To ensure more economical operation, modern boiler systems have auxiliary elements: a water economizer and an air heater, which serve to heat water and air, respectively; devices for fuel supply and ash removal, for cleaning flue gases and feed water; thermal control devices and automation equipment that ensure normal and uninterrupted operation of all parts of the boiler room.

Depending on the use of their heat, boiler houses are divided into energy, heating and industrial and heating.

Energy boiler houses supply steam to steam power plants that generate electricity, and are usually part of a power plant complex. Heating and industrial boiler houses are found in industrial enterprises and provide heat for heating and ventilation systems, hot water supply to buildings and production processes. Heating boiler houses solve the same problems, but serve residential and public buildings. They are divided into free-standing, interlocking, i.e. adjacent to other buildings, and built into buildings. Recently, more and more often, separate enlarged boiler houses are being built with the expectation of servicing a group of buildings, a residential area, or a microdistrict.

The installation of boiler rooms built into residential and public buildings is currently permitted only with appropriate justification and agreement with the sanitary inspection authorities.

Low-power boiler houses (individual and small group) usually consist of boilers, circulation and feed pumps and draft devices. Depending on this equipment, the dimensions of the boiler room are mainly determined.

Boiler room maintenance cost

Technical (service) maintenance of the boiler room

| Name of works | Volume | Price |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 1st scheduled departure | from 14 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 1st scheduled departure | from 20 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 2 scheduled trips | from 22 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 2 scheduled trips | from 30 000 ₽ |

| Service contract for wall-mounted gas boiler | with 1st scheduled departure | from 10 000 ₽ |

| Service contract for wall-mounted gas boiler | with 2 scheduled trips | from 15 000 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Boiler room repair, diagnostics and prevention

| Name of works | Volume | Price |

| On-site inspection and diagnostics (without repair) | up to 50 km from MKAD | from 3,500 ₽ |

| On-site inspection and diagnostics (without repair) | from 50 to 100 km from MKAD | from 5,500 ₽ |

| Cleaning the burner (atmospheric) | power up to 60 kW | from 2,000 ₽ |

| Cleaning the burner (supercharged) | power up to 60 kW | from 3,500 ₽ |

| Cleaning the burner (atmospheric) | power from 60 to 170 kW | from 8,500 ₽ |

| Cleaning the boiler combustion chamber | power up to 60 kW | from 4,000 ₽ |

| Cleaning the boiler combustion chamber | power from 60 to 170 kW | from 6,000 ₽ |

| Checking and pumping up pressure in the expansion tank | without dismantling work | from 2,500 ₽ |

| Checking and pumping up pressure on the expansion tank | with dismantling and installation | from 4 500 ₽ |

| Refilling the heating system with a pump | system volume up to 200 liters | from 3 000 ₽ |

| Replacement of heating element, pump, heat exchanger, with coolant drain | for a unit | from 3 000 ₽ |

| Conversion of a gas boiler to liquefied gas | for a unit | from 3 000 ₽ |

| Burner settings | gas / diesel | from 2 500 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

What can be placed in the furnace room

Before arranging a boiler room, you need to draw up a list of equipment that you plan to install in a country cottage. First of all, this includes units that ensure the operation of the heating system, cold and hot water supply (CW, DHW), and various electrical installations. Here is a complete list:

- heat sources – boilers using different types of fuel, internal units of a geothermal heat pump;

- units for preparing hot water - electric or indirect heating boiler, geyser, instantaneous water heater;

- buffer capacity of the required volume;

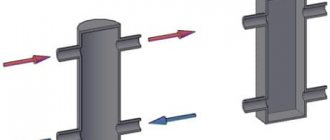

- hydraulic separator (hydraulic arrow) with manifold;

- comb with mixing unit for water heated floors;

- cold water treatment and water treatment equipment - filters, hydraulic accumulator, pump, automation (pressure switch);

- piping elements - pipes, circulation pumps, expansion tanks, shut-off and control valves;

- house electrical panel.

Note. The storage water heater does not have to be placed in the furnace room. An electric boiler can be placed in the bathroom, a gas water heater in the kitchen. But if the dimensions of the boiler room allow, it is better to assemble all the devices in one technical room.

The electrical panel can also be installed inside the heat generator room, on a separate wall. In the remaining free space, you can place bulky household appliances, for example, a washing machine, a freezer.

From the given list we select the necessary equipment, guided by the project or the current heating and water supply scheme. We draw the layout of the room to scale and move on to design - the placement of all water and heat supply units. But first you have to study...

Home boiler rooms - home boiler room

A home boiler room is a difficult step for the home owner, since there are a large number of types of home boiler rooms, from which you should choose the most optimal option that is suitable for all qualities and parameters.

Home boiler room using electricity Electric boiler rooms are boilers that operate entirely from the generation of electrical energy. Using these home boiler rooms is an expensive pleasure, since electricity is constantly becoming more expensive. The most common brand of this […] Read more

08.11.2021

What does a boiler system consist of?

← previous articleWhy build your own mini-CHP? A mini-CHP is a miniature combined power plant that can become the main source of electricity or heat supply in the absence of a centralized one, fully providing the consumer with the necessary energy....next article →Technical conditions for gas (Specifications for gas) Technical specifications for gas are a document that provides the opportunity for boiler room owners to connect it to the central gas supply system...

Author: Alyansteplo

Date: 03/23/2015

A boiler installation is a whole complex of various devices connected into a single system, the task of which is to convert fuel into energy. Some of the devices included in the system are strictly required - without them, the boiler room simply will not work; some perform auxiliary functions, and some serve to optimize the operation of the entire installation, improve production performance and save money. The final operation of the entire system depends on how each part of the boiler room works.

Basic devices

, without which the boiler installation simply will not work, are:

- boilers;

- fireboxes;

- flues;

- chimneys.

The boiler is the undoubted “heart” of the boiler installation, in which the heat from the burned fuel is transferred to water, heating it to the required temperature in water installations or turning it into steam - in steam installations. The process of fuel combustion occurs in the furnace, from where the smoke is transferred through the flue to the boiler, and then, in a spent and cooled state, is sent through the chimney into the atmosphere.

Even the simplest boiler room cannot operate without a boiler, firebox, flue and chimney.

To the list of auxiliary devices

boiler rooms include:

- pumps with which water is supplied to the boiler for further heating;

- fans for “pumping” air into the firebox and for increasing draft in chimneys (the stronger the draft, the smaller the diameter of the pipes can be);

- water purification devices that prevent the formation of scale in the boiler installation;

- an air heater that heats the air intended for “pumping” into the firebox;

- a water heater that heats the water entering the boiler;

- ash collectors (only for solid fuels: firewood, coal, etc.), purifying exhaust smoke and designed to reduce the amount of harmful emissions into the atmosphere;

- fuel return devices;

- dust preparation devices;

- various automation and control devices designed to ensure the normal operation of the entire boiler system.

Other devices for starting and installing a boiler room are not mandatory, but can be used to simplify the process of working with boilers, to save fuel, to increase productivity and improve other indicators - depending on the specifics of the objects “attached” to the boiler room and the characteristics of the installation itself.

For questions regarding the sale of a boiler room, please contact specialists. Our specialists will help you calculate the cost and create a boiler installation project!

To calculate the cost of the boiler room, please fill out the questionnaire for the boiler room. The questionnaire can be filled out online or downloaded. For any questions: phone email

Fill out the questionnaire online

Calculate the cost of the boiler room

You may also be interested in

Operation of a diesel boiler house Diesel boiler house up to 60.0 MW based on diesel boilers. It is important to know that when a boiler room operates on diesel fuel, soot can form in the boiler units...

Boiler house examination “Boiler house examination” most often means an examination of the industrial safety of a boiler house - a set of measures designed to identify equipment defects in the event of construction, repair, reconstruction or liquidation of a boiler house, as well as after accidents or changes in its operating mode.

Advantages and disadvantages of condensing gas boilers Despite the development of alternative energy sources, gas boilers remain the most popular in the heat power market and, as experts suggest, will remain so in the foreseeable future. They are cheap, available, economical and effective, especially in temperate climates.

Vortex boilers: what are they? What are vortex boilers and what are their advantages and disadvantages?

Cascade boiler houses The vast majority of boiler houses do not use their thermal energy 100%. Thus, during the heating season, power is consumed by only 50%, and during the non-heating season - approximately 25%, which is used to provide hot water to facilities.

Installation of a gas boiler in a private house

Gas is considered the most cost-effective type of fuel in terms of efficiency. Even if there is no gas main line to the holiday village, many owners of country houses use gas tanks, which, from an economic point of view, is often more profitable than using other types of fuel. In any case, you need to know the rules for connecting a gas boiler in a private house, which strictly regulate all the nuances [...]

Read more

24.07.2021

Unit layout options

Having studied all the requirements of regulatory documentation, we can begin designing the furnace and arranging equipment. If you are planning to equip a boiler room in a private house with your own hands, then you need to make a list of thermal power units in advance and find out their sizes. Then you’ll be able to play with the layout options on paper - draw a room plan and arrange the equipment in different ways.

Let's move directly to recommendations on how to fit equipment inside the boiler room:

- If you still have the opportunity to change the dimensions of the room, try to get away from the square shape in plan. Since water heaters and other elements are located along the walls, the middle of the square room will remain free, that is, unused.

- A good solution is a rectangular room with a window and a door on opposite short walls. Another option: the entrance and window are made in adjacent partitions, and the remaining 2 walls and 2 corners will be occupied by equipment.

- If there is not enough space, choose small-sized or suspended units. Examples: a horizontally mounted wall-mounted boiler or a slim-type floor-mounted tank extended upward.

- How to rationally use the area near the window: install low floor-standing equipment nearby, for example, a gas stationary heat generator. If the chimney is positioned well, the pipe will hardly block the light opening.

- Try to hang as many units as possible on the walls at a height of 1.6...2 m; under them the underfloor heating manifold and the rest of the heating distribution will fit.

- Push the bulky heat accumulator into a corner, but leave 5-10 cm gaps for laying piping pipelines.

- Any floor-standing boiler can be placed sideways close to the wall. Then on the other side there will be a passage for maintenance and cleaning of the chimney, as shown in the video below.

In a wide boiler room there will inevitably be free space, since all units are located along the walls

Note. If there is a catastrophic lack of space, the electric storage water heater can be moved to the next room. An indirect heating boiler is more difficult to move; the tank is connected by several pipes + a recirculation system.

The most difficult thing is to place 2 floor-standing large boilers in a boiler room, for example, a diesel + pellet boiler with a hopper. Try placing them near a long wall without a window, and assemble the heating circuit there. Leave a passage of 0.6 m between boilers and other equipment. Consider the option of arranging them near opposite walls or against each other, but then you will have to run the lines through the room.

Give the remainder of the area along the walls and partitions to a water treatment system with a hydraulic accumulator. If you managed to use only wall-mounted heating units, there will be room in the boiler room for various useful things - a sink, a small tub for shoes or a washing machine.