The clock generator is usually located inside the microcontroller, with the exception of the reference frequency source, which is usually a quartz resonator.

When making a schematic diagram, it is allowed to place various text data on the diagram field: instructions about the brands, sections and colors of wires and cables that should be used to connect the elements; For instructions on the electrical installation requirements for this product, see Setup involves adjusting the gas pressure. This does not in any way affect the operation of the control unit itself, but requires caution when carrying out repair work. Boiler NAVIEN Ace-13K Turbo. DIY repairs. Part 1: Repair of a three-way mixer.

Power circuits are designated in accordance with GOST 2. As a result, a charge accumulates on capacitor C3, creating a constant voltage of about 30 V.

When making diagrams on several sheets, the following requirements should be taken into account: when assigning positional designations to elements, observe continuous numbering within the product, draw up a general list of elements. The lines are numbered, and in the free field of the diagram there are inscriptions explaining the purpose of the individual circuits. At the moment, in this regard, single- and double-circuit gas boilers of domestic and foreign production are gaining increasing popularity. Taking into account the fact that in Russia, increased voltage in the network is a common phenomenon, microwave ovens supplied to our country, as a rule, do not have a varistor installed.

I assembled the circuit for testing - it’s also working. In the exploded method of depicting the circuit, these designations should be indicated on each component of the elements, and if the circuit contains several identical elements, the contact designation can be applied only on the image of one of the elements, see Fig.

Gas boiler Navien Deluxe 16k my review.

Features and types of Navien boilers

Navien is Korean-made heating equipment, popular in Russia due to its good price/quality ratio.

Here are the main design advantages of gas units:

- the control unit is equipped with a microprocessor chip with the function of protecting the automation from power surges;

- automatic maintenance of operating mode, many settings;

- long service life;

- can operate on natural and liquefied gas;

- coolant pressure is allowed to drop to 0.1 bar without equipment failure;

- the system does not freeze in the event of gas interruptions. In a normal situation, when the temperature drops to +5, the burner automatically turns on. If ignition is impossible, the forced circulation pump operates, this prevents the coolant from freezing;

- easy, intuitive adjustment of modes.

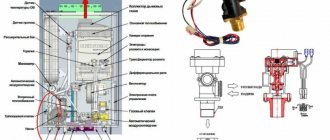

Diagram of the Navien gas boiler.

The power of Navien gas boilers varies in the range of 11-37 kilowatts. The brand’s assortment includes wall-mounted (what are gas boilers for heating a house), floor-standing (floor-standing gas boilers for heating a house), condensing models (what is a condensing boiler), with open and closed chambers, as well as diesel units. Wall-mounted boilers are equipped with corrosion-resistant heat exchangers made of high-carbon stainless steel.

Gas boiler Navien Deluxe 10k - review after 3 years. Identified pros and cons.

The choice in favor of the Navien DeLux 10K gas boiler in our house was made not by us, but by the developer of the cottage community in which we live. That’s why we got it from the very beginning, new, like the house itself.

I would prefer another brand of boiler, with a more successful design (for example, Proterm Gepard). I’ll tell you why later. But in general, we must conclude that the Navien showed its best side in operation and, on the whole, did not disappoint.

Power and area of the house

According to the technical data, the double-circuit gas convection boiler “Navien DeLuxe 10K” with a power of 10 kilowatts is designed to provide a heating area of 100 square meters. Efficiency – 91.2 percent.

Double-circuit means that the boiler heats the house and provides its residents with hot water.

Naturally, we initially had big doubts that the boiler’s power would be sufficient to efficiently “pump” the entire house with heat (total area - 130 square meters). But, fortunately, they were not justified at all. Firstly, because we live in the very south of the European part of Russia, and insulation - polyurethane foam - is pumped into the space between the brickwork.

Secondly, because immediately after connecting the gas, the same master with whom we entered into a contract for servicing the gas boiler, for a small fee, reconfigured the Naviena DeLux 10K to operate with twice the power.

And even during periods of prolonged frost, the boiler easily copes with ensuring a comfortable temperature in the house. Boiler installers shared that Naviens of various brands already occupy more than half of the total volume of all boilers in their practice. Due to its price, I guess.

First about the pros

- Navien is inexpensive compared to many other models. I suspect that this factor became the most decisive for our developer when he made his choice of a gas boiler.

- The boiler is very compact, weighs little, requires very little space for placement - in a corner, on the wall.

- Insensitive to changes in water and gas pressure; short-term power outages. It also works quietly on low gas (which is not uncommon in new villages). Even in the hottest summer period, when everything is diligently watered and the water pressure drops noticeably, the boiler works properly, continuing to regularly provide hot water.

- Economical! This is definitely a big plus for Navien: gas bills are very pleasing and don’t break any holes in the family budget.

Ineffective smoke removal system. In the already mentioned “Proterm” it was done much more competently: it is a pipe of a smaller diameter inserted into a pipe of a larger one. One pipe is “in”, and the other is “out”, and everything is simple, civilized and good! In “Navien” there is an ugly corrugation at the top. If you hang the cauldron in the kitchen or in some other prominent place, you will have to rack your brains about how to “drape” it.

Within a year, water began to leak through the make-up tap; I had to change it. Another year and a half later, water began to ooze along with air through the auto-air vent. The primary heat exchanger did not last up to three years. The repair is not very expensive, but I would still like greater durability of the components and parts. A little noisy when working. When operated in heating mode, the gas burner switches on/off quite often, and this action is accompanied by quite noticeable noise. If the boiler hangs in a practically non-residential room, such as a “boiler room” or “storage room” (like ours, for example), then this, of course, is not important and does not cause any inconvenience. But whoever has it hanging in their kitchen, I don’t think it’s very nice. Therefore, I definitely list this property as a minus.

In general, our Navien DeLux 10K boiler has been performing its functions well for three years. Its heating cycles are fast, the supply of hot water is always stable, and it is economical and energy efficient.

But this version of the boiler, of course, does not reach five points. And above all, due to the insufficient reliability and durability of its parts.

In general, the “service life” of a gas boiler is an elastic concept. After all, the body does not break, and components and parts can be changed even ad infinitum. Four points out of five, “Navien DeLuxe 10K” is one of the successful budget versions of a gas boiler.

Double-circuit means that the boiler heats the house and provides its residents with hot water.

Troubleshooting

Let's look at how to fix the main problems with a gas boiler. If error 01 occurs, you need to carefully inspect the pump, check the condition of the impeller and electrical unit, clean the dirt filter, and also remove air from the system.

To eliminate error 02 of the Navien boiler, perform the following steps:

- bleed air from the system;

- measure pressure;

- check the resistance on the pump coil, make sure there is no short circuit;

- check the position of the distribution valve, open if closed;

- clean the sensor flag.

Error 03 of the Navien boiler is often displayed if the flame sensor is clogged. It should be cleaned. Gray deposits on the electrode are removed with fine-grain sandpaper. When error 5 appears, you need to check the condition of the circuit section between the sensor and the controller; in case of serious problems, replace the sensor. In case of error 10 of the Navien boiler, you need to :

- check the serviceability of the fan, if repair is impossible, replace it;

- check the contacts in the tubes of the measuring device;

- clean the chimney.

If error 13 appears, replace the sensor. The noise in the system may disappear after flushing the heat exchanger; sometimes it needs to be replaced. The taps should be opened completely, and it is recommended to lower the coolant temperature.

Another important point in servicing a Navien gas boiler: how to refill the system after draining. Such a need may arise after repair/replacement of parts of the system or if the coolant was drained while the house was empty.

Causes of malfunctions

To solve a problem with a gas boiler, you do not always need to contact a service center. Most often, errors occur due to three factors:

- ignition does not function;

- problem with the coolant;

- no fuel supply.

Before planning to call a technician or calculating the cost of repairs, it is worth looking for the cause of the specified malfunction. There may be a failure of the signal indicating the normal flame level in the system igniter. Other possible faults:

- the ionization sensor has failed;

- the gas supply valve is closed;

- errors in the operation of the grounding circuit.

There are several factors for the occurrence of errors in the boiler.

It is best to start the inspection with the flame sensor. The part must be clean and must not be allowed to contain deposits or dirt. If there is contamination, you need to clean the sensor and then try to turn the system back on. It is also necessary to check the grounding connection and the position of the valve at the gas inlet to the equipment.

Navien Ace gas boiler series

Navien boilers of the Ice (Ace) series are a family of gas double-circuit units manufactured by the South Korean company KyungDong NAVIEN.

They provide heating to the home and at the same time supply it with hot water. A special feature of Navien equipment is its specialization in Russian conditions, climatic and technological.

It is possible to work at low pressure of gas and water, resistance to changes and sudden surges in pressure.

In addition, there is a protective system that compensates for voltage drops in the power supply network up to 30%.

In addition, the company’s pricing policy is such that the cost of Navien boilers is approximately 2 times lower than European equipment of the same power. Such advantages are highly appreciated by users; the demand for Navien units is stable and gradually growing .

Boiler malfunctions

All modern boilers, regardless of the type of power supply and method of connection to the heating system, have approximately the same design and structural modules similar in purpose. Therefore, we can consider general cases of boiler failure and repair, without paying attention to their type. In these identical situations, independent intervention is possible. In specific cases, qualified service is required.

Different boilers, depending on the version, include all or some of the following modules:

- Power supply system and its supply.

- Controls.

- Protection systems.

- Automatic operation control unit.

- Connection system to the heating system.

- The boiler itself and its actuators.

Practice constantly confirms the theory that any, even the highest quality equipment is not insured against breakdowns during operation, especially during the heating season. Heating boilers are no exception. The main reasons for their failures are as follows:

- Poor design and installation of the system.

- Incorrect operation.

- Damage to shut-off valves.

- The pressure in the heating system is lower than specified.

- Heat exchanger contamination.

- Triggering of the draft sensor due to a clogged chimney.

- Solenoid malfunction.

- Power supply failure - a drop in gas pressure at the boiler inlet, a decrease in network voltage or its absence, etc.

In accordance with reliability theory, operational failures leading to repairs are classified for boilers according to several criteria.

Classification of breakdowns

- Intermittent and final. Intermittent failure is one of the most difficult to diagnose. It appears when any parameters go beyond the required range. For example, when the mains voltage drops to 160-170 V, most gas heating boilers stop starting, and after the voltage is restored to 180-220 V, the system resumes operation.

- Secondary and primary, dependent and independent. The name speaks for itself. A secondary failure will certainly occur with a primary (independent) one, and for a dependent one, the probability of its occurrence with a primary (independent) one only increases.

- Gradual and sudden. The former arise during operation and are a consequence of wear of structural elements, accumulated fatigue of materials and changes in their properties. Sudden failures occur unexpectedly, without any apparent reason for their approach, and are characterized by an immediate cessation of operation.

- Non-obvious (hidden) and obvious (explicit). These failures differ in ease of detection - identifying a leaking heat exchanger is much easier than changing the parameters (capacitance) of the condenser.

If the boiler begins to heat water longer than usual, and its operation begins to be accompanied by extraneous sounds, or if other visible signs of malfunction appear, immediate diagnosis and repair are necessary. There is no need to wait until the unit fails completely - if repairs are not carried out in a timely manner, the boiler will eventually stop working.

Such signs may indicate the beginning of a malfunction of the heating element, possibly due to improper use of the boiler or its overload. But there may be other reasons.

What models and what power exist?

The Ace series included the following models:

- Ace Atmo

- Ace Turbo

- Ace Turbo Coaxial

Atmo models had an open (atmospheric) combustion chamber and required an effective smoke removal system.

Their efficiency was noticeably lower, but this was successfully compensated for by installing a copper heat exchanger, which has greater productivity compared to stainless steel units.

The Turbo model range was distinguished by a closed combustion chamber design and turbocharging - a special fan supplied fresh air, increasing combustion efficiency and increasing draft in the smoke removal system.

A Korean or European (coaxial) chimney model was used to remove gases.

The first option consists of two separate pipes - one for air supply, the other is a chimney.

A coaxial chimney is a “pipe-in-pipe” system, where a chimney is installed inside and an air supply pipeline is installed outside.

The power of all models was 10, 13, 16, 20, 24, 30 kW, etc. The most popular models are 16k and 24k, optimally suited for servicing a private home. .

Specifications

The technical characteristics of almost all models (with the exception of the Atmo series) are similar and differ only in the power of the unit.

It corresponds to the heated area - 13 kW boilers are capable of serving 130 m2, 24 kW - 240 m2, etc.

For ease of consideration, the main parameters of Ace series boilers should be summarized in a table:

| Parameter | Ace | Ace coaxial | Ace Deluxe | Ace ATMO |

| Boiler type | Gas wall-mounted double-circuit | |||

| Combustion chamber type | Closed | Open | ||

| Efficiency | 91,2 % | 86 % | ||

| Thermal power of the boiler according to the air conditioner | 9-16 kW | |||

| Primary heat exchanger material | Stainless steel | Copper | ||

| Coolant temperature in the heating system | 40°-80° | |||

| DHW temperature | 30°-60° | |||

| Control type | Electronic | |||

| Mains voltage | Single phase, 230 V, 50 Hz | |||

| Weight | 28 kg | 26 kg | ||

| Case dimensions | 440x695x265 mm | 430x720x340 mm | ||

The difference in performance is due only to the type of combustion chamber and all related design features.

It should be noted that the 16 kW models are a complete analogue of the 24 kW models with reduced software capabilities, which provides a large margin of safety for the units.

Advantages and disadvantages

The advantages of Navien Ace boilers include::

- The optimal combination of price and quality.

- Environmentally friendly process.

- Simplicity and convenience of adjustment and configuration of operating modes.

- Adaptation to Russian conditions, ability to work on unstable gas pressure, water pressure, and power supply voltage.

- Simultaneous provision of heating and domestic hot water.

- Long service life without service checks.

The disadvantages of Navien Ace boilers are::

- Dependence on the availability of electricity, gas and water.

- High noise level.

- Only original spare parts are suitable for repairs.

- The structure is not resistant to hard water.

Where is it used?

Gas double-circuit boilers Navien Ace series are designed for organizing heating and hot water supply of residential premises or offices of the appropriate area.

This limits the scope of use of these units, although they can be installed in any premises. The main task is to ensure that the serviced area matches the capabilities of the equipment and the availability of all the necessary resources - gas, electricity and water (coolant).

What's included

The unit components include the following elements:

- Heat exchangers (primary and secondary, the primary can be made of copper or stainless steel, the secondary can only be made of stainless steel).

- Remote control panel.

- Circulation pump.

- Expansion tank.

- Three way valve.

- Safety valve.

- Traction sensor.

- Automatic air vent.

- Connecting pipelines, other structural elements.

In addition to the main elements, the boilers are equipped with mounting brackets and other additional parts.

Navien boiler design

Gas convection boilers

Let's look at how the Navien boiler works, its main elements and operating principle. The company produces wall-mounted turbocharged and atmospheric gas convection devices, as well as condensation devices.

The Navien Ace Turbo series offers dual-circuit models with power from 13 to 40 kW, running on liquefied and natural gas. In devices from Navien 13K, Navien 20K to 30 kW with the Navien Deluxe Coaxial marking, the European smoke removal technique is used.

One coaxial pipe is installed at the top of the housing. Boilers with a power of 35 and 40 kW with the “Korea” prefix use the Korean smoke removal system. In the center there is a pipe through which combustion products are removed, and on the right there is a pipe that delivers air to the combustion chamber.

A flue gas collector is connected to the chimney from below. Below it is a tubular heat exchanger made of stainless steel with increased resistance to corrosion. Below is a modulating burner, which receives fuel from the gas valve, and ignition and ionization electrodes.

At the bottom there is a fan with a modulated turbocharging system, which regulates the volume of oxygen supplied to the combustion chamber depending on the intensity of combustion. This allows the gas to burn completely, thereby increasing the efficiency of the device.

The electronic control board is located vertically on the right. In the upper left part there is a rectangular expansion tank with a volume of 8 liters. Under the tank there is a circulation pump with an automatic air exhaust system.

Turbocharging of a heating boiler

There is a pressure gauge located at the bottom of the pump, which is brought out. To the right of the pump, a secondary heat exchanger is vertically mounted to provide domestic hot water. A three-way valve is attached to the pump, and underneath it is a heating water filter.

On the left, a pipe emerges from the heat exchanger through which hot water from the boiler flows into the heating system. Temperature and coolant flow sensors are installed on it; it comes out from the bottom first on the left.

To the right there is a return pipe on which there is a safety relief valve, which releases excess water when the heating fluid pressure reaches too high. Next is the hot water outlet, the cold water supply from the water supply and the gas inlet.

From the outside, the boiler is closed with a metal casing with a transparent round glass for a pressure gauge. The kit includes a remote control panel with a built-in temperature sensor and LCD display. It sets the desired temperature, operating mode and priority for heating or hot water supply, and also displays error codes in case of malfunctions.

The design of Navien Ace Atmo mounted atmospheric devices is slightly different. Here are four dual-circuit models from Navien 13K to Navien 24 kW. In them, the primary heat exchanger is made of copper, and the secondary one is made of stainless steel.

Equipped with an automatic system that reduces the burner power by up to 30% as the coolant heats up. This reduces the load on the heat exchanger, thereby extending its service life.

At the top there is a flue gas collector with a draft separator and one chimney. Oxygen enters the open combustion chamber naturally from the room where the boiler is located. A round expansion tank is mounted on the rear wall. The control board is located on the front wall.

Expansion tank for Navien boilers

The modern analogue of Navien Smart Tok is available in configurations from low-power Navien 13K and Navien 16K to 35 kW. They are equipped with a touch screen and a control panel at the bottom of the case. You can control the boiler using a smartphone anywhere in the world if you have Wi-Fi and the Internet. To do this, you need to install the application from the Navien website on a smartphone with the Android operating system.

Gas condensing boilers

Navien NCN condensing models are available in three configurations for 25, 32 and 40 kW. Their main difference is the presence of a highly efficient condensing heat exchanger. It allows you to use the latent heat of water vapor that is formed in the flue gases during combustion. It is located in place of a conventional heat exchanger. To the right of it there is a chamber for pre-mixing the gas-air flow.

It has built-in weather-dependent automation, which allows you to maintain the required temperature in the room regardless of the weather. To set it up, you need to install an external temperature sensor connected to the device outside. Primary and secondary heat exchangers are made of stainless steel. It has the ability to smoothly regulate the temperature of radiators and hot water.

The Navien NCB series of condensing devices is distinguished by the presence of a touch screen at the bottom of the housing. Has an ECO operating mode that saves water and electricity. A correctly installed and configured condensing boiler allows you to use gas more economically.

Floor-standing diesel and gas models

Floor-standing diesel models are represented by two series LST and LFA. The body has an elongated rectangular shape. Below is the coolant inlet from the heating system. The lower part is occupied by the combustion chamber. The nozzle from the burner enters into it on the side. A little above the injector there is a fuel pump, a photocell and an ignition transformer. Next is a diesel inflatable burner, in the upper part of which there is an air intake hole.

Smoke pipes extend upward from the combustion chamber. They are completely immersed in the flow of heating fluid. A tubular hot water heat exchanger is wound spirally around the chimneys; cold water enters it from below, and heated water comes out from above. At the very top there is a muffler and a smoke exhaust pipe.

A control unit is mounted in the upper front part, to which a remote control panel is connected. Conveniently, the pipes for connecting to the heating circuit are located on both sides, which simplifies installation into the system.

The device is equipped with a fuel filter with replaceable cartridges. Models marked “KR” have a heating element built into the nozzle. It heats the fuel, thereby increasing its fluidity and facilitating ignition. This is especially true during the cold winter period, when the viscosity of the fuel is increased.

Floor-standing boiler Navien GA series

Diesel boilers are well suited for economically heating a private home, since the price of liquid fuel is lower than that of solid fuel and gas. The gas floor models GA and GST have exactly the same device. Only instead of a diesel one there is a pressurized gas burner installed.

Device

The main design element of Navien Ace boilers is a primary tubular heat exchanger connected to the combustion chamber.

At the top there is a chimney connected or combined with an air supply pipeline. On the left side of the body there is an 8-liter expansion tank, under which a three-way valve and circulation pump are installed.

It ensures the movement of coolant and hot water through the system . Passing through the heat exchanger, the coolant receives a high temperature.

Then, using a three-way valve, a cold stream is added to achieve the desired system temperature. , the flow is removed from the boiler and sent to heating devices - radiators, convectors, etc.

Join the conversation

Data about the elements must be recorded in the list of elements, see. They are misers and don’t want to give anything.

Automation and electrical equipment circuits are performed in a spaced manner, that is, circuits containing many contactors, relays and various contacts. Initial installation and power control circuit This circuit performs a general reset even if for any reason the supply voltage on the microcontroller exceeds the permissible limit.

Serial numbers are assigned in accordance with the sequence of arrangement of elements or devices on the diagram from top to bottom in the direction from left to right. To disable this ad block, you must either log in with your account.

Subsequently, using a chain of zener diodes, it is converted into a series of stabilized voltages necessary for the operation of the control unit.

Here you will find some footwork and shines.

Det vi publicerar ska vara sant och relevant. When you press one of the buttons, a sequence of pulses passing along the scan line connected to it arrives at the corresponding response line and returns back to the microcontroller, to one of its inputs.

Due to its poor quality, the 3-way valve often breaks, as a result of which the heating stops working or cold water flows from the hot tap. Navien boiler, instructions.

Connection instructions

Installing the boiler is not difficult - you just need to install anchor bolts and hang the unit on the wall.

It is recommended to install elastic gaskets between the housing and the wall to dampen noise. Do not install the equipment on fragile or weak structures - plasterboard partitions or other similar surfaces.

You need a solid brick or concrete wall that can support the weight of the boiler (about 30 kg).

Communications should be connected to the appropriate pipes. It is necessary to carefully monitor the compliance and tightness of connections.

The main attention should be paid to connecting gas pipes. Check all connections for leaks using a soapy solution.

If there is a common chimney, separate pipeline connections are used - the air channel is led out into the street through the wall, and the smoke channel is connected to the common chimney of the house.

Coaxial chimneys are led outside through the wall, which is much simpler and more convenient for installation.

Basic malfunctions and their solutions

Malfunctions of Navien boilers are usually diagnosed independently and displayed on the display with the corresponding code. Based on a signal from one or another sensor, a message about the problem that has arisen is activated.

The most common mistakes are:

- 02. Lack/insufficient amount of water in the system. The issue can be resolved by recharging the system or replacing the flow sensor.

- 03. No flame in the combustion chamber. Indicates problems with the ignition system, or lack of gas.

- 05-06. Open circuit or short circuit of the fresh air sensor.

- 07-08. Open circuit or short circuit of the DHW sensor.

- 09. Fan failure.

- 10. Failure of the smoke removal system.

- 15. Problems with the control board.

- 16. Boiler overheating.

The solution to most problems is to replace the corresponding sensors or components, as well as to clean and remove deposits in the connecting pipelines.

Hydraulic circuit

The operation diagram of gas convection boilers shows how such a device should work. Water enters the heat exchanger using a pump, passing through a heating sensor. If its temperature is lower than the one set in the settings, the gas valve supplies gas to the burner and the ignition transformer produces a spark using electrodes.

The thermal energy generated from combustion is transferred to the heat exchanger and heating fluid, which is already distributed through the radiators in the house. In hot water priority mode, the three-way valve is switched and the coolant is redirected to the secondary heat exchanger.

Let's look at how a liquid fuel device works. Here is a step-by-step description of its hydraulic circuit:

- The fuel enters the burner, where it is filtered, preheated and supplied to the nozzle.

- Using a nozzle, fuel is sprayed into the combustion chamber and ignites there due to a spark from the ignition transformer.

- The heat generated from combustion is transferred to the walls of the combustion chamber and chimneys, from which the coolant is heated.

Navien boiler heat exchanger - The heated liquid transfers energy to a tubular secondary heat exchanger through which clean domestic water flows.