Coal is one of the most sought-after minerals, the extraction of which requires enormous effort and occurs in very unsafe conditions. Its deposits are located deep underground and are formed as a result of plant decay caused by lack of oxygen. In everyday life and industry, various grades of coal are used, corresponding to the accepted classification based on quality characteristics.

Coal grades vary. at least in terms of quality

Marking of finished products

In addition to the types of coal by color, the finished resource is assigned one of the markings according to quality:

- Category A is a product of the pyrolysis process of hard rocks with a maximum mass fraction of carbon of about 90%. The amount of minerals in such a product does not exceed 2.5%. This is the highest quality brand.

- Category B - coal obtained from the pyrolysis of soft and hard wood. The carbon content in the final product is 88%.

- Category B - charcoalization of all groups of raw materials leads to the appearance of a coal mixture. It contains no more than 77% carbon, and up to 4% minerals. For this category, standardization of other parameters is not provided.

Features of coal storage

You cannot buy a lot of good fuel at once, since long-term storage leads to weathering, oxidation of the rock, and it loses its characteristics. It is optimal to purchase fuel for the season and store it in a well-ventilated place, protected from moisture and light. The temperature in the compartment should not exceed +20 C, otherwise the pieces will begin to loosen and crumble.

The oxidation process causes spontaneous combustion of the rock, which is typical for brown, fine-grained coal. Anthracite is practically non-flammable, can be stored for a long time and, even at sub-zero temperatures outside, retains all thermal efficiency parameters.

It is most practical to store supplies in a shed open on one side under a roof. To maintain its integrity, cover the fuel with a hygroscopic membrane (not film) and regularly check for oxidation.

Why does coal burn poorly?

There are several reasons for insufficient fuel combustion - low temperature, lack of oxygen, traction problems. To eliminate all the nuances, clean the ash pan before flooding, properly ignite the firebox with wood, wait for the temperature to rise (the firewood has ignited well and no longer smokes), then make a stash. The first casting is in fractions up to 50 mm, more massive pieces are laid after scattering of fine-grained fuel.

Poor draft is indicated by the emission of smoke outside; you need to open the damper, clear the zone under the combustion chamber (ash accumulates there). Oxygen comes to the burning coal not from above, but from below, so thoroughly clean the entire area under the firebox.

Normal draft and a clean ash pan, but the coal does not burn - the problem is that the fuel is very dusty. It is recommended to eliminate the problem by wetting the energy carrier - a little water and the dust will be compressed and flare up well and quickly.

The boiler will not work if the quality of the coal is poor. This may be reduced calorie content, briquetting with the addition of peat or brown varieties that have been lying around for a long time and have lost their characteristics. It is not difficult to recognize such coal - large lumps quickly fall apart, leaving a lot of dust on your hands. In this case, purchasing a certain amount of high-quality fossil fuel to mix it with substandard energy will help.

Coal mining

In our time, hard coal is mined in three fundamental ways. Such as:

- career method

- mining through adits,

- mining method.

The quarry mining method is used when coal seams lie on the surface, approximately one hundred meters deep or higher.

Quarries involve simply digging up the ground or sand pit from which mining is carried out; usually in such cases the coal seam is quite thick, which makes its extraction easier.

Adits mean wells with a large angle of inclination. All mined minerals are transported upward along it, without the need to use serious equipment or dig out a basin.

Typically, deposits in such places are thin and not buried particularly deep. Therefore, the method of mining through adits allows for rapid production without special costs.

Mining through mines is the most common method of extracting minerals, at the same time the most productive, but at the same time dangerous. The mines are drilled to great depths, reaching several hundred meters. However, this requires a permit confirming the justification for such large-scale work and evidence of the presence of deposits.

Sometimes the mines can reach a kilometer or more in depth, and stretch for several kilometers in length, forming interconnected webs of corridors underground. In the 20th century, settlements and small towns were eventually formed around the mines, in which miners and their families lived.

It is precisely because of the mining conditions that work in the mines is considered very difficult and dangerous, because a huge number of times the mines collapsed, burying dozens or even hundreds of people working there.

Coal

The result of the next “step” of metamorphosis that occurs during the formation of coal is hard coal. This type of coal was formed at deeper levels, under greater pressure and at high temperatures. Accordingly, its chemical composition and physical characteristics are already significantly different.

The chemical composition of coal is a mixture of high molecular weight aromatic compounds with a high content of carbon, volatile substances and moisture. Coal also contains some mineral impurities, which form ash after burning the coal. Depending on the type of coal, its carbon content can vary from 75% to 95%. Due to its lower moisture content than brown coal, hard coal has a higher calorific value. Coal contains up to 32% volatile substances, which provide good ignition.

Types of coal

The basis for the industrial classification of hard coal in different countries is based on different parameters of the composition and properties of coal. Thus, in the USA, hard coal is classified according to the criteria of calorific value, fixed carbon content and relative content of volatile substances. Japan classifies coal according to the so-called fuel coefficient (essentially the same calorific value) and the strength of the resulting coke (or inability to coke).

Our country inherited the classification that was developed in the USSR. Until 1954 in the Soviet Union, the basis for the industrial classification of hard coal was the so-called Donetsk classification. It is called "vintage". At the same time, it is genetic (this is how coal is classified according to GOST 25543-88 according to technological and genetic parameters), since the metamorphoses of coal properties underlying it reflect their changes, which are caused by the genetic development of organic substances in coal. For industrial labeling of coal from different basins in the USSR, approved standardized classifications were used.

Based on the nature of the non-volatile residue (sometimes in addition to taking into account sinterability and the heat of combustion) and the average yield of volatile substances, hard coal is divided into 10 grades:

- long flame (D);

- gas (G);

- gas-fat (GZh);

- fatty (F);

- coke fatty (QF);

- coke (K);

- coke second (K2);

- low-caking (SS);

- lean sintering (OS);

- skinny (T).

The carbon content consistently increases from 76% to 92% from grade D to grade T. At the same time, the yield of volatile substances decreases to 7-12%. Each brand has several technological groups (except for brands D and G).

Areas of application of coal

Coal is a very popular raw material, so the supply of coal is carried out almost continuously by many companies.

Coal finds a wide variety of uses. It is used as technological, energy technology and energy raw materials. In the production of coke and semi-coke, many chemical products (phenols, naphthalene, varnish, etc.) are by-products of coal processing. They are used to produce plastics, synthetic fibers, varnishes, paints, fertilizers and many other important and valuable products.

One of the most promising areas for using coal is liquefaction (hydrogenation) to produce liquid fuels. The result of coal processing also includes activated carbons, artificial graphites and other products. When processing coal on a large scale, important chemical elements are obtained: molybdenum, zinc, vanadium, lead.

There are a variety of schemes for the non-energy use of coal based on chemical, thermochemical and other types of processing with the aim of its full integrated use. This topic is covered in more detail in the corresponding article.

Features of use

A popular question is which coal is best for heating a home. Experts in this field say - anthracite or coal. Anthracite is able to ensure long-term and uniform combustion of a batch of coal loaded into the boiler, the highest thermal output and a small amount of waste. A popular type of coal, which is intended for combustion in low-power boilers, is considered to be long-flame ordinary coal, seed, nut.

In recent years, anthracite has become increasingly popular due to its low sulfur content (up to 1%) and ash (up to 10%). Due to the low sulfur content, the combustion products formed during the combustion of anthracite contain less sulfur dioxide. In addition to benefits for the environment, this has a beneficial effect on the service life of boiler parts and chimney pipes, which are exposed to the least amount of sulfurous and sulfuric acid, which appear as a result of the interaction of sulfur and water vapor.

If you decide to purchase coal for a heating boiler, take note that the amount of fuel will directly depend on its quality characteristics. Therefore, make a purchase only from manufacturers who have the appropriate quality documents.

What coal is best to use for heating?

This type of fuel contains many elements that affect its energy properties. The cleanest and most valuable fuel is the one that contains the maximum amount of carbon. The lower the percentage of this substance, the lower the heat of combustion and the higher the number of impurities and humidity. When choosing coal, take into account the following characteristics:

- Heat of combustion. The indicator reflects how much heat a certain volume of fuel will produce per unit of time. It is measured in MJ/kg or Kcal/kg, in which case it is called calorie content.

- Ash content. Measured as a percentage, it shows the amount of non-combustible impurities. The lower this indicator, the more heat from the fuel. For high-grade coals its level is within 25%, for low-grade coals it exceeds 40%. The higher the ash content, the more often you will have to remove slag and ash.

- Humidity. If surface moisture is easily removed by drying and ventilation, then internal moisture evaporates only during combustion. The higher the internal humidity, the more thermal energy will be required to dry it and the less will be used for heating.

Marking

The first letter indicates the variety, the second - the size of the fraction. There are 17 brands in total. The main grades of solid fuel are marked: anthracite - “A”, long-flame - “D”, low-caking - “SS”.

Coal is classified according to the size of the pieces:

| Marking | Name | Fraction, mm |

| P | Plate | More than 100 |

| TO | Large | 50—100 |

| ABOUT | Nut | 25—50 |

| M | Small | 13—25 |

| WITH | Seed | 6—13 |

| Sh | Shtyb | until 6 |

| R | Private | 0—300 quarry 0—200 mine |

For example, the fuel is marked ASh - anthracite shtyb, DS and DPK - long-flame “seed” and slab with pieces of 50-100 mm.

Types of coal and its characteristics: hard, brown, anthracite, pressed briquetted

Three types of fuel are used: brown, stone and anthracite. The first one produces the least heat, for this reason it is not used in everyday life.

Hard coal emits a large amount of heat (up to 7000 Kcal/kg), has a humidity of up to 15%, and produces a little ash (up to 16%), so it is most often used to fire boilers.

Photo 2. Coal in hands. It consists of small black pebbles.

In turn, it is divided into subspecies:

- Long-flame - got their name for their ability to burn with a long flame like wood. The DPK brand is suitable for most boilers, DO, DS - for automated ones.

- Low-caking - burns without smoke or flame, is consumed economically due to the long combustion duration. They are used less frequently due to lower efficiency and difficulty of ignition.

- Skinny - inexpensive varieties are short-flame, more often used in industry in cast iron stoves. Lean coals are difficult to light, they produce up to 45% ash, but a lot of heat, so in everyday life they are used in boilers with good draft.

Anthracites have the highest quality indicators among all coals for home boilers: calorific value up to 8200 Kcal/kg, humidity 1-3%, ash content up to 9%. They emit almost no volatile substances (up to 9%), burn with a short, even flame, with minimal formation of smoke and ash residues. Due to their higher combustion duration, they are considered the most economical types of coal. Suitable for specialized boilers with a volumetric firebox designed for high temperatures and good draft.

Coal briquettes are a budget type of fuel. They are made from waste from the coal mining industry: fine coal fractions, crumbs and dust by pressing with the addition of binding components. The advantages include: low ash content and humidity, good calorific properties, provided that the briquettes are made from high-grade coal. Pressed fuel ignites well with the help of wood, burns for a long time (on average 6-8 hours), produces little smoke, soot and slag.

Photo 3. Pressed coal in oblong briquettes. This type of fuel is good for heating boilers.

Characteristics of groups

Stone minerals of grade D are considered the most suitable type of fuel, which ensures the operation of furnaces and heating boilers. It is a long-flame coal that gets its name from the high flames it produces, like firewood. It supports a long combustion process and releases a large amount of heat without sintering. This type of fuel can be used in almost any system (even those not equipped with a natural draft system or forced air injection). It flares up very quickly and allows for efficient heating of private homes and medical institutions, as well as administrative buildings.

The second most popular type of coal can be considered grade T. It is called “lean”, is characterized by the release of volatile substances in the range of 9-17%, does not sinter, and practically does not emit a flame when burning. It contains about 90% carbon, so this coal is considered the richest. It is indispensable in the fuel industry, chemical production, gas generating plants, housing and communal services and mobile power plants.

So, brand D is the most popular

The third group is long-flame gas DG coal, low-caking, with low fragility and high strength. Unsuitable for coke batches because the resulting coke is radioactive. The yield of volatile substances is in the range of 27-30%, refers to energy rocks.

Under the brand Zh there are two groups of fossils , the division of which is based on the yield of volatile substances and the reflection of vitrinite. This is a highly coking, especially valuable type of fuel, which, as a result of combustion, forms high-strength structural coke. For the production of cast iron or steel in ferrous metallurgy, grade Zh coal is most preferable, the characteristics of which make it possible to avoid technological difficulties associated with the combustion process.

Anthracite combines a group of coals with a VLV of about 8%, which are irreplaceable in the energy industry. Large and medium-sized specimens are used as smokeless fuel in the municipal and domestic sectors. In addition, anthracite is necessary for the production of carbide (aluminum and silicon).

How to correctly calculate the bulk density of sand, coal, cement - Repair and construction

The bulk density of a material is determined by the ratio of the mass of the material to the volume it occupies. For coal, sand and cement it is expressed in kg/cubic meter. m. Bulk density refers to the volume of material that it occupies in an uncompacted state. They scooped it up with an excavator bucket, poured it in - here it is, “bulk” density.

Sand

The sand is not always clean, very often it is not washed or washed poorly, here you can only rely on the conscience of the supplier, and don’t forget to control the quality of the sand yourself, at least visually: how much debris is in the sand and whether there are eroded lumps of clay visible. Below is the bulk density for clean dry sand.

If the sand is wet, then the weight is 1 cubic meter. m of this material can be safely increased by 10-12%.

Bulk density for clean dry sand:

- Quarry sand: 1500 kg.

- River sand: 1600 kg.

- Quartz sand: 1700 kg.

You can approximately check the bulk density of sand as follows.

Weigh the empty bucket, then fill the bucket, pouring sand into it from a certain height, without compacting the sand in the bucket.

Weigh the bucket, then divide 1000 by the cubic capacity of the bucket and multiply the resulting number by the weight of the sand, excluding the weight of the bucket.

For example, a bucket is 12 liters, empty it weighs 1 kg, filled with sand 19 kg. We divide 1000:12=83.33 (the number of such buckets in 1 cubic meter by volume). 19-1=18 (weight of sand in the bucket). 18 x 83.33 = 1499.9 kg of this sand occupies a volume of 1 cubic meter. m.

Cement

The bulk density of cement of different brands (M200, M300, M400, M500) will be approximately the same; during caking, the bulk density increases significantly, and this happens quite quickly. For the convenience of mutual settlements, it is generally accepted that 1 cubic meter. m of high-quality cement weighs 1300 kg.

Although this is not entirely true: freshly produced cement of the M500 brand has a bulk density of 1100 kg / cubic meter. m, and compacted (but still quite usable) 1600 kg/cu. m.

You can check the bulk density of cement by analogy with sand.

Coal

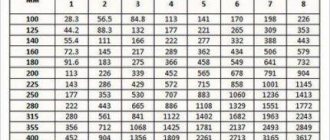

With coal, everything is much more complicated, since the bulk density very much depends on the size of the fractions, but with coal it is difficult: the size ranges from large lumps to coal dust, and different brands of coal also weigh differently. The weight of coal of the same brand and size class, but from different coal basins, can also vary significantly.

The following classification of coal is used in the Russian Federation. Since here we are considering bulk density, I will not give the combustion temperature and other useful characteristics; I will only give the name of the brands and classification by size of the pieces.

Coal grades:

Brown (B), Long-flame (D), Gas (G), Fat (F), Gas fat (GZh), Coke (K), Coke fat (KZh), Coke second (K2), Low-caking (SS), Skinny ( T), Lean-sintered (OS), Anthracite (A).

Classification by size of pieces:

- More than 100 mm – P (slab),

- 50-100 mm – K (large),

- 25-50 mm – O (walnut),

- 13-25 mm – M (small),

- 6-13 mm – C (seed),

- 0-6 mm – W (piece).

Without classes: P (private), 0-300 mm - quarry, 0-200 mm - mine.

The name of coal is written as follows: brand comes first, size comes second.

Most often you come across classes mixed in size, for example DKOM (long-flame, large + nut + small, i.e. from 13 to 100 mm).

The data that I will give is quite average - just to have an idea, in general, since at the moment coal is sold in most cases by weight, not volume.

| Coal grade | Specific gravity of 1 cubic meter m (Weight of 1 cubic meter of material, assuming that it is a monolithic piece with a volume of 1 cubic meter) | Bulk weight of some common types (by size) of coal |

| Brown (B) | 1250-1500 kg/cu.m. m | BKO 680-720 kg/cu.m. m |

| Long flame (D) | 1280-1350 kg/cu.m. m | WPC about 800 kg/cu.m. m, DKOM about 700 kg/cu.m. m |

| Fat (F) | 1250-1300 kg/cu.m. m | GZhO about 800 kg/cu.m. m |

| Gas (G) | 1280-1330 kg/cu.m. m | GZhO about 800 kg/cu.m. m |

| Skinny (T) | 1310-1390 kg/cu.m. m | TR 1250-1300 kg/cu.m. m |

| Anthracite (A) | 1000-1150 kg/cu.m. m | AC about 800 kg/cu.m. m |

You can also check the bulk density, which you learned from the seller, by analogy with sand, but it is better to take a larger container to reduce the error. The error in the results will be noticeably greater than for bulk materials. To determine the density of coal, there is a whole GOST (54246-2010), but it is used for industrial volumes of coal.

Classification and properties

In the Russian classification, it is customary to distinguish 8 groups. This division does not coincide with the labeling adopted in Western countries. Coal is available in several grades with the corresponding letter designation:

- brown (B) - with a calorific value of 7000-7500 kcal/kg;

- skinny (T) - from 7300 to 8700;

- long-flame (D) -7500-8000;

- gas (G) - when burning, it releases heat from 7900 to 8600 kcal/kg;

- anthracite (A) - 8100-8750;

- fat (F) - 8300-8700;

- coke (K) - 8400−8700;

- lean-sintered (OS) - 8400-8780.

The most common in private households and industry are long-flame coal (labeled DPK or DPKO, popularly called “fist” or “nut”), skinny coal (labeled TPK and TPKO, sizes 50-200 mm and 25-50 mm) and Anthracite coal (used most often in the energy sector).

Read also: about the main types of coal and their purpose.

Types of coal

Main article: Coal marking

Coal, like oil and gas, is an organic substance that has undergone slow decomposition through biological and geological processes. The basis for the formation of coal is bitumen masses and, to a lesser extent (not industrial reserves), from organic residues of plant origin. Depending on the degree of transformation and the specific amount of carbon in coal, four types are distinguished: brown coals (lignites), bituminous coals, anthracites and graphites. In Western countries, there is a slightly different classification - lignites, subbituminous coals, bituminous coals, anthracites and graphites, respectively.

Based on their origin, coals are divided into humus

(from the remains of higher plants: wood, leaves, stems, etc.) and

sapropelite

coals (from the remains of lower plants, mainly algae).

Anthracite

Main article: Anthracite

Anthracite

Anthracite

- the most deeply heated from fossil coals when it emerged, the coal with the highest degree of carbonization, a transitional form from coal to graphite. Characterized by high density and shine. Contains 95% carbon. It is used as a solid high-calorie fuel (calorific value 6800-8350 kcal/kg). It has the highest heat of combustion, but does not ignite well. It is formed from coal when pressure and temperature increase at depths of about 6 kilometers.

Coal

Main article: Hard coal

Coal

Coal

- a rock that is a product of deep metamorphism of bitumen masses that poured onto the surface of planet Earth as a result of global tectonic cataclysms in various geological eras of the planet’s development. The greatest metamorphism is observed near the formed mountain ranges, at greater depth under the influence of high temperatures, pressure and lack of oxygen. In terms of its chemical composition, coal is a mixture of high-molecular polycyclic aromatic compounds with a high mass fraction of carbon, as well as water and volatile substances with small amounts of mineral impurities, which form ash when coal is burned. Fossil coals differ from each other in the ratio of their constituent components, which determines their heat of combustion. A number of organic compounds that make up coal have carcinogenic properties.

The carbon content of coal, depending on its type, ranges from 75% to 95%. They contain up to 12% moisture (3-4% internal), therefore they have a higher calorific value compared to brown coals. Contains up to 32% volatile substances, due to which it ignites well. It is formed from brown coal at depths of about three kilometers.

Brown coal

Main article: Brown coal

Brown coal

Lignite

Brown coal

- hard fossil coal formed from peat, contains 65-70% carbon, has a brown color, the youngest of fossil coals. It is used as a local fuel and also as a chemical raw material. Contains a lot of water (43%) and therefore has a low calorific value. In addition, it contains a large amount of volatile substances (up to 50%). They are formed from dead organic residues under load pressure and elevated temperature at depths of about one kilometer.

Others

Based on their composition and origin, other types of coals are distinguished:

alginite, algogelite, algocollinite, attroseminiite, boghead, vitren, vitrinite, jet, gelite, gelitite, gelitolite, humite, humolite, desmite, duren, durite, intertinite, calginite, cardif, kasyanite, caustobiolite, kennel, claren, collinite, colloalginite, colloalgolit, colloseminite, collofusinite, colm, xylene, xylinite, xyloattrite, xylovitren, xylodesmite, culm, cutinite, leuptinite, lignite, lignite, lipoid, lipoidolite, lipoidotite, liptobiolite, lithotype, lopinite, metaanthracite, micrinite, mixtohumitite, mix tohumolite, mixtonite, parenchitis, semi-anthracite, resinite, saprohumolite, saprocollite, sapropelite, semianthracite, semivitrinitis, semicollinitis, seminit, semitelinitis, semifusinite, semifusinitis, sclerotinitis, sporinitis, sporopolinitis, suberinitis, talginitis, thelinitis, tellomoalginitis, telocollinitis, telosimenit, telofusinitis, ultraduren, ultra Claren, fellinite, fiteral, fusain, fusenite, fusenolite, fusinite, fusite, fusitite, cheremkhit, exinite, electric coal, yumit and others.

Description and purpose of the mineral

In wetlands, plants are converted into peat under the influence of many bacteria, then into brown coal, which, in turn, turns into stone after many years. The latter is characterized by a higher calorific value and is therefore used as fuel. The areas of its consumption are:

- electric power industry;

- thermal power equipment of industrial enterprises;

- chemical plants;

- Department of Housing and Utilities;

- heating systems of private houses.

Depending on the marking of coal, it can be used as a solid fuel for modern heating boilers and conventional stoves in old houses. Despite their external similarity and even belonging to the same type, fossils may differ, for example, in sulfur content, heat of combustion, humidity, etc.

In this video you will learn about the specifics of USSR grade coal:

The cost of each grade of coal is determined separately. Their characteristics affect how much a ton of fuel will be priced for an industrial or private facility. The study of properties and features is carried out in several directions:

- elemental analysis (detection and calculation of oxygen, hydrogen, organic sulfur, carbon and nitrogen in the total mass);

- technical research - analysis of quality indicators that must meet the requirements established by regulations (humidity and sulfur content, ash content and heat of combustion, yield of volatile components);

- mechanical analysis - the ability of a fossil not to crack or collapse, not to change size under the influence of friction or impact (important for foundry and electrode production);

- thermal tests - allow you to determine the strength of coal under the influence of high temperatures (grades intended for furnaces, semi-coking);

- determination of electrical properties - depending on the stage of transformation, coals can be dielectrics and semiconductors in the initial stages, and conductors in the later stages.

Special laboratories examine absolutely all types of coal. Their characteristics make it possible to sort pieces by size (size), as well as by other properties that affect quality.

What is charcoal and what is it used for?

Charcoal has been used by people for many thousands of years: it was found during excavations in the settlements of cavemen. It is unlikely that they made it themselves; rather, they collected it from fires or saved the remains of fires, but, apparently, they knew about its properties and knew how to use it.

Charcoal is a high-calorie fuel

Today in our country this type of fuel is used mostly for cooking: it is used in barbecues and barbecues, and added to fires. Sometimes used for fireplaces: it burns for a long time, produces a lot of heat (7800 KC/kg), and produces almost no smoke or soot. The remaining ash is an excellent fertilizer and is used to fertilize forest lands or agricultural fields. Charcoal ash is also used to produce fertilizers.

In industry, charcoal is used to smelt cast iron. To produce a ton of alloy, only 0.5 tons of this fuel is required. At the same time, cast iron gains increased corrosion resistance and strength. Coal is used as a flux in the smelting of brass, bronze, copper, manganese, zinc and nickel. It is used to make solid lubricants for mechanical engineering, used for grinding in instrument making and printing, etc. Filters for various purposes are made from charcoal.

Today, charcoal is beginning to be considered as an alternative to traditional fuel: unlike coal, oil and gas, it is a renewable material. Moreover, modern technologies make it possible to obtain charcoal even from industrial waste: from sawdust, dust, bushes, etc. Briquettes are formed from such crushed raw materials, which provide 1.5 times more heat than ordinary charcoal. In this case, heat is released over a longer period of time and the heat is uniform.

How to calculate coal consumption correctly

Having figured out how to choose coal for heating a private home, let’s consider the volume of fuel. To make a correct calculation, you need to know the insulation index, the area of the building, standard temperatures in winter and the type of boiler. The volume of coal purchases for a brick house is the highest, compared to wooden buildings; brick ones require 35% more fuel, and under conditions of poor insulation and harsh winters, consumption increases by 50%.

Objects made of slag concrete with a wall thickness of 45 cm and an area of 90 m2 consume up to 3.5 tons per season, other buildings of the same area - up to 8 tons of coal. The calculation is given for the northern regions; for zones with a mild climate, the volume of fuel is reduced by a third.

Example: in Novosibirsk, Krasnoyarsk, for a wooden house with an area of 40 m2 with good insulation, you will need at least 6 tons of DPK coal of the O, K, P grade - this is a fraction size of up to 10 cm, a long-flame grade. When calculating the average temperature from -30 C, the cost of coal is significantly lower than when installing a gas or electric heating system.

In a new house, the amount of coal is determined by testing. Several bags of fuel are purchased, the stove is heated to standard values, measurements of the combustion period are taken, and the air in the house is heated, taking into account the temperature outside the window. The standard level of heating a house is +18 C at +0 C outside the window; to calculate the heating of a house at low temperatures, the heating time period is multiplied by 3. It turns out that if at -5 C the house warmed up to +18 C in 20 minutes, then at -25 Outside the window, the warm-up time will increase to 60 minutes.

In this way, it will become clear which grades of coal should be chosen for domestic boilers in each individual building. It is worth knowing that during storage, fuel slightly reduces its characteristics and performance, so it is better to buy for the first time with a margin of 25%. This will prevent you from being left without heat during the spring frosts.

Standard energy consumption indicators for solid fuel boilers in a house with an area of 100 m2 by season:

- September October. One bucket for 12 hours of burning, taking into account that the night temperature in the room will be +17 C.

- November – February. Up to 3.5 buckets per day. Converted per kg, it turns out to be up to 65 kg per day.

- March, April. Up to 2 buckets per 24 hours, if in April the temperature rises to +10 C, one bucket of coal is enough. Reducing the volume is not recommended for drying the walls and floor of a building.

When calculating the weight of a bucket of coal at 20 kg, up to 10 tons of fuel will be required for the season. This is provided that the building is well insulated, the residents do not freeze at +18 C at night, and during the day the house is not heated with 100% boiler output.

When choosing coal, be sure to look at the certificates. Having bought skinny varieties, the owner will be left without heat and will freeze the entire heating system, provided that it is a water network.

Types

- Regular charcoal

is made from peat, coal, wood, coconut shells or petroleum. - Sugar charcoal

is produced by carbonizing sugar and is particularly pure. It is purified by boiling with acids to remove any minerals and then burned for a long time in a stream of chlorine to remove the last traces of hydrogen. - Activated charcoal

is similar to regular charcoal, but is made specifically for medical use. To produce activated charcoal, manufacturers heat regular charcoal in the presence of a gas, which causes the charcoal to form many internal spaces, or "pores." These pores help activated carbon traps. - Lump charcoal

is a traditional charcoal made directly from hardwood wood. It usually produces much less ash than briquettes. - Japanese charcoal

had pyrrolic acid, which was removed during charcoal production; therefore, when burned, it produces almost no odor or smoke. - Briquette-shaped pillows are made by pressing charcoal, typically made from sawdust and other wood waste, with a binder (usually starch) and other additives. Briquettes may also include lignite (heat source), mineral carbon (heat source), sodium tetraborate, sodium nitrate (ignition agent), limestone (ash bleaching agent), raw sawdust (ignition agent) and other additives.

- Sawdust charcoal

is made by pressing sawdust without binders or additives. It is preferred to be used in the Middle East, Taiwan, Korea, Greece, etc. It is mainly used for barbecuing, as it does not produce odor, smoke, little ash, has a high combustion temperature and a burning time of more than 4 hours. - Extruded charcoal

is made by pressing untreated shredded wood or carbonized wood into logs without the use of a binder. The heat and pressure of the extrusion process holds the coal together. If the extrusion is made from untreated wood material, the extruded logs are subsequently charred.

Pros and cons of using natural coal for heating

The fuel has a number of significant advantages:

- Possibility of use in various types of equipment. Coal for heating is used in stationary and portable boilers, and is used for steam and water heating systems.

- Duration of combustion. One full load is enough for 10 hours, but it all depends on the volume of the combustion chamber.

- High efficiency. The heat output of even the lowest-grade coal is higher than that of firewood.

- Relatively affordable cost, ease of transportation. Manufacturers offer fuel of different fractions, which can be transported in bulk (in trucks), bags, boxes.

- When installing a furnace, there is no need to lay steam pipelines or gas lines, and you do not need to obtain permission to use fuel furnaces.

- The heat transfer of the material is high, energy is transferred during the combustion of fractions and after the main combustion, so the heat in the room is retained for a long time.

- To maintain a constant temperature of the coolant, you should not fill the firebox to capacity all the time; after the first portion, a small amount of energy will be enough to ensure that the temperature of the water and air remains comfortable.

- Coal can heat very large areas in regions with the harshest winters.

There are also disadvantages, in particular:

- it is necessary to form a chimney of the correct design to generate draft;

- it will not be possible to automate the laying process in a private house;

- During the combustion process, a lot of slag is released, the ash pan will have to be cleaned regularly;

- Fuel is stored in a well-ventilated and dry area.

For the efficiency of a solid fuel boiler, it is recommended to add coal to the firebox heated by wood.