Myguru service technicians will help you solve problems related to the repair of Navien boilers in a short time. Our specialists are ready to go anywhere in Moscow. Our services are affordable.

Myguru service will help you repair your boiler. You can fill out an application by calling our service or online. The work will be carried out on site on the day of the call.

Frequent malfunctions

Despite the reliability of Navien, during operation you may encounter malfunctions that will affect the quality of work.

The main ones:

- The appearance of a leak

- The circulation pump does not work

- Clogged filters

- The occurrence of interruptions in the operation of sensors

- Gas supply is poor or completely absent

- Ignition problem

We are ready to repair the Navien boiler in the shortest possible time, eliminate all problems and establish uninterrupted operation. An experienced call technician will arrive on site anywhere in Moscow. You will forget about the problems and get advice on how best to operate it to avoid problems in the future.

Features and types of Navien boilers

Navien is Korean-made heating equipment, popular in Russia due to its good price/quality ratio.

Here are the main design advantages of gas units:

- the control unit is equipped with a microprocessor chip with the function of protecting the automation from power surges;

- automatic maintenance of operating mode, many settings;

- long service life;

- can operate on natural and liquefied gas;

- coolant pressure is allowed to drop to 0.1 bar without equipment failure;

- the system does not freeze in the event of gas interruptions. In a normal situation, when the temperature drops to +5, the burner automatically turns on. If ignition is impossible, the forced circulation pump operates, this prevents the coolant from freezing;

- easy, intuitive adjustment of modes.

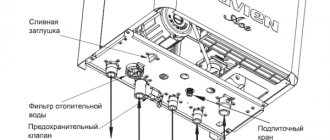

Diagram of the Navien gas boiler.

The power of Navien gas boilers varies in the range of 11-37 kilowatts. The brand’s assortment includes wall-mounted (what are gas boilers for heating a house), floor-standing (floor-standing gas boilers for heating a house), condensing models (what is a condensing boiler), with open and closed chambers, as well as diesel units. Wall-mounted boilers are equipped with corrosion-resistant heat exchangers made of high-carbon stainless steel.

We repair all models

- Turbocharged: Navien Deluxe 13k, 16k, 24k, 30k, 35k, 40k;

- Navien Deluxe Plus, Deluxe S

- Navien SMART TOK

- Navien Ace 13, 16.24 A

- With coaxial chimney: Navien Deluxe Coaxial; With an open combustion chamber; Navien Prime

- Condensing: Navien NCN, NCB 700, NPE

- Atmospheric: Navien Ace Atmo 13, 16,24

- Floor-standing: Navien GA, GST

- Commercial Medium Power: Navien GTD/GPD, RTD/RPD

We repair all gas boilers, including

- ACV

- Alphatherm

- Ariston

- Baxi

- Beretta

- Bosch

- Buderus

- Dakon

- De Dietrich

- Electrolux

- Ferroli

- Fondital

- Frisquet

- Immergas

- Junkers

- Kiturami

- Mora

- Navien

- Protherm

- Rinnai

- Roca

- Sime

- Siberia

- Thermona

- Tiberis

- Vaillant

- Viadrus

- Viessmann

- Westen

- Wolf

- Zhukovsky

- Lemax

The most common error codes

- The explanation of error codes is contained in the instruction manual.

- 01E – equipment overheats. The reason is a blockage or malfunction of the circulation pump.

- 02E – problems with coolant circulation.

- 03 – there is no signal about the occurrence of a flame. Associated with gas supply problems;

- 05E, 06E - indicate problems in the coolant temperature measurement circuit, including a possible short circuit;

- 07E, 08E – circuit sensor is faulty;

- 09E fan malfunction;

- 10E – problems with smoke removal;

- 12E – the flame in the burner went out;

- 14E – no gas supply;

- 16E, 18E – equipment overheating;

- 27E – problems with the air pressure sensor.

Troubleshooting

Let's look at how to fix the main problems with a gas boiler. If error 01 occurs, you need to carefully inspect the pump, check the condition of the impeller and electrical unit, clean the dirt filter, and also remove air from the system.

To eliminate error 02 of the Navien boiler, perform the following steps:

- bleed air from the system;

- measure pressure;

- check the resistance on the pump coil, make sure there is no short circuit;

- check the position of the distribution valve, open if closed;

- clean the sensor flag.

Why us?

- Our service technicians have extensive experience and high qualifications.

- We will eliminate any problem in the operation of the Navien boiler.

- We service and repair gas equipment of all models.

- Fast, cheap, reliable.

You just need to dial our number, by phone or fill out a request on our website, and our specialists will advise you on any questions you are interested in, be it repair or maintenance of the boiler.

And most importantly, we save your time, money and ensure the safety of your home.

- Flushing the Navien boiler heat exchanger

- Navien boiler board repair

Do-it-yourself replacement of units

Some units and components are replaced or cleaned independently. It is recommended to order and purchase spare parts from Navien dealers.

Before opening the lid, it is recommended to disconnect the boiler from the water, gas and electricity supplies. Here are some examples of replacement.

To replace the fan, and it is only replaced as an assembly, you should:

- Disconnect the gas line.

- Remove the hose between the fan and the air sensor.

- Disconnect the connectors (there are two of them) connecting to the control unit.

- Unscrew the screws (3 pcs.) and pull out the fan. Next, install a new one and return everything to its previous state in the reverse order.

In the video you can see how to flush the Navien boiler:

If you change the main heat exchanger, then you need to do it as follows:

- First remove the following units - gas supply pipeline, ignition transformer, fan and overheating sensor.

- Then disconnect the grounding, unscrew the fastening screws and remove the combustion chamber.

- Next, unscrew the mounting screws (8 pcs.) and remove the flue gas collector.

- After this, unscrew the screws holding the combustion chamber cover (9 pcs.) and unscrew the screws connecting the heat exchanger to the combustion chamber body (6 pcs.)

- Pull out the heat exchanger and install a new one, performing the steps in reverse order.

If the heat exchanger is cleaned and there is no damage, then use the old one. But be sure to check the integrity of the ceramic seal. If necessary, it is changed.

How to properly adjust and start

Procedure:

- The boiler startup procedure begins with filling with water. Gas dual-circuit units do not need to install additional devices, so you just need to open the make-up valve and increase the pressure to 1.5-2 At.

- After this, the valve is closed, air pockets are removed from the system and on the unit itself, for which Mayevsky valves on the radiators and an air valve in the boiler are used.

- Then you need to bleed the air from the circulation pump. The casing is removed and the water heating controls are turned on. Specific sounds appear, indicating the operation of the system. On the pump, gradually unscrew the screw in the middle until water appears. This procedure must be done 2-3 times, after which the air from the pump will be completely removed.

- As soon as the circulation pump is brought into operation, the burner will start electronically and the heating system will begin to function.

This completes the initial startup and adjustment procedure.

Prices for repair of Navien heating boilers

The website shows approximate prices for boiler repairs at home.

You can find out the exact cost of repairs only after a detailed inspection of the heating system.

It will depend on the following factors:

- complexity of work;

- Type of equipment;

- gas boiler brand;

- scope of work.

Call and order gas boiler repair.

We care about our customers, so we will do everything to keep you warm even on the coldest day!

Possible causes of malfunctions and ways to eliminate them

Accurate determination of the cause of failure of system elements can facilitate their repair. Based on the codes, you can understand which one has stopped performing its functions normally. Most often, owners of Navien Deluxe boilers encounter the following problems:

- 01E. Overheating of the system can be caused by blockage in the ducts or malfunction of the water pump.

- 02E. There may be air in the system, insufficient water, the water pump impeller is damaged, or the flow sensor has failed.

- 03E. The boiler has improper grounding, problems with the ion sensor, and a gas supply failure.

- 05E. Short circuit in a section of the temperature sensor circuit or lack of proper contact between it and its controller.

- 10E. The fan is faulty, the sensor tubes are not connected to the fan correctly, the chimney is clogged.

- 13E. The heating water flow sensor is located in the short circuit.

Boiler structure

Prices

- ServicePrice

- Engineer visit during working hours from 8:00 to 22:00

- Within a small concrete ring 2000 rubles.

- Tariff for visiting a site outside the small concrete ring, per km. in both directions 30 rub.

- Departure on holidays ×1.5

- Departure after hours from 22:00 to 8:00 am ×2

- Diagnostics

- Fault diagnosis (up to 2 working hours) RUB 2,000.

- Fault diagnosis (more than 2 working hours) RUB 1,500. at one o'clock

- Replacement/installation of gas and fuel fittings and appliances

- Cleaning, replacing the electrode with setting the gaps 1000-2000 rubles.

- Cleaning, replacing the photocell 1000-2000 rubles.

- Replacement of the combustion control unit and combustion manager 1000-2000 rubles.

- Replacing a fan 1500-3000 rubles.

- Replacing the burner servo drive (without setting) RUB 3,000-5,000.

- Replacing the transformer 3000-4000 rubles.

- Injector replacement from RUB 3,000.

- Replacement of the fuel filter from 5,000 rubles.

- Replacement of a diesel burner fuel pump from RUB 5,000.

- Installing a fuel level sensor

- Bleeding the fuel line

- Replacement/installation of water fittings and devices

- Circulation pump from RUB 3,000.

- Pump group from 3000 rub.

- Top-up heating system with pump from RUB 1,500.

- Security groups from 3000 rub.

- Automatic air vent from 2000 rubles.

- Mixer servo drive RUB 3,000.

- Distribution comb from 5000 rub.

- Installation of a coarse filter from RUB 4,000.

- Cleaning the coarse filter from RUB 600.

- Repackaging of an engineering system for 1 point from RUB 3,500.

- Replacing a wall-mounted boiler pump from RUB 3,000.

- Replacement of the primary heat exchanger of a wall-mounted boiler from RUB 4,000.

- Replacement of the secondary heat exchanger of a wall-mounted boiler from RUB 4,000.

- General

- Repair, replacement, installation and commissioning of automation

- Replacement of electronic board 3000 rub.

- Replacement of the control panel from RUB 3,000.

- Replacing the thermostat 3000-5000 rubles.

- Replacement of thermocouple from 3000-5000 rubles.

- Replacing the thermostat 2000 RUR.

- Installation, commissioning of weather-independent automation from 7,500 rubles.

- Installation, commissioning of weather-compensated automation for up to 3 heating circuits from RUB 7,500.

- Installation, commissioning of weather-compensated automation for up to 5 heating circuits from RUB 8,500.

- Controller assembly from 6,000 rubles.

- Setting up weather-independent automation from RUB 5,000.

- Setting up weather-dependent automation from RUB 5,000.

- Connecting an additional boiler automation module from RUB 3,500.

- Installation of outside temperature sensor, room regulator (not including cable installation) RUB 2,000.

- Installation of a main temperature sensor RUB 1,000.

- Installation of a flue gas temperature sensor RUB 1,000.

- Installation of a traction rollover sensor from RUB 1,000.

- Installation of a boiler body temperature sensor from 1000 rubles.

- Installation of a boiler sensor from RUB 2,500.

- Installation and configuration of a servo drive from 2500 rubles.

- Installation and connection of a relay contactor from 2500 rubles.

- Installation of an additional automation module from RUB 3,500.

- Replacement of an additional automation module similar to the installed one from 2000 rubles.

- Replacement of an additional automation module that is not similar to the installed one from RUB 2,500.