The correct installation of a chimney for a gas boiler in a private house is the basis for high-quality heating operation. It is necessary to strictly follow the rules and regulations here, since otherwise it may jeopardize the safety of the residents of the house. Let's take a closer look at how chimneys for gas boilers are installed: requirements and recommendations in our article today.

Regardless of the location of the chimney, there are certain installation rules Source strojdvor.ru

Requirements for chimneys and installation rules

Installation of a chimney and ventilation for a gas boiler occurs in compliance with the chimney installation standards SNiP 2.04.05, and the manufacturer’s recommendations are taken into account:

- The size of the channel is chosen to be the same as that of the boiler socket or slightly larger. The height of the pipe is at least 5 meters.

- In rooms with traditional hoods, the exhaust air is replaced by air coming from the street and partly from other adjacent rooms.

- The chimney is made of non-combustible material.

Important! It is prohibited to use the ventilation duct to exhaust smoke.

After putting a gas boiler or other equipment with a chimney into operation, a chimney inspection report is drawn up.

Principle of operation

The operating principle of any chimney is based on a simple law of physics - warm air and vapors are always lighter and tend to rise, while cold air is heavier and, accordingly, settles below.

Due to the difference in temperature between the street (outside the pipe) and hot gases (inside the system), draft appears. Thanks to it, combustion products do not disperse throughout the room, but escape into the atmosphere.

Requirements for installing a chimney

Installation work is carried out by specialists using all regulatory rules. They are as follows:

- Every heating unit has a single chimney outlet.

- Free and complete exhaust of smoke into the atmosphere is ensured due to the correctly selected height and cross-sectional size of the pipe (clause 5.1.1.VDPO).

- The wall thickness of the metal pipe is not allowed less than 2 mm.

To make a pipe, metal with a thickness of 2 mm or more is taken Source pech-kamin.ru

- To clean smoke channels from soot, recesses with a size of about 250 mm are provided (clause 3.74 of SNiP-91 and clause 5.1.1.VDPO).

- When installing a pipe, the smoke channels are made taking into account no more than three turns, and their rounding is equal to the diameter of the pipe (4.2.17.VDPO).

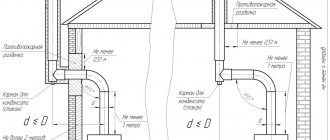

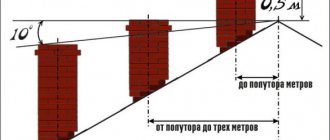

- The chimney for a gas boiler in a private house and the exhaust pipe are installed above the roof ridge in accordance with clause 3.73.SNiP-91: up to 0.5 m - with a flat roof; at the level and above the roof itself - when the pipe is located more than 1.5 meters from the roof ridge.

Metal chimneys are made of high-quality alloy steel with anti-corrosion coating.

By condensation or smoke

We must not forget about the main feature of the chimney for a gas boiler: they have high efficiency and a fairly low temperature of the exhaust gases:

Condensation always and quickly forms in the chimneys of a gas boiler.

Therefore, the chimney installation must be done in such a way as to solve the condensation problem. Due to the low temperature of the exhaust gas, chimneys on modern gas boilers are made “through condensate” and not “through smoke”.

VadimProFORUMHOUSE Member

For smoke, this is when the pipe of the lower bend goes inside the pipe of the upper bend, and, accordingly, for condensate - vice versa.

Chimneys for modern gas boilers are collected strictly according to condensate.

This installation method allows condensate to flow calmly down inside the chimney without leaking out (this is dangerous and can cause a fire).

Types of chimneys

Pipes are made from different materials, which we will consider in more detail.

Brick

Classic brick chimneys for gas boilers are still in demand, regardless of their many disadvantages and weak thermal characteristics. At the same time, they meet sanitary standards and rules, which state:

- The pipe is made of fireclay bricks.

- To build the walls, a clay solution or special glue is used.

- To improve draft, the chimney rises above the level of the roof ridge.

Standards regulate the height of the pipe in relation to the roof ridge depending on the distance between them Source kamin-estet.ru

- The masonry ensures tightness.

- At the internal hole, the deviation is no more than 3 mm per 1 m.

- To protect against precipitation, a deflector is installed on the head of the pipe.

The chimney can also have a mono design, which, due to low thermal characteristics, is repaired every 5-7 years.

See also: Catalog of companies that specialize in installing fireplaces and stoves and insulating country houses..

Galvanized pipe

The “sandwich” type device today is the most effective option for chimney designs. The undoubted advantage of these chimneys is their resistance to aggressive environments and various mechanical influences.

The product consists of two pipes of different sizes, with one inserted into the other. Basalt wool is usually used as a filler between them.

Coaxial chimney

Currently, gas boilers use closed combustion chambers. Here, air enters and smoke is exhausted by a coaxial pipe. This is an original device, relatively recently introduced, but already very popular among users.

The non-standard solution lies in the supply of air through a pipe that removes combustion products. It turns out that one pipe performs two functions due to the design features.

A coaxial chimney is a pipe in a pipe Source rubankom.com

And its characteristic difference from ordinary pipes is the following... A smaller pipe (60-110 mm) is located in a larger diameter pipe (100-160 mm) in such a way that they do not touch each other.

At the same time, the structure is a single whole due to jumpers along the entire length and is a rigid element. The inner pipe serves as a smoke exhaust, and the outer pipe serves to supply fresh air.

Air exchange at different temperatures creates draft and sets the air mass in directional movement. The air in the room is not used during operation of the boiler, thus maintaining the microclimate in the room.

Ceramic

Such a chimney is a composite structure that includes:

- Smoke exhaust duct made of ceramic material.

- A layer of insulation or air space.

- Expanded clay concrete outer surface.

This complex design is due to several reasons. First, the chimney pipe is too fragile to be left unprotected.

The ceramic pipe is always located inside some solid block Source heatylab.com

Boiler structures and chimney outlet

Structurally, a gas boiler is a device consisting of a gas burner, to which gas is supplied through nozzles, and a heat exchanger, which is heated by the energy obtained during gas combustion. The gas burner is located in the combustion chamber. Heat movement occurs using a circular pump.

In addition, modern types of gas boilers are equipped with various self-diagnosis and automation modules, allowing the equipment to be used in autonomous mode. When choosing a chimney, pay attention to the type of boiler combustion chamber. The method of intake of air necessary for gas combustion, and as a result, the optimal type of chimney, will depend on its design.

Different types of chimneys are suitable for different types of combustion chambers

The combustion chamber of gas boilers is of two types:

- open - provides natural traction. The air is taken from the room in which the heating equipment is installed. The removal of combustion products is carried out through natural draft using a chimney with an exit through the roof;

- closed - provides forced traction. Air intake for fuel combustion comes from the street. In rare cases, air can be taken from a special room equipped with forced ventilation. To simultaneously remove flue gases and intake fresh air, a coaxial type chimney is used, which is vented outside through the nearest load-bearing wall.

Knowing the type of combustion chamber, you can easily select or manufacture a chimney suitable for the design. In the first case, when the boiler is equipped with an open combustion chamber, a conventional thin-walled or insulated chimney is used.

For boilers with a closed combustion chamber, a coaxial chimney is used, which is a structure consisting of pipes of different diameters. A pipe with a smaller cross-section is fixed inside a pipe of a larger diameter using special racks. Carbon dioxide and other combustion products are removed through the internal channel, and through the gap between the outer and inner pipes, fresh air enters the closed combustion chamber.

Methods for installing chimneys

According to the method of installation, chimneys are divided into:

- internal - chimneys made of metal, brick or ceramics. They are available in both single-wall and insulated double-wall constructions. Positioned vertically upward. There may be several elbows with a 30° offset;

- external - coaxial or sandwich chimneys. They are also located vertically upward, but the chimney is led out horizontally through the load-bearing wall. After the pipe is removed, a 90° rotary elbow and support brackets are installed, allowing installation in the desired direction.

The chimney can be vented to the street through a wall in the immediate vicinity of the boiler or in the traditional way through the roof.

When choosing a chimney installation method, you should take into account the size of the building in which the equipment is located. For small buildings, it is more advisable to use external chimneys, as they allow the chimney to be taken outside the room.

In other cases, you should build on your personal capabilities. If space allows and it is possible to provide high-quality insulation where the pipe passes through the ceilings, then an internal chimney will be the best solution. Especially if the structure is lined with brick or protected by a ceramic box.

Main mistakes when choosing a flue for a gas boiler

The most common mistakes when installing a pipe for a gas boiler in a private house are:

- Incorrectly chosen height and cross-section of the pipe.

- Lack of heat-insulating material when installing an external chimney or in a transition hole into an unheated attic space.

- Failure to comply with fire safety standards (fire safety rules).

- The pipe removing gas from the boiler is led into the brick channel shaft without liner, which leads to the rapid destruction of this hole.

Installation of steel chimneys made of material that does not meet the requirements (resistance to aggressive environments, high temperatures or thin walls).

How does a water heating system with a furnace work?

A brick stove, supplemented with a water circuit, allows you to quickly and evenly heat the rooms of a fairly large (up to 100 square meters) house; It is advisable to install it in a house with an attic or second floor. The operating principle is simple: the heat released during fuel combustion heats the coolant (in private systems it is water), which circulates throughout the premises and distributes thermal energy.

For a system to work effectively, it must be built according to certain rules. The easiest way to implement a water circuit is with natural circulation of water. It is based on the physical phenomenon of expansion of water (like any liquid) when it is heated.

The basis of the system is a furnace with a heat exchanger. The functions of the heat exchanger are performed by a metal container equipped with pipes (fittings) and connected to the pipes of the system. The heated water is distributed along the heating circuit, and circulation becomes possible due to the difference in the specific gravity of hot and cooled water.

Water heating organization diagram Source holodine.net

The water heating system also includes the following elements:

- Expansion tank. A storage tank that prevents damage to the system when pressure increases.

- Circulation pump. It increases the speed of movement of the coolant along the circuit, causing thermal energy to be distributed faster and more evenly.

When installing water heating with a stove, you can rely on standard wiring diagrams. But the stove is a specific source of heat; it heats up and cools down slowly, and the heat is released unevenly. Therefore, for high-quality home heating, it is necessary to take these features into account.

Installation: recommendations and diagrams, main stages of chimney installation

Chimney installation is divided into several stages - preparatory work, installation itself, then connection, startup and, if necessary, debugging of the entire system.

General requirements

When several heat-generating installations are combined, each of them creates its own chimney. In exceptional cases, a tie-in to a common chimney well is allowed, but a difference in height of at least one meter must be maintained.

First, the chimney parameters are designed and calculated, which are based on the recommendations of gas boiler manufacturers.

When summing up the calculated result, the internal cross-section of the pipe cannot be less than the diameter of the boiler outlet pipe. And according to testing according to NPB-98 (fire safety standards), the initial speed of the natural gas flow should be 6-10 m/sec. And besides, the cross-section of such a channel must correspond to the overall performance of the unit (8 cm2 per 1 kW of power).

Installation steps

Chimneys for gas boilers are mounted outside (attached system) and inside the building. The simplest is the installation of the outer pipe.

Installation of an external chimney Source astroyresurs.ru

Installing a chimney on a wall-mounted boiler is done as follows:

- A hole is cut in the wall. Then a piece of pipe is inserted into it.

- The vertical riser is assembled.

- The joints are sealed with a fireproof mixture.

- Fixed with wall brackets.

- An umbrella protecting from precipitation is fixed on top.

- An anti-corrosion coating is applied if the pipe is made of metal.

Proper installation of the chimney guarantees its impermeability, good draft, and does not allow soot to accumulate. Installation performed by specialists will significantly reduce the cost of maintaining this system.

When constructing an opening for a pipe in the roof of a house, special boxes with aprons are used. In this case, the design as a whole is influenced by such factors as:

- The material from which the pipe is made.

- External design of the chimney.

- Type of roof covering.

The main factor influencing the choice of design is the temperature of the gas that passes through the pipe. At the same time, according to standards, the distance between the chimney pipe and combustible materials must be at least 150 mm. The most advanced assembly system is considered to be in segments, where all elements are assembled using the cold forming method.

Required components

The standard list includes:

- Boiler adapter. The initial section of the pipe. Responds to the required rotation during installation. Suitable for assembly in the direction of condensation.

- Starter sandwich. With its help, a transition is made from a single-wall to a sandwich (double-wall) structure.

- The gates are rotary. A valve or damper with several holes. The damper blocks the flow of carbon monoxide.

- Crimp clamps. Fasteners for tensioning are made of steel. Fix the chimney system in a stationary state and do not allow it to come into contact with the stove.

- PPU (ceiling-passage unit) with mineralite. Used in cases where the pipe will pass through the ceiling or roof. The composition includes fireproof insulating material, followed by a layer of air and space for fastening a layer of thermal insulation.

- Tees at 45, 90 degrees. Change the direction of exit of flue gases.

- Cap or head. Performs the function of an umbrella, protecting the internal cavity of the chimney from precipitation.

- Sandwich sections. Straight, 3-4 pieces. Length from 25 to 100 cm.

- Brackets, screws. They will connect the structural parts.

- Knees at 90, 45 degrees. Allows you to mount the chimney at the desired angle.

- End caps.

- Various adapters, condensate collectors.

- Support platform. Distributes the load evenly.

- Window for cleaning the chimney.

The list of elements is incomplete, since each heating system has its own characteristics. There are options for direct smoke channels with condensate drainage and stands.

Video description

How to install a chimney pipe, see the following video:

Connecting a ceramic chimney

Ceramic chimneys themselves are practically eternal, but since this is a rather fragile material, you need to clearly understand how to correctly connect (docking) the metal part of the chimney and the ceramic one.

Docking can only be done in two ways :

- For smoke , a metal pipe is inserted into a ceramic one. It is important to remember here that the outer diameter of the metal pipe should be smaller than that of the ceramic one. Since the thermal expansion of metal is much greater than that of ceramics, otherwise the steel pipe, when heated, will simply rupture the ceramic one.

- For condensate , a metal pipe is placed over a ceramic pipe.

For both methods, specialists use special adapters, which, on one side, are equipped with a gasket for contact with a metal pipe, and on the other, which contacts directly with the chimney, are wrapped in a ceramic cord.

The joining should be carried out through a single-wall pipe - it has a higher heat transfer coefficient. This means that the smoke will have time to cool down a little by the time it reaches the adapter, which ultimately extends the service life of all materials.

Heat exchanger location options

Stoves with a water circuit are used not only in residential buildings, but also in large baths equipped with a rest room, a separate shower or, for example, a locker room. The design of a stove with a boiler (heat exchanger) is most often implemented in two ways: the boiler is mounted directly in the firebox or in the chimney. Less commonly, a container of water is mounted in the body of the stove, next to the fireplace.

Securing the heat exchanger pipe in the side wall of the furnace Source 1-teplodom.ru

Improving system efficiency

When choosing the configuration of a boiler for a heating furnace, many factors are assessed and their influence taken into account as a whole. To improve the efficiency of the heat exchanger, the following ideas are taken into account when designing it:

- Efficiency increases if you use materials with increased thermal conductivity. Copper has the best thermal conductivity, but it is expensive. Therefore, the optimal solution would be heat-resistant stainless steel.

- Provide the maximum possible surface area (with given dimensions).

- Calculate the optimal height difference between the forward and return pipes.

- The heat exchanger should not interfere with the combustion of fuel (if located in the firebox) and the removal of gases (if it is installed in a chimney).

- The amount of energy transferred is directly dependent on the area of the heat exchanger and the temperature difference between the different media.

Homemade copper coil for heating from a stove Source ultra-term.ru