When thinking about the ventilation system in your home, you most likely wondered how much it is necessary to install a ventilation fungus on the roof, and if there is such a need, then which fungus should you choose?

In fact, the fungus, or as it is also called the deflector or ventilation cap, performs several very important functions. Its absence, as well as the wrong choice, can lead to cessation of draft and damage to ventilation equipment.

We will help you understand the useful functions that the device performs. Let's tell you what kind of ventilation fungi there are. We will advise you on how to make the right choice.

Purpose and types of ventilation fungi

If the pipe leading above the roof is not equipped with any fungus, then it can effectively remove air from the room only in complete calm.

Even the slightest rain will disrupt the draft or cause the air flow to flow in the opposite direction. In addition, dust, snow, fallen leaves raised by the wind, branches and other objects that can damage the ventilation system will get into the open pipe.

When choosing what type of ventilation fungus to make in your home, give preference not to a simple umbrella, but to a more advanced deflector. This will ensure stable draft in the ventilation duct and protect against wind blowing

To eliminate such phenomena, a ventilation hood is installed on the ventilation pipe, which performs three functions:

- Protects the ventilation pipe from precipitation and foreign objects;

- Does not allow the wind to stop or direct the air flow in the ventilation duct in the opposite direction;

- Increases traction in windy conditions.

There are several types of fungi that have their own advantages and disadvantages, but at least one of them must be installed. The simplest design installed on a ventilation pipe is a deflector umbrella.

It has sufficient functionality, is able to increase traction and protect the pipe only from precipitation getting into it. It is used mainly in areas with medium and high wind loads. There is no need for additional tricks to increase the draft in the exhaust pipe.

If you need to protect ventilation from precipitation and there are no additional requirements for creating draft, then an umbrella-deflector will be a practical and inexpensive solution

The ventilation umbrella has become widespread due to its low price and the possibility of self-production from scrap materials. However, it is undesirable for use in ventilation systems, especially natural ones, since it practically does not prevent the occurrence of reverse draft.

More complex and effective types of ventilation fungus from an umbrella are distinguished by the presence of additional parts, such as a diffuser, rings and blades. The most widely used are TsAGI and Wolpert deflectors, turbo deflectors, weather vanes, and similar products.

When choosing the type of deflector, study not only its advantages, but also its disadvantages. This will allow you to make a decision that is appropriate for your area and minimize the risk of the deflector stopping working

Regardless of the design, all deflectors are united by the ability to increase ventilation draft during windy conditions. This property is given to them by the specific shape of the parts, bending around which the wind creates areas of high pressure and rarefaction.

It is in the region of rarefaction that air rushes from the ventilation duct, while the speed of its movement increases, and the thrust increases accordingly. Most deflectors are energetically passive devices and do not require connection to a power supply.

In addition to their advantages, deflectors have several disadvantages:

- In calm weather, they reduce draft, preventing the free exit of air;

- In cold weather, parts of the device may become covered with frost, narrowing the air outlet openings;

- The turbo deflector and weather vane provide less protection from rain, and their rotating parts require periodic maintenance and cleaning.

Despite the listed disadvantages, it is necessary to install a ventilation hood on the exhaust pipe. The deflector model is selected based on the standard wind load in the area.

In places with low wind activity, in settlements surrounded by forest, it is better to equip the mouth of the hood with a turbine deflector.

Selection rules

You can select the optimal deflector based on the goals and tasks assigned to it. It is also worth considering the conditions in which it will operate.

A simple chimney is a cap on a wood-burning chimney, made in the form of a regular umbrella, and has the following advantages:

- maintains the necessary traction both in calm conditions and in the movement of air masses with a power of up to 10 points;

- does not create excessive pressure on the pipe, due to which even in a severe storm the chimney remains in its place; rather, the umbrella itself can break off and fly away;

- has a simple and understandable design;

- practically does not coke or clog, and is quite easy to clean;

- due to the imperfection of the aerodynamic structure, it is insensitive to the shape of the umbrella; if the building is located in the wind, then the chimney can be made in the form of a tent, this greatly simplifies its use and opens up great opportunities for the implementation of design ideas.

At the same time, there are serious disadvantages, such as:

- in weak winds it reduces draft, and the stronger the heating element works, the weaker it is. This is quite dangerous, since in cold winter weather, in the absence of wind, the stove can “choke” and breathe fumes into the living quarters;

- in strong winds, on the contrary, it creates too much draft. This significantly reduces the efficiency of indoor stoves and fireplaces;

- in gusty winds it can cause blowing into the pipe and creating a reverse draft effect.

The aerodynamic open model maintains sufficient draft in any wind for efficient operation of stoves and boilers using liquid fuel and gas. Such deflectors can freeze, they easily become littered and quickly become covered with soot and soot, however, they are easy to clean.

The disadvantages include the following:

- complex body of rotation;

- as a result of the load created by air masses, the umbrella itself can easily fly off the chimney, and at the same time, the direct mechanism of the device can collapse the pipe itself;

- with strong gusts of wind from force 8, the lateral pressure on the structure increases significantly and further increases in accordance with the power law;

- open structures are quite poor at reducing strong dynamic loads resulting from gusts of wind, which is why in no case should such a model be placed on pipes made of brick;

- the modification cannot be used for pyrolysis heat-generating mechanisms, otherwise, when wind occurs, all pyrolysis gases will be sucked out and the stove or boiler will simply go out;

- not suitable for creating design elements, since it is unsuitable for decoration; all kinds of blotches and figures only worsen the overall aerodynamic status of the structure as a whole.

By the way, an interesting study was conducted in the USA. There, at one time, they studied issues related to open deflectors and installed them on locomotives to check the degree of increase in efficiency at low speed. At the same time, the result was the most depressing - at mid-speed, fire began to burst out of the pipe and not a single train was able to reach its maximum speed. In general, the open version of the deflector should be recommended for all types of heating devices, with the exception of pyrolysis ones. At the same time, it must be checked and cleaned at least once a quarter. It is optimal for a chimney with low draft force, it is most effective for wood-burning sauna stoves; not a single case of people burning out due to the ventilation deflector in saunas has been recorded.

The closed or as it is called “perfect” type has such advantages as:

- provides stable draft, which is sufficient for stoves and boilers of any type;

- not prone to freezing and clogging from the inside;

- Dust and ice formed on the outside do not significantly change the operation of the device.

There are also disadvantages, however, users claim that they are not so significant, namely:

- when exposed to strong winds, it gives maximum pressure on the pipe, and then increases linearly, so the chimney under the deflector should be further strengthened with guy wires;

- has rather complex design and technological parameters;

- cannot be used as a design element, since any additional elements significantly reduce the overall level of aerodynamics.

Models may differ in appearance, purpose and material. Most often, plastic, stainless steel or aluminum are used to produce deflectors. In rare cases, copper may become a raw material for production. Many users prefer the sandwich model.

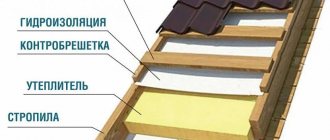

Is roof ventilation really necessary?

Some may ask: why do you need to carry out ventilation at all and spend additional money when you can do without this work. The answer is obvious. First of all, ventilation maintains a beneficial microclimate inside the roof. This will help each of its elements to calmly carry out their work without fear of destruction. The quality of thermal insulation also depends on ventilation, if you performed this work when installing the roof, taking into account the height of the pipe above the ridge.

Incorrect operation of ventilation or its absence at all can lead to the following problems:

- Formation of condensation on materials. Wooden materials, such as rafters and beams, will deteriorate or rot prematurely. And condensation on metal and other elements will cause their corrosion, and subsequently complete destruction (read the article: “How to eliminate condensation under the roof”).

- Moisture also forms on the surface of the roof. This can already lead to the formation of ice and the destruction of some types of roofing material.

- Steam condensation on insulation. The insulation layer will get wet and subsequently lose its thermal insulation properties. This means that with insulation it can be worse than without it.

Additional types of deflectors

For some types of chimney, reflectors, which are also deflectors, may be suitable. They are mainly used on heating appliances running on liquid fuel.

Additional fastenings are installed on these devices, because they are exposed to strong winds. However, this device must be made in accordance with the characteristics of the gas installation.

It is important to take into account that if you make a large reflector, it will not be able to provide the necessary thrust, and what’s worse, it will slow down the combustion itself. This is due to the fact that a large deflector can allow large masses of air to pass through, which, in turn, extinguishes the flame. This type of device contains an additional device similar to a fan.

Inside the body itself there are blades bent at a certain angle. These blades are connected at a central hub, which serves as the axis of rotation

This type of device contains an additional device similar to a fan. Inside the body itself there are blades bent at a certain angle. These blades are connected at a central hub, which serves as the axis of rotation.

Make it yourself or order it

It is advisable to make a decision on the construction of a ventilation system at the building design stage. This is especially true if you have to drill an air duct through a metal tile roof.

In most cases, mounting the fungus requires the installation of a support platform. It will take time to calculate it correctly. If it is not there, then it is better to contact specialists who will do all the work quickly and efficiently. But, if you have experience and equipment, you can make a ventilation duct yourself.

Tips for choosing

You can make a fungus from scrap materials that you have on the farm. Plastic or cast iron sewer pipes and tin left over from roofing work are suitable for this. But working with such materials is difficult; they are not strong and durable.

It is advisable to take advantage of modern developments.

The retail chain has a wide range of ready-made mushrooms with different angles of inclination of the base plate. The products have a large margin of safety, are easy to install and operate. Their price is high, but the investment is worth it.

Life time

pipe cap If the product is made from stainless steel or asbestos concrete mixture, it will last about 10 years. But only on condition that the installation is carried out in a calm atmospheric zone, where there are no strong winds or hurricanes. This impact significantly reduces the service life.

Modern polymer products can last at least 50 years. But they cost several times more, so they are less often chosen by consumers.

How does a fungus work?

Initially, the roof fungus was made of galvanized steel. Especially popular are designs made of impact-resistant polypropylene, which is slightly exposed to the sun, frost, and corrosion. In some types of hoods, the inner tube is made of a steel alloy. The ventilation fungus includes a number of elements:

- 2 pipes (for gas removal, fastening with a horizontal section of the air duct);

- fastening units (flanges);

- container for condensate accumulation;

- an air valve responsible for the necessary air circulation;

- rings for support, fastening;

- aerator (a device that saturates the room with oxygen);

- deflector (a device that increases the draft of air flows);

- valves

Ventilation fungus on the roof

Ventilation fungus on the roof

Additional types of deflectors

For some types of chimney, reflectors, which are also deflectors, may be suitable.

They are mainly used on heating appliances running on liquid fuel. Additional fastenings are installed on these devices, because they are exposed to strong winds. However, this device must be made in accordance with the characteristics of the gas installation.

It is important to take into account that if you make a large reflector, it will not be able to provide the necessary thrust, and what’s worse, it will slow down the combustion itself. This is due to the fact that a large deflector can allow large masses of air to pass through, which, in turn, extinguish the flame. An additional device similar to a fan is built into this type of device

Inside the body itself there are blades bent at a certain angle. These blades are connected at a central hub, which serves as the axis of rotation.

This type of device contains an additional device similar to a fan. Inside the body itself there are blades bent at a certain angle. These blades are connected at a central hub, which serves as the axis of rotation.

Dimensional parameters of the ventilation fungus

The total height of the structure, including valves and caps, averages 500-700 mm, although there are also 400 mm models. From the point of view of productivity and throughput, in principle, the internal diameter is also important. The standard thickness of the fungus on a ventilation pipe is 110 mm, and the outer diameter can vary from 125 to 160 mm. The difference between the sizes of the inner and outer pipes is determined by the type of heat insulator used and materials that increase the rigidity of the structure.

Expert advice

Ventilation duct installation specialists recommend not saving on this event. Even with a limited estimate, it is necessary to include the maximum number of exhaust ducts in the construction plan. After its completion, ventilation will be difficult and expensive, and in some cases impossible.

How to insulate

You can insulate the exhaust fungus with your own hands in several ways:

- Wrap it with basalt wool, on top of which secure a cylinder made of stainless steel sheet.

- Screw a heating cable onto the pipe and cap with automatic switching on when the temperature drops.

- Cover the channel with polyurethane foam and then paint it with acrylic paint.

Modern models of fungi consist of external and internal pipes, between which there is a layer of insulation.

Principle of operation

The ventilation system is based on the principle of moving warm air mass upward and cold air downward. For air extraction and natural ventilation, the distance between the source of pollution and the upper section of the air duct is important: the greater this distance, the more efficient the process.

Umbrellas are mounted on air ducts coming from the bathroom, basement, and chimneys of the heating boiler. During the cold season, ice build-up may form in the ventilation pipe and on the umbrella, so they are insulated with heat-insulating materials (mineral wool, polystyrene foam, polypropylene foam, polyethylene foam insulation).

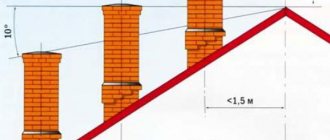

Building regulations

Installation requirements:

- Mandatory installation of a ventilation system in bathrooms, in the kitchen, as well as in places where vegetables are stored;

- Access to fresh air. Fungi must necessarily protrude beyond the roof; it is not enough to bring them into the attic;

- Fungi should not be located flush with the ridge of the roof; their protrusion is required;

- If a long air duct is installed, its design must contain a fan to increase the efficiency of the ventilation system;

- Heating boilers require a chimney and a separate flue.

All installation requirements are strictly regulated, and you can find out more about them in SNiP 2.04.05-91.

Do-it-yourself manufacturing and installation

Installing fungi on ventilation ducts is not particularly difficult for people who have the skills to handle household tools.

Two aspects to pay attention to are careful design and safety precautions when working at height. The service life of a structure and the quality of its work largely depend on the materials chosen for construction.

Material selection

When preparing for construction, you should be based on the following criteria:

- For the pipe, it is better to choose polymer plastic or stainless steel.

- The caps should be made of plastic, which changes configuration under the influence of high temperature.

- For fastening, you should choose hardware made of aluminum or stainless steel. These metals are not subject to corrosion.

Wood, sand-lime brick, black steel and asbestos cement should be avoided. They will not last long; subsequent dismantling and new installation will require large investments.

Drawing and diagrams

Depending on the length of the ventilation ducts, several diagrams and one general drawing to scale are drawn up. They are made on plain paper or on a computer.

The project must contain the following information:

- separate and common air ducts;

- all layers of the roof;

- support platform;

- connecting flanges;

- exhaust pipe;

- valve;

- fan;

- support ring (plate);

- glass to collect condensate.

Based on the project, the need for building materials and tools is determined.

Size calculation

Exhaust fungi are installed in such a way that the possibility of smoke from operating stoves entering them is completely eliminated. In addition, their internal cross-section should not be smaller than that of the supply channel. If the diameter of the flue is 20 cm, then the cross-section of the fungus should be similar.

When installing on slopes, the upper cut of the channel must be installed at a height of at least 25 cm above the highest point of the slope.

If flat roofs are used as a recreation area, then the pipes rise to a height of at least 200 cm.

Installation video

Watching a training video will be a good help for beginners.

Installation features

The reader is offered instructions for installing ventilation mushrooms:

- Mark a contour for penetration on the roof.

- Use tin snips or a reciprocating saw to make a through hole in the roof.

- Drill holes for mounting bolts or screws.

- Clean the working area from dust, dirt and grease deposits.

- Fill all gaps between the roofing layers with sealant. Apply it to the sealing gasket.

- Reinstall the gasket. Insert the passage element and secure it with hardware.

- Insert the ventilation kit into the penetration and secure it firmly.

- Insulate the connecting flange from the attic side.

Finally, the ventilation duct is checked for functionality. This is done with the help of a burning match or flavoring.

Frequent errors and problems during installation

When installing exhaust systems, craftsmen make a number of mistakes:

- no sealant is used to seal joints;

- use of moisture-resistant materials for ventilation ducts;

- connection into a single passage of several pipes leaving rooms at different levels;

- ignoring the insulation of channels.

A common mistake is the wrong choice of location for installing the fungus, which leads to weak or absent traction.

Protection of deflectors from low winds

Due to the presence of this feature of wind flows, deflectors began to be equipped with special protective devices that help increase the level of draft in the pipe in any weather. To do this, an axis is installed inside the chimney on two bearings located at different levels.

A semi-cylindrical screen, a weathervane and a cover are installed on the axis. It is this design that protects the entire chimney from the effects of the lower wind flow.

After the direction of the wind flow changes, the weather vane rotates, thereby closing the chimney from the wrong wind flow. Thus, any direction and strength of the wind is not able to block the path of the exhaust smoke, and the draft in the chimney remains the same power.

Do not forget that the deflectors are designed for round pipes, which can become a problem if you have an old brick pipe with a square cross-section. In order to solve this problem, special pipes are used that act as adapters.

For chimneys with a large square cross-section, which are built for fireplace heating systems, it is necessary to use adapters in the form of spacer legs that connect the pipe and the deflector itself. These legs are made of metal strips that can be galvanized or high-quality painted.

Brick pipes require an appropriate transition with an inlet in the desired direction, which allows you to connect a round deflector and a square chimney. In other words, it is not difficult to secure this element of the chimney system in the presence of any type and shape of chimney structures.

You don’t have to buy a deflector at a hardware store, because you can make it extremely easily with your own hands. To do this, you need to calculate the size and shape of the element, after which you can begin the manufacturing process.

On galvanized steel sheet it is necessary to draw the upper and lower cylinders of the future deflector, which can be easily done using an ordinary pencil. You can cut out the necessary elements using metal scissors, which can easily cope with this task.

Once these two parts have been cut and filed, which is required to properly join the two edges of one part, you can begin to secure these edges. As a rule, a welding machine, bolts or rivets are used for this.

It’s worth noting right away that connecting a galvanized steel workpiece using a welding machine is extremely difficult, because it burns through thin metal quite quickly. It is for this reason that rivets or small bolts are most often used.

The finished cone cap must be secured to the upper cylinder of the deflector. This is done using small brackets made of the same sheet steel. The brackets are secured to the pipe using rivets. Do not forget that the brackets should be attached only to the outer side of the deflector, so as not to create additional interference in the internal part for proper air flow and smoke extraction.

A reverse type cone must be attached to the element umbrella. In addition, the assembly of all parts of the deflector must be carried out directly on the pipe itself, which will allow for high-quality installation and fastening of each individual part of the structure.

Otherwise, it is possible to connect two elements of the system poorly, which will subsequently cause a malfunction of the structure and the entire chimney as a whole. In some cases, it is simply impossible to make this design on your own.

As a rule, this happens with brick chimneys, which require high-quality adapters or stands. From this we can conclude that it is much easier, more profitable and faster to buy this inexpensive element of the system than to try to make it yourself.

It is worth recalling that only galvanized steel can be used to make the deflector, which successfully resists the formation of rust, which negatively affects the life and quality of service of such a system element.

Advantages of buying from us

- only leading brands - the catalog includes products from Krovent, Master Flash, Vilpe, TechnoNikol;

- variety of choice - several hundred items are available for order for all types of roofing;

- balanced price - we work with manufacturers directly, so the price of roof ventilation is without additional extra charges

- first-class service - customers have access to competent advice, various forms of payment, prompt delivery throughout the country.

To place an order, just add the selected product to your cart or contact our manager by phone.

Types of ventilation pipes for roofs under metal tiles

If we consider fungi intended for ventilation pipes on metal tiles, then they can be ordinary and heat-resistant. Conventional ones, as a rule, are used primarily for exhaust from the kitchen, cellar, and bathroom. Heat-resistant fungi are installed on pipes that are designed to remove combustion products from furnaces and pipes. Thus, ventilation of a metal roof is impossible without the use of fungus.

Material

To remove the ventilation shaft, structures made of several types of materials are used. In the production of ventilation pipes, plastic and galvanized steel are considered the most popular.

- Plastic products are one of the most popular ventilation parts in the home. They are often installed for a number of advantages, including corrosion resistance and a smooth wall surface. Both qualities increase the efficiency of the ventilation shaft and its service life.

- Products made of galvanized steel are elements of high strength and a good protective coating that prevents the formation of corrosion on the material.

Requirements for ventilation structures

There are different designs available on the market. Regardless of the material of production, ventilation elements with suitable properties are selected. This is necessary to increase the quality of the entire system.

General requirements:

- The number of connections between elements. The smaller this parameter, the higher the throughput of the pipe.

In addition to the number of connections, it is recommended to minimize the number of turns of the smoke exhaust duct Source en.decorexpro.com

- The smooth inner surface reduces air resistance. This increases the efficiency of ventilation.

- Sufficient rigidity of the material . In this case, the walls of the structure themselves should be thin. This combination increases throughput.

- Moisture and corrosion resistance . When the air temperature drops, condensation forms on the walls of the ventilation shaft, which begins to spoil the material. That is why designs with sustainable characteristics are chosen.

See also: Catalog of companies that specialize in ventilation.