Every building, from residential buildings to industrial facilities, must have a working ventilation system. Its proper installation guarantees long service life. But the quality of fresh air and the service life of the entire system will depend on how the air ducts are insulated. Let's look at how you can insulate the ventilation in your house yourself.

Air duct insulation Source ognezashita-bataysk.ru

Do I need to insulate the ventilation pipes in the attic?

Ventilation pipes in the roof and attic are insulated in order to reduce the risk of condensation: it accumulates inside the uninsulated pipe. The resulting condensate flows down the pipes, penetrating into joints and cracks, causing wet spots to form on the walls or ceilings. At sub-zero temperatures, this can cause frost to form, which reduces the internal diameter of the pipe. This occurs due to the large amount of moisture contained in warm air. During the cold period, warm air comes into contact with a cold pipe, it cools sharply, resulting in the formation of steam and then condensation. This process can be stopped by insulating the pipes.

The ventilation pipe is being prepared for insulation

Why is this necessary?

The key word is condensate. Without insulation, it will inevitably form on the inner surface of the ventilation duct and flow down the inner walls, flowing through leaky joints into the main walls and ceilings. The consequences are obvious: dampening of the walls and ceiling, the appearance of mold and their gradual destruction.

The effect of condensation on the ventilation duct itself depends on what material it is made of:

- Galvanization can be damaged if the protective anti-corrosion layer is damaged. Which, however, is inevitable when cutting sheets.

- PVC and corrugated aluminum pipes tolerate contact with moisture without any consequences.

Another trouble associated with moisture condensation is the gradual freezing of frost on the inner walls of the ventilation duct outside the warm room. Over several weeks of operation in severe frosts, the pipe clearance can decrease from 100 - 150 millimeters to zero.

Where does condensate come from?

There are two reasons for its appearance.

- Human life is associated with excessive air humidification. When washing dishes, cooking, doing laundry, even just breathing, the atmosphere is saturated with water vapor.

- Meteorologists have long used the concept of relative humidity. The higher the air temperature, the more water vapor it can hold. 100 percent relative humidity is the maximum amount of water that can be contained in the air in a vapor state. However, as soon as the temperature changes, with the same amount of steam in the air, the relative humidity will change. With significant cooling, it can exceed 100%, after which excess water will inevitably begin to condense on the surface with a low temperature. In our case, on the inner surface of the ventilation duct.

Consequences of moisture condensation in the ventilation duct.

A special case

In production, there is often a need for forced ventilation with high air flow rates. In particular, to remove harmful volatile production products, sawdust, shavings, etc.

The noise of the air and what it carries becomes a serious problem in some cases. In factory premises, ventilation insulation is often aimed not so much at combating condensation, but at banal sound insulation. The methods, however, are the same.

Negative consequences of lack of insulation

Condensation accumulating in the ventilation shaft negatively affects the ceilings. The appearance of condensation also leads to:

- Formation of rust on a galvanized pipe;

- Depressurization of the ventilation system;

- Reducing the internal part of the air duct;

- Reduced quality of air exchange;

- The appearance of moisture in floors between floors, in the middle of wall structures, etc.

Consequences of the negative impact of condensate from an uninsulated pipe

Lack of pipe insulation can lead to rapid wear and tear of the building during the cold season. Cooler temperatures will cause more condensation to form, so insulating vent pipes in cold attics and roofs is essential.

Mandatory rules

- Installation of flexible and semi-flexible air ducts is carried out in full tension.

- The air hose should not sag in any area - pressure is lost at each deflection.

- Grounding the air duct is mandatory: during operation, static electricity accumulates in the line.

- When the ventilation system operates, the air in the ducts moves in a spiral (aerodynamics), this must be taken into account during design and installation.

- Flexible air ducts cannot be used on vertical sections of the main line longer than 2 floors.

- In rooms below ground level (basements, ground floors), in contact with the ground, in concrete structures passing through floor/ceiling ceilings - only rigid air ducts.

- If the air duct is damaged during installation, it should be replaced. The same applies to the external thermal insulation coating.

- When passing through walls, adapters and metal sleeves must be used.

- When making a sharp turn, the aerodynamic properties of the pipe are reduced; the turning radius must be no less than twice the diameter of the air duct.

In what places do pipes need to be insulated?

Thermal insulation is necessary in places where there is the largest area of contact between cold air and warm air. If your house has a ventilation pipe through the wall, then it is necessary to insulate the part leading to the deflector. In private homes, another cold place is the attic. If pipes pass there, they must be insulated.

An insulated ventilation valve is created in office and industrial premises. It opens or closes access to air flows of different temperatures. The valve can heat the exhaust air, since the flaps are treated with heating elements, which reduces the risk of condensation. This method is quite expensive.

Important! To start installing insulation yourself, you need to find the place where condensation appears - the temperature dew point.

Table for determining dew point depending on % humidity and air temperature

How to calculate the thickness of insulation

The thickness of the thermal insulation is calculated according to SP 61.13330.2012 Thermal insulation of equipment and pipelines (SNiP 41-03-2003), Appendix B.2.4 and B.2.3.

When calculating, the thickness of the pipe wall is neglected, since it is small, and metal also has high thermal conductivity. The indoor temperature is assumed to be 20 °C, outdoor temperature is the minimum winter temperature, relative humidity is 70% for residential premises and 100% for bathrooms, toilets, saunas, and laundries. We calculate the estimated temperature difference (in the ventilation duct and on the surface of the thermal insulation) at a given humidity.

Table B.4

| Design difference, °C | Relative humidity , % | |||||

| 40 | 50 | 60 | 70 | 80 | 90 | |

| 10 | 13,4 | 10,4 | 7,8 | 5,5 | 3,5 | 1,6 |

| 15 | 14,2 | 10,9 | 9,1 | 5,7 | 3,6 | 1,7 |

| 20 | 14,8 | 11,3 | 8,4 | 5,9 | 3,7 | 1,8 |

| 25 | 15,3 | 11,7 | 8,7 | 6,1 | 3,8 | 1,9 |

| 30 | 15,9 | 12,2 | 9,0 | 6,3 | 4,0 | 2,0 |

The thickness of the heat insulator is calculated using formulas.

For rectangular and square ventilation ducts:

- λiz – thermal conductivity coefficient of insulation;

- αн – heat transfer coefficient; accepted for surfaces with a high emissivity equal to 7 W/(m2*°C), for surfaces with a low emissivity equal to 5 W/(m2*°C);

- tв – temperature of air masses inside the ventilation duct;

- tо – air temperature;

- tп – temperature of the thermal insulation surface;

- diz – diameter of thermal insulation;

- dtr – diameter of the air duct;

- Rн – thermal resistance of thermal insulation (tabular data).

Table B.3. Approximate values of Rн, m °C/W

| Nominal pipe diameter, mm | Indoors | On open air | |||||||

| For surfaces with low emissivity | For high emissivity surfaces | ||||||||

| at coolant temperature, °C | |||||||||

| 100 | 300 | 500 | 100 | 300 | 500 | 100 | 300 | 500 | |

| 32 | 0,50 | 0,35 | 0,30 | 0,33 | 0,22 | 0,17 | 0,12 | 0,09 | 0,07 |

| 40 | 0,45 | 0,30 | 0,25 | 0,29 | 0,20 | 0,15 | 0,10 | 0,07 | 0,05 |

| 50 | 0,40 | 0,25 | 0,20 | 0,25 | 0,17 | 0,13 | 0,09 | 0,06 | 0,04 |

| 100 | 0,25 | 0,19 | 0,15 | 0,15 | 0,11 | 0,10 | 0,07 | 0,05 | 0,04 |

| 125 | 0,21 | 0,17 | 0,13 | 0,13 | 0,10 | 0,09 | 0,05 | 0,04 | 0,03 |

| 150 | 0,18 | 0,15 | 0,11 | 0,12 | 0,09 | 0,08 | 0,05 | 0,04 | 0,03 |

| 200 | 0,16 | 0,13 | 0,10 | 0,10 | 0,08 | 0,07 | 0,04 | 0,03 | 0,03 |

| 250 | 0,13 | 0,10 | 0,09 | 0,09 | 0,07 | 0,06 | 0,03 | 0,03 | 0,02 |

| 300 | 0,11 | 0,09 | 0,08 | 0,08 | 0,07 | 0,06 | 0,03 | 0,02 | 0,02 |

| 350 | 0,10 | 0,08 | 0,07 | 0,07 | 0,06 | 0,05 | 0,03 | 0,02 | 0,02 |

| 400 | 0,09 | 0,07 | 0,06 | 0,06 | 0,05 | 0,04 | 0,02 | 0,02 | 0,02 |

| 500 | 0,075 | 0,065 | 0,06 | 0,05 | 0,045 | 0,04 | 0,02 | 0,02 | 0,016 |

| 600 | 0,062 | 0,055 | 0,05 | 0,043 | 0,038 | 0,035 | 0,017 | 0,015 | 0,014 |

| 700 | 0,055 | 0,051 | 0,045 | 0,038 | 0,035 | 0,032 | 0,015 | 0,013 | 0,012 |

| 800 | 0,048 | 0,045 | 0,042 | 0,034 | 0,031 | 0,029 | 0,013 | 0,012 | 0,011 |

| 900 | 0,044 | 0,041 | 0,038 | 0,031 | 0,028 | 0,026 | 0,012 | 0,011 | 0,010 |

| 1000 | 0,040 | 0,037 | 0,034 | 0,028 | 0,026 | 0,024 | 0,011 | 0,010 | 0,009 |

| 2000 | 0,022 | 0,020 | 0,017 | 0,015 | 0,014 | 0,013 | 0,006 | 0,006 | 0,005 |

| Notes 1 For intermediate values of diameters and temperatures, the value is determined by interpolation. 2 For coolant temperatures below 100 °C, data corresponding to 100 °C are accepted. | |||||||||

Internal and external insulation: pros and cons

There are two ways to insulate pipes: internal lining or external insulation. Each method has its own advantages and disadvantages.

Internal lining

- More difficult to install, but not subject to external mechanical temperature effects.

- To avoid reducing the internal part of the duct, it is necessary to carry out some work to increase the original area.

- The material must be vapor-tight and airtight to avoid absorption of moisture from the air.

- The outer part of the material should be smooth so as not to impede air circulation.

Example of external ventilation duct insulation

External side insulation

- Easier to install, but the material must also be vapor-tight.

- It is necessary to provide for insulation of the exhaust pipe and installation of a hydraulic barrier.

- The material must withstand mechanical stress.

- The insulation must be non-flammable, since in the event of an open fire it comes into contact with air.

- This type of insulation does not reduce the internal cross-sectional area of the pipe.

- It is not susceptible to the formation of pathogenic bacteria.

Materials for insulating ventilation pipes

This is what properly insulated attic ventilation system pipes look like

Must meet these criteria:

- Non-flammability.

- Good thermal insulation qualities.

- Budgeting.

Let's look at the materials most commonly used for this purpose.

Mineral wool

Insulation - mineral wool

It has its positive sides:

- The most inexpensive and accessible insulation.

- Fireproof.

There are also negative aspects:

- The process of insulation with mineral wool is quite complex. First, it is wrapped around the pipe, then galvanized or foil is wrapped around the cotton wool, then the structure must be tightened with a bandage.

- It cakes over time. Because of this, open areas are formed between the insulation and the surface of the pipe.

- Cotton wool can lose its thermal insulation properties if the humidity level rises sharply.

Important! Mineral wool is toxic to humans! Protective equipment is required during installation.

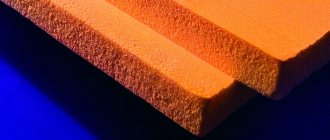

Styrofoam

Foam insulation for pipes

For thermal insulation of pipes, ready-made detachable structures made of polystyrene foam are used.

Advantages of polystyrene foam:

- Easy to install: the finished pipe has tongue-and-groove connections. The structure is put on the pipe and pressed against each other, thereby forming a strong connection.

- Does not change its characteristics due to a sharp increase/decrease in humidity levels.

- Budgeting.

Disadvantages of polystyrene foam:

- Flammability. Also, during combustion, polystyrene foam releases fumes that are toxic to humans.

- Ready-made forms cannot be used on bends; they are only suitable for open straight sections of pipe.

Polyurethane foam and polypropylene foam

Polyurethane foam shell for insulation of steel pipes

The design is similar to a foam pipe

- They are distinguished by a high price.

- They are distinguished by their special mechanical strength.

- They require an additional layer during installation: it is necessary to use a bandage made of knitting wire.

Foamed polyethylene

Quite a common solution and inexpensive

It consists of tubes with different diameters and sizes.

Advantages:

- Easy to install - you just need to put it on the pipe.

- Not subject to external mechanical influence.

- The structure of foamed polyethylene makes it impossible for rodents to appear.

For residents of predominantly cold climates, the following materials are suitable:

- Penofol is polyethylene foam with a layer of aluminum foil. The use of penofol prevents the accumulation of dust and other types of contaminants.

- Self-adhesive insulation based on polyethylene foam. This material is very easy to install: you need to remove the protective film and press it to the surface of the pipe. For greater insulation, it can be glued in two or more layers.

This is what ventilation ducts look like, thermally insulated with penofol

In this material, you learned some of the features of a ventilation pipe in an attic or roof and became familiar with the different types of materials. The next choice is up to you.

Recommendations from experts

If mineral wool is used outdoors, it must be carefully waterproofed. Roofing felt is often used for this purpose. If you use ready-made shells made of PPS or polyurethane foam, then in dark rooms you don’t need to use the top covering layer at all. Do not coat or glue plastic insulation onto bitumen or bitumen primer (mastic). External insulation made of PP, PPU, PPS cannot be covered with bituminous shingles for decorative purposes. You can wrap it.

Particular attention should be paid to waterproofing the passage of the air duct through the roof. Master flash is ideal for waterproofing this unit. Ventilation passages through the attic floor also need to be insulated.

Thermal insulation of cold air supply ventilation ducts up to the point of entry into the room or heat recuperator (or heating device for incoming air), as well as a section of the air supply duct to the boiler, fireplace, stove up to the point of entry into the heating device, is important. Exception: coaxial chimneys. When laying air ducts between joists in the floor, thermal insulation of sufficient thickness is necessary, otherwise the floor structures will get wet and rot.

When installing ready-made shells, ready-made glue is used as a sealant. The technology for installing thermal insulation of air ducts can be clearly seen in the video:

Procedure for insulating pipes

To insulate a vent pipe with foam, follow these steps:

- Find out the exact dimensions of the pipe, including the internal diameter.

- Make cuts with a knife or saw.

- Place the cylinder fragments on the pipe and move them a few centimeters.

- Forcefully close the parts on the sides using a tongue-and-groove locking joint.

This design is easy to install and dismantle.

It is also possible to use structural elements with factory insulation.

To insulate a pipe with a finished shell of foamed polyethylene, you need to perform the following steps:

- To ensure a tight fit of the insulation, take all necessary measurements.

- Find a special seam on the capsule.

- Separate the capsule along this seam.

- Fix the material on the pipe.

- Insulate the joints with tape or glue.

To insulate from fire-resistant polypropylene or polyurethane foam, you must do the following:

- Taking the necessary measurements from the pipe to determine the size of the material used.

- Cutting the workpiece into semi-cylindrical pieces. It is necessary to take into account the margin for the cover layer.

- Formation of capsules from cut blanks.

- Securing joints with bandages.

For a rectangular ventilation opening:

- You need to find slab or roll insulation of the required thickness (basalt fiber is suitable).

- The material is cut into pieces necessary for mounting.

- The pieces of material are fastened together with pre-calcined steel wire.

- The seams are sealed with strips of foil with an adhesive layer.

All these insulation methods have a common drawback - “cold bridges”. To avoid their formation, it is necessary to follow the operating technology during the installation process. You also need to take special care to insulate the joints and seams between the house structures and ventilation ducts.

Video: example of insulation of air ducts of an air conditioning system of a residential building

Insulating a chimney in the attic

Condensation may also form inside a chimney pipe passing through an uninhabited, cold attic or roof. To avoid this, you can insulate the pipe with polyurethane foam (PPU). The second option is to use sleeves - “sandwich pipes” - composite insulated parts of the chimney.

In addition to liquid insulation in the form of foam, it is possible to use double pipes made of sandwich pipes, sleeves and thermal insulation material. This type of insulation performs the function of heat conservation and prevents the formation of condensation due to the foil screen.

The principle of thermal insulation of a chimney

If there is a high probability of pipe freezing, a heat-insulating electrical cable is used. It is wrapped around the pipe or fixed next to it. Some pipes have a heating cable built into them.

Kaolin slabs are used to insulate a brick pipe. To install them, prepare a special solution and glue them to the pipe. The top of the slabs is covered with plaster. Kaolin boards are one of the most reliable methods of thermal insulation of brick pipes.

Insulating pipes in a roof or attic is a simple task that you can handle alone if you know some of the technical features.

Misconceptions about ventilation

It is not enough to ventilate the attic; it is important that it is done correctly. However, there are several common misconceptions among people who are planning to deal with this issue.

They should be discussed in more detail.

- There is a need for ventilation only in the summer. In fact, the attic not only needs to be ventilated in the heat, but also to smooth out the large temperature difference between inside and outside the attic in winter. If this is not done, then the humidity will inevitably increase - an excellent environment for the existence of mold and mildew. It is extremely difficult to combat these phenomena, and in advanced cases, mold can penetrate inside the rooms - then there will be no need to talk about any comfort.

- Ventilation removes warm air from the room in winter. In fact, if heat is poorly retained in a house, then it is not the ventilation that should be blamed, but poor-quality thermal insulation. It is because of this that conditions are created under which moist and cold air enters the attic.

- The size of the ventilation holes does not matter. In fact, the area of these holes is important. With a small ventilation area, the effect will be practically zero. So that the room is well ventilated, and at the same time heat leaks are not allowed, for 500 sq.m. area required 1 sq.m. ventilation holes.

Advantages and disadvantages of ready-made insulated pipes

For those who do not want to do the insulation themselves, there are ready-made insulated pipes with a layer of factory insulation. They have a simple design: a protective layer of basalt fiber is inserted between two channels of different diameters.

Specifications

Such pipes are used in the construction of ventilation systems and chimneys. In the first case, it is necessary to use galvanized products, in the second - stainless steel. Protection from moisture and heat preservation is provided by a layer of mineral wool with the following characteristics:

- flammability - G1 (low flammability).

- thermal conductivity coefficient - 0.038−0.051 W/(m*K).

- strength - from 5 kPa to 80 kPa.

- water absorption - 2%.

Ready-made insulated pipes

The mineral base prevents the formation of fungus and mold, and the fiber structure is maintained even after a long period of use. The melting point of the insulating liner is 1100 ºС, which indicates the fire safety of the product. The combined composition makes the product absorb internal noise and durable. The disadvantage of this product is the high price.

Insulation for industrial systems

For insulation of industrial ventilation air ducts, all the materials described earlier in the section on domestic premises and some other products are used.

Polyurethane foam

Polyurethane foam is polyurethane foam, a very common synthetic elastomer. For thermal insulation of air ducts, solid polyurethane foams are mainly used. They are used to produce all kinds of pierced mats and shells for insulating round pipelines.

Often the shells are covered with a shell made of galvanized steel, fiberglass, polyethylene, or fiberglass. Polyurethane foam is resistant to moisture, has high strength, durability, and is not resistant to ultraviolet radiation. Operating temperature range – from -60 to +80 °C. A good thermal insulator, and also affordable. The method of spraying polyurethane foam onto insulated surfaces is also used. In everyday life, foam is used in aerosol cans; in production, industrial units are used.

In terms of price, this is a relatively inexpensive thermal insulation option. If selected in aerosol packaging, the price increases. Products made from polyurethane foam are also produced for large-diameter pipes.

Thermally insulated air ducts

Installation of air ducts with applied thermal insulation is much faster than traditional assembly with subsequent insulation. But their price is much higher. For insulation, polyurethane foam coated with fiberglass, fiberglass, or polyethylene is usually used.

What is better to choose

The choice of thermal insulation for industrial pipes depends on many conditions:

- Air duct sizes.

- Air duct shapes.

- System locations. In the workshop and ventilation chamber (and now also in the heat recuperator) most of the system is often located, only small pipes for air intake or exhaust are located outside the room. It can be cold in the workshops in winter, down to negative values, so the air ducts in the room require thermal insulation.

- Exhaust gas temperatures and fire requirements.

- It depends on whether a new workshop is being built, an old production facility is being modernized, or thermal insulation of air ducts is simply being installed in an old workshop.

If local suction is insulated in hot shops, then it is often necessary to use mineral and basalt wool - they have the highest operating temperature. The cost of materials is also of considerable importance.

When thermally insulating air ducts in an old production facility, you should take into account the expected service life of the equipment and the building as a whole: if this period is 15-20 years, then perhaps you should not choose modern expensive materials, but make do with more budget-friendly options. It’s a completely different matter when launching new lines or workshops - it makes sense to use ready-made thermal insulation or pipes with a potential service life of 50 years.

Nowadays, ready-made shells with a coating layer are being chosen more and more often. They do not need to be protected from ultraviolet radiation or atmospheric moisture.

Installation Features

Important! For correct and high-quality installation, you must have experience in installing intra-house communications. If you lack experience, we recommend turning to professionals.

If you decide to install the structure yourself, the following reminders may help you:

- With a wide cross-section of pipes, air circulation is better (recommended minimum diameter is 14 cm).

- Short channels must be made wide enough.

- To maintain draft force, all air ducts in the house must correspond to each other.

- It is better to use the same type of thermal insulation and pipes.

- Forced ventilation should be installed when natural heat exchange is disrupted.

Insulation installation process

Video: an effective way to insulate a chimney

Shell for thermal insulation

The shell can be monolithic (in this case it is strung on a pipe) or prefabricated. The last option is used for ready-made operating systems. The shell can help out in places where the pipe runs through the wall. When winding roll insulation in such cases, difficulty may arise. Quite good results can be achieved in outdoor open areas. However, those points where the air duct turns cannot be covered with a cylinder. In such conditions, it is recommended to use insulating mats.

The shell can be made of:

- Foam plastic.

- Mineral wool.

- Extruded polystyrene foam.

- Polyethylene.

- Rubber.

During operation, a lot of noise occurs in the supply and exhaust air ducts. As the cross-section of the pipe increases, the throughput becomes higher, but the resistance also increases. Internal finishing allows you to make the surface as smooth as possible, which slows down the air flow less.

Possible ways to prevent deficiencies

Insulated pipes have no disadvantages that would affect operation.

However, it is worth considering that several steel layers will be heavier than corrugated or polymer insulation. However, the installation quality is not affected by the installation process, so this characteristic is rarely taken into account.

If you have any doubts about the cost, you can make a simple calculation: compare the difference between insulated structures with the sum of the costs of pipe sets, insulation with waterproofing and the cost of fixation means. If the difference is small, you need to choose a material that is easier to install.