The availability of the "Warm Floor" system has allowed homeowners to effectively use thermal energy to heat their homes. In some cases, this heating option can even replace the usual radiators for everyone. However, before creating such a system, a pipe for a warm floor is always selected. We will tell you the criteria for its selection. Read and find out which pipes are most often used, their main advantages and the most commonly used diameters.

Layed pipes of the heating system in the floor Source yut-dom-org.ru

Main features of pipes

One of the options for heating a home is the creation of water heating. A type of it is heated floors. It is also called underfloor heating. Its creation is carried out by laying the heating circuit. During its installation, tubes for heated floors are used. Lay the contour in a cement screed. This is today a popular option for heating various rooms in a private residential building.

Warm floors differ from radiator heating systems in the following ways:

- Uniform heating of air in rooms.

Heating in the floor allows you to optimally distribute the temperature throughout the entire volume of a single room. In other words, near the floor the air heats up to approximately +24°C. This temperature is optimal for human feet. At the same time, in the middle part of the room it will be approximately +22°C.

Warm floors are the optimal way to warm up a room Source sv-servisvostok.ru

- A more energy-efficient way to warm rooms at a relatively low water temperature in the heating circuit.

Underfloor heating works effectively when the coolant is heated to approximately 30-50°C. At the same time, the heated screed gives off heat over a long period of time. This allows you to reduce energy costs and increase efficiency.

- There remains more free space in the premises.

The absence of radiators under the windows in the rooms allows you to improve the interior. In addition, the premises will not have horizontal and vertical pipelines, which often spoil the design of the living space.

Before installation, always determine which pipe to choose for the heated floor. After all, this is one of its main elements. He is obliged to ensure uninterrupted operation of the underfloor heating.

Important! The pipes are hidden in the screed. Therefore, they must be durable and reliable. After all, a person will not be able to visually determine the location of the coolant leak. For this purpose, special devices are often used - thermal imagers. Pipes must be installed efficiently. Otherwise, flooding of the lower floor or basement may occur, which will lead to significant costs for repairing the entire house.

Using a thermal imager to determine the location of a leak Source wolfgroupweb.com

When creating a system, different pipes are used for heated floors - specialists will definitely help you choose which one is best. Professionals will select the best option, even taking into account a large assortment. After all, manufacturers use copper, metal-plastic, polyethylene and even stainless steel to make pipelines. Each pipe for a warm water floor has a different cost.

The most expensive are copper and stainless steel pipelines. Polymer pipes have a lower price. Therefore, they are in great demand among homeowners. Their characteristics are almost the same as those of metal pipelines.

Products made of metal-plastic and products made of cross-linked polyethylene have an optimal balance between cost and quality. These are the main options. They are more often used when creating underfloor heating. In this situation, the homeowner will still have to decide which pipe is best to use for the heated floor. Therefore, the best option is to turn to professionals. Moreover, popular products differ slightly in price.

XLPE pipes Source yandex.net

When choosing, experts take into account the characteristics of the pipes. At the same time, they always take into account the advantages of plastic pipelines:

- High sound absorption capacity - does not allow people to hear water moving through pipelines.

- Durability – pipes made of polyethylene and metal-plastic are designed to operate for 50 years.

- Complete absence of corrosion processes - rust does not appear in plastic pipes.

- Light weight – plastic pipelines have significantly less weight compared to their steel counterparts.

- Environmentally friendly - polymer materials are safe for humans, which even makes it possible to create drinking water supply systems from them.

Corrosion-resistant lightweight plastic pipelines Source energy-crimea.online

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Criteria for selecting the optimal option

The underfloor heating pipe must meet certain requirements, because it will create a reliable, durable and safe heating system. However, ordinary pipelines for cold water supply and domestic hot water cannot be used for such a heating circuit. After all, they are unable to withstand the loads of an underfloor heating system.

The diameter of the pipe for underfloor heating is of considerable importance. It is selected taking into account the installation and operation conditions of the system. Typically, products with a diameter of 16 or 20 mm are used. It is much less common to lay products with a cross section of 25 mm.

When creating underfloor heating, pipes with a diameter of 16 and 20 mm are often laid Source stroy-podskazka.ru

When choosing a pipe for a heated floor, be sure to take into account its durability. The pipeline must withstand sudden changes in pressure and temperature. At the same time, no damage should appear in it. In addition, it must withstand bacteriological and even chemical exposure.

When selecting pipes for an underfloor heating system, be sure to pay attention to their tightness. In addition, they should not oxidize. Such pipelines must also be flexible. The master should bend them without difficulty. At the same time, they must not crack. In addition, no kinks should occur at the bending points.

The pipeline for a heated floor must bend easily Source gallery.profi.ru

Important! Cast iron pipes do not meet the listed criteria. Therefore, they are not used to create underfloor heating. However, pipelines made of stainless steel, copper, polyethylene and polypropylene meet these requirements.

Many manufacturers produce such products. Therefore, when choosing a pipe for a warm water floor, specialists will help you figure out which one is best from the available range, taking into account specific operating conditions. You should always contact them so as not to make mistakes when purchasing products.

Calculation of the required quantity

According to SNiP, pipe consumption per 1 m2 is 5 m. But this is an average figure. More accurately, the number of pipes can be calculated using the formula:

L = S/P*k+(K*2) , where:

- L—contour length in m;

- S is the area of the room in m2;

- P - laying pitch in mm (optimal - 150 mm);

- k is the coefficient of elongation of the heat pipe (ranges from 1.05 to 1.3);

- K is the distance to the collector in m.

To get the overall result, you need to add up the length of all the contours.

The calculation of a pipe for a “warm floor” can also be done using the online calculator, which is located here.

For lazy Internet users, here is a cheat sheet where the corresponding calculations have already been carried out.

| Pitch, mm | Pipe consumption per 1 m2 in linear m. |

| 100 | 10 |

| 150 | 6,7 |

| 200 | 5 |

| 250 | 4 |

Pipe products made of cross-linked polyethylene

A large number of manufacturers make pipelines from cross-linked polyethylene. It is designated PE-X. This is an ethylene polymer. Its molecules are cross-linked. Tubular products made from it are relatively new products.

The material is distinguished by a three-dimensional thermally stable structure consisting of elongated hydrocarbon molecules. Thanks to its cross-linked molecular lattice, cross-linked polyethylene is able to withstand significant temperatures for long periods of time. Therefore, pipes made from it are used in floors during the creation of heating systems.

Coils of polyethylene pipes Source tdrodnik.rf

Steam and waterproofing

When using the “wet” method of installing heated floors on floors, if the architectural and construction part of the project does not provide for vapor or waterproofing, it is recommended to lay a layer of glassine over the leveled floor to prevent the flow of cement milk through the floor during pouring the screed, as well as to avoid the formation of condensation between the insulation and the concrete base.

If the project provides for an interfloor vapor barrier, then additional waterproofing is not necessary.

In wet rooms (bathrooms, lavatories, showers, etc.), in addition to the vapor barrier under the insulation, waterproofing is installed in the usual manner on top of the heated floor screed.

Many suppliers of underfloor heating system elements recommend laying a layer of aluminum foil on top of the insulation layer. Ready-made foil-coated thermal insulation mats and slabs are also produced.

In cases where heated floor pipes are installed in an air gap (for example, in floors along joists), foiling the thermal insulation makes it possible to reflect most of the radiant heat flow directed downwards, thereby increasing the efficiency of the system. The same role is played by foil when constructing porous (gas or foam concrete) screeds.

If the screed is made from a dense cement-sand mixture, foiling the thermal insulation can only be justified as additional waterproofing, since the reflective properties of the foil cannot manifest themselves in this case due to the absence of an air/solid boundary.

It must be borne in mind that the layer of aluminum foil poured with cement mortar must have a protective coating of polyethylene film, otherwise, under the influence of the highly alkaline environment of the cement mortar (pH = 12.4), the aluminum will quickly collapse.

Video description

It is recommended to watch the video about the molecular memory of pipes:

There are three common types of cross-linked polyethylene pipelines. They differ in the degree of crosslinking. It is always taken into account when deciding which pipes are best to use for a warm water floor:

- PE-Xa – a fairly high degree of cross-linking through the use of peroxide technology. In other words, polyethylene is heated under high pressure while simultaneously using peroxides. The technology makes it possible to obtain a material with a durable structure. The maximum temperature it can withstand is 95°C.

- PE-Xb – medium degree of crosslinking due to the use of silane technology. The starting material is chemically attacked when silane is used.

- PE-Xc – the lowest degree of cross-linking achieved by irradiating polyethylene with electrons.

All three types of pipelines are used to create underfloor heating. However, PE-Xb and PE-Xc products are more often used. The reason for this is their lower price and greater elasticity.

Pipe made of cross-linked polyethylene with high elasticity Source vodoprovod55.ru

Installation

As you know, pipes are installed in the floor (that is, simply laid), and then filled with concrete mortar. If the pipes are damaged, the surface will have to be cracked.

The installation process goes like this:

- You should draw a layout diagram on graph paper; first, draw the location of large objects;

- in another part of the proposed room (on the diagram) draw the arrangement of pipes in a “snake” or “spiral”;

- if the pipes do not hold their shape, they are often fixed with clamps; if the pipes are PP, then their length in the circuit should be 60 m. If this recommendation is not followed, the water will cool very quickly and the floor will not sell to the expectations;

- if the room is large, then it should be divided into sectors, with a separate circuit laid in them. If it retreats 15 cm from the walls, then the distance between adjacent contours should be 35 cm.

Metal-plastic pipe

Metal-plastic pipes are often used for floor heating. After all, they bend easily. However, they do not need to be heated. Thanks to these properties, pipelines are quickly laid.

Manufacturers produce metal-plastic in coils up to 50 m long. This is enough to create underfloor heating systems in the rooms of private houses without the use of connecting fittings in the screed. Moreover, homeowners have the opportunity to order coils with pipes from 80 to 90 m in length.

Plastic pipelines are three-layer products. Their inner layer is made of cross-linked polyethylene. At the top they are protected by PEX polymer. It withstands mechanical stress. In the middle there is an aluminum layer of varying thickness depending on the manufacturer.

All layers are connected using reliable glue. The durable three-layer structure allows the pipes to withstand temperature changes and eliminates the appearance of deposits and corrosion. The service life of such pipelines is about 50 years.

Requirements for the screed

The heated floor screed must have sufficient density to reduce heat loss from the pipelines, and also have sufficient strength to withstand loads on the floor.

As a rule, the screed is made from cement-sand mortar or concrete using a plasticizer. The plasticizer allows you to make the screed more dense, without air inclusions, which significantly reduces heat loss and increases the strength of the screed. However, not all plasticizers are suitable for this purpose. For heated floors, special non-air-entraining plasticizers are produced (for example, shown in Fig. 6

plasticizer "Silar" or Kilma Therm), based on fine flaky particles of mineral materials with a low coefficient of friction.

Most other plasticizers used in construction are air-entraining, which will result in a decrease in the strength and thermal conductivity of the screed. As a rule, the plasticizer consumption is 3–5 liters per m3 of mortar or concrete. The minimum thickness of the screed above the pipes should not be less than 30 mm.

In the case when it is necessary to make a 20 mm screed, an additional layer of reinforcing mesh must be laid over the pipes. Even a reinforced screed should not be thinner than 20 mm. The reasons for the appearance of cracks in a heated floor screed may be low strength of the insulation, poor compaction of the mixture during installation, lack of plasticizer in the mixture, or too thick a screed (shrinkage cracks).

To avoid cracks, you should adhere to the following rules:

) at the rate of 1–2 kg of fiber per 1 m3 of solution. For power-loaded floors, steel fiber is used for the same purposes.

Rice. 6. Plasticizer "Silar"

Rice. 7. Polypropylene fiber

After pouring, the screed should gain sufficient strength. After three days under natural hardening conditions (without heating), it gains 50% strength, and in seven days – 70%. Full strength gain to the design grade occurs after 28 days. Based on this, it is recommended to start the “warm floor” no earlier than three days after pouring. It must be remembered that filling the heated floor with a solution must be done by filling the floor pipelines with coolant with a pressure of at least 3 bar.

In table 6

Recipes of recommended solutions for installing screeds of heated floors installed using the “wet” method are given.

Table 6. Compositions of cement-sand mortars

| Brand of solution | Composition of the solution in parts by weight | ||||

| Water | Cement1 | Sand2 | Fiber PP3 | Plasticizer3 | |

| 150 | 0,55 | 1 | 3 | 0,005 | 0,012 |

| 200 | 0,48 | 1 | 2,8 | 0,005 | 0,012 |

| 300 | 0,4 | 1 | 2,5 | 0,004 | 0,011 |

Notes: 1Stamps no less than 400. 2Piece no less than 0.5 mm. 3Recommended use.

Copper pipe

Copper is a ductile, strong and durable material. Unfired pipelines from it are produced in coils. They simply bend even without a special tool. However, professionals use pipe benders.

Copper has high heat transfer and corrosion resistance. At the same time, pipes made from it are not often used when installing underfloor heating, since they are sold at a high price.

When choosing which pipes are best to use for a warm water floor in a private house, every specialist will say that copper pipelines are an excellent option if the allocated budget allows them to be used. They will withstand heating up to +115°C. In addition, copper pipelines are highly environmentally friendly and have minimal hydraulic resistance.

Heating in the floor from a copper pipe Source tsm-company.ru

Special fittings are required to connect copper pipes. Soldering of products is carried out using special solder, equipment and only by professionals.

Requirements for insulation

The insulation layer in the heated floor structure reduces heat loss in the lower direction, thereby increasing the efficiency of underfloor heating (the ratio of heat flow in the direction of the heated room to the total heat flow from the underfloor heating pipes).

In addition to thermal insulation properties, the insulation must have strength that ensures the absorption of loads from the own weight of the overlying floor structure and the payload on the floor. These conditions are best met by expanded polystyrene slabs with a density of at least 40 kg/m3.

The design of the heated floor must be designed to withstand the loads set out in the table. 7

.

Table 7. Floor loads

| Purpose of the premises | Load, kg/m2 |

| Attics | 70 |

| Residential, educational, sleeping, hospital wards | 150 |

| Offices, classrooms, cabins, classrooms, laboratories | 200 |

| Dining rooms in cafes, restaurants, canteens | 300 |

| Places where there may be crowds of people | 400 |

| Archives, book depositories | 500 |

When calculating, the thickness of the insulation layer should be determined from the condition that heat loss in the lower position does not exceed 10% of the total heat flow from the pipes.

Especially for the installation of water heated floors, thermal insulation boards with protrusions for fixing the heated floor pipes are produced. Connecting the plates to each other can be done in different ways. For example, in Ecopol 20 slabs, the connection of the slabs is ensured by “fastening” the release of the polystyrene cover layer onto the adjacent slab ( Fig. 8

).

Rice. 8. “Lock” connection of “Ekopol 20” slabs

And boards such as EasyFix have a tongue-and-groove connection ( Fig. 9

).

These boards are available with or without polystyrene coating. The main technical characteristics of the Ecopol 20 and EasyFix slabs are given in table.

8 .

Rice. 7. EasyFix plate

The protrusions of the slabs are designed in such a way that they provide a pipe pitch (raster) that is a multiple of 50 mm when laying straight, and a multiple of 70 mm when laying diagonally. Methods for attaching pipes to insulation boards that do not have protrusions are described in the next section.

Table 8. Technical characteristics of polystyrene foam boards for heated floors

| Characteristics, units measurements | Characteristic value for slabs | ||

| "Ecopol 20" | EasyFix | ||

| Coated | Without cover | ||

| Thickness without protrusions, mm | 20 | 20 | 20 |

| Dimensions, m | 1.1 x 0.8 | 1.0 x 0.5 | 1.0 x 0.5 |

| Height of protrusions, mm | 18 | 20 | 20 |

| Density, kg/m3 | 30 | 45 | 45 |

| Outer diameter of fixed pipes, mm | 16 | 16; 20 | 16; 20 |

| Thermal conductivity coefficient, W/m K | 0,035 | 0,036 | 0,036 |

| Compressive strength at 10%, deformation, kPa | 190 | 300 | 300 |

| Bending strength, kPa | 200 | 500 | 500 |

| Noise absorption, dB | 30 | 23 | 23 |

Corrugated stainless steel pipe

This type of pipeline is a high-quality and relatively new product. They have flexibility, strength, and tightness. The main producers of such products are Korea and Germany.

Stainless steel pipes can withstand up to +110°C and pressure up to 50 atm. The material used is resistant to corrosion and is not attractive to rodents. This allows pipelines from it to be laid in the basement without a concrete screed.

The disadvantages of corrugated stainless steel pipes include their high price. It is more than the cost of similar metal-plastic products. In addition, during installation of such products it is necessary to additionally use a protective casing, since they cannot withstand large mechanical loads.

Corrugated stainless steel pipe Source kanalizaciya1.ru

Manufacturers rating

In addition to the characteristics, when choosing a pipe product, you need to pay attention to the brand and manufacturer. It is better to give preference to proven brands that are popular in the market.

The main and well-established manufacturers include:

- Rehau - country of origin: Germany. Specializes in the production of PEX pipes for underfloor heating and water supply, with noise-absorbing properties and an anti-oxygen barrier. The company produces products in several series, which differ in color: white, red, orange. The warranty period is 10 years, and with proper use it will work for more than 50 years. Products of this brand have high thermal insulation, strength and elasticity.

- Sanext (Italy) - produces multilayer PEX contours. They have protective properties against noise and gas penetration. The warranty period is 10 years. The permissible bending diameter is 10 cm. The company promises uninterrupted operation of the circuit for up to 50 years.

- Uponor is a Finnish manufacturer. The range is huge - metal-plastic and polyethylene reinforcement products that are not subject to corrosion and destruction under the influence of chemicals. Protective layers protect pipes from mechanical stress.

- Emmeti (Italy) - produces metal-plastic and PEX-polyethylene pipes. The company monitors the technological process, all products have quality certificates.

- Valtec is a joint production between Italy and Russia. The company produces kits for standard conditions, and has also developed fittings for non-standard premises. Kits from this brand for underfloor heating are easy to install on your own. The product is an excellent heat conductor and is not affected by chemicals.

Purchasing high-quality material guarantees efficient and durable functioning of the heated floor. In addition, with the right choice, you can create an economical and visually aesthetic floor heating system in your apartment.

Polypropylene pipe

This type of product is also often used when installing underfloor heating. These are durable products, but only if there is a reinforcing layer. Polypropylene itself is a chemically inactive material. Therefore, the pipelines are corrosion-resistant and any coolant can be transported through them.

Propylene pipes also have good thermal conductivity. Therefore, the screed will warm up quite quickly. However, the disadvantages include the difficulty of bending polypropylene pipelines. Typically, specialists for this product first heat it. However, even in this case the bending radius is quite large.

Screed reinforcement

- The reinforcing mesh in the construction of a wet heated floor is laid on top of the insulation layer. The grid performs the following functions:

- perceives tensile forces when the heated floor slab bends;

- blocks channels in the insulation layer when pipelines of other systems (radiator heating, water supply, sewerage) are laid in the floor structure ( Fig. 18

); - is a convenient frame for fastening underfloor heating pipes.

Rice. 19. Laying pipelines of other engineering systems in the heated floor structure: 1 – radiator heating pipes; 2 – floor slab; 3 – layer of insulation (expanded polystyrene); 4 – heated floor pipes; 5 – screed; 6 – reinforcing mesh.

A number of imported manufacturers supply special galvanized mesh for underfloor heating with mesh sizes of 150 x 150 mm. In domestic construction practice, masonry mesh made of reinforcing wire ВрI Ø 5 mm with a mesh pitch of 50 x 50 mm is more often used.

Briefly about the main thing

Pipe products for water heated floors must have high corrosion resistance, withstand exposure to fairly high temperatures and the pressure of the cement screed. Typically, to create underfloor heating, pipelines are used, which manufacturers produce in coils. This prevents them from being docked.

During installation work on the arrangement of heated floors, pipes with a diameter of 16 and 20 mm are most often laid. They mainly use metal-plastic, corrugated stainless and polypropylene pipelines, as well as products made of cross-linked polyethylene and copper. The first and last types of products are most often used. Although corrugated stainless steel and copper pipes are considered the best options.

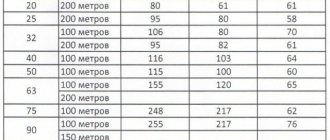

Selection of the optimal diameter

When choosing the diameter of the circuit, you should proceed from the length of the loop and the thermal conductivity of the material. Common sizes used in the construction of heated floors are 16, 20 and 25 mm.

When determining the diameter of the product, the following points must be taken into account:

- the smaller the diameter of the pipes, the higher the hydraulic resistance increases, and the level of heat transfer decreases;

- The larger the cross-section, the thicker the screed must be made, which increases the load on the floors and reduces the height of the ceiling.

Important! If the length does not correspond to the diameter of the circuit, this may lead to the hydraulic resistance exceeding the technical capabilities of the circulation pump.

With a pipeline length of 70 meters, it is recommended to take a pipe diameter of 16 mm. For a loop size of 90 meters, the appropriate cross-section is 20 mm, and for 120 meters, 26 mm.

When choosing the diameter of the product, it is necessary to take into account the level of heat transfer of the pipe material. When laying a copper or metal-plastic coil, it is better to use a contour with a cross-section of 14 or 16 mm. When using polymer pipes - 20 or 25 mm.

conclusions

As with other types of equipment and materials, when choosing a specific manufacturer, we recommend choosing European manufacturers. The fact that the manufacturer is European must be determined by the barcode and the inscription “Made in...”. Many sellers offer an Italian pipe, but cannot confirm that it was made in Italy, because... The pipe is actually produced in China, and the real homeland of the brand is Russia. And of course, if the pipe is produced in Europe, then the price for such a pipe will not be the lowest, because... quality cannot be cheap. If you compare an inexpensive German pipe and an expensive Chinese one, decide for yourself how confident you are in the real characteristics and quality of the Chinese pipe, for example, in the level of cross-linking of cross-linked polyethylene.

If we draw conclusions about the materials for underfloor heating pipes, then our experts arrange the materials in the following order, starting with the best:

- Cross-linked PEXa polyethylene with anti-diffusion layer

- Metal-plastic with an inner layer of PE-RT

- Cross-linked polyethylene PEXb,c

- Heat-resistant polyethylene PE-RT