Solid fuel boilers of individual manufacturers and brands operate without problems on various fuels, however, before purchasing a large amount of coal, it would not hurt to find out which type is best suited for use. As a rule, information about recommended products allowed for kindling is contained in the instructions for the unit. If for some reason it is not possible to obtain reliable information from the boiler manufacturer, then it is enough to purchase a bag of fuel of different grades and fractions, and then experimentally select the most effective one.

Which fuel to choose

Coal is a chemical compound containing a number of hydrocarbons and impurities with a low combustion rate.

These substances are formed in the lower chamber of the boiler after combustion. This is slag and ash that needs to be regularly cleaned out of the ash pit. Moreover, each species, depending on geography and period of occurrence, contains a certain level of carbon. It is the age and the ratio of flammable and non-flammable components that determine the quality and grade of the solid fuel mineral. There are several types:

- The youngest of the subspecies is lingitis. It is a loose stone structure. It often crumbles and crumbles. Ineffective for heating houses. However, it is considered the cheapest and is used for energy production in thermal power plants.

- Anthracite is the variety that warmed up most deeply when buried. It is a transitional form from coal to graphite. The amount of carbon reaches 95%. The most effective among all varieties.

- Hard coal is the result of the transformation of bitumen masses. Divided into several grades depending on carbon content, from 75-95%. Humidity reaches 12-15%.

- The brown subspecies, unlike other varieties, is formed from peat and includes up to 70% carbon. It has a characteristic white color. Can be used as fuel or raw material. Also includes a large number of volatile compounds.

Different grades

Due to its minimal weight and significant carbon content, it is anthracite that has the maximum specific heat capacity. Indicators can reach 9 thousand Kcal/kg. Coal, due to its lower content of flammable substances and higher humidity, has up to 5.5 thousand kilocalories per kilogram. Brown has an even lower rate of 3 kcal/kg. Therefore, anthracite is considered the optimal choice.

Power selection

The choice of boiler equipment should also be based on the power level of the model. Excessive or insufficient power with the same “success” will lead to:

- uncomfortable temperature conditions inside heated rooms;

- rapid breakdown and failure of equipment.

To accurately determine the required power level of the unit, it is recommended to contact specialists who can make a competent calculation based on the level of insulation of the house, its area, number of floors and other parameters. But there is also a universal formula for independent calculation, although it is still approximate, that is, not entirely accurate, but still close to reality.

The formula looks like this: Q = S × 100. The letter Q denotes the required power, expressed in kilowatts (kW), the letter S traditionally denotes the volume, area of the room or rooms requiring heating in square meters. The number 100 denotes the norm in which power is expressed per unit area.

In simpler terms, then, say, the area of a house is 120 square meters, you just need to multiply it by 100. Having received an amount of 12,000 watts, it is concluded that a boiler with a power of approximately 12 kW is required. We repeat that such a calculation is approximate, since a more detailed calculation must take into account many other specialized parameters and structural factors.

How to reduce coal consumption

An increase in the rate of coal consumption, after several years of operation of the boiler, occurs quite often. The increase in costs is primarily due to clogging of the heat exchanger and chimney pipe with soot. It is recommended to completely clean the chimney and internal components of the boiler at least 2 times a year.

To reduce coal consumption, you need to fire the boiler correctly. To reduce the amount of soot, add fuel in layers - firewood and coal. This installation will ensure maximum heat transfer. Coal consumption changes depending on the boiler efficiency. Consequently, the higher the efficiency, the lower the fuel costs.

Another way to reduce coal consumption is to burn only high-quality fuel. Cheap raw materials, brown coal, have a large percentage of underburned coal, quickly clog the chimney and heat exchanger and, as a result, are more expensive than anthracite.

Why is coal the best fuel for home boilers?

When choosing fuel for heating a private home, it is important to know how well it will burn. This is the main indicator. Each type of fuel has its own characteristics.

Below you can see the efficiency indicators of different types of fuel.

We have included the most important parameters in the table.

Among them:

- Heat of combustion - how much heat the material will release

- Ash content - non-combustible residue

- Humidity - the lower it is, the higher the heat of combustion

- Bulk density - how many kilograms will one cubic meter weigh?

- Price – this point needs no comment

We will talk about all these parameters regarding coal a little later. In the meantime, you can compare its performance with that of other types of fuel.

Table of indicators of different types of fuel

| Heat of combustion | Ash content | Humidity | Bulk density | Price* | |

| Coal | 5795-7459 kcal/kg | 2,1-3,2% | 3,2-12,4% | 800 kg/m3 | from 4400 RUR/t (with delivery) |

| Brown coal | 3100-3600 kcal/kg | 15-27% | 14-22% | 900kg/m3 | from 4200 RUR/t (with delivery) |

| Anthracite coal | 6700 kcal/kg | 5-20% | 5-7% | 850 kg/m3 | from 8000 RUR/t (with delivery) |

| Firewood | 2500-3400 kcal/kg | 2,4-3,2% | 20-25% | 480 kg/m3 | from 2100 RUR/t (with delivery) |

| Eurodrova | 4500 kcal/kg | 1% | 8-12% | 1200 kg/m3 | from 7500 RUR/t (without delivery) |

| Peat briquettes | 4200 kcal/kg | before 18% | up to 25% | 250 kg/m3 | from 9000 RUR/t (without delivery) |

| Pellets | 4300-5200 kcal/kg | 0,4-1,5% | 8-12% | 650-750 kg/m3 | from 5300 RUR/t (without delivery) |

*Prices are valid for Ekaterinburg

If we compare all the parameters, then only anthracite is more profitable than coal. But its closest deposit, in relation to Yekaterinburg, is located in the Rostov region. Considering delivery to the Sverdlovsk region, the cost of such fuel will be unreasonably high. Chopped firewood and brown coal are cheaper than coal. But their heat of combustion, as can be seen from the table, is much lower. We must not forget that wood burns faster, so you need to purchase it more often. Thus, in our region it is more profitable and efficient to heat houses with coal.

In addition to the characteristics, you need to understand whether coal is suitable for your boiler. This will be discussed below.

Fuel requirements

In order for the system to work properly, it is necessary to use high-quality fuel. Coal for long-burning boilers can be used in different ways. Typically, the technical data sheet of the device indicates the most preferred types.

Most often, brown coal, bituminous, stone, semi-anthracite and anthracite are used for heating private houses. The latter is considered the highest quality. European-made boiler models are more sensitive to the composition and properties of the coal used. Domestic ones are unpretentious.

For models from any manufacturer, anthracite will be an ideal option. It has several advantages:

- when burned, it emits 80% more heat than natural gas;

- burns out almost completely and does not clog the boiler;

- emits less harmful fumes;

- has high efficiency.

In addition, coal is sold in fractions of several sizes. Some manufacturers sell it in bulk, others package it in bags. The second option for a private home is considered more preferable, since in this form the fuel does not contain dust, which impairs combustion and leads to rapid clogging of the boiler.

It is worth noting that wet anthracite burns better than dried one, so there is no need to worry about it getting wet during storage.

Features of fuel storage

To provide a residential building with coal for the autumn-winter-spring period, owners must provide conditions for its storage. With their proper organization, the operation of solid fuel equipment will become safe and the maximum efficiency of the unit will be achieved.

The main storage conditions:

- ease of access to fuel for transporting it to the stove;

- the presence of a special storage room near the house and maintaining comfortable conditions in it;

- good lighting and sufficient ventilation for loading and unloading operations, etc.

When the warehouse is fully loaded with fuel for the entire cold period, the main condition for its storage must be met - it must not lose its functional (combustible) properties. The main weakness of coal after mining and raising it to the surface is oxidation. The larger the pieces, the longer they will retain their properties. For example, coal with a fraction of more than 100 mm can be stored (without loss of quality) for up to 3 years, and fine coal - less than 1 year. The latter is recommended to be purchased only for 1 season.

Requirements for place and storage conditions:

- It is advisable to package the fuel in bags or wooden boxes;

- the room (except during loading and unloading) should be dark;

- if coal is poured into a special pit, it must be compacted to reduce the air gap;

- if fuel is stored in the yard, it is advisable to cover it with a lid or thick plastic wrap;

- the warehouse space must be voluminous: annual coal requirement (for 100 m² of area - 4 m³ of fuel) + passage + 5% reserve;

- the warehouse must be equipped with drainage systems for the removal of groundwater, melt water, and rainwater.

Prohibitions to the location of the storage room:

- it cannot be equipped with communications: electrical lines, gas pipelines, heating plants;

- it should not be located above underground pipelines, gas pipelines, electrical cables, etc.

Owners need to remember: if storage conditions are violated, coal can ignite.

Therefore, small pieces must be well compacted, without leaving air gaps, to avoid spontaneous combustion.

Preparing the stove for lighting

If the boiler is used infrequently, before starting operation, it is necessary to conduct a visual inspection of the masonry to exclude the presence of cracks. Carbon monoxide can penetrate through the holes, which normally should leave the firebox through the chimney. If such cracks are found, be sure to eliminate them using a heat-resistant mixture of clay and sand. Otherwise, during heating, the hole may expand, with a subsequent increase in the risk of rupture of the furnace or boiler.

When conducting an external inspection, it is imperative to remove from the direct accessibility area all objects that could ignite if struck by a spark. Then, you need to completely remove the ash and slag. Then, wipe the walls of the firebox with a rag to prevent the spread of unpleasant odors from combustion products.

a3e6d0a551d2f8605c1c1a74133e1cf1.jpe eadc92b0b05f10f9edb881dd73312c8d.jpe

It is advisable to light the coal boiler several times a day. The duration of one such process should not exceed 2 hours. Load dry coal in small sizes. If the fuel is wet, steam may form, which will subsequently settle on the walls of the chimney, leading to a narrowing of the clearance. As a result, traction will drop significantly.

Popular models

Today, various companies produce solid fuel boilers at affordable prices. A popular model is Protherm Beaver. The device is manufactured in Slovenia, made of cast iron and is distinguished by high quality and original design. Capable of heating a room up to 350 square meters.

An affordable option for everyone is Danko 20 TN. It has an attractive design and is economical. Fuel is loaded once every 8 hours. The firebox is small in size, which reduces the amount of fuel used. Allows you to heat a house up to 180 square meters.

Dakon is a Czech-made boiler with many advantages. It is affordable, economical, has high efficiency and an attractive design, and does not depend on the energy source. Often installed in private homes, it works well on different types of coal.

A solid fuel boiler is an excellent alternative to a conventional Russian stove in populated areas where there is no possibility of connecting to gas.

With proper selection and operation, it allows you to create an optimal microclimate in the house. In contact with

Pros and cons of wood-burning boilers for long-burning fuel

Advantages:

- no need for frequent refueling - depending on the chosen model, you need to add firewood to the combustion chamber from once every 3-4 hours and up to 12 hours;

- possibility of using different types of fuel and their combination;

- In most cases, the boiler operates autonomously and does not require connection to other communications;

- relative cheapness of fuel.

Solid fuel boiler in a private house

Flaws:

- the cost is higher than classic boilers;

- due to the low calorific value of firewood, the efficiency is from 70 to 89%;

- There is no mechanism for regulating the temperature regime.

Another important disadvantage is the inability to operate heating equipment without human intervention

Operating principles of long-burning boilers

The principle of operation of a conventional solid fuel stove is probably known to everyone. Firewood (coal, briquettes) is placed in the combustion chamber, and from the ash chamber located below there is a flow of air containing oxygen necessary for the combustion process. The combustion intensity is limited only by the volume of incoming air and the area of the outer surface of the fuel fill.

Conventional burning of wood does not fully utilize its energy potential.

In essence, this is an ordinary fire, only enclosed in stone or metal walls, and requiring constant replenishment of the fuel supply. In this case, combustion products are almost directly discharged into the chimney system, the labyrinths and turns of which only improve heat transfer to structural elements and, in a certain wall, lead to an increase in efficiency, but cannot in any way increase the overall energy return from a particular type of fuel. The process of thermal decomposition of wood is very intense and fleeting, leaving quite a lot of waste and releasing unused opportunities into the atmosphere.

And these possibilities lie in the special properties of wood, which are determined by its biochemical composition. During the heating process, this material does not simply oxidize to the state of coal with the release of ordinary carbon dioxide (CO2) and carbon monoxide (CO). High-temperature exposure always leads to the synthesis of volatile hydrocarbon compounds with a complex chemical formula, and they themselves are an excellent gaseous fuel, which in conventional furnaces is simply released into the atmosphere.

Burning wood with a limited supply of oxygen leads to the formation of pyrolysis gases, which are an excellent fuel.

The process of thermal decomposition of wood is called pyrolysis, respectively, the hot gaseous components released during this process are called pyrolysis gas. It is characteristic that the temperature of its combustion, and therefore the heat transfer, is incomparably higher than that obtained during ordinary combustion of wood. At the same time, the oxidation processes of wood are so deep that after them there is practically no waste left in the form of ash, and after combustion of the gaseous component, mainly water vapor and carbon dioxide are released into the atmosphere.

This means, from the point of view of the technology for the most rational use of wood fuel, it is advisable to minimize the process of open combustion, to achieve maximum release of pyrolysis gas, which, during combustion, will, in fact, be the main source of thermal energy. It is these principles that are incorporated into the design of long-burning boilers.

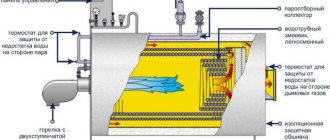

Combined heating boiler ZOTA “Mix”

The main feature of the ZOTA “Mix” boiler is its versatility. It mainly runs on wood and coal, but in a pinch gas, diesel and electricity can be used. This flexibility is achieved by a special design that allows you to install different types of burners and operate equally efficiently on different types of fuel.

Photo 3: Combined heating boilers using solid fuel Zota Mix

Let's look at what other advantages the Mix solid fuel boiler has:

- The heat exchanger has an unusual X-shape, which ensures maximum heat removal, which in turn ensures high efficiency values.

- Operating efficiency is also improved by insulating the water jacket. Heat loss due to its use is reduced, and therefore efficiency increases. In addition to improving efficiency, insulation also improves fire safety.

- Easy access to the flue and a spacious ash tray make cleaning and maintenance very convenient.

- The optimal pressure for a heating system is 3 atm. In emergency cases, the device can withstand a pressure surge of up to 4 atm, without the danger of explosion as is the case with the installation of a cast iron solid fuel heating boiler.

- The operating power is adjusted by a built-in draft generator and a draft control damper in the chimney. Temperature and pressure are controlled via a thermomanometer on the front panel.

The ZOTA “Mix” model is available in four sizes with power from 20 to 50 kW. Their main characteristics are as follows:

| power, kWt | 20 | 31,5 | 40 | 50 |

| Room area, m² | 200 | 315 | 400 | 500 |

| Efficiency, % | 80 | |||

| Firebox volume, l | 35 | 45 | 63 | 79 |

| Heat exchanger capacity, l | 50 | 70 | 120 | 140 |

| Chimney diameter, mm | 150 | 180 | ||

| Chimney height, m | 6 | 7 | 8 | 9 |

| Price, rub | 34 900 | 38 700 | 49 900 | 54 500 |

Feedback from a real owner of the ZOTA “Mix” boiler about the experience of use:

Eldar Vladimirovich, Irkutsk

If you are looking for a solid fuel boiler that can, if necessary, operate on gas or liquid fuel, while maintaining high efficiency and remaining safe, then the ZOTA “Mix” is exactly what you need.

Ways to save coal

Coal consumption is high during the heating season, so home owners want to reduce it. There are several ways to help you save some money:

- Insulate the windows and prevent cold air from entering through other cracks. Thanks to this, the room will be warm if the boiler operates in moderate mode.

- Providing quality heating throughout your home also saves fuel by keeping rooms at the optimal temperature.

- It is allowed to reseed combustion residues that are regularly removed from the ash pan. They often contain lumps of coal that can be re-loaded into the firebox. However, it is necessary to carefully sort out the waste, since those that are unsuitable for combustion will worsen the process and reduce the efficiency of the new portion of fuel.

- During the combustion process, it is necessary to control the air supply. If the draft is too strong, the coal burns out faster, so refilling is required. At the same time, the house does not become warmer, since a significant part of the heat is lost due to increased draft.

- Insulate the windows and prevent cold air from entering through other cracks. Thanks to this, the room will be warm if the boiler operates in moderate mode.

- Providing quality heating throughout your home also saves fuel by keeping rooms at the optimal temperature.

- It is allowed to reseed combustion residues that are regularly removed from the ash pan. They often contain lumps of coal that can be re-loaded into the firebox. However, it is necessary to carefully sort out the waste, since those that are unsuitable for combustion will worsen the process and reduce the efficiency of the new portion of fuel.

- During the combustion process, it is necessary to control the air supply. If the draft is too strong, the coal burns out faster, so refilling is required. At the same time, the house does not become warmer, since a significant part of the heat is lost due to increased draft.

Some people remove the damper altogether, mistakenly assuming that this will help warm up the room faster. As a result, the coal burns instantly, but there is no heat in the house. If none of the methods help reduce the amount of fuel used and the rooms are still cool, it is recommended to re-check all windows and doors, and also ensure that there is no possibility of cold air entering through openings in the floors. Quite often they are invisible under the baseboards and do not allow achieving optimal temperature conditions.

3eeb01feaa154e4bff8a36d63e994dd7.jpe

Main advantages

Several decades ago, a stove was the only option for heating a private home if it was impossible to connect to a centralized gas supply line. Today, long-burning coal boilers have replaced it because they have many advantages:

- have smaller dimensions compared to a Russian stove;

- can be installed in any convenient place, since they involve the installation of radiators and pipes throughout the house;

- in contrast to a stove, which, even if there is heat, cannot heat the entire house equally, they ensure uniform heating of all rooms;

- in the absence of coal, another type of solid fuel can be used;

- moderate fuel consumption due to proper air supply and slow smoldering;

- no need to interrupt the operation of the device in order to clean ash and other coal residues;

- minimal intervention in the operation of the boiler;

- ease of maintenance.

- have smaller dimensions compared to a Russian stove;

- can be installed in any convenient place, since they involve the installation of radiators and pipes throughout the house;

- in contrast to a stove, which, even if there is heat, cannot heat the entire house equally, they ensure uniform heating of all rooms;

- in the absence of coal, another type of solid fuel can be used;

- moderate fuel consumption due to proper air supply and slow smoldering;

- no need to interrupt the operation of the device in order to clean ash and other coal residues;

- minimal intervention in the operation of the boiler;

- ease of maintenance.

In addition, modern and high-quality materials are used in the production of boilers, which extends the service life. Models that do not require electricity are also available. This allows them to work smoothly in any conditions. A significant advantage that affects the environmental situation of the planet is that coal reserves are renewable, so humanity will be provided with fuel for many years.

How to use solid fuel units correctly?

The operating principle of a solid fuel boiler is known, and the issue of choosing the type of coal has been resolved. All that remains is to learn how to properly light the stove. There are several simple rules that everyone who chooses the described installations for organizing heating of a country house must learn.

Let's look at all these points in more detail.

Preparing the stove for lighting

If the stove in a country house is used occasionally, before starting its operation, for safety reasons, it is necessary to exclude the presence of cracks inside the masonry.

Why are they dangerous? Through them, combustion products and carbon monoxide can enter the room, which must be removed outside using drafts. If such a defect is discovered, it must be eliminated before kindling by covering the cracks with a mixture of clay and sand. Otherwise, when heated, the cracks may increase in size even more. And this will lead to dangerous situations.

When inspecting the stove from the outside, we remove flammable objects away from it and clean it inside. We remove the ash and slag with a shovel, freeing the internal compartment. It is advisable to wipe the inner walls of the firebox with a dry cloth. If this is not done, then during kindling the dust will begin to burn, filling the room with an unpleasant odor.

The coal stove needs to be lit several times a day. The duration of one fire should not exceed two hours. For loading, it is better to use well-dried medium-fraction coal.

Do not use household waste or flammable liquids such as gasoline or kerosene to ignite coal. Do not leave the stove unattended while it is burning. This rule must be observed especially strictly if there are small children or animals in the house.

How to properly melt coal?

The stove must be lit as follows:

- First, we place sheets of newspaper or any other dry paper on the bottom of the firebox. On top of it we place a layer of small wood chips. And on them we stack small firewood, for example, birch logs. To make them burn faster, they need to be folded in the form of a well or a small hut.

- Set fire to the paper. We close the oven door and open the ash pan. Using it, it is easy to control the intensity of fuel combustion. The stronger the air flow, the faster the stack of firewood burns out.

- After the firewood has completely burned out and only a pile of smoldering ash remains, you need to lay a 15-centimeter layer of fine coal directly on it.

Tips from experienced stove makers

If you have a stove or boiler in your home that runs exclusively on coal fuel, you will still have to light the heating device using paper and firewood. Only after the required temperature has been reached in the firebox can the coal itself be poured. If you don’t know what volume to take, then you need to focus on a layer of about 5-6 centimeters.

When this volume of material burns well, it will be possible to add the remainder in such an amount that the layer is already 15 centimeters. With this approach, you can be sure that the stove will light up well and there will be sufficient temperature in the house.

When kindling, the pipe valve should be moved back slightly, and the coal itself should be placed on the grate. At the moment when the fuel has already ignited well, it is necessary to open this valve to the maximum.

At the next stage, you should add a portion of small coal (if it is large, you will have to split it). Its layer will be approximately 5-8 centimeters, and the area should correspond to the grid. When the filling is completed, the firebox door should be closed, and at the same moment the ash pan should be opened. After the material flares up, the volume is increased to 12-20 cm.

Black fuel

As for subsequent portions of coal that will be added after the batch of material burns out, some rules should be followed:

- A new bookmark is made only when you are convinced that the previously filled coal has already flared up well enough.

- Before adding a new portion of coal, if the firebox doors are opened at this time, it is necessary to cover the ash pit.

- You should not allow the material to burn out right up to the grate; combustion should be uniform throughout the entire layer.

If you pay attention, you will notice that purchased coal comes not only in large pieces. It may contain small particles, as well as typical dust.

To prevent it from combining into a single layer during combustion, the material should be moistened with water before laying.

The same applies to those who use fatty coal of the PZh or Zh brands. However, the volume of water should not be large, because the material burns better in a dry form. When lighting a stove, fuel of the PS and SS grades, where small elements predominate, must be moistened with a slightly larger volume of liquid.

There is also skinny coal, which is marked with the letter T; it is this that should be moistened generously, but long-flame material is only sprayed to remove dust. As for the “Anthracite” brand, it does not need to be wetted at all, only if it is dusty, it is lightly irrigated with water.

When the combustion process itself is underway, the combustion chamber door must be closed. It should be opened only when it is planned to throw in a new batch of coal. Unlike firewood, this material does not need to be turned over as often, otherwise the firebox will cool down and some of the material will fall through the grate.

Now it becomes clear what is the best way to heat the stove and how to do it correctly. Of course, the process may not work out the first time, but don’t despair, because after two or three attempts all actions will be performed automatically, and the house will be filled with comfortable warmth and the pleasant crackling sound of burning coal or wood.

What coal to choose for the fire?

What is coal? This is a product of plant origin, which contains carbons and non-flammable impurities. It is they who form ash and slag-like substances after burning. The ratio of the two components is different everywhere. It is this, as well as the “age” of natural fuel, that determines the grade of coal. Experts distinguish several varieties.

The “youngest” type of coal is lingite. It has a rather loose structure. If you pick up a lump of lingite, it will quickly crumble and lose its shape. This type of coal is most often used in thermal power plants, but lingite is not suitable for heating a home.

In addition to lingite, brown coal, hard coal, and anthracite are also mined - the most ancient carbon deposits. All varieties have different humidity levels. In brown coal, for example, humidity is 50%; in anthracite its threshold does not exceed 7%. Therefore, anthracite has the highest specific heat. Its indicators are 9 thousand kcal/kg. Coal has a lower figure - 5.5 kcal/kg. The brown variety has a specific heat of only 3 kcal/kg. Considering all this, it is easy to understand what type of fuel to purchase for heating the house.

Device features: single circuit or two circuits

Differences in one or two circuits are fundamental when choosing the right model. And this choice should be made based on the requirements, needs and tasks of the user.

Thus, single-circuit solutions are designed to perform only one function - heating. Such products are directly connected to the functional parts of the heating system - radiators and batteries - and work only to heat them.

But dual-circuit solutions have already expanded functionality, and, in addition to heating batteries and radiators, they also ensure the operation of the domestic hot water supply system, which includes both hot water for sanitary needs and “warm floors”.

Technology for lighting a coal boiler - how to fire it correctly

Coal boilers are operated using the following technology:

- First of all, dry kindling material - rolled up newspaper or paper - is placed in the firebox. A small layer of wood chips is placed on top, and even higher - small firewood (for example, birch). It is best to lay out the firewood in a hut or in the form of a well so that it burns better.

- The paper placed in the firebox is set on fire. The boiler door closes and the ash pan opens. Using a blower, you can regulate the intensity of combustion - increasing the supply of oxygen directly affects the rate of burning of wood.

- A layer of small coal is placed on top of the completely burnt wood, which has turned into smoldering ash. The thickness of the coal layer is about 15 cm. Each time the door is opened, the ash pan must be completely closed.

- After the first layer of coal burns out, another layer is laid directly on top of it, but a coarse fraction is used for it. The thickness of the main fuel layer should be about 60 cm. Before laying a new batch of fuel, it is better to stir up the previous one a little to increase the intensity of air movement and prevent the coal from sintering into one large piece.

- Low-quality fuel may coke during combustion. To avoid this phenomenon, it is advisable to dilute the main coal layer with small layers of firewood - this will give the boiler the opportunity to warm up normally and ensure maximum heat transfer. The presence of a layer, among other things, will also greatly simplify the process of cleaning the boiler after fuel combustion.

- Proper lighting of the boiler requires that natural circulation is used to burn out the paper and wood chips, which is achieved if the ash pan is open. Due to this effect, the chimney will warm up, and the draft will increase gradually, and at a certain point you will only need to close the ash pan and turn on the fan.

Layer-by-layer coal combustion method

Many people think that a long operating period is ensured by the increased dimensions of the loading chamber: the more fuel is placed, the longer the operating period. But this idea is misleading. Of course, the volume of the loading chamber has an impact on the operation and efficiency of the equipment. But the mode of long continuous combustion is achieved due to the upper method of air supply. This air supply principle is also called “top combustion”. It is worth noting that conventional, standard boiler installations supply air through the grate from below.

The upper method of supplying air to the combustion chamber makes the process of burning coal as controllable as possible, and the fuel burns according to the principle of smoldering in layers, while there is no open flame. Smoldering from the top layer to the bottom, the fuel burns evenly and provides the appropriate level of heat transfer.

Features of models with DHW support

There are boilers that already have a boiler installation in their basic configuration, which allows you to heat water as the fuel burns. Other models allow the possibility of optionally adding water tanks, but this solution will be more expensive and less profitable in terms of reliability.

Therefore, you should plan the DHW support option in advance. Its basis, as already noted, is a boiler installation, that is, a container for heating water, which is usually located next to the equipment. Its volume can vary from 50 to 200 liters, if we are talking about home use of a solid fuel boiler. In this case, coal will act as the basic energy resource for both heat supply and hot water supply. As the water heats up and flows, the controls will open or close the shut-off valve. The liquid resource can be used for heating needs and for servicing the bathroom and kitchen. For each of these cases, its own configuration of water supply and heating circuits is provided.

What should you pay attention to when choosing?

Choosing a suitable coal boiler should be based on your personal needs for heat and hot water. But, of course, not only. It is also extremely important to take into account the characteristics of the house and the premises that need to be heated, the total area of the house, the climatic zone of its location, the nature of residence in the house (permanent or seasonal), the number of floors, the level of insulation of the building and many other parameters.

Attention! You should not make mistakes when choosing, because later they may entail additional expenses, for example, on changing equipment or harness.

It is recommended to carefully study all the characteristics of the selected model and carefully correlate its parameters with the individual characteristics of the house. Let's consider the main characteristics of the units that matter when choosing a specific model.

Types of solid fuel boilers

traditional fuels,

- The first type of boiler is called cast iron. It is designed to burn fuels such as coal and wood. Despite all its positive aspects, it is still dependent on people and energy supply. Wood in such a boiler usually burns for no more than 5 hours, which means fuel must be constantly added. Currently, domestic and foreign manufacturers produce such boilers, some of them are called KChM and Solida.

- The second type differs in many ways from the first and is called pyrolysis heating boilers. There are two combustion chambers, in one of which the fuel immersed in the boiler burns, and in the second the gas synthesis burns out. The main type of fuel is wood. It has a longer burning time than a cast iron boiler; here it is 10 hours. One of the most successful boilers of this type is called Dakon, made in the Czech Republic.

- Pellet boilers, the name comes from the word pellets (granulated wood). It is she who needs to heat the room using such boilers. It has a convenient additional advantage - it independently adds the required amount of fuel using an auger and ignites it. The burning time in this case depends on the boiler model and the capacity of its hopper. But there is also a significant drawback - you cannot burn anything except wood pellets in such a boiler.

- The most modern and popular type is long-burning boilers. Firewood, sawdust, coal, and peat can be used as fuel. They surpass their analogues in combustion time; with such a boiler no human intervention is needed for 2 days or more thanks to the latest top-down combustion system, this allows the fuel not to burn, but to smolder for a long time.

Solid fuel boilers are a good alternative to gas. If you live in a country house or your street is not gasified, a long-burning boiler using coal, wood and other fuels will perfectly heat a room of any size.

How to choose a solid fuel boiler

When choosing a boiler, you should pay attention to the following criteria:

- boiler design;

- principle of operation;

- power;

- type of raw materials used;

First of all, you should pay special attention to power. This is one of the most important criteria and the operation of the boiler depends on it, since not every model can cope with a home heating system that is too large

You need to check the power of the boiler with a specialist; he will compare criteria such as the area of the house, the climatic region and even the height of the ceilings. The approximate required power can be calculated independently based on the following rule: 1 kW of power is required for 10 square meters.

An error in choosing the boiler power can have a bad effect on the quality of heating. With a lower degree of heating, the room will be cold, and with a higher degree, the equipment may fail.

Boiler installation location

separate room. separate boiler room

Three important rules when choosing a boiler installation location:

Ventilated area. If additional gas is used as fuel, a slight leak may occur. If the installation is done correctly, there is no need to be afraid of leaks, but if they accumulate for a long time, there is a high probability of poisoning. Deep cellar. Not the easiest option for installing a boiler, but still, if the house has the opportunity to install it at a depth of 2 - 3 meters from the heating radiator, this would be an ideal option

Thanks to this installation, no additional circulation is needed, you don’t need to use circulation pumps, but if the installation option is only in the house, circulation is required, if it is missing or installed incorrectly, carbon monoxide can leak, it is impossible to determine its presence in the room without special devices, and you can be poisoned by it easily. Chimney. It is important to provide the necessary draft. If these calculations are incorrect, the boiler power may be reduced and combustion products may enter the room.

The installation of the chimney must be carried out by a specialist, since it is easy to make a mistake in this difficult task and lose heat.

If all rules are followed, the solid fuel boiler will work properly for many years.

Advantages and disadvantages

Boilers have their advantages and disadvantages that should be considered before purchasing.

Advantages:

- economical fuel consumption;

- the design in the combustion chamber allows increasing efficiency up to 70%;

- high-quality assembly;

- maintains the required temperature for a long time;

- ability to use a variety of fuels;

- automatic switching to long burning mode;

- affordable price;

- resistant to power surges;

- built-in security automation;

- There are three options for choosing power;

- the presence of a hob in some models;

- durable parts.

Flaws:

- sometimes marriage occurs;

- fuel burns out quickly;

- The power is not enough to heat a large house.

What coal is best to heat a boiler?

The manufacturer initially carries out thermal calculations and adapts the design of the combustion chamber and heat exchanger to the specific type of fuel. Therefore, in order to increase the efficiency of a household boiler, it is enough to use coal of the grade and fraction specified in the operating instructions.

What brand of coal to burn?

Coal contains carbon and non-combustible impurities, which form ash and slag after combustion. The ratio between carbon and impurities depends on the type of fuel chosen. Coal has (depending on the brand) different degrees of moisture, loose or hard structure, and age of formation.

To effectively heat a coal boiler, you need to have a good understanding of the characteristics that distinguish this or that type of fuel:

- Lingite – this type of fuel has a loose structure and a large percentage of ash residue. Lingite is used in industrial power plants. This type of fuel is not suitable for heating a house.

Hard coal – has a calorific value of 5500 kcal/kg. The percentage of carbon is at least 75%. Ash content from 2 to 4%. Most classic-type household boilers are heated with coal. For gas generator type equipment, not suitable due to humidity above 20%.

4bb4a03c33af9ddacb3695161fb5289f.jpe

Brown coal – calorific value is only 3000 kcal/hour. When burned, a large amount of ash residue and coking substances are formed. Humidity is at 50%. Brown coal is not recommended for heating domestic boilers, due to the rapid clogging of the chimney and heat exchanger.

Anthracite – the humidity threshold is within 7%. It has high specific heat values, equal to 9000 kcal/hour. The share of ash carried away by gases from the coal boiler is no more than 7%. Manufacturers of heating equipment recommend heating gas-generating boilers with Anthracite. Coal is divided into several grades according to size: fist, nut, seed.

Is it possible to burn with coal briquettes?

Coal briquettes are made by pressing small fractions (dust). Special organic or mineral compounds are used as a binding element. The latter greatly increase the ash content of the fuel, but are cheaper. The most popular are coal briquettes, in which coal tar acts as a binder.

Heating with compressed coal has the following advantages:

- Easy to install in the combustion chamber.

- Good flammability.

- High calorific values, identical to anthracite.

- Easy storage and transportation - briquettes have a regular geometric shape, so they are easier to store and take up less space.

The only disadvantage of compressed coal is its high cost, which is approximately one third higher than the price of lump raw materials. The advantage is the ability to fire the boiler on coal, without contamination by combustion products.

How to burn with coal dust

The safest and most effective method of burning dust is considered to be using a special burner device.

Is it possible to burn with charcoal?

With all these advantages, charcoal has one serious drawback. The cost of a kilogram of purchased charcoal will cost almost 2 times more than the cost of hard coal. You can somewhat reduce the cost of raw materials by establishing its independent production. To obtain 1 ton of charcoal, you will need to burn about 10 m³ of wood.

Which is better, coal or gas?

It is generally accepted that the most profitable option for heating is main gas.

However, having learned the cost of supply and connection, many residents are looking for alternative heating options. It is better to compare these types of fuel according to three criteria:

- Energy. When burning 1 m3 (0.62 kg) of natural gas, you will receive 9.45 kW/h of heat without taking into account the boiler efficiency. A kilogram of anthracite will give 7.16 kW/h.

- Economic. Tariffs for the population for gas supplies are taken into account, as well as the cost of transporting coal and the efficiency of boilers.

- Ease of use. In all cases, a chimney and ventilation will be required. Storage of coal fuel requires space; it will have to be stored manually, while gas is supplied through a pipeline.

Reference. If the house is already connected to the gas main, then you don’t have to look for a more profitable heating method. If there is no connection, the best option is coal boilers operating in automatic mode.

What coal to choose for the fire?

Fuel is selected in accordance with the recommendations of the boiler manufacturer.

The fact is that there are several types of coal, and they differ significantly in characteristics:

- brown coal. The most common and least quality: burns quickly, smokes and emits an unpleasant odor, produces a lot of waste: structure - earthy, color - brown or black, heat capacity: 16-22 MJ/kg, cost: 3.5-4.5 thousand rubles . per ton;

- coal. Black with a metallic or resin tint. Good quality and affordable price. There are several varieties, the most common is long-flame coal: heat capacity: 26-32 MJ/kg, cost: 5.5-7 thousand rubles. per ton;

- anthracite. Gray-black with a glass or metal sheen. The highest quality and most expensive: heat capacity: 32-36 MJ/kg, cost: 8-10 thousand rubles. per ton.

Using the “wrong” coal leads to cost overruns or damage to the heater. Thus, when anthracite burns in optimal mode, the temperature in the firebox reaches 2200-23000C. When loading such fuel into a boiler made of ordinary steel, designed for brown coal, it will quickly burn out.

Or you will have to “hold back” the combustion by cutting off the air supply, which will cause the efficiency of anthracite to drop sharply and the cost of purchasing this expensive coal will be unjustified.

Anthracite

Another example: long-flame coal, due to its high humidity, is unsuitable for a pyrolysis boiler - condensate forms abundantly in the chimney, mixing with combustion products and thereby turning into a viscous, tarry substance. Such heaters require gas coal.

There are toxic types of coal containing more than 2% sulfur. It is strictly prohibited to use them as fuel for furnaces and boilers: during combustion, sulfur oxide (sulfur dioxide) is formed, which poisons the air and destroys metal parts.

Cleaning the firebox and pipe

When coal burns, tar and soot are released, which settles on the walls of the combustion chamber and chimney. The boiler can only be cleaned when it is cool. To do this, we stop adding fuel. When the flame goes out completely, open all the dampers and wait for everything to burn out.

It is important to note that this will lower the temperature in the heated room.

Boiler cleaning brush

For mechanical cleaning, a lathe, various scrapers, pokers, metal brushes and spatulas are used. There are special windows in the case for access inside. For particularly difficult places, you can attach a scraper to a long handle. It is convenient to clean the chimney with a brush tied to a cable.

Chemicals are also used that are added to the fuel. Reacting with soot, they come out with smoke.

How to melt correctly

The algorithm of actions looks like this:

- It is required to place sheets of dry paper at the bottom of the firebox. Then, a small layer of wood chips, logs, preferably fruit varieties. To speed up the combustion, it is necessary to arrange them in a pyramid.

- Set the paper on fire. Then close the door, but leave the ventilation hole open. Due to which you can regulate the rate of combustion of firewood. Moreover, depending on the volume of oxygen, the fuel will burn faster or slower.

- After complete combustion of the wood, you need to place a layer of small coal, up to 15 cm, on the resulting pile of ash.

- When it burns sufficiently, you can pour a larger mineral on top in the form of a pillow. The height can reach 60 cm. Before doing this, be sure to move the hot stones apart so that the coal does not bake.

If you use fuel of insufficient quality, coking may occur. Therefore, if you are not sure of the quality of the purchased raw material, put it in the form of a sandwich, mixing it with firewood. Several layers of logs, successively mixed with stone, make it possible to sufficiently warm up the installation and release heat into the premises.

Principle of operation

To figure out how to properly heat a boiler with coal, let’s understand the principle of operation of such devices. When coal burns, heat is released, which heats the heat exchanger with liquid. It is already, under the action of a pump system, supplied to the radiators, heating the air in the necessary rooms.

The equipment is quite simple. At the bottom there is an ash pit where slag and ash are collected. Above it are the grate bars, on which the fuel directly burns. The heat exchanger can be located either around the firebox or on top.

There are also air-heated coal boilers. They directly heat the air in the room. Their design is much simpler, since there is no intermediary in the form of a liquid coolant. They are used more for heating garages and industrial premises.

Long-burning models and pyrolysis devices have an increased level of efficiency. In the first, air is supplied from above, due to which only the top layer of fuel constantly burns. This allows you to load a lot of coal at one time, which will smolder slowly.

Stable combustion stage

The stable combustion stage lasts about 5-9 hours. The main technique on how to properly heat a boiler during this period is to uniformly supply fuel to the firebox. Usually, if at the first filling ¼ of the fuel is used, then during the period of maintaining stable combustion, the remaining fuel is divided into 3 equal parts. After adding anthracite through the vent grate, the burning mass is stirred to prevent slagging of the firebox.