirements for safety, economy and efficiency. The CIAO 24 CSI model is manufactured in accordance with the most advanced technical developments and is capable of meeting the needs of a modern residential building.

The units are manufactured in a wall-mounted design, have a compact and visually attractive body, which allows them to be installed directly in the kitchen and without having to allocate a separate room for the boiler room.

NOTE!

The successful combination of price and quality of the Beretta CIAO 24 CSI model is highly appreciated by specialists and users, which confirms the steady demand and relevance.

Beretta City

The Beretta City boiler is equipped with lights, as well as a display that shows possible errors. Two light diodes installed on the central control panel are configured to notify of possible faults.

p, blockquote 18,0,0,0,0 —>

The green light blinks once every 3.5 seconds

This means that the unit is stopped and in standby mode. The burner is off.

p, blockquote 19,0,0,0,0 —>

The light bulb blinks once every half second

This means that the Beretta boiler stopped due to an accident. In this case, several types of breakdowns are possible. The device stopped at a signal from the hydraulic pressure switch; the stop lasted no more than 10 minutes. Stop by signals from the smoke exhaust pressure switch. The stop lasts no more than 10 minutes. The unit is operational and is currently in an intermediate state before ignition. When this error code appears, the device is in standby mode. As soon as conditions for full operation are restored, the device is put into operation. If after the set time the operation is not restored, the stop will change from temporary to emergency. In this case, a red light will be added to the green LED, located on the same control panel.

p, blockquote 20,0,0,1,0 —>

The green light blinks quickly, once every 0.1 seconds

SARA function input/output (automatic room temperature setting system). The automatic control system is activated if the temperature controller responsible for the temperature in the heating system switches to auto mode. In this case, the boiler automatically sets the water temperature, based on the readings of the thermostat that measures the temperature in the room. After the water reaches the set temperature, 20 minutes are counted down. If during this time the thermostat continues to send a signal that the room temperature is lower than the required one, the unit will automatically set the temperature of the water supplied for heating by 5 degrees more. After another 20 minutes, the device again compares the set temperature in the room and the signal coming from the thermostat. If the temperature is again insufficient, a new increase in water heating follows by 5 degrees. After the second increase in temperature, the system will automatically return the settings to those specified by the user. And this will be repeated until the temperature in the room reaches the required value.

p, blockquote 21,0,0,0,0 —>

The green lamp is on continuously

The Beretta boiler is operating normally. The flame is present.

p, blockquote 22,0,0,0,0 —>

A red light always indicates that the device has been stopped in an emergency. Various indications of this diode indicate the type of fault.

p, blockquote 23,0,0,0,0 —>

Red LED lights up continuously

There is no flame. After the end of the transition stage in the operation of the boiler, a signal came from the smoke removal pressure switch. The NTC sensor in the heating system is broken. Due to an electronic failure, the unit stopped. After the end of the transition stage in the operation of the unit, a signal came from the hydraulic pressure switch.

p, blockquote 24,0,0,0,0 —>

The red light is flashing

This fault code appears when the limit thermostat is activated. In order to put the Beretta City boiler back into operation, you need to move the mode switch to the required positions. Next, you need to wait about 6 seconds, and then set the words to the operating mode that is required. If this does not help, then further repairs are carried out by service specialists.

p, blockquote 25,0,0,0,0 —>

The green light and red LED flash simultaneously

This operation of the indicator lights indicates that the NTC sensor of the DHW circuit is faulty. In this case, the unit will continue to operate, but it will not be able to maintain a constant temperature of the water supplied for household needs. To fix the problem, you need to contact a specialized service center. If these two lights flash alternately, this means that the device is currently in setup mode.

p, blockquote 26,0,0,0,0 —>

What do the indicator signals mean?

In some models of Beretta gas boilers, for example Beretta City, the occurrence of malfunctions in the operation of the units can be judged by the signals of the red, yellow and green indicators.

The indicators are two or three light diodes located on the central panel, which begin to blink with different intensities when a particular failure occurs.

In some models of Beretta gas boilers, signals about errors and malfunctions are provided by light indicators located on the control panel

A blinking green indicator may mean the following:

- 1 time/3.5 sec - the equipment is switched to standby mode, the fire is extinguished;

- 1 time/0.5 sec - the boiler is stopped due to a breakdown;

- 1 time/0.1 sec - the unit is switched to the auto-regulation system;

- the indicator is on and does not blink - the boiler is working normally, the fire is burning.

Beretta City can stop on its own due to a breakdown if it receives a signal from pressure and smoke sensors.

The boiler may pause operation for 10 minutes, during which the correct parameters must be restored. During this time, the system will automatically scan. A detailed guide on how to check the sensor readings of a Beretta gas boiler should already be included in the self-diagnosis system.

The indicators on the Beretta boiler panel can produce signals in different combinations and with different intensities. The type of light signal depends on what error occurred during the operation of the unit

The red indicator turns on in the following cases:

- the indicator is on and does not blink - if after stopping the boiler operation is not established, the unit goes into emergency mode;

- the indicator is flashing - the limit temperature sensor is triggered. Sometimes you can eliminate the error using the operating mode switch.

Simultaneous flashing of the red and green diodes occurs in the event of a breakdown of the NTC sensor.

The yellow indicator lights up and stays lit when preheating of the coolant in the circuit is turned on.

If you are not confident in your abilities and knowledge, it is strongly recommended to invite a qualified specialist to repair your Beretta gas boiler

To eliminate all the above-described problems with Beretta gas boilers, it is strongly recommended to use the services of specialists from authorized service centers and organizations with which an agreement has been concluded for the maintenance of gas units and the supply of blue fuel.

Independent intervention in the complex design of boilers can lead to an even more serious breakdown, which will result in expensive repairs and a long shutdown of the autonomous heating system.