Gas boilers from the South Korean company Navien are well known to Russian users.

They have an optimal combination of price and quality and are adapted to Russian climatic and technological conditions.

The cost of Navien equipment is half that of its European counterparts.

The manufacturer made sure that the boilers withstand changes or low pressure of water and gas, and independently compensate for up to 30% of the voltage drop in the electric current network.

Let's look at the setup technology and methods for eliminating the most common errors that occur during the operation of units.

Repair instructions for gas boilers Navien

Basic boiler settings are carried out simultaneously with the initial installation.

Connection is made to all necessary communications and systems:

- Gas supply.

- Water supply.

- Connection of the direct and return pipelines of the heating system (OB, coolant).

- Connection to the power supply network.

- DHW supply system (distribution to distribution points).

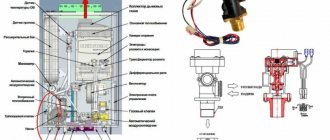

The initial setting of the boiler is carried out using DIP switches and a resistor that regulates the gas supply (pressure). They are located on the unit control board.

IMPORTANT!

Self-tuning of Navien gas boilers is strongly not recommended. To perform this procedure, you should invite a specialist from the service center.

About company

Currently, the South Korean company Navien is one of the world's largest manufacturers, whose main specialization is the creation of gas and diesel boilers that are used for domestic use.

Navien works according to four main principles: sustainable development, the discovery of ethical values for society, ecology and care for the environment and people.

The company began its activities in 1978, and has been operating successfully since then. For almost 40 years, the described manufacturer has been able to take a strong position in the market and win the trust of users.

Korean Navien gas boilers are inexpensive, reliable, but at the same time easy-to-use equipment that has a lot of positive consumer reviews.

Reviews for the Navien Ace boiler

How to properly adjust and start

Procedure:

- The boiler startup procedure begins with filling with water. Gas dual-circuit units do not need to install additional devices, so you just need to open the make-up valve and increase the pressure to 1.5-2 At.

- After this, the valve is closed, air pockets are removed from the system and on the unit itself, for which Mayevsky valves on the radiators and an air valve in the boiler are used.

- Then you need to bleed the air from the circulation pump. The casing is removed and the water heating controls are turned on. Specific sounds appear, indicating the operation of the system. On the pump, gradually unscrew the screw in the middle until water appears. This procedure must be done 2-3 times, after which the air from the pump will be completely removed.

- As soon as the circulation pump is brought into operation, the burner will start electronically and the heating system will begin to function.

This completes the initial startup and adjustment procedure..

Navien presents a universal water heating system

Navien Ace gas boilers are not afraid of low pressure of gas and water, they are not afraid of voltage drops in the network. The operation of Navien gas boilers is characterized by a long service life and economical gas consumption. All Navien gas devices comply with the standards and regulations of the Russian Federation and have the appropriate certificates.

Frost protection system stability

If the room temperature drops, the automatic protection system is activated

from freezing. When the temperature of the heating water drops by more than 10 degrees Celsius, the circulation pump automatically starts, resulting in constant circulation of the coolant in the heating system. If the temperature of the heating water drops to 6 degrees Celsius, the burner is automatically turned on and the coolant warms up to 21 degrees Celsius.

Safety of operation during frequent power surges

According to the instructions, the voltage can fluctuate within ±30 percent due to the triggering of the Switched - Mode Power Supply (SMPS) protective chip on the microprocessor. At the same time, the boiler operation does not stop

, which prolongs its service life and prevents breakdowns.

Operating conditions for heating and hot water:

- provided there is low inlet pressure in the gas pipeline system, stable and safe operation of the Navien Ace gas boiler is possible at a gas pressure of four mbar (40 millimeters of water column);

- subject to low incoming water pressure in the water supply system - stable operation of the Navien Ace gas boiler is possible provided that the incoming water pressure drops to 0.3 bar, which allows this gas device to be used in homes

where there is low water pressure in the water supply system, including where there are frequent pressure drops in the water supply system.

Rational design

Navien gas boilers are small in size and light in weight, they are convenient to transport, they are easy to install and there is the possibility of rational use of room space. For ease of installation, the connecting tubes are located on both sides of the device, which greatly simplifies the piping and installation of the Navien Ace gas boiler.

Fuel preheating (KR series)

At low temperatures, the viscosity of the fuel increases, resulting in a waxing effect, which significantly impairs the flammability of diesel fuel

and the operation of the Navien gas boiler becomes unstable. This feature of operation is relevant for regions with harsh climates, therefore arctic and winter diesel fuels were created for these conditions.

Navien gas devices operate on any Russian-made diesel fuel

However, the cost of winter or arctic diesel fuel is much higher than that of summer diesel fuel, and the use of summer fuel is impossible at low temperatures without preheating it.

The heating element, which is built into the burner of the Navien gas unit, preheats it before supplying fuel to the nozzle, resulting in high-quality fuel atomization and uninterrupted ignition. Due to preheating in Navien Ace gas boilers, it is possible to use inexpensive summer diesel fuel

, which leads to significant savings.

User manual

Navien gas boilers are operated automatically, with minimal human intervention.

The owner only needs to observe the readings on the display and respond in a timely manner to the appearance of an error code.

In addition, the user determines the operating mode - summer or winter:

- Summer mode is determined only by DHW heating.

- Winter mode starts the heating system simultaneously with the supply of hot water.

The display has a button with a corresponding icon (symbol of a snowflake or sun).

If it is necessary to adjust the extract air temperature or other parameters of the heating system, the winter operating mode must be turned on. Exhaust temperature is adjusted when the radiator icon is flashing.

If it lights up steadily, the display shows the current temperature . By pressing the “radiator” button so that the icon flashes, press the “+” or “-” buttons to change the set coolant temperature.

The icon stops flashing after a while (a few seconds), and the boiler will begin to heat or cool the coolant in accordance with the instructions received.

Innovative solutions in Navien products

Ease of operation

Technological solutions that are implemented in the products are innovative. The introduction of advanced developments forms the basis for the design and production of gas boilers of this brand. The equipment of the South Korean brand is characterized by:

- Easy to use and reliable. The designs provide mechanisms that eliminate emergency situations and increase the efficiency of the equipment.

- All information about the system status is displayed on the liquid crystal display. Process management does not require special skills and is accessible to inexperienced consumers.

- The company's devices are universal. They are used both for heating the stove and for supplying hot water.

- Controlling the operation of the equipment is as convenient as possible. Using a timer, the time frame for performing certain operations is set. The presence of a remote control allows you to make changes to processes remotely.

- The boilers are adapted to operate in manual and automatic modes. The use of one or another operating procedure depends on weather conditions and the preferences of the owner.

- Navien devices can use not only main gas, but also liquefied gas as raw materials.

- Closed combustion chambers require the installation of a coaxial chimney. This is a huge plus that increases operational safety. To support the combustion process, the equipment uses air from the street, preserving oxygen inside the house.

Read further:

Gas boilers "Navien Ace" - operating instructions and advantages of the model

Gas boilers "Navien" for autonomous heating

Gas boiler Navien - technical characteristics, design features and model range

We study the Navien wall-mounted double-circuit gas boiler - design features, advantages and disadvantages

Gas boiler Navien: faults and their elimination

Running self-test

The Navien boiler self-diagnosis system operates constantly and does not require a separate startup.

The probability of a failure of one or another node exists at any time, so the sensors send signals about the status of certain elements 24/7, never stopping.

If the sensor stops working for any reason, the corresponding error code immediately lights up on the display. This is an important function that helps maintain performance and timely troubleshooting .

Differences between Navien and analogues

The Korean manufacturer is among the few that use their own designs. The brand does not produce modified or slightly improved versions - each new modification is worked out to the finest detail. Among the design advantages it is worth noting:

- Remote control via iOS and Android systems. This is for the SMART TOK series.

- Modulating burners. Quiet operation depends on them; they are responsible for maintaining a comfortable temperature for humans.

- Thanks to voice prompts, the operation and configuration of the devices is simplified. If the user is not well informed about how the device works, voice prompts and error codes will help him.

- Meets our conditions - possible decrease in pressure, voltage surges in electrical networks, pressure drops in gas pipes.

- Self-diagnosis. The device itself determines its “diseases” and notifies the user about them by displaying an error code on the display.

The Korean manufacturer, taking into account possible risks, created safe and easy-to-use equipment. If you take an interest in the statistics of reviews, it becomes clear that consumers have managed to evaluate the quality of heat exchangers and burners, as well as the uninterrupted operation of Korean heaters. Only 2% of buyers contact service centers, and even then, the problems are usually caused by incorrect connection or operating errors. To prevent the boiler from creating problems, you need to connect it correctly and configure it correctly

It is also important to know how to use gas equipment - for this purpose, instructions are attached to each piece of equipment. The kit also includes a passport and connection diagram.

Basic error codes and their interpretation

Let's look at what error codes may appear on the unit display:

| Error code | Fault type |

| E01-02 | Lack of coolant in the system (flow sensor malfunction) |

| E03 | No flame |

| E04 | False evidence of the presence of a flame (spark breakdown to the sensor) |

| E05 | Exhaust temperature sensor break |

| E06 | Exhaust temperature sensor short circuit |

| E07 | Broken DHW temperature sensor |

| E08 | Short circuit of DHW temperature sensor |

| E09 | Fan failure |

| E10 | Malfunction of the smoke removal system |

| E13 | Short circuit of the OM flow sensor |

| E15 | Malfunction or failure of the control board |

| E16 | Exceeding the permissible boiler heating temperature |

| E18 | Smoke sensor overheating |

| E27 | Short circuit or break in the air pressure sensor |

The appearance of most errors is accompanied by a shutdown of the boiler, which is dangerous in winter, so you should respond to them as quickly as possible.

Common malfunctions and their elimination

Let's look at the main ways to eliminate errors that have arisen.:

E 01-02

This error indicates overheating of the equipment due to the lack of coolant in the system. The solution to the problem is to clean the pipelines or check the pump. Alternatively, it is necessary to remove air from the system (primarily from the pump).

E 03

The functionality of the flame sensor is checked. Cleaning ignition electrodes.

It is also necessary to check the presence of gas in the line or cylinders.

E 05

A malfunction of the temperature sensor can be eliminated by checking its condition. The resistance of the sensor is measured at a certain temperature. If the readings correspond to the standard ones, it is necessary to clean the contacts.

If the sensor readings do not correspond to the table values, replacement with a new, functional unit is required..

E 09

First of all, you should measure the resistance on the fan windings, which should be 23 Ohms.

Check if there is power supply at the terminals. If serious problems are detected, the fan is completely replaced.

E 10

Most often, the problem lies in the sensor itself. It is necessary to check its condition, clean the contacts, and replace it if necessary.

E 13

The flow sensor often gets stuck due to clogging of the actuator with small debris, lime deposits, etc. If cleaning the sensor does not give the expected result, a possible breakdown to the control board is checked.

If there is no result, the sensor is replaced.

E 16

Overheating of the boiler can have several reasons, the most common of which is clogging of the heat exchanger and poor flow of the coolant. The protection is triggered at 98°, the alarm is switched off when the boiler cools to 83°.

There are two ways to solve the problem - first you should clean (in difficult cases, replace) the heat exchanger; if there is no positive result, replace the sensor.

E 18

Overheating of the smoke exhaust sensor occurs when the chimney is blocked . The cause may be condensation freezing, strong winds from outside, or foreign objects or debris getting into the chimney. If eliminating interference with the output of combustion products does not bring any results, the sensor should be replaced.

E 27

Lack of air pressure when the fan is running most often indicates a clogged air duct or the need to replace the sensor . Most often, the reason lies precisely in this, since the entry of foreign objects into a closed air channel is extremely difficult.

Kinds

There are two types of Navien boilers:

- Floor-standing.

- Wall-mounted.

Floor structures are more massive and easier to install. Wall samples are compact, do not fill the room, and fit harmoniously into the interior.

In terms of functionality and design, they differ little from each other, representing only different placement options.

Based on the principle of operation, the following designs are distinguished:

- Atmospheric. These are open burner boilers. They need active ventilation of the room in which they are located. Cheaper compared to other models, they have a relatively low efficiency, which is partially compensated by the use of a copper heat exchanger.

- Turbocharged. These are designs with a closed combustion chamber. The process is supported by the supply of fresh air (turbocharging), as a result of which the efficiency of the installations significantly increases and reaches 91.7%. This design is somewhat more expensive, but more convenient for use in a residential building, which is why turbocharged boilers are most popular.

- Condensation. This category of installations has an additional heat exchanger that uses steam energy from the exhaust smoke. The addition allows you to obtain about 30% more thermal energy, which significantly increases the efficiency of the boilers. At the same time, the cost of condensing units is much higher, which limits demand.

In addition, boilers differ in the type of chimney.

Exist:

- Coaxial type. The “pipe-in-pipe” principle, popular in Europe, is used, where the outer circuit provides air supply for turbocharging, and the inner circuit serves as a chimney. The technology is convenient in that the pipe is brought out through the wall, without requiring complex passages through the floors or roof.

- Korean (separate) chimney. The air supply and the chimney are two separate pipes. Often the chimney is connected to the common chimney of the house, and air is taken in by leading the pipeline through the outer wall.

Despite the presence of various design options, any unit from Korean manufacturers demonstrates high performance and quality.

Why does blood pressure drop?

The cause of a drop in water pressure in the system can only be a leak. At the same time, it can be both in the boiler itself and outside it - in pipelines, radiators, etc.

It is necessary to open the feed valve, start the boiler and carefully inspect the entire system, step by step. If no leaks are found, the boiler must be inspected. When looking for the cause, you should be guided by the rate of pressure drop.

Perhaps the water goes into the expansion tank, in which the membrane has ruptured. Another reason could be a worn safety valve. If it is connected to the sewer, the leakage will not be noticeable.

NOTE!

In any case, the drop in pressure indicates that it is going somewhere. It is necessary to find the leak, otherwise it may get wet and destroy the structure of the house.

Where is it used?

Gas double-circuit boilers Navien Ace series are designed for organizing heating and hot water supply of residential premises or offices of the appropriate area.

This limits the scope of use of these units, although they can be installed in any premises. The main task is to ensure that the serviced area matches the capabilities of the equipment and the availability of all the necessary resources - gas, electricity and water (coolant).

NOTE!

In addition to the area, it is necessary to take into account the volume of the room, which may be too large for this Navien boiler model. The product passport indicates the maximum volume possible for the normal functioning of the system.

Reasons for increased pressure

An increase in pressure in the boiler is primarily demonstrated by the safety valve, which begins to release excess pressure. This problem often confuses even experienced specialists.

The reason lies in the secondary heat exchanger. Hot water is heated from the already heated heating agent, receiving energy in a plate secondary heat exchanger. Both liquids exchange thermal energy without mixing with each other.

But, if a fistula occurs, allowing water from the hot water system to penetrate into the heating system, the pressure will increase and tend to balance with the higher pressure of domestic hot water.

If such a problem occurs, the secondary heat exchanger should be replaced, since repairing it is complicated and ineffective.

Specifications

Modern Navien units are equipped with a remote control panel, which receives a signal from a temperature sensor.

Its readings are instantly transmitted to the control unit chip, which gives a signal to the actuator to increase/decrease the gas flow rate to the double-circuit boiler. Similarly, a command may be received to completely shut down the unit if an emergency situation occurs in its operation.

The most popular modifications of Navien gas boilers are double-circuit wall-mounted units with a closed firebox, a thermal power of 20-24 kW, capable of efficiently heating a room from 160 to 240 m2 and preparing hot water for the domestic needs of a family of 4 people.

Technical characteristics of Navien wall-mounted gas units with a closed combustion chamber:

- Navien Deluxe Plus - 20k, heating - 160 m2, maximum/minimum performance - 20/9 kW, expansion tank - 8 l, electric pump - yes, heating + hot water, efficiency - 91.7% gas consumption - 2.15 m3/hour, price - 31,080 rub.

- Navien Deluxe Plus - 24k, heating - 192 m2, maximum/minimum performance - 24/9 kW, expansion tank - 7.5 l, electric pump - yes, heating + DHW, efficiency -90.5%, heat exchanger - steel, gas consumption - 2.58 m3/ hour, price - 31,230 rub.

- Navien Deluxe Plus -24k COAXIAL, power 24 kW, heating - 240 m2, maximum/minimum performance - 24/9 kW, expansion tank - yes, electric pump - yes, heating + hot water, efficiency - 90.5%, heat exchanger - steel, gas consumption — 2.58 m3/hour, price — 28,500 rub.

- Navien ACE-20AN, heating -190 m2, natural combustion, maximum/minimum performance - 20/9 kW, expansion tank - yes, electric pump - yes, heating + hot water, efficiency - 91%, heat exchanger - plate, gas flow - 2.06 m3 /hour, price - 29,130 rub.

- Navien Deluxe - 20k White, heating - 186 m2, maximum/minimum performance - 20/9 kW, expansion tank - yes, electric pump - yes, heating + hot water, efficiency - 90.5%, heat exchanger - steel, gas consumption - 2.15 m3/hour , price — 32,160 rub.

- Navien Deluxe - 24k White, heating - 220 m2, maximum/minimum performance - 24/9 kW, expansion tank - yes, electric pump - yes, heating + hot water, efficiency - 91.5%, heat exchanger - steel, gas consumption - 2.58 m3/hour , price — 29,980 rub.

- Navien Deluxe-20k COAXIAL White, heating - 190 m2, maximum/minimum performance - 20/9 kW, expansion tank - yes, electric pump - yes, heating + hot water, efficiency - 90.5%, heat exchanger - steel, gas consumption - 2.15 m3/ hour, price - 32,160 rub.

- Navien Deluxe-24k COAXIAL White, heating - 220 m2, maximum/minimum performance - 24/9 kW, expansion tank - yes, electric pump - yes, heating + hot water supply, efficiency - 90.5%, heat exchanger - steel, gas flow - 2.15 m3/ hour, price - 29,090 rub.

- Navien SmartTok - 24K, heating - 220 m2, maximum/minimum performance - 24/9 kW, expansion tank - yes, electric pump - yes, heating + hot water, efficiency - 91.0%, heat exchanger - steel, gas consumption - 2.6 m3/hour, price — 34,430 rub.

- Navien Deluxe S COAXIAL-24k, heating - 200 m2, maximum/minimum performance - 24/9 kW, expansion tank - yes, electric pump - yes, heating + hot water supply, efficiency - 91.2%, heat exchanger - steel, gas consumption - 2.58 m3/ hour, price - 31,060 rub.

Date: September 25, 2022

Power-on problems

There may be several reasons for such a malfunction.:

- There is no voltage in the network (or it has decreased too much, it has become less than 150 V).

- No gas.

- The boiler is blocked by a protection system that was activated due to a critical error (overheating above 98°).

Other reasons for failure may also occur . First of all, you should check the voltage in the network.

The boiler is capable of compensating for fluctuations of up to 30%, but with more significant changes, it simply will not start. You can solve the issue by using a separate outlet and installing a stabilizer.

If all possible causes have been checked and eliminated, but the boiler continues to be silent, you should invite a specialist . Perhaps the cause was a failure of the control unit, a breakdown, or another serious problem.

You should not attempt to resolve the issue yourself; this may cause the final destruction of the unit.

Doesn't start for a long time

The boiler is started when certain conditions are reached. If the temperature or pressure of water (OB, DHW) is within the specified range, heating will not start until it cools down .

A possible cause may also be partial clogging of the water filter, which slows down the flow and changes the circulation mode. It may be difficult for the circulation pump to operate if it is clogged with lime deposits or small debris.

Download instructions

You can download the instructions here.

What to do if the aspirated air leaks?

For the Atmo model range with an open (atmospheric) burner, the primary heat exchanger is made of copper.

The appearance of a leak is almost always associated with its destruction. Purchasing a new heat exchanger is not an easy and expensive task, so most often the issue is solved by soldering the fistula .

To carry out repairs, you should contact a technician from the service center, since this requires a qualified specialist who can dismantle the unit, find the fistula that has arisen, solder it properly, simultaneously rinse the heat exchanger and install it in place without damage.

The work is complex and requires the participation of a trained person.