Pellet boiler: device

The main parts of the boiler are the firebox (burner), fuel supply system (auger), pellet hopper, heat exchangers for transferring heat to the coolant and control automation.

There are hybrid models of boilers with built-in electric heating elements, which take on the function of maintaining a set temperature in the absence of solid fuel in the boiler. This allows you to avoid freezing of water in the heating system if an unattended boiler has exhausted all its fuel or is faulty. The automation of the boiler affects the degree of its autonomy and convenience: human participation is limited to periodic adjustment of the main operating parameters and adding fuel to the bunker. Expensive models have self-cleaning systems for the burner and heat exchangers, the ability to remotely control and monitor from a PC or smartphone (GSM/Wi-Fi modules), automatic temperature control depending on weather conditions, etc. They can be found on sale as single-circuit (heating only), and double-circuit boilers (heating + DHW, with DHW priority).

Pellet boiler

Buleryan

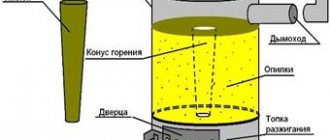

This is a convection oven that maintains a long combustion cycle. Such a device is used extremely rarely for heating a greenhouse. Buleryan combines several functions. It acts as a gas generator, furnace, and heater. The unit has a fairly simple design, which makes it possible to build it yourself.

The oven is presented in the form of a metal container, which has a barrel shape. The firebox has two tiers. Convection pipes are directed towards its center. The principle of operation is that in the first chamber the firewood smolders, resulting in the release of gas. In the second part of the furnace, gases are burned. The design is equipped with a chimney damper, a draft regulator and a door through which fuel is loaded.

Why are pellets considered an economical fuel?

Pellets are elongated granules with a diameter of 6-8 mm, made from wood waste. In production, wood raw materials are cleaned, crushed, dried and pressed under pressure of 300 atmospheres. It is noteworthy that no chemical additives are used to form granules: the binder is natural lignin contained in wood.

Indeed, the price for them is higher than for firewood: a ton of good quality pellets costs from 7 to 13 thousand rubles. However, in the process of processing wood raw materials, the amount of pure carbon in it increases, as a result, the calorific value of pellets is approximately 1.5 times higher than that of firewood. In the popular science program “Galileo,” they even conducted an experiment by burning equal amounts of wood and pellets in a calorimeter, and the superiority of the latter was confirmed. That is, in simple terms, to obtain a certain amount of heat, pellets will require significantly less than firewood. In addition, pellets are more environmentally friendly: during their combustion, less CO2 is released and less waste (ash) is generated. It is significant that in Europe, which is seriously concerned about environmental and economic issues, pellets are considered a very promising type of biofuel, their production volumes are growing, and in some EU countries the share of households using pellet boilers for heating is approaching 2/3 of the total. It is important that pellets, unlike firewood, have the same small size and can be supplied in uniform portions using mechanical devices, which allows pellet stoves to have a much higher degree of automation than wood-burning devices.

Pellets

Comparison of furnaces and traditional heat generators

Most heating devices operate on the principle of rapid combustion of fuel. It is set on fire from below, and the fire goes upward. In this case, oxygen access to the combustion zone is open. The disadvantage of such a system is that the temperature constantly fluctuates. The fuel resource is not completely consumed, and as a result of combustion, soot and soot are formed. Throughout the operation of the unit, it is necessary to constantly adjust the draft and frequently add fuel.

As for long-burning units, their operating principle is somewhat different from heat generators. In this case, the fire moves in the opposite direction: from top to bottom. This makes it possible to fully load the firebox as much as possible. The fuel burns gradually. Oxygen is supplied directly to the fire itself. Burning is slow. This generates less heat. Thanks to this, it is possible to create a comfortable temperature that is optimal for greenhouses.

Among the most efficient units, it is worth highlighting gas generator or pyrolysis furnaces. Their peculiarity lies in the fact that with the slow combustion of fuel, flammable vapors are formed, which subsequently also enter into the combustion process. Thus, the efficiency of the unit increases and fuel costs are reduced. The disadvantage is that when gases are removed, condensation forms in the chimney. Therefore, the pipe must be insulated.

A gas boiler has the following advantages:

- Economical and high efficiency. Fuel is relatively inexpensive. In this case, it is possible to use wood and other things. Such units are relatively inexpensive. The efficiency of the unit is close to 85%.

- Easy to maintain. It is enough to do only a few downloads throughout the day. When the desired temperature is reached, the operation of the unit is controlled using the combustion chamber draft.

- High functionality. The stoves are ideal for the construction of heating systems of various types, as well as hot water supply.

Modern units can be built independently or purchased ready-made. To make the right choice, it is worth considering the main characteristics of existing models.

Boilers operate on different fuels

Disadvantages of pellet heating

- High cost of equipment. A domestic boiler with a capacity of 20 kW will cost 170 - 200 thousand rubles; imported, from a manufacturer with a good reputation in the Russian market, will cost 200-250 thousand or more. It is important to understand that the chimney and its installation are not included in this amount.

- Large dimensions and weight. A 20 kW pellet boiler weighs from 200 to 400 or more kilograms, and is equipped with a hopper with a capacity of 150 - 300 liters. It is clear that the installation of such equipment can only be floor-mounted.

- Large combustion area for a pellet boiler. On average, one boiler requires at least 9 m2 of area, since according to safety requirements, the gap between the boiler and the wall (or other structures) must be at least 1 m on each side, and for a device with side service it is advisable to increase it to 1.5 m.

Pellet boiler in the boiler room

- The pellet boiler is absolutely dependent on electricity and cannot be used during a power outage.

- Loading pellets requires labor. The bunker is loaded manually; You can quite imagine how many kilograms of fuel you will have to carry on yourself if the capacity of the bunker is hundreds of liters.

- The boiler requires regular cleaning; with constant use, this should be done 2 times a month. Neglecting this rule can lead to damage to the fuel supply screw, and carbon deposits reduce the efficiency of the boiler.

- A separate large room is required to store pellets. If the house is used for permanent residence, then one heating season may require up to 10 tons of pellets - this is approximately 20 m3. You cannot store pellets in the open air or under a canopy: they are very hygroscopic (it’s not without reason that they are used to make inexpensive litter for cat litter boxes), and burning raw pellets leads to the accumulation of creosote in the boiler. Therefore, the main requirement for a room for storing them is good waterproofing, a more or less constant temperature and distance from sources of fire and strong heat.

Loading pellets into the boiler

Bubafonya

Making previous models with your own hands is quite difficult and almost impossible. As for the Bubafoni stove, the situation here is completely different. Having knowledge and skills in plumbing and welding, you can easily make a unit at home. It is home-made installations that are most often used for heating greenhouses and other auxiliary buildings that are located on a personal plot.

To make a boiler for a greenhouse with your own hands, you use various materials that can be found on the site or purchased in a store. An old gas cylinder or steel barrel is ideal for creating an equipment housing. It contains an ash pan and a fuel chamber with a door through which fuel is loaded. The design includes a metal pancake that ensures smoldering of firewood.

Important! The advantage of Bubafoni is that, thanks to its design and operating principle, it is able to function on one bookmark for a long time.

Installing equipment in a greenhouse is easy

The main problem of pellet boilers

The main enemy of pellet boilers is low-quality fuel. Theoretically, the quality of pellets depends on the raw materials and adherence to production technology. White pellets, which are made mainly from coniferous wood, are considered the best. They are characterized by high calorific value, very low humidity and minimal impurity content. Pellets with a small amount of gray and brown inclusions are not much inferior to them in terms of characteristics: they have a slightly higher ash content (the amount of non-combustible residue), in terms of calorific value they are slightly inferior to white ones, but they are cheaper. Agropellets are considered the lowest quality - they are dark in color, made from bark, branches, log trim and other “waste” raw materials.

In practice, the situation is much more complicated. Pellets offered for sale may contain not only wood shavings and sawdust, but also straw, peat, various husks, and even construction waste. Almost all domestic pellets contain sand in varying quantities. Production technologies and storage conditions at the supplier’s warehouse may not be followed; as a result, the pellets will reach the consumer wet. Impurities in pellets are dangerous because when they are burned in the firebox, solid deposits and abundant ash are formed, which reduce the efficiency of the boiler and can lead to breakdown. Low fuel quality has a particularly bad effect on foreign-made boilers, especially German ones.

There are few ways to check the quality of pellets. Good pellets should have a uniform structure and a smooth surface and break with force. Light crumbling, a large number of broken granules and debris in the packaging clearly indicate that the purchase should be abandoned. If possible, throw a few granules into the water: if they immediately swell and release sediment in the form of sand and other heavy inclusions, the product is of poor quality. Good pellets, when wet, hold their shape for several minutes, then turn into a homogeneous mass. If the granules stubbornly do not swell, this may be a sign that a chemical binder was used to create the shape. It is not recommended to buy such a product.

Greenhouse heating power calculator

The presence of a suburban area very often involves carrying out some kind of agricultural work on it. Agree, any person is pleased to have on his table vegetables, fruits or berries grown with his own hands and guaranteed to be “clean”. But it’s true that the summer “gardening” season in many regions is quite short. Therefore, prudent owners build special agricultural structures - greenhouses and hotbeds. And in order to bring the period of agricultural work to the maximum possible, or even switch to a year-round cycle, you will definitely need to equip the greenhouse with a heating system.

Greenhouse heating power calculator

The heating system of a greenhouse can be different - long-burning stoves, water or electrical circuits buried in the ground according to the “warm floor” principle, convectors that ensure the movement of warm air masses, infrared heating. But any of the selected systems must fulfill the main task - to create and maintain in the room the temperature required for the crops being grown, that is, to have a certain thermal power. But which one? – a calculator for calculating the heating power of a greenhouse will help us in this matter.

Prices for heaters for greenhouses

infrared heater

Below, under the calculator, are explanations and necessary reference data.

Greenhouse heating power calculator

Go to calculations

Explanations for calculations

The power of the greenhouse heating system must be sufficient to compensate for heat loss, and given the large glazing areas of these structures, they are quite considerable.

The calculation of the required thermal power is based on the following ratio:

Qt = Sw × Kinf × Δ t × τ w

Qt – calculated heating power.

Sw is the glass area of the greenhouse. It is this that is taken into account, since not only insolation (penetration of solar energy), but also the maximum amount of heat loss passes through transparent walls.

The area is calculated independently, using known geometric formulas.

For those who have difficulty calculating the area...

Some geometric figures do not want to directly “submit” to simple formulas, and they have to be divided into sections. How to calculate the area - including for complex cases, with examples and calculators - in a special publication on our portal.

Kinf is the so-called infiltration coefficient. It depends on the approximate operating mode of the greenhouse, that is, on the required temperature inside the structure, and the possible temperature level outside, on the street. Naturally, it is advisable to take into account the most unfavorable possible conditions in order to ensure the necessary operational power reserve.

The infiltration coefficient values can be taken from the table below:

| Planned air temperature in the greenhouse | Possible outside air temperature | ||||

| 0 °C | — 10 °С | — 20 °С | — 30 °С | — 40 °С | |

| + 18 °C | 1.08 | 1.13 | 1.18 | 1.24 | 1.30 |

| + 25 °C | 1.11 | 1.16 | 1.21 | 1.27 | 1.33 |

Δ t is the maximum temperature amplitude, that is, the difference between the normal value indoors and the minimum value outdoors, in the coldest week during the operation of the greenhouse. In the calculator, the Δ t value will be calculated based on the specified values outside and inside.

— As a rule, + 18 ºС is enough to grow most vegetables. For seedlings or flowers, about + 25 ºС is required. When growing some exotic plants, the temperature regime requires higher values.

— In the field for entering external temperatures, the level of minimum negative air temperature characteristic of a given region during the operation of the greenhouse is indicated.

τ w is the thermal conductivity indicator of the greenhouse glazing material.

Different materials (in composition and structure) have their own thermal conductivity - it is already taken into account in the calculator algorithm. The option of a greenhouse with a film coating is not being considered, since taking it seriously as a “winter” structure would be an exaggeration.

The resulting value, in kilowatts, will become a guideline when choosing the most suitable greenhouse heating system.

Is it difficult to build a greenhouse yourself?

The question is ambiguous, since greenhouses can vary significantly in size, basic design, equipment and other characteristics. However, this is quite doable, and a number of useful recommendations on this problem can be obtained in a special article on the portal - about building a greenhouse with your own hands .

How to make briquettes with your own hands? ↑

Someone will say - why make them, waste your time and effort, if you can buy or order them - and they will be delivered straight to your home. But many people believe that making briquettes with their own hands will be more economical, because the raw materials from which they are made are waste and can be easily found. In order to make a fuel briquette on your own, you need crushed combustible material, which is no longer needed on the farm. But dry material cannot be compressed by itself; it needs a binder. Typically, clay is used for these purposes (in a ratio of 1:10 dry matter). When the mixture is ready, it is placed in molds - and under a press. True, you need to dry such bricks very well, otherwise if there is moisture left inside, they will not burn. In addition, there is a problem with their compaction; it is necessary that they do not crumble - otherwise storing them will be a little problematic. There are many enthusiasts who make pressed briquettes from paper, some from sawdust, some from dry leaves - some are very good at what. You can watch the combustion of fuel briquettes in this video:

How to choose the best boiler?

When choosing a boiler with which you plan to heat the greenhouse, it is necessary to take into account the footage and cubic capacity of the room, as well as material costs associated with purchase, installation, etc. Preferable is equipment that uses long-burning technology - in this case, two boilers are produced per day. fuel bookmarks.

However, the cost of such boilers is high. The larger the area of the heated room, the sooner the payback period will occur. In small greenhouses (about 20 sq. m.), the payback period for technical equipment can last up to 10 years. In these circumstances, it is recommended to install solid fuel or gas devices, which, for greater efficiency, are equipped with a system for pumping water through pipes, which will allow the room to be evenly heated.

An electric boiler is not economical, consuming a large amount of electricity. When using it, the upper part of the greenhouse room warms up, but the lower part does not receive full heating, which causes the plants to freeze. Combined long-burning models are industrial and operate on gas or liquid fuel.

Did you know? The cauldron is depicted on the coat of arms of the city of Kronstadt. This is due to the fact that the mentioned city is located on the island of Kotlin.

The cost of such equipment is high and economically justified for large greenhouses when growing plants that are extremely demanding on temperature changes (strawberries, raspberries, eggplants). A long-burning pyrolysis solid fuel boiler has high heat transfer, is economical and at the same time highly productive.

However, it is large in size: due to the high heat transfer, plants must be planted at a distance of more than half a meter from the boiler. Therefore, it cannot be installed in small greenhouses. In case of unforeseen circumstances, a stationary wood stove or a mobile pellet boiler will come to the rescue, which, if necessary, is heated with any solid fuel (wood, corn cobs, etc.).

Requirements and heating scheme

When installing solid fuel boilers for greenhouses, you should pay attention to the following parameters:

- construction area;

- calculate the system power;

- presence of insulation;

- the ability to control the operation of the system;

- material opportunities.

If you take all these factors into account, you can choose a truly effective system that will allow you to heat the greenhouse without much expense. It is worth carefully considering all available options.

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...

Fuel briquettes ↑

Briquettes are waste of various types, compressed into blocks. By the way, they are also called eco-firewood. Eco - because the emission of carbon dioxide from them is negligible. Peat waste, wood residues (sawdust, wood chips, shavings), as well as agricultural waste (straw, corn stalks, buckwheat and sunflower husks) can be pressed. This happens when heated from 250 to 350 degrees Celsius and under pressure. High temperature is needed to melt the surface of the mass, due to this it becomes denser and stronger. This makes it easier to transport fuel briquettes. Advantages of briquettes: heat transfer from combustible briquettes is higher than from firewood, it will be very convenient to use such raw materials for heating greenhouses; compactness - 1 cubic meter of briquettes weighs a ton, and a cubic meter of firewood weighs approximately 600 kilograms; The briquettes are very dry, due to which they burn well (the humidity of fuel briquettes is about 6-8%, and for well-dried firewood 24-26%), 2 times longer than the same volume of firewood. Suitable for heating baths and saunas, fireplaces, greenhouses, in general, anywhere that requires a flame with a small amount of harmless smoke, burning for a long time, long-lasting heat and a small amount of residues after combustion. The disadvantage is the price. A cubic meter of briquettes costs about 5 thousand rubles, while a cubic meter of firewood costs about 2,000 rubles. But on the other hand, a cubic meter of firewood is usually not enough to heat a room (for example, a house) all winter. Yes, and you have to chop the wood, find a place for it and take it there - with briquettes everything is much simpler.

Greenhouse heating methods

To maintain the temperature regime, the following types of heating are applicable:

- steam, water;

- air;

- gas;

- electric;

- stove

Air

Air heating is carried out in two ways:

- heated air is taken from the external environment and heated in the supply ventilation system;

- Using gas convectors or fan ovens, the internal volume of air is heated.

Water

Water heating is the most popular type of heating in winter. Possessing unique physical and chemical properties, water is a coolant for most heating systems. Units to which cool-water systems are connected can operate on any type of fuel. In this case, it is possible to equip the stoves with a water circuit, and, therefore, the system functions according to all the principles of water heating.