Advantages and disadvantages of a battery tank

Let's now see what the user gains by using heaters with various types of heaters:

With electric boiler

As you know, electric heating is not only superior to any other in terms of ease of use, but can rightfully be considered ideal. Judge for yourself:

- there are no emissions, which means there is no need for a chimney;

- absolutely silent operation;

- heat dissipation power varies from 0% to 100% with constantly high efficiency;

- easy to automate.

But all these advantages are crossed out by one drawback - the high cost of electricity. Anyone who has a TA can significantly reduce the cost of electric heating. The fact is that, along with the usual form of payment for electricity, there is a so-called multi-tariff, which provides for different prices for electricity day and night.

The daytime rate is slightly higher than usual, but the night rate is about 3 times lower. By switching to this form of payment, you can operate the electric boiler only at night, heating the house during the day using the heat accumulated in the heating unit.

With solid fuel boiler

Here the meaning of installing a TA is obvious: the user will be able to add fuel less frequently, which is especially valuable at night. But this is only the “first benefit” that lies on the surface. The fact is that solid fuel boilers operate with maximum efficiency only in rated power mode.

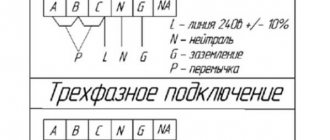

Heat accumulator connection diagram

If the heater is “screwed down” using an air damper, which has to be done during most of the heating season, a whole series of undesirable phenomena immediately appears:

- efficiency drops sharply (incomplete combustion of fuel);

- the formation of soot and toxic condensate increases;

- the exhaust becomes especially toxic due to the increased content of carbon monoxide and other partial oxides, as well as heavy hydrocarbon radicals.

Having a heat storage device, the user has the opportunity, even in the off-season, to operate the solid fuel boiler only at maximum performance: the boiler will absorb excess heat and then gradually release it to the heating system.

With gas boiler

The vast majority of gas boilers operate in a “start-stop” mode, that is, they are periodically turned on to heat the coolant, and then turned off again. Only units with modulated burners (their power is regulated), which are relatively expensive, operate without shutdowns.

The “start-stop” mode is accompanied by temperature changes, which shorten the service life of the boiler elements. Moreover, with a decrease in the load on the heating system (thaw or off-season), the frequency of switching on increases. If there is a TA, the gas boiler will operate stably at rated power, and then turn off for a long time.

Heating a private house with a gas boiler

It should, however, be recognized that you will have to put up with some shortcomings:

- you will need at least two circulation pumps, valves and automation for the mixing unit;

- to accumulate a more or less decent heat reserve, a large volume of coolant is required,

TA usually takes up quite a lot of space and needs a foundation.

How to choose a suitable heat accumulator

When choosing which heat accumulator to purchase, you should familiarize yourself with its characteristics, take into account the size of the heating system and the requirements for it. When selecting a device, you should take into account the features of heating devices:

- the power of which the boiler is endowed;

- maximum pressure volume;

- temperature for warming up;

- presence of other heat sources;

- the size of the area that will be heated;

- degree of thermal insulation.

When choosing a heat accumulator, you should focus on the following details:

- on the dimensions of the device;

- on volume;

- the material from which the unit is made;

- protection located inside;

- is there a removable casing;

- efficiency;

- simplicity and ease of use;

- period of operation;

- work automation;

- the presence of additional functions, for example, is there a built-in heat exchanger, is there protection against possible overheating, is there a temperature control sensor, and others.

When choosing and installing heat accumulators, many buyers encounter difficulties, and in order to resolve them and ensure the safe operation of heating systems, it is worth seeking the help of specialists.

When choosing a heat accumulator model, you should not save money and settle on unfamiliar brands; the fact is that cheap devices have the appropriate quality, which will affect not only the efficiency, but also the quality of operation of all heating equipment. You should also take into account recommendations for selection, since in the absence of a heat exchanger it will not allow heat to linger for a long time, and poor coating will lead to rapid wear. All this will lead to the fact that the unit will not perform its intended functions and will not be able to ensure the safe operation of the main parts that provide heat.

Purpose of the heat accumulator

The heat storage tank can be connected to any type of boiler.

The heat storage tank for various types of heating boilers is an impressively sized water-filled tank that allows you to solve problems that arise during the operation of the heating boiler:

- excessive energy consumption;

- excess heating power;

- overheating of water in the boiler;

- periodic fluctuations in heating temperature due to the unevenness of the combustion process itself and untimely placement of firewood and coal;

- discrepancy between the peaks of production and consumption of thermal energy.

Some problems can be solved by installing a long-burning pyrolysis boiler, but in the latter case it will not help. The peculiarity of the boiler operation is that after adding fuel, the power of thermal energy output gradually increases, reaching peak values, and then also gradually decreases. If you do not add fuel to the boiler in time, it stops, the coolant begins to cool, and at the same time the temperature in the house drops. During the period of peak heat production, the system is not able to efficiently distribute all the energy, since it is equipped with thermostats, so some of the heat is wasted. If the boiler is electric, it is much more profitable to accumulate heat at night, when electricity is calculated at a preferential night tariff, in order to consume as little electricity as possible during the day.

The heat accumulator reservoir for the heating system is made of stainless or ordinary steel; the inside can be coated with a protective varnish. The walls are painted on top with heat-resistant paint, then covered with heat-insulating material and leatherette. In fact, when a heat accumulator is connected, the volume of coolant in the heating system increases, which makes it possible to compensate for the peak power of the boiler and at the same time accumulate heat to transfer it to the coolant when the boiler’s thermal energy generation capacity drops. Thanks to high-quality insulation, the water in the heat accumulator cools down for a long time. It is kept in a heated state for several hours and even days and is fed into the system through a pump. The operating principle of a heat accumulator is based on the different heat capacities of different media, in particular water and air. A decrease in the temperature of 1 liter of water by one degree leads to an increase in the temperature of air with a volume of 1 m3 by 4 degrees.

Background

It so happened that some time ago I purchased a private house at some distance from civilization. The distance from civilization is determined mainly by the fact that there is no gas there in principle. And the permitted power of the electrical connection does not provide the technical ability to heat the house with electricity. The only real source of heat in winter is the use of solid fuel. In other words, the house was equipped with a stove, which the previous owner heated with wood and coal.

If someone has experience using a stove, then they do not need to explain that this activity requires constant monitoring. Even in not too cold weather, it is impossible to put wood in the stove once and “forget” about it. If you put too much wood in, the house will become hot. And after the fuel burns out, the house will still cool down quickly. Willy-nilly, to maintain a comfortable temperature you need to constantly add firewood little by little. And in severe frosts the oven cannot be left unattended even for 3-4 hours. If you don’t want to wake up in the morning in a cold room, be kind enough to go to the stove at least once a night...

Of course, I had no desire to work as a fireman. And so I immediately began to think about a more convenient heating method. Of course, if it was impossible to use gas or electricity, this method could only be a modern solid fuel heating system, consisting of a solid fuel boiler, a heat accumulator and simple automation for turning the recirculation pump on and off.

Why is a modern boiler better than a conventional stove? It takes up much less space, you can put more fuel in it, it ensures better combustion of this fuel at maximum load, and theoretically with its help you can leave most of the heat in the house rather than release it into the chimney. But unlike a stove, a solid fuel boiler is practically impossible to use without a heat accumulator. I am writing about this in such detail because I know many people who tried to heat their houses with such boilers, connecting them directly to the heating pipes. They didn't do anything good.

What is a heat accumulator or, as it is also called, a buffer tank? In the simplest case, it is simply a large barrel of water, the walls of which have good thermal insulation. The boiler heats the water in this barrel during its two to three hours of operation. And then this hot water circulates through the heating system until it cools down. As it cools down, the boiler needs to be lit again. The simplest heat accumulator can be easily made by any welder. But after some thought, I abandoned this idea and bought a ready-made one. Since I live in Ukraine, I turned to it and have never regretted it: here they make storage tanks professionally and of very high quality.

Depending on the volume of the heat accumulator, the power of the boiler and how much heat the house needs, the boiler does not have to be heated constantly, but once or twice a day, or even once every two or three days.

Types of hydraulic accumulators

These devices can be in vertical or horizontal configurations.

The operating principle of the devices is no different, except that vertical hydraulic accumulators with a volume of more than 50 liters have a special valve in the upper part for bleeding air, which gradually accumulates in the water supply system during operation. Air accumulates in the upper part of the device, therefore the location of the valve for bleeding is chosen in the upper part.

In horizontal devices for bleeding air, a special tap or drain is mounted, which is installed behind the hydraulic accumulator.

From small devices, regardless of whether they are vertical or horizontal, air is released by completely draining the water.

When choosing the shape of a hydraulic tank, proceed from the size of the technical room where they will be installed. It all depends on the dimensions of the device: whichever fits best into the space allocated for it will be installed, regardless of whether it is horizontal or vertical.

Types of heat accumulators

The heat accumulator for the heating system is a capacious tank equipped with solid thermal insulation - it is responsible for minimizing heat loss. Using one pair of pipes, the battery is connected to the boiler, and using the other pair, to the heating system. Additional pipes may also be provided here to connect the DHW circuit or additional sources of thermal energy. Let's look at the main types of heat accumulators for heating systems:

With a circulation pump, it becomes possible to use several buffer tanks at once, which allows you to evenly heat several rooms at once.

- Buffer tank is a simple tank without internal heat exchangers. The design provides for the use of the same coolant in the boiler and batteries, at the same permissible pressure. If you plan to pass one coolant through the boiler and another through the batteries, you should connect an external heat exchanger to the heat accumulator;

- Heat accumulators for individual heating with lower, upper or several heat exchangers at once - such heat accumulators allow you to organize two independent circuits. The first circuit is a tank connected to the boiler, and the second is a heating circuit with radiators or convectors. The coolants do not mix here; there may be different pressures in both circuits. Heating is carried out using a heat exchanger;

- With a flow-through heat exchanger of the DHW circuit or with a tank - for organizing hot water supply. In the first case, water can be consumed throughout the day and evenly. The second scheme involves the accumulation of water for the purpose of quickly releasing it at a certain time (for example, in the evening, when everyone takes a shower before going to bed) - indirect boilers that accumulate water are designed in a similar way.

The design of heat accumulators for heating can be very different; the choice of a suitable option depends on the complexity of the heating system, its characteristics and the number of sources of hot coolant.

Some heat accumulators are equipped with heating elements with thermostats, which makes it possible to provide consumers with heat at night, when the coolant has already cooled down and there is no one to throw firewood into the firebox. They are also useful when using heat pumps and solar panels.

Features of operation of solid fuel boilers

The process of burning wood or coal is somewhat more complicated than burning the same methane (natural gas). Methane is a simple inorganic compound that decomposes at high temperatures into carbon dioxide and water with some carbon monoxide. Wood and coal are complex organic substances that, when burned, form several substances and gases, some of which are aggressive. This leaves its mark on the longevity of the heat generator. Individual piping of solid fuel boilers is done in order to create an optimal operating mode and thereby extend their service life.

One of the features of the operation of water heating units that burn solid fuel appears after the firebox is ignited and reaches operating mode. If the installation of heating pipelines is carried out directly to the heating installation and, during heating, cold water is passed through the water jacket of the unit, then condensation will begin to form intensively on the internal walls of the firebox. It reacts with combustion products, mixes with ash and firmly adheres to a metal or cast iron surface. The results are as follows:

- The steel walls of the combustion chamber are corroded by corrosion.

- A cast iron firebox is not as susceptible to corrosion, but its rough surface allows plaque to stick, which is very difficult to remove. The same coating will appear on the walls of the steel chamber.

To successfully combat condensate, it is necessary to install a small circulation circuit with a three-way valve; it is not recommended to connect a solid fuel boiler to the heating system directly.

Another feature of the operation of wood heating systems is inertia. When the water temperature in the system is sufficient, the automation closes the access of air to the firebox and stops the process. Nevertheless, combustion continues for some time, the coolant temperature exceeds the set one. The same phenomenon is observed when the circulation pump stops as a result of a power outage. Water in the jacket can boil, forming steam, and destroy the jacket or rupture pipes. To avoid this, a safety group with a relief valve set to a certain critical pressure is installed on the supply pipe or directly in the boiler water tank.

Operating principle and design

The main task of a heat accumulator is to accumulate additional heat in its capacity and, if the boiler is unable to release energy, perform this function for it. The operation of such a device can reduce energy consumption by several percent if it is installed in an electric boiler, and this in turn reduces the home owner’s money costs for electricity.

This equipment, embedded in a solid fuel boiler, works as follows: if there is no source of thermal energy in the boiler, it stops working, and accordingly, the water in the main pipelines gradually begins to cool. It is the water that squeezes the hot coolant out of the battery tank into the system, which makes its operation uninterrupted.

Design

In fact, the heat accumulator used for connection to the heating system has a simple design: a tank with thermally insulated walls and several pipes necessary for connection to the boiler.

When choosing equipment, you should carefully calculate the required level of thermal insulation of its walls - it is best to play it safe and purchase a container with thick walls.

As a rule, the volume of a heat accumulator for a solid fuel boiler is calculated based on the ratio that 1 kW of boiler power should account for 25 liters of tank volume.

Application cases

Experts recommend installing a heat accumulator into the heating system of a house in the following cases:

- large daily need for hot water;

- if a solid fuel boiler is used (the amount of fuel used is reduced);

- if the house has an electric boiler, and at night the tariffs for electricity consumption are not reduced.

How to calculate volume

Calculation of the required capacity can be done in two ways:

- multiply the boiler power by 25;

- multiply the heated area by 4.

If we have a house of 100 square meters, according to the second formula we will need a heat accumulator for heating boilers of 400 liters. The boiler power is selected at the rate of at least one kilowatt per ten meters (multiply by the correction factor, plus a margin).

Our house will require approximately 15 kW. One kilowatt warms up 25 liters, i.e. according to the first formula, you get 375 liters. Almost the same.

DIY connection methods and diagrams

A heat accumulator with an empty tank is installed if the pressure in the system is low.

The complexity and features of the connection depend on the type of heat accumulator. Therefore, you should figure out what they are.

- The simplest design is an empty tank inside. The boiler and consumers are connected directly. Use is optimal if the same coolant is used in all circuits, the pressure in the system does not exceed the permissible values of the storage tank and the temperature of the coolant supplied from the boiler does not exceed the permissible values for the heating circuit. If the first two requirements are not met, additional external heat exchangers must be used when connecting to the system. In the latter case, mixing units with three-way valves should be installed.

- Buffer tank with an internal heat exchanger - one or more. The heat exchanger is a spiral pipe made of copper or stainless steel. In such a storage tank, the coolant is mixed. The coil, located in the lower part, heats the coolant, hot water rushes upward as it is less dense. At the top there is another coil, which takes energy and outputs it to the heating circuits. A device of this type is optimal when using different types of coolants, at high pressure and temperature of the coolant, and connecting several heat generators.

- A tank with a flow-through hot water supply circuit. The heat exchanger is mostly located at the top of the tank. It must be made of metal that meets food water consumption standards. The circuits are connected directly. This system is preferable for uniform flow of hot water.

- Heat accumulator with internal boiler. The storage tank stores heated water for domestic consumption. This type of heat storage battery can be easily integrated into open and closed heating systems equipped with solid fuel, electric boilers and solar collectors. Buffer tanks of this type are especially relevant when using electric boilers, when the coolant is heated at night and water is consumed during the day. A 150 liter boiler is quite enough for the daily water consumption of an average family.

A system with three-way valves allows for more precise temperature control

Other types of systems:

- The simplest strapping scheme, limiting the possibilities of adjustment. Hot water rises up and is taken from the top point, after cooling it falls and enters the boiler again. Used if the pressure and temperature in the heat generator and heating circuits are the same. The temperature is regulated only by increasing/decreasing the coolant flow.

- The system contains mixing units and bypasses, so more precise adjustment of the coolant temperature is possible. Equipment efficiency is achieved through the installation of, for example, three-way valves.

- The system includes an additional tank, so that a small volume of hot water is available immediately after starting the boiler. The consumer does not have to wait for the system to warm up completely, but the water supply is not large, and the system heats up more slowly than a classic one.

- There is one coil inside the buffer tank; thermal energy from the source passes through it, and the coolant in the heat storage tank is heated from the coil. This type of system uses different coolants. You can choose those that cannot be mixed due to incompatible chemical characteristics. Heating or DHW can be powered through the coil, or coolant from the source will circulate through this circle.

- The system has an additional external heat exchanger. It allows you to maintain the desired temperature in the battery.

- System with a flow-through hot water supply circuit. It is optimal if hot water is used evenly. Otherwise, it is recommended to purchase an energy accumulator with a built-in boiler.

- A system with one coil and connection to an alternative energy source, for example, a solar collector. It's called bivalent. The connection is made in such a way that the collector plays a leading role in heating the system, and the boiler is connected when there is not enough thermal energy.

- A multivalent system where the main heating is carried out by low-temperature sources, such as a solar collector and a geothermal heat pump. They are connected at the bottom of the heat accumulator. A high-temperature boiler is used as an auxiliary source of thermal energy.

Expensive units

The section of expensive units includes those whose cost exceeds 100,000 rubles; as a rule, they have all the additional functions that ensure the necessary operation of the heating systems.

Electric boiler Heat Tank

This model is industrial, holds about 1500 liters of water and allows you to maintain temperatures from +35 to +85 degrees. Suitable for use with gas and solid fuel boilers. A heating element with a power of 30 kW allows you to use electrical energy as a backup power source. The container is made of stainless steel and has a thermal insulation of 25 mm, as well as additional protection in the form of a nylon cover that protects against corrosion. Small dimensions (diameter 1 m, height 2 m) make it easy to place the device in the right place, and the location of the pipes makes it easy to connect the model. If desired, you can install a tubular heat exchanger, thereby increasing the power of the heating element to 150 kW.

Electric boiler Heat Tank

Advantages:

- has precise thermostat settings;

- smoothly adjustable;

- there is an automatic heater switch;

- warms up in less than 3 hours;

- there is a safety valve;

- pressure 0.6 atmospheres.

Flaws:

- price;

- not suitable for using process water.

Oso Accu AS

A fairly compact model Oso Accu AS, has a volume of 100 liters and is suitable for working with solar collectors or small heat pumps. The inside of the container is made of stainless steel, and the structure itself can withstand a pressure of 9 atmospheres. The large dimensions of 45 by 45 cm allow you to install the device anywhere in the room and easily make a simple connection with the harness. The model is sold without thermal insulation and allows you to independently select and install the appropriate level of protection to prevent heat loss. Maximum safety in case of source failure is ensured by full load on the tip.

Oso Accu AS

Advantages:

- the device is made in a modern design;

- has high corrosion resistance;

- the eyeliner is located on the side;

- efficiency;

- The heating element is built-in;

- Double connections are provided.

Flaws:

- high price;

- no heat exchangers.

S-Tank Hfwt DUO-1000

The thermal accumulator S-Tank Hfwt DUO-1000 is suitable for use in both residential and small industrial premises. The tank volume reaches 1000 liters and is equipped with two spiral-shaped stainless steel heat exchangers. The model is equipped with solar collectors, boilers running on natural gas or solid fuel, as well as heat pumps. The coil located at the bottom of the tank is connected to a heating source; the water passing through the coil from above is heated to a temperature 2 degrees lower than the liquid accumulated in the tank itself. The owners regularly use about 1000 liters of hot water. The unit comes with a heat-insulating casing made of flexible polyurethane foam and polyester. The operating pressure in the heat exchanger can reach 6 atmospheres.

S-Tank Hfwt DUO-1000

Advantages:

- the highest heating temperature reaches 95 degrees;

- increased resistance to corrosion;

- in this model, water-glycine solutions can be used as a coolant;

- The warranty period from the manufacturer is 5 years;

- stable design.

Flaws:

- price.

Drazice Nado 300/20 v6

An excellent unit that has two heat exchangers, one of which is designed to heat 20 liters of technical fluid, and the second is for connection to the solar collector. Drazice Nado 300/20 v6 with a volume of 300 liters is covered with enamel inside, the maximum heating temperature reaches 110 degrees. The kit includes two pipes for screw-in fluid heaters operating from the mains. The required level of heat is maintained due to the installed thermal insulation in the form of a layer of polyurethane and a removable casing. The vessel is painted with a special heat-resistant paint, which provides a high level of protection against rust.

Drazice Nado 300/20 v6

Advantages:

- the coil is located along the entire length of the container, which increases heat transfer;

- the dimensions are so compact that they allow it to be installed even in a small room;

- insulating material is presented in separate packaging;

- The pipes are well located.

Flaws:

- price.

Calculation

The power accumulated by a heat accumulator (TA) is calculated based on the volume of the container, more precisely the mass of the liquid in it, the specific heat capacity of the liquid used to fill it, and the temperature difference, the maximum to which the liquid can be heated, and the minimum target at which it can still be carried out. heat intake from the heat accumulator to the heating circuit.

Formula:

- Q = m*C*(T2-T1);

- m – mass, kg;

- C – specific heat capacity W/kg*K;

- (T2-T1) – temperature delta, final and initial.

If the water in the boiler and, accordingly, in the heating element is heated to 90ºС, and the lower threshold is taken equal to 50ºС, then the delta is equal to 40ºС. If we take TA water as filling, then one ton of water, when cooled to 40ºC, releases approximately 46 kW*hours of heat.

| Volume | 0,5 | 1 | 1,5 | 2 | 3 | 5 |

| Accumulated heat at ΔT = 40ºC, kW/h | 23 | 46 | 69 | 92 | 138 | 230 |

The stored energy must be sufficient for the intended use of the heat accumulator.

To select the required volume of the heat accumulator, it is necessary to determine:

- The time during which the accumulated energy in the heat exchanger should be enough to cover the heat loss of the house;

- The time during which the coolant in the heat exchanger must heat up;

- Power of the main heat source.

For periodic operation of the boiler during the day

If it is needed to switch the boiler operation only to night or day mode, when heat is supplied for a limited time, then the TA power should be enough to cover the heat loss of the house for the remaining time. At the same time, the boiler’s power should be enough to heat the heating unit in a timely manner and, again, to heat the house.

Let's assume that a solid fuel boiler is used with firewood only during the day for 10 hours, the estimated heat loss of the house for the coldest period of the year is 5 kW. 120 kW*hours are required per day for full heating.

The battery is used for 14 hours, which means that it needs to accumulate 5 kW * 14 hours = 70 kW * hours of heat. If you take water as a coolant, you will need 1.75 tons or a heat exchange volume of 1.75 m3

It is important that the boiler must produce all the necessary heat within just 10 hours, that is, its power must be more than 120/10 = 12 kW

If the heat accumulator is used as a backup option in case of boiler failure, then the stored energy should be enough for at least a day or two to cover all heat losses in the house. If we take the same 100 m2 house as an example, then heating it will require 240 kW*hours in two days, and a heat accumulator filled with water must have a volume of at least 5.3 m3.

But in this case, the TA does not necessarily have to heat up in a short period of time. A boiler power reserve of one and a half is enough to accumulate the required amount of heat in a week or two.

The calculation is approximate, without taking into account the reduction in the thermal power of radiators depending on the temperature of the coolant and air in the room.

Heat treatment

It was unprofitable to sell heaters to residents at that time: heat accumulators are expensive equipment, and at the beginning of the 2000s there were few particularly wealthy people and, in addition, they were not as concerned about saving as they are today. Alexander Anisimov started working on heating stoves. I went to Finland and studied their experience. As a result, he created his own stove, which in terms of thermal performance is not inferior to, and in some areas superior to, Finnish stoves.

— There is enough radiation. You don’t get energy from being cooked like borscht at a temperature of over 100 degrees. Our heat is not transferred by convection, but by radiation from the stone - like a good Russian stove. This is our invention. The radiation from the stone deeply warms the body. It's like comparing a synthetic shirt and a cotton shirt. Which one do you feel better in? This is ecology,” explains Alexander Anisimov.

Head: Alexander Anisimov. Photo: “Republic” / Sergey Yudin

Alexander said that after the tragedy at the Chernobyl nuclear power plant, the accident liquidators were treated at the Kivach clinic. Soapstone slabs were installed in the wards, and behind them were electric heating elements. These were the simplest devices that had a healing effect. The inventor says that doctors confirmed that people recovered faster.

Energoresurs-T also produces stoves for black saunas. Experts have found an interesting solution: to use Russian fireclay slabs as the heat-storing core of the furnace (fireclay is burnt, crushed clay, as well as refractory bricks made from such clay). The company received a patent for the assembly technology, that is, now the entire structure can be loaded into a container, delivered to the customer and assembled on site as a construction set. You can do without a stove-maker: the stoves are numbered. You just need to connect everything according to the instructions. There are not many competitors in the production of heavy collapsible stoves. The order can be sent even to Petropavlovsk-Kamchatsky.

The base of the stove is made of fireclay. Photo: “Republic” / Sergey Yudin

Alexander tried to sell his stoves abroad. With the support of the government of Karelia, he participated in exhibitions in Europe. We managed to sell something. But obtaining documents and patents is an expensive matter: for a foreign patent they paid 2 thousand euros, for certification - 8 thousand euros. And we had to stop there.

The company will now apply for a patent for an eco-friendly white-wash stove made of fireclay bricks with a soapstone lining. For now, the new technology is kept secret.

Using a heat accumulator in different heating systems

DHW scheme

Heat accumulators show themselves effectively when used in a wide variety of heating systems. Moreover, in each case, such a storage device allows you to significantly save on heating.

Most often, solid fuel heating systems are equipped with heat accumulators. The installation will contribute to more economical fuel consumption and efficient heating, and will also prevent premature wear of heating radiators.

A heat accumulator would also be useful in an electric heating system, especially in regions with double tariffs for electricity. At night, when electricity is sold to consumers at a more affordable cost, the battery will accumulate heat. During the day, it will be possible to turn off the boiler for a while and heat it using the heat accumulator.

Storage tanks are also used in multi-circuit heating systems. Thanks to them, the distribution of coolant between the circuits is ensured. Installation of pipes can be done at different heights, which will allow receiving water heated to different temperatures.

Stages of installing a heat accumulator at home

The first step is to assess the load-bearing capacity of the floor at the installation site. It may turn out to be insufficient, since the weight of the TA is quite substantial. In this case, it is necessary to build a concrete foundation. You need to lay an expanded clay bedding on top of the foundation and place the tank on it.

Harness

In our example, a piping scheme with hydraulic separation is used, in which the TA plays the role of a hydraulic switch. According to it, the drive must be connected as follows:

- On one side - to the boiler: supply pipeline (from the boiler) - to the upper pipe, return pipe - to the lower one. In this case, as usual, a jumper is made in the boiler piping with a mixing unit that prevents cold water from entering the heat exchanger.

- On the other side - to the heating circuit, also equipped with a jumper and a mixing unit. Water should be taken into the circuit from above, and returned from below.

A circulation pump is installed into each circuit. The one that is installed between the heating element and the boiler drives the coolant through the heat generator, charging the storage tank. The second pump, installed on the side of the heating circuit, drives the coolant through the radiators.

Heat accumulator - installation diagram

As soon as its temperature drops below a certain level, the valve of the mixing unit opens and a new portion of hot water enters the circuit from the TA.

Settings

For the correct movement of the medium inside the heat accumulator, it is necessary to ensure that the pump between the heat accumulator and the boiler pumps more liquid than the second unit.

In order to accurately determine the power of each pump, it would be necessary to perform a complex hydraulic calculation, because the resistance of the circuits differs significantly. In practice, instead, it is possible to adjust the performance of each supercharger, which makes it possible to precisely coordinate their operation.

- Install superchargers with stepwise adjustable engine speed. Today you can find 3-speed circulation pumps on sale.

- A control valve can be installed at the connection point of the heating circuit return to the heat accumulator. By changing its flow area, we will achieve a change in the flow rate through the circulation pump of the heating circuit.

The pump performance is adjusted with the heating circuit mixing valve fully open. With proper balancing, the temperature on the thermometer on the heating circuit side should be lower than on the thermometer on the boiler side.

Manufacturing recommendations

From the previous section it follows that you won’t be able to get away with an ordinary 200 liter barrel, unless its capacity is at least half a cube. This is enough for a house with an area of 30 m2, and even then not for long. In order not to waste time and effort, you need to

From the point of view of placement in the boiler room, it is better to make a rectangular container. The dimensions are arbitrary, the main thing is that their product is equal to the calculated volume. The ideal option is a stainless steel tank, but ordinary metal will also work.

At the top and bottom, a self-made heat accumulator must be equipped with pipes for connection to the system. To prevent the steel walls from bulging outward under water pressure, the structure must be strengthened with ribs or jumpers.

The battery tank must be properly insulated, including from below. For this purpose, foam plastic with a density of 15-25 kg/m3 or mineral wool in slabs with a density of at least 105 kg/m3 are suitable. The optimal thickness of the thermal insulation layer is 100 mm. The resulting device, filled with coolant, will have a decent weight, so a foundation will be required for its installation.

Advice. If you need a container for a gravity heating system, you should install it yourself on a metal stand, not forgetting to insulate the lower part. The goal is to raise the tank above the level of the batteries.

Connection diagram

After installing the tank in place, it must be correctly connected to the pipeline network. The most popular standard connection diagram for a heat accumulator is shown in the figure:

To implement it, you will need 2 circulation pumps and the same number of three-way valves. Pumps provide circulation in separate circuits, and valves provide the required temperature. In the boiler circuit it should not fall below 55 ºС in order to avoid the appearance of condensation in the solid fuel boiler; this is what the valve on the left side of the diagram does.

The coolant in the heating pipelines is heated depending on the heat demand, and therefore the connection of the heat accumulator on the other side is also carried out through the mixing unit. The valve can control the water temperature automatically, based on a sensor or using a thermostat. To connect the container to an electric boiler that is not afraid of condensation, you can use a simpler diagram shown in the video:

https://youtube.com/watch?v=fmEx6Gzfq3I

Buffer tanks for heating

Typical thermal storage design

In autonomous heating schemes, constant operation of the boiler is almost always provided. This entails an increase in energy costs and a decrease in the service life of expensive equipment due to wear and tear. The heating accumulator is designed to optimize the operation of the entire system.

Purpose of buffer tanks

It is a container inside which the heating line runs. The heat transferred from the pipes to the water in the tank warms it. When the boiler is turned off, the coolant temperature decreases and the reverse process begins - thermal energy comes from the water in the tank through the walls of the coolant pipes. In this way, heat accumulators in heating systems make it possible to maintain a comfortable heating level for a long time after the boiler is stopped.

Why aren’t heating accumulator tanks installed in every autonomous system? There are a number of specific factors that must be taken into account before installing them:

- Volume. To maintain the temperature in a house with an area of 120 m² for 10-12 hours, you will need a container with a volume of 1.5-1.8 m³. It is not always possible to place such a water accumulator for heating in the system;

- Price. The average price of a 750 liter buffer tank. is about 90 thousand rubles. In fact, it turns out that the heat accumulator in the heating system will be the most expensive element.

The latter is the main reason not to install a thermal buffer tank. But if you make approximate calculations of efficiency, it turns out that heating with a heat accumulator requires 10-15% less energy (gas, firewood, coal, etc.) compared to the traditional scheme.

Thermal accumulator design

Thermal storage functionality

Making your own heating battery at home will not bring the desired result. This is due to the specific design and materials used. It is almost impossible to make such a tank from available materials without the use of special equipment.

In addition to the main function of heat accumulation, most manufacturers are trying to improve the design so that the heating system with a heat accumulator can be used in other areas of life support for a private home:

- Hot water supply. The water heated in the tank can be used as hot water - for taking a shower, washing dishes, etc. The main thing is that the container is indirectly heated;

- Switching element for connecting alternative heat sources - solar systems, heat pumps. This heating scheme with a heat accumulator allows you to heat water in it using conditionally free solar energy. As a result, a reduction in current costs;

- Connecting several boilers into one circuit. In this way, you can organize heating with a boiler using solid fuel and gas.

To reduce heat losses in heat accumulators in heating systems, two walls are provided - external and internal. The space between them is filled with insulation, most often basalt wool. In addition, most models have an additional heat source - an electric heating element. It allows you to maintain the temperature of the water in the heating storage tanks at the required level. This also makes it possible to use the container even when the boiler is not working, like an ordinary electric boiler.

Regenerative balls

Application : Suitable for selecting regenerative ball combustion system of gas and non-gas fuel industrial furnaces.

Our advantage : the highly efficient heat storage balls produced by our company have a specific surface area of 240 m2/m3.

Description of regenerative balls

Regenerative balls are also called spherical heat storage bodies. The spherical heat storage body has the advantages of good heat resistance, large heat storage, high strength, easy to clean and reusable. It is suitable for selecting regenerative ball combustion system of gas and non-gas fuel industrial furnaces. The highly efficient heat accumulators produced by our company have a specific surface area of 240 m2/m3.

Numerous small balls divide the air flow into very small streams. When the air flow passes through the heat storage body, it creates strong turbulence, which effectively breaks through the surface layer of the heat storage body. In addition, because the spherical diameter is small, the conduction radius is small, the thermal resistance is small, the density is high, and the thermal conductivity is good, so it can meet the requirements of frequent and rapid reversal of regenerative burner.

Classification of regenerative balls:

The main assortments of the ball for heat accumulation: Φ16mm Φ18mm Φ20mm Φ25mm. The product materials are divided into: mullite, high alumina and corundum.

Application of regenerative balls

It is suitable for selecting regenerative ball combustion system of gas and non-gas fuel industrial furnaces, especially suitable for accumulator furnaces in iron and steel industry, regenerative ladle roasting plants, thermal accumulators of air separation equipment in air separation industry, and non-ferrous metal industry. It can also be used as a heat carrier in industries such as regenerative cart furnaces, regenerative electric boilers and regenerative incinerators in large forge plants.

Advantages and disadvantages of TA

The dimensions of the TA are impressive

Let's start with the advantages that using a battery tank for hot water and heating gives:

- temperature stability in the circuit;

- fuel economy;

- reducing the number of fuel loads into the boiler;

- the heater fully realizes its power potential;

- the possibility of saving if an electric boiler acts as a heater;

- simultaneous heating of the coolant in the heating circuit and hot water.

There is nothing that does not have its shortcomings. Same with heat accumulators:

- take up a lot of space;

- are expensive;

- need a more powerful boiler.

Everyone understands that every task must be done well and efficiently, preferably adhering to all the rules. In practice, unfortunately, this is not always possible. Here you need to count money, because everything always depends on it. The use of buffer tanks really helps to reduce fuel costs and stabilize the temperature in the circuit. In this case, initially you will need to buy a boiler twice as powerful, which is naturally more expensive, and buy a heat accumulator itself, which is also not cheap. You can make purchases gradually, first make a circuit without a storage tank, and then buy it over time if the desire continues. In this case, you will need to slightly adjust the heating pipe layout.

Interesting on the topic:

- Is there any harm to health from heated floors?

- How to choose heating pipes

- How to connect an electric boiler

- Polyethylene, polyurethane, polymer, etc.