A heater is a device that creates air heat flow to heat rooms. Externally, it looks like a section of the air duct where air masses are heated. Depending on the coolant, they can be water, electric or steam. In addition, air coolers are also called heaters. When choosing a heater, take into account the following circumstances:

- room area;

- weather;

- ventilation power.

Any heating equipment sooner or later exhausts its service life and must be replaced. Scheduled preventative maintenance will protect you from breakdowns and help significantly increase the service life of your equipment.

Why is heater repair required?

When errors appear in the automation or the automation fails altogether, the heat exchanger defrosts and, as a result, it fails. When the first “bells” appear, you should immediately seek repairs. But this repair will be advisable only when it amounts to no more than 30% of the cost of a new heat exchanger. Otherwise, it would be better to buy a new and better heat exchanger.

| Job | price, rub. |

| Carrying out troubleshooting with on-site visits | 500 |

| patch for kalach | 700 |

| replacing the roll | 1400 |

| heat exchanger pressure testing | 1500 |

Overhaul and modernization

After the end of the service life of individual components, the units are inspected and a decision is made on further use. If the service life of the units and air ducts is not exhausted, they replace damaged and worn elements, draw up documentation, and establish a new period of operation until the next inspection. A major overhaul helps to fully restore network functionality. The list of actions includes installing new blocks and dismantling worn elements.

Modernization or expansion of the network is carried out if the requirements for air supply have changed. In the process, it is possible to lay new air ducts, install modern equipment, combine air supply with heating, install recovery units, automation and control. If necessary, bends for new workplaces are added to the diagram, and parameters for premises whose use format has changed are adjusted.

VENTILATION SYSTEMS SERVICE

The frequency of maintenance of ventilation systems has not been established by standards. But, for all types of premises and equipment, scheduled diagnostics are provided 2 times a year.

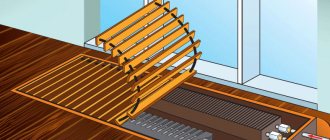

- We carefully dismantle the heater to leave the pipes and lamellas intact;+picture

- We clean the heater from foreign objects, dirt and scale using special means; + picture

- We position the heater in such a way that it is convenient to carry out work; + picture

- We connect the parts for systematic testing work to our heater.+picture

When the heater is operated incorrectly for a long period during the cold season, freezing of the ventilation occurs.

The main reasons why this can happen:

- Air valve servos not connected correctly

- The air damper is not closed tightly

- No air filter

- Wrong choice of water or air valve servomotor (or lack thereof)

- Incorrect setting of the opening/closing direction of the water and air valve

- Incorrect position of the water valve stem or hemisphere in the closed position

- Incorrect connection of the anti-freeze thermostat or its absence

- Incorrect installation of temperature sensor

- Insufficient coolant temperature

- Incorrectly selected mixing unit

- Incorrect operation of automation

- Temperature sensor type mismatch

- The “Winter/Summer” operating mode is not switched

- Incorrect assembly of the mixing unit

The need to maintain cleanliness standards

First of all, in addition to a number of requirements for the heater itself and its coolant, these are also imposed on the incoming air. The main ones are considered to be:

- limitation on the percentage of pollutants (which include dust, fibrous structures, fats, various sticky components, etc.);

- restrictions on chemically aggressive substances (standards are given in GOST 12.1.005-88).

Low quality air masses that do not meet the above conditions will necessarily lead to a rapid deterioration in the performance of heating equipment - corroding the surface, clogging air channels, settling on impellers, radiators and, ultimately, creating such a level of defects that it is sometimes necessary to repair the units fails.

REPAIR OF HEATERS

If the heater fails, the owner faces a problem: repair it or buy a new one? Basically, troubleshooting involves either soldering the air heater itself, or requires repairing fan heaters or simply replacing automation sensors. Experienced craftsmen will carry out any heater repair work in a couple of hours, and the price will be significantly lower than replacing it with a new part.

Stages of repair work and approximate cost of services:

- Identification of the cause of a breakdown with a site visit: diagnostics of damage, analysis of gaps and scope of work - from 500 rubles;

- Soldering damage with applying patches to the roll - from 700 rubles/piece;

- Replacing or repairing a roll - from 1400 rubles/piece;

- Pressure testing of the heat exchanger - from RUB 1,500/piece;

- Test check of the entire system.

The sooner you notice a drop in performance and contact a technician, the less the cost of repairing the heater will be.

Strapping methods

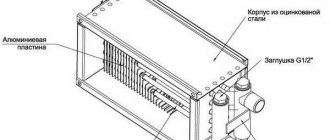

The heater piping is a complex of devices and elements for regulating the supply of coolant to the device. It includes the following elements:

- Pump.

- Two or three way valve.

- Measuring instruments.

- Shut-off valves.

- Filter.

- Bypass.

Depending on the operating conditions, these elements can be located in close proximity to the device, or at a considerable distance from it. Based on the connection conditions, there are:

- Flexible harness. Mounted on control units located next to the device. The installation of such harnesses is considered easier, since it makes it possible to carry out all work on threaded connections, with virtually no need for welding.

- Rigid harness. Used on devices remote from control nodes and requiring strong communications.

Despite the difference in installation techniques, both types perform the same function - they provide setting and adjustment of the heater operating mode.

Types of heaters

- A water heater is used for efficient and economical heating of large rooms. It is a tubular heat exchanger made of steel. Installed in places with a well-functioning heat supply system. Allows you to heat the air within 70-100 degrees, especially large rooms that need additional heating.

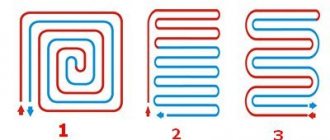

- Heating coils are used to quickly heat air in large premises: production workshops, shopping centers, sports and exhibition halls, as well as to create thermal curtains at the gates with local heating in the right places inside such buildings. The installation is a network of tubes in which coolant circulates. A fan blows air through it, which is heated by contact with the surface of the thermal elements.

- Electric heaters are designed to heat rooms with an area of no more than 150 square meters. Compact, it can be easily installed in a residential apartment. It does not require complex communications - you just need to connect the device to the power supply line.

- The steam heater is used to heat supply or circulation air. Ideal for heating industrial premises. The coolant temperature should not exceed 180 C degrees. They are made in a single-pass design for the internal coolant, have pipes on both sides and are installed in systems with a vertical arrangement of heat-transfer elements. Steam heaters are made from carbon and stainless steel.

- KSk heaters are used to heat air in heating, ventilation and air conditioning systems. They consist of heat transfer elements, tube sheets, collectors and removable side shields. Manufactured from carbon steel.

- An oil heater is used to heat small rooms. Its advantage is that it does not dry out the air. The coolant in the heater is mineral oil with a very high boiling point and heat capacity.

- Gas heaters are heat guns running on gas fuel (liquefied gas): propane-butane mixture or methane (natural gas). Used to heat large areas (from 100 to 600 square meters).

- Freon evaporator cooler (heater) is a device for cooling supply and circulating air. The heat exchanger consists of evaporators represented by copper tubes arranged in several rows. The refrigerant is freon gas.

- A dry cooler heater is a heat exchanger for cooling the liquid flowing through it - water, antifreeze. It is a coil in the form of thin pipes made of copper and aluminum fins, through which the coolant circulates and air flows blown by a fan.

- A water heater with a fan is capable of quickly and evenly heating a large volume of air, including in rooms with high ceilings. The design of the device is a metal frame, inside which steel tubes are installed in rows, connected to each other.

- A heater with a drop eliminator is designed to remove condensate drops in ventilation ducts. It has the appearance of an installation with a round or rectangular cross-section with sections.

The heat exchanger repair will be carried out efficiently and accurately, on time. Call now.

Features of the work

The technique differs from separately eliminating problems in supply and exhaust structures - it requires coordinated functioning of the equipment. There are several network layout options:

- With natural air exchange. The design does not use fans; air movement occurs due to the difference in pressure indoors and outdoors. Repair of such complexes usually consists of restoring air ducts, insulation, tightening and replacing fasteners, cleaning, eliminating leaks, and adjusting check valves.

- Mechanical system. Axial, radial, in-duct, bladeless, vortex, diagonal and other types of fans are used to supply air. The system is more complex; additional elements are often used for filtration, heating, vibration and noise elimination. The repair consists of servicing air ducts, collectors, fan units, replacing filters, and vibration inserts.

- Combined system. The kit includes fans only for supplying or removing exhaust air; air replacement occurs naturally.

The technology, complexity and cost of repairing breakdowns depend on the layout, problems, requirements and tasks for a particular facility. In all cases, an integrated approach is required: initial examination, visual identification of defects, equipment diagnostics, search for methods to restore or maintain normal functioning, cost calculation, supply of components, performance of work.

Installation recommendations

Experts advise adhering to the following recommendations when doing the installation yourself:

- The diagonal dimensions of the heater determine the distance to the bend of the channel, damper, and other elements of the system.

- In order for an air supply unit with a water heater to work effectively, it must be installed in rooms where the temperature is not lower than zero degrees. Because otherwise the heater may freeze.

- When starting installation, double check the integrity of the plates, tubes and other components.

- Connection using butt-welded flanges (or others, it all depends on the location) is considered the simplest solution for connecting a device to a pipeline.

- It is recommended to place direct-flow air exhaust valves in the highest sections of the supply and discharge manifolds.

- The connection of the heater to the ventilation components must be made using sealants at the joints. This will help prevent accidents in the future.

- You can also do the piping and connection of the water heater yourself, because this process cannot be called extremely complicated. But if you do not have experience in such work and you are not confident in your abilities, then it is better to entrust these activities to professionals.