If there is no gas pipeline near you, and you do not want to carry gas in cylinders or use electricity to heat your home because of its high cost, then you can use coal for heating - an old and proven way to heat a house over the years. Despite the fact that this type of heating is considered classic and almost ancient, in modern times the equipment for this is already high-quality and created using the latest technologies.

Probably everyone is familiar with the image of a typical Russian brick stove, and now, using coal for heating, the system will work on the same principle. However, there is a significant difference: the room is heated by coal boilers not due to the heat from the flame, but due to the heating of the water heat carrier, which is driven by a pump to the radiators.

Coal for heating

Differences

The main differences include:

- Storage conditions . Firewood requires a dry room and is afraid of moisture. Coal can be stored open without fear of loss of quality.

- Burning duration and heat transfer . For coal, these figures are much higher.

- Room pollution . Firewood leaves significantly less dirt.

- Availability . In some regions, coal is not always available.

- Efficiency of different breeds . Almost all types of coal have high heat transfer. Firewood, depending on the breed, manifests itself differently. Some give off heat well, others have a high smoke emission, and others help clean the chimney.

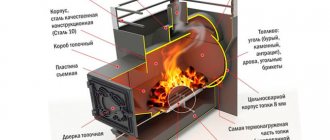

Features of coal boilers

Boilers that use coal for heating have one significant advantage over other heating systems - versatility. So, in addition to coal, other solid fuels can be loaded into such a heating boiler - firewood, waste (household garbage), briquettes, pellets, sawdust, etc.

Note that corner heating and cooking stoves can not only heat your home, but you can cook food on them.

And long-burning stoves have another important advantage - this is the fact that a lot of time passes between refueling. Thus, coal heating can operate for quite a long time without human intervention. Also, such boilers are easy to operate - you just need to throw coal into the boiler. The systems are quite economical and at the same time have high heat transfer parameters. The boiler can be used throughout the heating season – without interruption.

Heating and cooking stove

Of course, coal-fired boilers of older models will not be able to compare in heat transfer and performance with new models. Modern equipment can effectively heat different types of rooms, while burning half as much fuel as older models.

Tips from experienced stove makers

If you have a stove or boiler in your home that runs exclusively on coal fuel, you will still have to light the heating device using paper and firewood.

Only after the required temperature has been reached in the firebox can the coal itself be poured. If you don’t know what volume to take, then you need to focus on a layer of about 5-6 centimeters. When this volume of material burns well, it will be possible to add the remainder in such an amount that the layer is already 15 centimeters. With this approach, you can be sure that the stove will light up well and there will be sufficient temperature in the house.

When kindling, the pipe valve should be moved back slightly, and the coal itself should be placed on the grate. At the moment when the fuel has already ignited well, it is necessary to open this valve to the maximum.

At the next stage, you should add a portion of small coal (if it is large, you will have to split it). Its layer will be approximately 5-8 centimeters, and the area should correspond to the grid. When the filling is completed, the firebox door should be closed, and at the same moment the ash pan should be opened. After the material flares up, the volume is increased to 12-20 cm.

As for subsequent portions of coal that will be added after the batch of material burns out, some rules should be followed:

- A new bookmark is made only when you are convinced that the previously filled coal has already flared up well enough.

- Before adding a new portion of coal, if the firebox doors are opened at this time, it is necessary to cover the ash pit.

- You should not allow the material to burn out right up to the grate; combustion should be uniform throughout the entire layer.

If you pay attention, you will notice that purchased coal comes not only in large pieces. It may contain small particles, as well as typical dust. To prevent it from combining into a single layer during combustion, the material should be moistened with water before laying.

To prevent it from combining into a single layer during combustion, the material should be moistened with water before laying.

The same applies to those who use fatty coal of the PZh or Zh brands. However, the volume of water should not be large, because the material burns better in a dry form. When lighting a stove, fuel of the PS and SS grades, where small elements predominate, must be moistened with a slightly larger volume of liquid.

There is also skinny coal, which is marked with the letter T; it is this that should be moistened generously, but long-flame material is only sprayed to remove dust. As for the “Anthracite” brand, it does not need to be wetted at all, only if it is dusty, it is lightly irrigated with water.

When the combustion process itself is underway, the combustion chamber door must be closed. It should be opened only when it is planned to throw in a new batch of coal. Unlike firewood, this material does not need to be turned over as often, otherwise the firebox will cool down and some of the material will fall through the grate.

Now it becomes clear what is the best way to heat the stove and how to do it correctly. Of course, the process may not work out the first time, but don’t despair, because after two or three attempts all actions will be performed automatically, and the house will be filled with comfortable warmth and the pleasant crackling sound of burning coal or wood.

The nuances of firing stoves with coal in winter

In winter, at low temperatures, it can be quite difficult to light the stove. In addition, the special draft that is formed due to cold air does not allow smoke to escape freely. There is no way to light the stove quickly. You can improve the kindling process by using a hairdryer, which warms up the inside of the heating equipment.

Such heating of the furnace device will avoid smoke, which is typical for cold structures. The stove should be warmed up several times a day in winter so that the system does not have time to cool down too much.

Coal is considered the most efficient type of fuel. It is successfully used to kindle stoves. The level of heat transfer of such raw materials is higher than that of wood raw materials. A good result from using coal for a stove can only be obtained by following all the rules for kindling and operating the heating device.

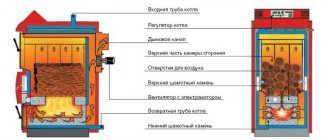

The principle of operation of a coal boiler

Coal-fired boilers have a slightly different combustion process than other systems. Inside the device, the fire does not burn from bottom to top, but vice versa. This increases the burning time of one batch of coal and ensures its most complete combustion.

In the boiler, almost the same process occurs as the burning of an ordinary candle. Coal burns for a long time, the heat that is produced goes into the heat exchanger. During combustion, air comes from above using a special fan. The combustion chamber in a boiler that uses coal heating in a private house can be quite large and reach a volume of up to 500 liters. This means that at one time you can load a lot of different fuels, which will heat the house for several days.

Briquettes for heating

Long-burning solid fuel boiler

Such boilers are also equipped with temperature control sensors. The use of coal will reduce the amount of harmful substances that appear as a result of combustion. Coal boilers consist of a firebox, where this process takes place, a heat exchanger for heating coal, and a grate. The heat exchanger can be made of steel or cast iron. Steel boilers for coal are a little cheaper, while cast iron boilers will last longer.

Today, heating with coal has become a practical solution for those people who like to relax in the country.

And one of the most important issues in arranging a heating system is the cost of the equipment. Unfortunately, many will find the cost of the device quite high - after all, even the cheapest boiler models cost at least 20,000 rubles.

For those who have small country houses and other buildings that require heating, domestic models of low-power coal-fired boilers are suitable.

Domestic solid fuel boiler

How to stay safe

But the “lobsters” don’t just eat their yeast-free bread. Along with the discovery of all kinds of dirty tricks, they also discover ways to reduce the amount of this dirty trick. Here's some advice you can glean from numerous works on this subject:

- Use stable fuel combustion. It's better to cook with gas rather than wood. Then less harmful substances will be released. Charcoal is also better to prefer to firewood.

- When grilling, smoke is one of the sources of contamination of the prepared product. If the smoke is removed without passing through the product, the benzopyrene content in the product is halved.

- Avoid dripping fat and other biological substances even onto coals. Fat burns, but not completely, hence the increased formation of pollutants. This is just that delicious smoke. Reduction of benzopyrene by almost 90%.

- Cooking in foil allows you to almost completely protect the product from contact with benzopyrene.

- Using a microwave, for example, to fully or partially cook a dish, is the best way to reduce the content of nastiness in the final dish.

- Do not overcook until a crust forms; use lower temperatures for cooking.

In general, forewarned is forearmed. It is for this reason, after listening and reading all sorts of research, that I decided to try a relative novelty on our market - a vertical barbecue.

Coal and coal consumption for heating

Of course, an important question is the problem that affects everyone who has already installed coal heating - which coal is better for heating? Many experts say that the most acceptable type of coal is anthracite - hard or brown coal. These types of coal for heating can be purchased almost everywhere and in any quantity. You can buy coal for heating in bags, and even order several tons with delivery to your storage location.

For ease of transportation, coal is often transported in bags.

What kind of coal is used for heating?

Note that the concept of “hard coal” includes several types of minerals:

- Brown coal: has the lowest combustion temperature and is not currently used for heating because it is inefficient.

- Hard coal, grade D: is ideal for heating a house with coal, as it has a long flame.

- DPK coal: very often this type of coal is called long-flame “nut” and “fist”. Typically used for heating small boiler rooms in private houses.

- TPKO coal: lean coal, usually used for private purposes.

- Anthracite: ideal for powerful boilers.

|

|

Pressed coal is also used for heating.

Undoubtedly, all experts will say that anthracite is the best option. But why? And all because of its properties, since this type of coal is very hard and has excellent heat transfer during combustion. It has a glassy luster and a bright black color. The carbon content in this coal is almost 90%, and impurities are only a small amount. When burned, anthracite produces almost no odor or smoke. It is also non-flammable.

For those boiler houses that have special furnaces, anthracite coal is the ideal solution. When burning 1 kg of coal, approximately 3 kg of CO2 is released - therefore, in this case, up to 6.5 kW/h of energy is obtained.

Coal consumption

As for coal consumption, a scheme is used to calculate the amount of firewood for one heating season, since coal is the same solid fuel. This calculation of coal consumption for heating is the most accurate and simplest. So, the simplest unit of measurement in everyday life is a bucket. On average, a bucket filled with coal weighs about 18 kilograms. If you believe those who constantly use solid fuel heating, then based on their readings for coal heating of a house of 200 sq.m., the consumption is:

- September-October – 1 bucket per day (18 kg);

- November-February – 10 buckets per day (180 kg);

- March-April – 1-2 buckets per day (22-24 kg).

Now we will calculate the total consumption of coal for heating a house in buckets:

60+120+400=580

We multiply what we got by 18 kg to get the consumption in kilograms: 10,440 kg. Thus, coal consumption for heating for one heating season is 10-10.5 tons.

But if you don’t like such a simple method for determining coal consumption for heating, then you can use a more “scientific” method using coal consumption standards for heating. To get 1 kW of energy, you will need about 0.2 kg of coal. On average, approximately 50,000 kW of energy is consumed per heating season. So, we multiply 0.2 kg by 50,000. We get a result similar to the previous one - 10,000 kg (10 tons).

Characteristics of different grades of coal

But it is worth noting that when purchasing coal, be sure to take into account its grade, since each type of coal has a different level of energy output.