The Arderia gas boiler is a popular equipment for arranging heating and hot water supply systems. A manufacturer from South Korea produces two types of boilers, bithermal and with two heat exchangers. The equipment is characterized by reliability. To ensure safety, a pump with a dry rotor is used. This prevents blockages and avoids water contact with the engine. Any equipment can one day fail and the error codes of the Arderia gas boiler will help to find out the cause of the malfunction.

Who is the manufacturer

The ARDERIA boiler brand appeared on the Russian market relatively recently, 12 years ago, then a joint Russian production was created with the South Korean company DAYSUNG SELTIC, first in the form of an OEM project with adaptation to Russian heating equipment, then the SAUDI CERAMIC line and Bulgarian ELDOM were added. and Italian "ELBI".

In 2015, the ARDERIA company in Russia expanded with new production facilities, a logistics and support technical complex with a modern laboratory, all of this is located at 6.5 thousand. m2 in the Krasnodar village of Enem.

Design Features

Gas appliances from Arderia are fully adapted for Russian heating systems. For stability and comfort, the following elements are provided:

- The most common cause of boiler breakdowns is power surges. The manufacturer has equipped the device with a voltage stabilizer. Their stability is maintained in a network with voltage from 150 to 285 volts.

- The reducer and gas valve maintain the burner operation in the event of a drop in gas pressure.

Specifications

The Arderia line of gas boilers is presented with one or two circuits with a power from 10 to 40 kW. They are capable of heating a house with an area of 60 to 400 m2 and preparing hot water for a family of 4-6 people. The units integrate well into Russian engineering networks, although to protect electronic boards, it is recommended to install stabilizers along the electrical line.

Arderia boilers are energy-efficient devices, the efficiency reaches 90.5-91.7%. This is ensured by a modern thermal process and the use of auxiliary equipment: a DC blower fan and a centrifugal circulation pump.

Design characteristics of ARDERIA devices:

- Heated area, from 60 to 400 m2;

- Dimensions (WxDxH), 460x205x700 mm.

- Weight, from 23 to 26 kg.

- Efficiency, from 90.5 91.7 to% 91.1 90.4 91.3 91.7.

- Useful thermal power, 10 to 400 kW.

- Hot water productivity, at a temperature difference of 25 C 8.7 to 23.3 l/min.

- Minimum/maximum coolant pressure is 3/10 bar.

- Electrical power consumption, from 110 to 155 W.

- Coaxial chimney internal/external diameter 75/100 mm.

- Expansion tank volume, 5.3 l.

Price range

The cost of Arderia gas boilers is significantly lower than that of similar devices made in Europe.

For a Russian buyer they cost 23-36 thousand rubles . The price of the unit depends on its power and additional functions. It must be taken into account that the chimney and remote control devices, room thermostat, etc. sold separately.

IMPORTANT!

You should not skimp on warranty service. The danger of being left without heating in winter is much more serious than the costs of concluding a warranty agreement.

Arderia gas boilers appeared on the Russian market relatively recently. Most users do not yet know about them, although a considerable number of units are already in operation.

They demonstrate stable operation, efficiency, and resistance to external loads . Self-diagnosis prevents boilers from malfunctioning; the built-in voltage stabilizer corrects fluctuations in the network. The quality and low cost of Arderia boilers allow them to take their rightful place among alternative options.

Design and principle of operation of Arderia boilers

The operation of the units is fully automated and has several levels of protection. The gas boiler has two heat exchangers on the heating circuit made of copper, and in the DHW system - made of steel.

The first main heating circuit, water is supplied through the boiler by a centrifugal circulation pump, which is controlled by temperature sensors in the apartment or outdoors, with weather-dependent automation. They give a signal to increase/decrease the speed of rotation of the pump impeller and, accordingly, the speed of movement of heated water along the heating circuit. It must be equipped with a high pressure relief valve and an expansion tank.

The second circuit begins to operate when the hot water tap on the mixer is opened; in this case, the DHW heat exchanger has heating priority if a three-way valve is installed in the circuit.

Flue gases obtained from burning fuel in the furnace enter the central barrel of the coaxial chimney; air is sucked through the outer ring by a blower fan onto the burner distribution nozzle. Moving along the hot central pipe, the air is heated through the wall by the exhaust gases, which increases the efficiency of the equipment and, accordingly, increases the efficiency.

Operating principle

The Arderia gas heating boiler has two varieties: it can have one bithermic heat exchanger or two radiators. The first type is distinguished by the fact that water is simultaneously heated for both water supply and heating.

The second type consists of two nodes. They are each heated separately. One radiator is made of copper, the second is made of stainless steel. Water circulation occurs using a pump. The removal of combustion products is also forced. This happens with the help of a special fan.

The control of such gas boilers can be either electronic or remote. The remote control is always sold included.

All Arderia gas heating boilers have a number of features, which include:

- this equipment is fully suitable for Russian heating systems;

- boilers have a special voltage stabilizer, which helps the device operate smoothly even during power surges;

- boilers have a gearbox that stabilizes operation when gas pressure drops;

- Arderia gas heating boilers are practical, stylish and of high quality.

The operating principle of these boilers is as follows:

- first of all, you need to set the required temperature using the remote control;

- the boiler turns on automatically using a temperature sensor and operates until it reaches the set parameters;

- after this, the sensor turns off the boiler;

- as soon as the temperature drops by 15 degrees Celsius, the sensor turns the boiler on again.

The pressure in the boiler is constantly regulated by an air valve, as well as a gas flow sensor.

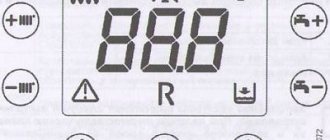

Arderia error codes

The boiler has a modern diagnostic system for the current state of the unit, with error codes displayed on the operating panel. All errors are marked with the letter A followed by a number that characterizes the cause of the failure. Using the factory operating instructions, the user can independently figure out why it is not working and what needs to be done to repair the boilers.

Arderia boiler errors:

- A2 - low fan rotation speed, debris may have gotten under the impeller.

- A3 - malfunction of the feed pump, perhaps debris has gotten under the centrifugal wheel, bad contacts in the wiring. Possible error in the operation of the temperature sensor. If the primary device is working properly, the pump will need to be replaced with a new one.

- Error A4 - the overheating sensor has tripped: there is no coolant circulation, the three-way valve is faulty, the flow sensor is faulty.

- Error A5 - low pressure in the heating circuit: air lock, break in the heating circuit, circulation pump does not work, valves on the heating line are blocked.

- Error A6 - malfunction in the ignition system: low gas pressure, gas shut-off valve is faulty.

- A7 - a problem with the control valve; there may be a failure in signal transmission from the primary sensors.

- A9 - the temperature in the heating circuit is below 5 C, you will need to start it manually.

- AA - boiling water in the heating circuit or DHW heat exchanger; most likely there is no circulation through the heating system or the pipe surfaces are clogged with scale.

Summary

In this article we looked at the most common cases when the boiler does not turn on or ignite. No one anywhere on the Internet will definitely tell you why your boiler won’t turn on; this requires at least an external inspection. This material will help you get acquainted with possible situations in general and is written on the basis of our statistics over several years.

If there is a malfunction, you need to determine the error and read the boiler operating manual. Also, for many boiler models, error descriptions with recommendations are available on our website. Malfunctions can be simple, which the user can fix independently, or complex, requiring qualified assistance and spare parts. We strongly do not recommend performing any actions with the boiler if you do not fully understand its structure and principles of operation, disabling protective devices or changing the boiler’s operation circuit to restore its operation. If there is a malfunction, it must be eliminated! If the cause of the malfunction is not completely clear to you, it is better to call a specialist.

Other malfunctions and their repairs

In addition to the standard failures that occur in the Arderia device, which can be diagnosed by the electronic control board, other errors also occur, such as the clocking of the unit, when it often turns on and off, overheating of the coolant, lack of stable ignition and combustion, and others.

Frequent outages

In a heating circuit, the boiler often turns on/off due to high coolant temperatures, usually during the transitional heating period in autumn and spring. In this case, it is better to configure the device using a room thermostat.

In DHW mode, the boiler often turns off during emergency modes due to the water pressure in the municipal water supply being less than 1.5 atm. and water flow below 2l/min. If the water utility cannot ensure the operation of the water supply system according to the specified parameters of the boiler, it will be necessary to install an additional storage tank and pump in the DHW circuit.

Temperature fluctuations

Such a failure can only occur in the DHW circuit. This happens for the only reason when there is an increased simultaneous water intake from several points in the house. To eliminate the failure, residents of the house need to maintain the alternate use of hot water services or switch to an external hot water storage tank.

Boiler overheating

This failure can occur for several reasons at once. The most serious of them is scale on the internal heating surfaces. This error can only be eliminated by flushing the heat exchanger. If the boiler operates on hard water, the owner must plan such a procedure at least once every 2 years.

Also, overheating of the coolant is caused by impaired circulation in the heating circuit due to a clogged filter, closed fittings or faulty pump, which can be corrected quite quickly, including by the user.

Doesn't light up

The first reason for such a failure is low parameters in the gas network; before disassembling the housing, you need to make sure that the gas service supplies gas with parameters exceeding the minimum permissible standards.

Another common cause could be a clogged filter, boiler valve or burner. Maintenance work on gas equipment can only be performed by a gas service representative.

Strange flame color when burning

The color of the flame and flue gases directly depends on the quality of the gas and the completeness of its combustion in the firebox. With a low oxygen content at the combustion mouth, chemical underburning of the fuel occurs, and the smoke will be black or dark gray in color, and the torch will be dark yellow, cloudy, or brown. The reason is that the blower fan does not work, the air duct is clogged or the air damper is closed.

If there is a large amount of air, white flue gases will come out due to the large amount of water vapor. In this case, reduce the air supply using a damper or fan.

Water takes a very long time to heat up or there is no hot water supply at all

This problem in the DHW network is caused by the presence of scale on the inner surface of the boiler, large simultaneous water intake, and also an incorrectly selected boiler in terms of power.

For a heating system, the reason for prolonged heating may be poor circulation due to air locks, ultra-low ambient temperatures when the house has not been heated for a long time and the boiler unit’s power is insufficient to operate in peak mode.

Extraneous sounds during operation

The Arderia boiler undergoes basic adjustment at the factory; it is sent to the retail chain only if its noise background does not exceed the sanitary standards that apply in Russia. Extraneous noise during operation of a gas boiler can be created by a fan, pump and burner device, as well as when the heating circuit is aired.

If noise occurs, the boiler must be stopped urgently to conduct an inspection and identify noise sources.

Low coolant pressure

- Restart the boiler: press the Power button on the front panel, thereby turning off the boiler and rebooting .

You can also turn off the boiler from the outlet or stabilizer/UPS.

- Problems in the boiler electrical network : a common cause of many errors.

It is strictly recommended to connect heating boilers through a stabilizer (for the boiler) or a UPS; this will save you from unnecessary costs for replacing the control board.

- Low coolant pressure in the system: if the boiler pressure gauge needle leaves the green sector and turns to red), it is necessary to increase the pressure to the minimum threshold of 1 Bar

The make-up valve is located at the bottom of the heating installation, next to the connection pipe for the cold water pipe.

It opens counterclockwise until the characteristic noise of the incoming liquid appears; do not forget to close the tap in the reverse order, otherwise the pressure will creep into the reverse red zone and the relief valve will begin to operate (water will flow).

- Bleed the air

Check automatic valves installed in the heating system. For complete guarantee, bleed manually, since the air exhaust channel in the fittings regularly becomes clogged with low quality fluid and requires cleaning.

Ideally, an automatic air vent should be installed in at least 1-2 batteries on each floor.

Replacing the sensor does not require special skills: turn off the power from the boiler (remove the plug from the socket or turn off the stabilizer), then unscrew 2 screws and disconnect the sensor, assembly is performed in the reverse order.

- The boiler pump is faulty/not working correctly: the boilers are equipped with pumping devices with a “DRY” type rotor.

You can check the performance visually or auditorily, i.e. We put our hand on the pump at the moment of starting the boiler and feel it or not - rotation; also, this type of pump is very noisy.

- Pressure sensor faulty.

- Electronic board is faulty : a fault in the electronic circuit also causes an error to appear in the boiler.

Defects are identified by inspection for deformation, melting, breaks, etc.

If the cause of equipment failure is the board, contact the service center indicating the alphanumeric marking of the node.

Brief operating instructions

The first start-up is carried out by representatives of the service center, otherwise the owner will not receive a warranty for the boiler. At the first start-up, specialists perform correction of the thermal regime and provide detailed training to users on the operation of the boiler. Once the boiler is started and configured, its operation is not difficult since it will take place automatically.

From time to time you will need to monitor the operation of the boiler using the readings on the display and set the thermostat to the desired temperature in the room.

User reviews indicate that the Arderia gas boiler demonstrates high reliability during operation, while having a simple maintenance process. It also has good thermal and economic indicators, which allows you to obtain heat at the lowest cost.