The premises in which the gas boiler will operate are specified in SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000 - these documents eliminate or minimize any emergency situations. Premises for placing gas boilers fall under the classification of fire and explosion hazards, therefore, when designing, planning, installing and setting up equipment for gas heating, all requirements for the premises for installing a gas boiler must be strictly observed.

General requirements for the installation of gas appliances

In the room intended for the installation of a gas boiler, according to the above standards, there must be good natural lighting: per 1 m3 there must be at least 0.03 m2 of window opening area (but not windows - partitions, frames and imposts are not taken into account). It is imperative to equip the room with a supply and exhaust ventilation system according to the following rules: the total volume of forward and reverse air flows per hour, multiplied by 3, is equal to the volume of the entire exhaust device. In addition to a window equipped with a window, a door with access to the street is installed in the room. The table shows the requirements for room volume:

| Gas boiler power | Total combustion volume |

| < 30 kW | 7.5 m3 |

| > 30-60 kW | 13.5 m3 |

| > 60-200 kW | Requirements according to the conditions of installation and operation of a gas boiler, but not less than 15 m3 |

Attention! For gas-fired units with a power of more than 6000 W, 0.2 m3 should be added for each extra unit of power.

Supervisory requirements for the premises for installing a gas boiler stipulate that the operation of any appliances for heating an apartment is permitted on each floor of a multi-storey building and in any room of the apartment. Kitchens in multi-storey buildings also meet these requirements, since they are already equipped with appropriate communications. The only condition is that the total thermal power of all devices for heating water and heating the apartment (boilers, boilers, heating elements, heating radiators, batteries or registers) should not exceed a total of 150 kW.

The ceiling height in the room is 2 meters or more. The room in which the gas boiler will be installed and operated must be separated from adjacent rooms by solid fire-resistant walls. Material for walls or partitions must have a fire resistance time limit of 0.75 hours (45 minutes). The boiler room must be designed so that in the event of an operational fire there is no possibility for the fire to spread throughout the apartment.

Attention! Gas boilers of the TLO brand, operating on the principle of natural coolant circulation, can be installed and should be operated only in the basement of the house or in the basement.

Fire safety standards in liquid fuel boiler houses

Requirements:

- fuel tanks:

- steel, reinforced concrete external with sprinkling or underground. For light types of fuel and additives, plastic ones with a safety certificate are allowed;

in climates from t° to +9 °C, make thermal insulation;

- capacity according to table 13.1 SP 89 (for 2 – 10 days);

- quantity: for main stock – at least 2; for backup – more than 1;

- consumable tanks are mounted outside the building, but they are allowed in separate boiler rooms;

- for block-modular placement, the main and receiving tanks can be combined;

- on fuel oil pipelines, bends, inlets:

- steel reinforcement 1 class. tightness;

seamless welded joints, and flanges only near the fittings;

- locking unit with manual and electric drive;

- connection to a flange for a plug with a release device;

- purge unit;

- emergency shutdown;

- for boilers from 1 MW - flow meter;

- control valve, as well as a slam-shut valve with an inertia of up to 3 seconds;

- check valve;

- on boilers with a capacity of 100 Gcal/h or more, a shut-off valve, an electrically driven shut-off unit, is installed in front of each burner.

Installation of a gas wall-mounted boiler - kitchen requirements

- Ceiling - 2 meters and above.

- The total volume of the kitchen is more than 7.5 m3, ventilation is equipped, a window is installed and there is a door opening onto the balcony.

- For air exchange, it is necessary to install a grille at the bottom of the wall or door that opens into the next room; the area of the grille is at least 0.02 m2.

To install a gas boiler in the kitchen, you may need permission from the gas service.

If the kitchen in the apartment does not meet the requirements of SNiP, then gas heating equipment can be installed and operated only with the permission of the gas supervision authority.

Attention! It is strictly forbidden to install more than 2 heating devices or more than 2 boilers in one room if the volume of the room is less than 7.5 m3

The existing rules for installing a gas boiler in a private house largely repeat the requirements for boilers that operate in apartments in multi-storey buildings. The differences are caused only by the fact that often in a private house a separate room or building is allocated for heating equipment, which is subject to additional requirements listed below.

Smoke removal from the boiler room

Solid fuel installations are equipped with flue gas purification systems (ash collectors). Gas ducts must be free of ash deposits. When using wood fuel, “wet” spark arrestors are installed. Each boiler is equipped with draft units (smoke exhausters, fans).

Supply ventilation should provide 3 air changes in 1 hour and a sufficient supply of oxygen for the burners. For each kW, 8 cm² of cross-sectional area of the ventilation duct will be required, or 30 cm² if the air is taken from the building system.

Rules for installing a floor-standing gas boiler

- In a house under construction, it is necessary to plan a separate room for installing a gas-fired boiler. The room should have a natural flow of air through a grille in the door or through a hole in the wall.

- A separate hole must be made for supply and exhaust ventilation - it must be located under the ceiling.

- A hole in the wall for the chimney pipe, a hole below the chimney for a soot brush (for cleaning the chimney pipe), which is made below the main chimney by 20-30 cm.

- The chimney is made airtight so that smoke and carbon dioxide do not flow back into the room. To ensure tightness, a smaller diameter pipe is installed inside the large chimney pipe, through which gas combustion products are discharged.

- The room intended for installation and operation of a gas boiler must be spacious and provide easy access and operation, maintenance and repair of the boiler. The floor in the furnace room must be made of non-combustible materials - concrete screed, natural stone, paving stones. The furnace room must be connected to the water supply for the operation of the water heating device, and be equipped with a sewerage system.

- The area of the room for the boiler is 4 m2, the height of the ceilings in the room is at least 2.5 m2.

- The outer door must be 80 cm wide.

- The top of the chimney should be higher than the roof. The cross-section of the chimney pipe must be larger than the diameter of the boiler outlet.

- To supply power, the boiler room must be equipped with an electrical panel with grounding.

- The gas line is brought into the room in advance. A separate valve must be installed for each gas appliance.

- The walls of the boiler room are plastered - it is strictly prohibited to decorate the walls with flammable materials (MDF, fiberboard, plastic).

Requirements for the premises of a boiler room in a private house

It is prohibited to store flammable liquids and objects near the furnace room and in the room itself. The foundation under the AOGV (gas heating unit or gas heating water heating unit) should not freeze in winter, therefore its depth should be below the level of soil freezing in a given region. The air from the vent should be clean, that is, the chimney should be located far from the vent. The room or building in which the gas boiler is installed cannot be equipped for other purposes.

Boiler room category for explosion and fire hazard

The boiler room is a room with a functional fire hazard class F5.1, respectively, categorized according to SP 12.13130. In SP 89.13330 it is assigned cat. D, but this provision is not categorical - calculations are carried out individually.

The boiler room almost always has a cat. D. In exceptional cases, if the calculation of the category shows this, one of the positions B is possible. Different parts of the building may have different values (see SP 89.13330).

Built-in, attached, roof-type structures are made with fireproof parameters no lower than those of the structures they serve. Detached buildings must fully comply with the rules for production facilities.

Other parameters for the PB classification are:

| Type | Fire resistance degree | Structural fire hazard class |

| Separate attached, built-in | I and II | C0 |

| III | C0, C1 | |

| Separate with reliability of release 2 tbsp. | IV | C0, C1 |

| Roof | III | C0 |

Rules for installing wall-mounted gas boilers in an apartment

Typically, in an apartment, a gas boiler is installed in the kitchen, since it already has a gas line, water supply and sewerage. That is, a priori, all requirements for the installation of gas equipment have already been met - all that remains is to connect the boiler. This state of affairs automatically reduces the cost of laying utilities and energy resources. It is prohibited to install a gas boiler in rooms with high humidity - in a bathroom, laundry room, etc.

There are several additional requirements for wall-mounted boilers:

- The wall or partition for hanging the boiler must be able to support it - equipment cannot be hung on a plasterboard or other light partition.

- If the wall is decorated with flammable materials (wallpaper, vinyl, plastic, MDF, fiberboard), then a 3 mm thick gasket of non-flammable material is installed between the gas wall-mounted boiler and the wall. In this case, the boiler must be secured with special hardware that ensures a distance from the boiler body to the wall of at least 4-5 cm.

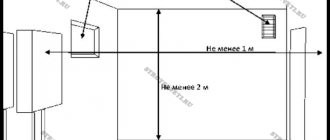

- The minimum distance from the boiler to the ceiling and walls of the room is 0.5 meters. The distance from the boiler to the floor is 0.8 meters.

Before installing and starting up gas equipment, you must obtain all relevant documents. The main condition when installing a boiler in a private house that runs on gas is that an agreement on connecting the gas main is first concluded, and a project for the installation of gas equipment and gasification of the house is drawn up. These documents are developed and approved by the gas supplier in the region.

Primary fire extinguishing agents

The boiler room has subclass F5.1 (industrial buildings), accordingly, they comply with the standards for fire extinguishing agents.

A fire shield is needed if there is no fire hydrant, AUPT, and the distance to water intake points is more than 100 m. A box of sand (from 0.5 m³) is required for fire class. B, E. The procedure for using primary fire extinguishing agents is prescribed in the safety instructions.

What fire extinguishers should be in the boiler room?

In boiler rooms, the fire class is usually A, B, C, and also E (electric boiler fire). According to the table NN 1 and 2 PPR (post. N 390) conditions for manual fire extinguishers are as follows:

| Fire class | Number and fire extinguishing capacity of fire extinguishers |

| A | 2 – 6A 1 – 10A |

| B | 2 – 144B 1 – 233B |

| E | 2 – 6A, 144BCE 1 – 10A, 233BCE 2 – 144BCE 1 – 233BCE |

| WITH | 2 – 6A, 144BC 1 – 10A, 233BC 2 – 144BC 1 – 233BC |

According to the table 1 NPB 166 list of fire extinguishing means in the form of fire extinguishers is as follows:

| Boiler room category | Maximum area, m² | Fire class | ORP, 10 l | , l | for 2 (3) l | , l | |||

| 2 | 5 | 10 | 2 | 5 (8) | |||||

| G | 800 | B | 2 | – | 2 | 1 | – | – | – |

| C | – | 4 | – | – | – | ||||

| G, D | 1800 | A | 2 | 4 | – | – | – | ||

| D | – | – | – | – | – | ||||

| E | – | 2 | 2 | 4 | 2 | ||||

According to SP 41-104-2000 clause 14.2, mobile OPs are prescribed for areas up to 150 m³; additional standards are in Table. N2 NPB 166. It is recommended to follow the rule: the boiler room must have at least 2 fire extinguishers.

Regulations

A boiler room in a private house is an object of increased explosion and fire hazard. The regulations provide for measures aimed at increasing the reliability of these premises, preventing accidents and destruction of building structures due to gas leaks.

When designing and installing gas heating, we are guided by:

- instructions MDS 41.2-2000 for the placement of boilers;

- SNiP -87 clause 6.29-48;

- SP chapter 4;

- SP clause 6.17-25;

- SP paragraph 7;

- SP clause 6.6;

- SP clause 6.12.

The standards have been developed for boiler houses where the source of thermal energy is automated factory-made units. They are designed for a maximum coolant temperature of 115°C and a network pressure not exceeding 1 MPa. For the use of equipment on the territory of the Russian Federation, Rostechnadzor issues a special permit.

Rules and regulations for installing a gas boiler in a private house

The standards regulate design solutions and layout when placing gas equipment in country estates:

Boilers are not allowed to be installed in a room with a height below 2.5 m. The minimum combustion volume is regulated - 15 m³. With these characteristics, the area of the technical room is 6 m². The recommended size for ease of maintenance of the heat generator is 7-10 m².

If additional equipment is installed in the room or the room is used for domestic purposes (laundry, ironing), the area is increased to 12 m².

The boiler room in a private house is fenced off from neighboring rooms by walls or partitions made of non-combustible materials. The finish should also not support combustion.

In wooden houses classified as high fire hazard objects, the boiler is installed at a distance of 400 mm from the walls. This restriction applies to wood furniture and other flammable items.

If screens made of asbestos cardboard covered with roofing steel are used, the distance can be reduced by 2 times. In this case, the condition must be met - the protection is 25 mm away from easily combustible structures and extends beyond the horizontal dimensions of the equipment by 150 mm, and beyond the top surface by 300 mm.

Natural lighting is a mandatory standard for boiler rooms. The standards do not limit the height of windows or dictate their geometric shape. The glazing area is calculated taking into account the volume of the room. It is 0.03 m² per 1 m³ of boiler room.

For a room with a volume of 15 m³, the required glazing size is 0.45 m². This is the area of the average opening 60x80 cm. The norm does not provide for good lighting. Clearance is needed to absorb the shock wave during a possible explosion and preserve building structures from destruction.

With a glass thickness of 3 mm, its minimum area is 0.8 m², with 4 mm - 1 m², with 5 mm - at least 1.5 m².

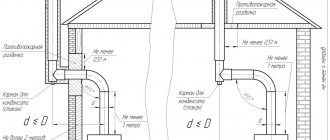

The boiler room provides natural ventilation and smoke removal. Depending on the model of the unit, it may be forced. The chimney pipe is brought to a level above the roof level.

The location of the boiler room is taken into account in the space-planning solution of the house. All technical rooms are located on the north or east side. It is better to plan living rooms in the southern and western parts of the building.

For convenient maintenance, it is recommended to group the boiler room with other rooms containing technical equipment - a bathroom, kitchen, garage.

The boiler room provides for the supply of water and the possibility of its removal when draining from the system. It is prohibited to install an electrical panel nearby so as not to cross electrical wiring and water communications.

How to protect a coaxial chimney from icing and wind

The main problem associated with the operation of coaxial systems is the possibility of pipe freezing during severe frosts. Icing of the air supply channel leads to a decrease in the flow area and, as a consequence, a lack of oxygen in the combustion chamber. This leads to a sharp increase in gas consumption and a significant drop in the efficiency of the heat generator.

The appearance of icicles at the end of the chimney clearly indicates violations made during the design and installation of the coaxial gas exhaust system. With correct calculation of the chimney parameters and high-quality installation, the likelihood of icing is minimized.

In order to prevent and eliminate icing, it is recommended to use the following methods:

- Installation of a special tip that allows you to eliminate icing even if the coaxial device is installed incorrectly;

- Installation of a chimney with a slope towards the boiler. This allows the condensate not to stagnate in the pipe, but to flow into a special collection located inside the unit. If there is a condensate drain, the pipe head should be extended to a distance of 55 - 65 cm from the outer wall;

- Insulating the outer pipe with mineral wool or other heat insulator also helps reduce the intensity of condensation and freezing.

Another problem that may arise during the operation of a coaxial chimney is the possibility of reverse draft. In order to avoid this phenomenon, it is necessary to take measures to provide protection from wind and draft. Installing a special diaphragm will help prevent the burner from going out and carbon monoxide entering the living room.

639d6cb323448e7db74f6fcc3e2177f7.jpe

In addition, when installing a chimney, SNiP should be strictly observed, which stipulates the distance from the outlet pipe to window and door openings. The minimum permissible distance is 1 - 1.2 m. For efficient and safe operation of the coaxial installation, you should first of all follow the equipment manufacturer's instructions.

Chimney freezing

Quite often, owners of boiler equipment wonder why the coaxial pipe freezes. In this case, the boiler room may even stop functioning

In order to avoid such a nuisance, it is important when connecting the boiler to try not to ignore the manufacturer’s advice. It is necessary to observe the length of the pipe, its location and slope

The presence of a fan will free the chamber from combustion products; it will provide rarefaction, which is necessary to suck in new air.

Coaxial kits also differ in the material of manufacture, as well as in design, so some of them may freeze, while others function normally. If the vertical coaxial pipe is frozen, the problem can be partially solved by removing the plugs that are located in the upper part of the boiler. In this case, the flue gases will go outside, and the air will come from the room.

The plug should be installed in its original place as soon as the ice melts. After all, the boiler will not be able to operate in this mode all the time. Unit breakdown is inevitable if airborne particles such as kitchen dust and soot get into the equipment. When icing does not happen so often, this method can be used, but if freezing occurs regularly, you should purchase an anti-ice kit.

Instructions on fire safety measures in the boiler room

The fire extinguishing plan and compliance with safety regulations are specified in several versions of instructions for each type of room. The document establishes the responsibilities of personnel who must undergo emergency and fire training.

An example of the main aspects of instructions on fire safety measures in a boiler room:

- personnel actions must ensure the evacuation of workers and the organization of fire fighting before the arrival of firefighters;

- operator (stoker) actions:

- call the fire department;

stop and de-energize the equipment;

- when gas pipelines catch fire, the pressure is first reduced to a minimum, then the flame is extinguished, and then the gas is turned off;

- general fire safety measures:

- before lighting the boilers, check their serviceability, ventilation, control units;

the fireboxes are ventilated for 10–15 minutes by opening the dampers and/or turning on the smoke exhausters for 3–5 minutes;

- traction is checked;

- Drying any items on or near boilers is prohibited;

- the tightness of gas pipelines is checked with a soap solution;

- It is forbidden to supply fuel when the burners are extinguished, as well as ignition without pre-purge;

- checking water level and pressure is mandatory;

- When stopping the boiler, you must disconnect it from the main line and open the purge plug.

Download: Sample instructions on safety measures in a solid fuel boiler room.pdf Download: Sample instructions on safety measures in a gas boiler room.doc Download: Sample instructions for a boiler room operator.doc

Coaxial chimneys from the best manufacturers are the key to reliability and quality ↑

Coaxial chimney Ariston

Italian-made Ariston chimneys are suitable for most modern boilers. They also come with sealing gaskets and wall trims.

Coaxial chimney Baxi

The chimney in its design should have a length of up to 5 m. If it is directed towards the street, it is given a slope at the rate of 1 cm for each meter of its length. For Russian climate conditions, insulated options with the following changes made to the design are more suitable:

- head lengthened

- the design of the air intake duct is especially protected,

- made of composite material.

Such a system makes it possible to prevent icing of the chimney and cause the boiler to stop in emergency mode if the outside temperature drops to -50 C.

Coaxial chimney Proterm

These products are very easy to install and help increase the efficiency of the corresponding Protherm boilers. In addition to them, the company also offers extensions for chimneys, adapters designed for separate smoke removal, and more.

Coaxial chimney Vaillant This company is considered one of the leaders in the European market. Its products have been quite in demand in recent years.

When choosing a chimney, it is especially important that its cross-section matches the cross-section of the Vaillant boiler pipe. During installation, it is necessary to ensure a distance of at least 100 mm between the chimney and flammable structural elements

Viessmann coaxial chimney

In addition to the coaxial outlet (diameter 60/100, 90°), the kit usually includes: a coaxial pipe equipped with a tip (diameter 60/100, length 0.75 m) and wall linings. Its special design prevents the pipe from freezing in winter.

Regulatory documents and installation rules

- SP 60.13330.2012 Heating, ventilation and air conditioning (SNiP 41-01-2003. Updated edition) (733.0 KiB, 6,365 hits)

- SP 60.13330.2012 Heating, ventilation and air conditioning (SNiP 41-01-2003. Updated version): pdf file (5.3 MiB, 2,664 hits)

dec007f9af930ef54d024d0bebe54610.jpg:large

4d01afbefb8dd909a26bbcb60c52edcf.jpe - Installation rules for coaxial chimneys De Dietrich: classification, standards (8.0 MiB, 6,592 hits)

2020 stylekrov.ru

- Safety

- Types of roofs Mansard

- Flat

- Pitched

- Glass

- Keramoplast

- Types of jobs

- Mauerlat

- Flexible

- Hydro- and vapor barrier

- Ventilation