A double-walled coaxial chimney is used to remove combustion products from gas boilers and water heaters equipped with a closed combustion chamber. It significantly simplifies the installation of water heating devices in terms of smoke removal; you do not have to build a classic pipe from a modular sandwich or ceramic blocks. The procedure is as follows: get acquainted with the design, study the requirements of the standards for installing a coaxial chimney and do the installation work yourself, using this manual.

Requirements to be observed during installation

When installing a coaxial chimney, a number of installation requirements must be observed.

- Strict adherence to the rules for installing a coaxial chimney will ensure the safety of your home;

- It is necessary to follow the recommendations of SNiP 2.04.08 - 87; 2.04.05 - 91.3. You need to know that these rules do not prohibit the installation of vertical chimneys in private houses;

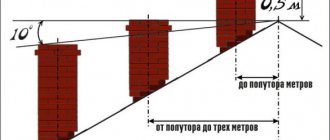

- The distance to neighboring buildings must be at least 2 m, provided that there are no other openings for smoke removal within 3 m. If there are such openings within 3 m, the distance to the building must be at least 3 m;

The most common are vertical chimneys in private households. However, there is another area of their application - a coaxial chimney in an apartment building. The use of a collective chimney ensures high safety in the use of gas appliances.

The rules for installing a coaxial chimney regulate the maximum length of the installed chimney to be no more than 4 m.

The following rules for installing a coaxial chimney must be observed.

- A maximum of 2 folds can be used;

- The slope of the area facing outside when installed horizontally should be approximately 3 º;

- Parts of the chimney must be accessible during routine inspection;

- The chimney cannot be installed below the soil surface;

- The distance to neighboring buildings should not be less than 8 m. If there is a deflector, it can be reduced to 2-3 m, depending on the presence of holes on the wall;

- If the chimney is installed in such a way that its outlet is located below 1.8 m above the ground, it must be equipped with a special grille;

- If there are winds in the area where the chimney is installed, directed in the opposite direction from the smoke exit, it is necessary to install a special barrier at a distance of at least 40 cm;

- If the house is located in an area with very severe frosts, it is better to use a coaxial output with an extended channel;

- There is no need to install additional ventilation sources

Installation diagram of a coaxial chimney

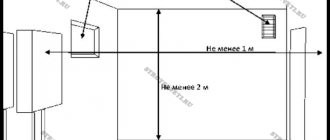

In addition to the above rules, the following requirements must also be observed. The distance from the coaxial chimney to the window must be at least 60 cm. The distance to the gas pipes is no less than the radius of the outer pipe. Be sure to have a very tight fit between the pipe parts

It is important to pay special attention to fire safety at the point where the pipe exits on the roof. Special casings must be used to protect the chimney from contact with all kinds of objects.

If the gas boiler is located too far from the wall facing the street, the question may arise of how to extend the coaxial chimney. For these purposes, special coaxial chimney extensions are used. Such devices are sold in many building materials stores. An extension for a coaxial chimney will help you install it without violating the established requirements.

Selecting the installation type

A coaxial chimney can have a horizontal or vertical outlet. Both options have their significant advantages and disadvantages.

The horizontal one is easier to install, it requires fewer parts, but the vertical one allows you to bring the outer part in the usual way - onto the roof, and without making a hole in the wall. Vertical is often installed in multi-apartment buildings with a height of more than one floor, when it is necessary to remove combustion products from several heating devices at once.

In private houses, horizontal ones are more often used, diverting exhaust gases to the local area from the back of the building, where they are dispersed in the air. This method has a limitation: according to sanitary standards, there should be no housing within a radius of 50 m.

How to protect a coaxial chimney from icing and wind

The main problem associated with the operation of coaxial systems is the possibility of pipe freezing during severe frosts. Icing of the air supply channel leads to a decrease in the flow area and, as a consequence, a lack of oxygen in the combustion chamber. This leads to a sharp increase in gas consumption and a significant drop in the efficiency of the heat generator.

The appearance of icicles at the end of the chimney clearly indicates violations made during the design and installation of the coaxial gas exhaust system. With correct calculation of the chimney parameters and high-quality installation, the likelihood of icing is minimized.

In order to prevent and eliminate icing, it is recommended to use the following methods:

- Installation of a special tip that allows you to eliminate icing even if the coaxial device is installed incorrectly;

- Installation of a chimney with a slope towards the boiler. This allows the condensate not to stagnate in the pipe, but to flow into a special collection located inside the unit. If there is a condensate drain, the pipe head should be extended to a distance of 55 - 65 cm from the outer wall;

- Insulating the outer pipe with mineral wool or other heat insulator also helps reduce the intensity of condensation and freezing.

Another problem that may arise during the operation of a coaxial chimney is the possibility of reverse draft. In order to avoid this phenomenon, it is necessary to take measures to provide protection from wind and draft. Installing a special diaphragm will help prevent the burner from going out and carbon monoxide entering the living room.

639d6cb323448e7db74f6fcc3e2177f7.jpe

In addition, when installing a chimney, SNiP should be strictly observed, which stipulates the distance from the outlet pipe to window and door openings. The minimum permissible distance is 1 - 1.2 m. For efficient and safe operation of the coaxial installation, you should first of all follow the equipment manufacturer's instructions.

Features of a brick exhaust pipe

The brick chimney, once very popular, is gradually losing its position. Due to the fact that it turns out to be heavy, a good foundation is needed. Building a foundation is costly and time consuming.

The shape of the pipe and the rough hygroscopic surface of the inner walls of a brick chimney lead to soot accumulating there and draft deteriorating. The flowing condensate gradually destroys the chimney and the wall of the house.

These shortcomings are eliminated with the help of a combined chimney made of brick, steel, and asbestos.

A liner pipe is installed inside the brick chimney. The assembly of a stainless steel chimney is carried out “by condensate”, that is, the upper pipe is inserted into the lower one. When asbestos-cement pipes are used, it is important to pay attention to the tightness of the joints. Some try to seal them with cement mortar - this is not correct; such a structure cannot be called airtight. Even clamps, as a rule, do not give a good result either. It is advisable to use heat-resistant sealants that can withstand temperatures up to 200 degrees.

A brick outline will not save you from the cold. To insulate pipes, you need to choose materials that are resistant to moisture.

A removable glass is attached to the pipe, which plays the role of a liner, to collect condensate. It must be freely accessible. If you take into account all these recommendations, then such a chimney will last a long time.

Kinds

Depending on the installation method, chimneys can be vertical, through the roof, or horizontal, through a wall or window. Durability and performance parameters are determined by the properties of the material from which they are made.

Aluminum

It is lightweight and can withstand temperature fluctuations and all kinds of corrosive effects without damage. But due to the low operating temperature, it is extremely rarely used for the production of coaxial chimneys. Typically used in combination with plastic.

Stainless steel

For the manufacture of chimneys, acid-resistant stainless steel is used, which can safely withstand sudden temperature changes and can operate at temperatures up to 550 ⁰C. Guaranteed service life - at least 30 years. Manufacturers produce two varieties:

- Pipes without insulation are used in heating systems in industrial and domestic facilities. The disadvantage is the formation of a large volume of condensate during operation. To reduce it, it is necessary to install a layer of thermal insulation.

- Insulated - most often used as vertical collective chimneys in multi-storey buildings. They have improved aerodynamic properties. The rules do not prohibit the connection of heating systems with both forced and natural draft. Installation is carried out during the construction of the house according to a project developed by a specialized organization.

Double-channel plastic chimneys

They are made of heat-resistant material with operating temperatures up to 205 ⁰C. Plastic is inexpensive, weighs little, and is easy to install. Coaxial structures of this type are designed to work with gas condensing boilers with low-temperature flue exhaust. Disadvantages include a short service life and restrictions imposed on use in conventional gas boilers.

When choosing coaxial pipes, it should be taken into account that some manufacturers produce boilers with non-standard pipes. Therefore, for installation it is necessary to use components from the same manufacturer.

Materials for installing a chimney in a private house

The efficiency and durability of a chimney for a gas heating boiler depends not only on a well-chosen design, but also on the material from which it is made. The main requirements are gas tightness, non-flammability, resistance to chemically aggressive environments, and a smooth inner surface.

Traditionally, chimneys are of the following types:

- brick;

- stainless steel (single-wall and sandwich);

- ceramic;

- asbestos-cement.

Each case has its own advantages, as well as disadvantages. It is no secret that most often the selection criterion is the lower cost of pipes and installation work.

The construction industry is developing rapidly and offering new materials for the construction of durable and easy-to-use chimneys. Chimneys made of heat-resistant glass are becoming more and more common, which provide ideal draft and are almost eternal. However, glass chimneys are still very expensive.

Special Benefits

When considering the main positive qualities of coaxial chimneys, it should be noted once again that such a design may not be connected to all types of heating boilers. For the highest quality operation of such a chimney, it should be taken into account that it must be installed with heating boilers with a closed combustion chamber using forced draft. It is the built-in fan that allows the entire smoke removal system to operate at the highest possible quality. Such boilers can be either floor-mounted or wall-mounted.

The most important advantage in favor of a coaxial chimney is the simplicity of the system and the installation of the heating device in any desired location.

Let's take a closer look at all the undeniable advantages:

- Horizontal placement of the chimney. There is no need to break through the roof to remove combustion products. The pipe is led outside through the wall or window closest to the boiler.

- The coaxial chimney system is not connected to the air in the room. When the boiler is operating, oxygen in the room is not burned, and carbon monoxide does not enter the interior of the rooms, as happens when operating conventional gas boilers.

- The air taken from the street enters the combustion chamber heated. This is possible due to the fact that it passes between the outer pipe and the inner one, through which hot, exhaust smoke is discharged outside. This allows you to increase the efficiency of the heating boiler.

- A coaxial chimney is easy to install; the work does not require special knowledge or major redevelopment to install the chimney. Thanks to this smoke removal, it is possible to install a heating boiler even in an apartment.

- The coaxial chimney has an excellent degree of protection against possible fire. This is achieved by cooling the entire system with cool street air, which enters through the channel between the pipes.

- For such a chimney there is no need to arrange a separate equipped boiler room. Any of the boilers - wall-mounted or floor-mounted - can be installed in a selected convenient location: in the kitchen, in the basement, in the outbuilding, in the pantry.

Advantages and disadvantages

What are the positive characteristics of a coaxial chimney system?

- The air required for combustion is taken from the street, which does not create a stuffy environment;

- Minimal heat loss, since air is supplied through an external pipeline, and it is heated by the internal structure;

- Meets all environmental requirements: a gas boiler has a high percentage of efficiency, and all fuel burns completely, so components harmful to nature and humans are practically not emitted into the atmosphere;

- Meets all fire safety requirements: both pipes compensate for heating and cooling, and therefore even if they come into contact with flammable objects, a fire cannot occur;

- The compact design allows installation in any, even small, room;

- Installation does not involve violating the integrity of the roof of the house.

There are very few disadvantages of such a chimney exhaust system, these include high cost and low aesthetic perception: if you install it in the basement, it can slightly reduce the harmony of the room.

Basic requirements for the placement of a coaxial horizontal chimney

To ensure that the gas service does not have any complaints, you need to correctly determine the point where the pipe exits through the wall in accordance with the standards specified in SP 60.13330.2012. First of all, it is necessary that the internal cross-section of the product is no less than that of the outlet part of the boiler. Installation is carried out in accordance with the basic requirements:

- The length of the coaxial pipe should not exceed 3 m. When installing an exhaust fan, an increase of up to 5 m is allowed. Only two bends are allowed to be installed to change the direction.

- The chimney is laid at an angle of 3⁰ towards the boiler. If a condensate collector is installed, from it.

- The boiler is installed in such a way that its outlet is at a distance of 0.5-1 m from the opening in the wall through which the structure is discharged.

- If the pipe exits next to a window, the gap between them should be at least 0.5 m. Placement below the window sill is not recommended. But when there are no other options, laying under the window at a distance of 1 m is allowed.

- If there is a gas pipeline nearby, the chimney is mounted at a distance of at least 20 cm from it.

- A hole in a wall made of brick or concrete is made such that there is a gap of 1 cm. After laying the pipe, it is not necessary to fill it with heat-insulating material; it is enough to close it with a flange.

- In wooden walls, the size of the gap increases to 5 cm. The gap is filled with basalt wool or filled with heat-resistant foam.

- The height of the passage of the coaxial pipe to the outside must be at least 2 m from the ground surface. This is enough to reliably protect the surrounding area from the negative effects of flue gases.

- When installing a structure under a balcony or canopy, the length of the protruding part is determined based on their size. Mentally draw a circle in the horizontal plane. The center is taken as the line connecting the balcony and the wall, and the radius is equal to the width of the canopy. The end of the pipe should be located outside the circle.

Do-it-yourself chimneys for gas boilers

As with other heating equipment, a chimney for a gas boiler can be purchased in specialized stores. This will be a standard modular product, which is selected taking into account the type of boiler and its power.

What to make a chimney for a gas boiler from

A chimney for a gas boiler can be made from various materials. The main thing is that the material is non-flammable, resistant to chemically aggressive environments and does not allow gases to pass through the smoke duct.

For the manufacture of steel chimney parts, steel with the addition of molybdenum, titanium and nickel is used

Taking into account regulatory requirements, the following materials are used for the manufacture of the chimney:

- brick is a traditional material for making chimneys for solid fuel stoves. For laying the chimney, fire-resistant bricks of class A or B are used. When using gas equipment, a combined approach is often used, when a steel or asbestos-cement pipe is used as an internal channel;

- steel - used to create chimneys of any configuration. The quality and heat resistance of a material is determined by its alloy, which is indicated by a special marking. Thus, for the manufacture of chimneys, products made of AISI 316i, AISI 321 or AISI 310S steel are better suited;

- ceramics - a fired mixture of clay and sand, from which combined chimneys are made. The internal channel is made of a ceramic pipe of a certain cross-section. A box made of expanded clay concrete shell or brick is used as a protective casing.

If we carry out a detailed comparison, the best material in terms of price and quality ratio is galvanized steel AISI 321 and AISI 310S. Chimneys made of such steel are designed for flue gas temperatures up to 800 and 1000 °C, respectively.

Ceramic chimneys have high performance characteristics, but their cost is noticeably higher than their steel counterparts

The average service life of steel chimneys is 13–17 years, but due to the high standardization of parts, there is no need to completely change the design. During repairs, only part of the burnt-out modules are replaced.

Ceramic chimneys have high performance characteristics and a service life of more than 50 years, but their cost is noticeably higher than their steel counterparts. Therefore, this type of chimney is recommended to be used only if there is a sufficient amount of funds and you want to build a structure for a long time. The use of brick chimneys in conjunction with gas equipment is unjustified both in terms of labor costs and the final cost of the structure.

How to calculate chimney parameters for a gas boiler

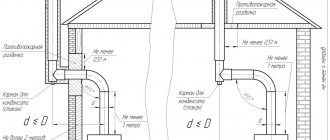

In order to correctly select or manufacture a chimney, it is necessary to calculate the cross-section of the chimney, as well as its height relative to the level of the ridge. The total height of the chimney is selected in accordance with the regulatory rules specified in SNiP 2.04.05–91.

Table: dependence of the chimney cross-section on the power of the gas boiler

| Chimney cross-section, mm | Peak power of gas boiler, kW |

| 120 | 24 |

| 130 | 30 |

| 170 | 45 |

| 190 | 55 |

| 220 | 80 |

| 230 | 100 |

To calculate the pipe cross-section, the following formula is used - F = (K ∙ Q) / (4.19 ∙ √ˉ N), where:

- K is a constant value, the value of which varies from 0.02 to 0.03;

- Q is the maximum performance of gas equipment specified in the specification;

- H is the estimated height of the chimney according to SNiP.

For gas boilers, the minimum height of the chimney must be at least 5 m. The height relative to the ridge is selected from the rules described at the beginning of the article. Let us remind you that the minimum height relative to the ridge must be at least 0.5 m.

After the pipe area has been calculated, it is necessary to compare the obtained value with the data shown in the table. If necessary, the calculated diameter of the smoke channel is rounded to a larger value.

DIY chimney installation

To assemble the chimney, single-circuit steel pipes or special sandwich pipes of the required diameter are used. If the first option is chosen, then after assembling the chimney it is recommended to insulate it. In the second case, there is no need to insulate the chimney.

When using a sandwich chimney, additional insulation of the chimney is not required

As an example, we will give the technology for installing a steel chimney for a gas boiler. To assemble the chimney, you will need straight steel pipes 50 or 100 cm long, 30° chimney outlets, a passage box for walls and ceilings, a deflector, crimp clamps and heat-resistant sealant.

If the diameter of the outlet pipe does not match the diameter of the chimney, then an appropriate adapter is used. It is better to use basalt wool as an insulating material.

Installation of a chimney for a gas boiler is carried out in the following sequence:

- A single-wall or insulated pipe is connected to the outlet pipe of the gas boiler. To do this, the pipe is coated with a heat-resistant sealant, after which an adapter is put on it, which is tightened with a crimp clamp.

- A similar approach is used to connect the adapter to the pipe. First, the mounting end of the adapter is treated with sealant. Next, a straight pipe is placed on it to the required depth. After which the connection is tightened with a clamp. Before assembling the chimney, it is recommended to check its completeness for the presence of all modules and fasteners

- To bring the chimney through the ceiling, you will need to cut a square hole in it. The size of the hole is selected so that there is a distance of at least 20 cm from the chimney to the ceiling.

- A steel box is mounted into a hole cut into the ceiling. For fastening, steel screws 30–50 mm long are used. Then a pipe is passed through the box, which is mounted on a module connected to the pipe. The space between the pipe and the box is filled with mineralized insulation. The top of the box is closed with a steel plate. The outlet of the chimney through the ceiling must be insulated with a steel box

- If, after introducing the pipe into the inter-attic space, its displacement is required, then a 30° elbow is installed according to the scheme described above. In other cases, a straight section of pipe is installed.

- To remove the chimney through the roof, similar actions are performed. First, a square hole of the required size is cut out. Next, a mounting plate with a hole for the pipe is installed. Then a straight section of the chimney is installed. Finally, a conical additional element made of steel or non-flammable plastic is put on the chimney. A deflector must be installed at the chimney outlet

- At the final stage, the remaining section of the chimney is installed. A head and a deflector are installed at the end of the pipe. After assembly, the functionality of the assembled structure is checked. To do this, it is enough for the equipment to operate at 50–60% of maximum power for one hour.

When installing an external chimney, a 90° rotary elbow is used. The elbow is connected directly to the adapter, which is also mounted on the gas boiler pipe.

To remove the chimney, you will need to cut a hole in the load-bearing wall. The size of the hole is selected in the same way as in the case of the ceiling and roof. Next, a steel box is mounted in the wall through which the pipe is passed. Basalt or mineral wool is used to fill the box.

To re-rotate the pipe, another 90° elbow is installed. A special support with a bracket is used as a supporting structure, which is installed under the rotating elbow. The installation step of the hanging brackets is 1–1.5 m. Further steps are similar - you need to assemble a chimney from straight products that are connected using clamps and sealant.

What makes the coaxial design unique?

The term “coaxial” implies the presence of two objects inserted into one another. Thus, a coaxial chimney is a double-circuit structure made of pipes of various diameters, located one inside the other. There are jumpers inside the device that prevent the parts from touching. The equipment is installed in heat generators equipped with closed combustion chambers. These include, for example, gas boilers.

289274b671aedb603cc895fa225a7085.jpe

The coaxial chimney is designed in such a way that the inner pipe is designed to discharge combustion products into the atmosphere. The outer one, which has a larger diameter, is used to supply fresh air to ensure combustion

Thanks to the special design of a standard coaxial chimney, it performs two functions at once: it creates an uninterrupted supply of air necessary to ensure the combustion process, and removes combustion products outside. The length of the device most often does not exceed two meters. It is mainly intended for horizontal placement and is exposed to the street through the wall. Less often you can find a structure that extends through the ceiling and roof.

The special design of a coaxial chimney allows it to function according to a completely different principle from a conventional device. The oxygen required for combustion enters the boiler from outside. Thus, there is no need to ensure a constant flow of fresh air into the room through ventilation, which is inevitable for traditional smoke exhaust ducts. In addition, a number of problems typical of standard chimneys are successfully solved:

- Reduction of heat losses by heating the air coming from outside from the internal hot smoke exhaust pipe, which results in higher system efficiency.

- Reducing the risk of fire in areas of contact between flammable surfaces and the smoke exhaust duct, since the internal pipe, transferring heat to the external one, is cooled to safe temperatures.

- The high efficiency of the system allows for complete combustion of fuel, so unburned particles are not emitted into the atmosphere and do not pollute it. A boiler equipped with a coaxial chimney is environmentally friendly.

- The combustion process, including the supply of oxygen and the removal of gases, takes place in a closed chamber. This is safer for people, since hazardous combustion products do not enter the room. Therefore, additional ventilation is not required.

- Save space due to the compact size of the device.

- A wide range of chimneys designed for systems of varying power.

Device

Since this system requires not only an influx of oxygen, but also an autonomous removal of condensate and combustion products, it consists of several components:

- Double straight pipe for carbon dioxide removal;

- A small container to collect the resulting condensate: under no circumstances should it enter the combustion boiler;

- The connecting triple structure is used to assemble all the parts;

- An elbow bent at 90 0, intended for turning the chimney pipe;

- Cleaning systems: with its help, repair or maintenance work is carried out;

- Tip - it is designed to protect the system from precipitation.

Coaxial chimneys from the best manufacturers are the key to reliability and quality ↑

Coaxial chimney Ariston

Italian-made Ariston chimneys are suitable for most modern boilers. They also come with sealing gaskets and wall trims.

Coaxial chimney Baxi

The chimney in its design should have a length of up to 5 m. If it is directed towards the street, it is given a slope at the rate of 1 cm for each meter of its length. For Russian climate conditions, insulated options with the following changes made to the design are more suitable:

- head lengthened

- the design of the air intake duct is especially protected,

- made of composite material.

Such a system makes it possible to prevent icing of the chimney and cause the boiler to stop in emergency mode if the outside temperature drops to -50 C.

Coaxial chimney Proterm

These products are very easy to install and help increase the efficiency of the corresponding Protherm boilers. In addition to them, the company also offers extensions for chimneys, adapters designed for separate smoke removal, and more.

Coaxial chimney Vaillant This company is considered one of the leaders in the European market. Its products have been quite in demand in recent years.

When choosing a chimney, it is especially important that its cross-section matches the cross-section of the Vaillant boiler pipe. During installation, it is necessary to ensure a distance of at least 100 mm between the chimney and flammable structural elements

Viessmann coaxial chimney

In addition to the coaxial outlet (diameter 60/100, 90°), the kit usually includes: a coaxial pipe equipped with a tip (diameter 60/100, length 0.75 m) and wall linings. Its special design prevents the pipe from freezing in winter.

Regulatory documents and installation rules

- SP 60.13330.2012 Heating, ventilation and air conditioning (SNiP 41-01-2003. Updated edition) (733.0 KiB, 6,365 hits)

- SP 60.13330.2012 Heating, ventilation and air conditioning (SNiP 41-01-2003. Updated version): pdf file (5.3 MiB, 2,664 hits)

dec007f9af930ef54d024d0bebe54610.jpg:large

4d01afbefb8dd909a26bbcb60c52edcf.jpe - Installation rules for coaxial chimneys De Dietrich: classification, standards (8.0 MiB, 6,592 hits)

2020 stylekrov.ru

- Safety

- Types of roofs Mansard

- Flat

- Pitched

- Glass

- Keramoplast

- Types of jobs

- Mauerlat

- Flexible

- Hydro- and vapor barrier

- Ventilation

Preventing condensation problems

The most noticeable disadvantage of coaxial chimneys is the formation of condensation at negative ambient temperatures. To prevent condensate from entering the boiler, you need to take care in advance of installing a container to collect it. Condensate should not be allowed to flow freely into the street - it contains a number of aggressive acids.

It is not possible to solve the problem with the formation of condensation by thermally insulating the chimney from the outside due to the peculiarities of its design. In addition, condensed moisture can freeze - and this is an even bigger problem, leading to the appearance of plugs in the structure.

One solution to this problem is to shorten the inner pipe - but this method is only suitable if the slope of the pipe is directed in the direction opposite to the boiler. The length of the chimney directly affects the air temperature at the exit point - if you lengthen the coaxial chimney for a gas boiler excessively, this will lead to cooling of the smoke and freezing of the condensate.

The cause of condensation may be that the heating equipment is too powerful. In this case, the chimney is not able to provide full draft, so condensate will be produced much more actively. To know for sure whether the coaxial chimney matches the boiler you are using, it is worth purchasing a complete set of equipment that includes all the necessary elements.

Conclusion

A coaxial chimney is a fairly effective solution for gas boilers, especially if they are used in a region with mild climatic conditions. Correct calculation of the system and compliance with the rules for its installation will allow you to create high-quality heating that can last for decades.

New publications

- Why is Tyvek vapor barrier a good choice?

- Specifics of foil vapor barrier: characteristics, conditions of use, installation

- Mansard roof truss system: diagrams, device

- How to fasten rafters: fastening to beams, mauerlat and other roof elements

- Snow load on the roof: subtleties of calculation when designing

2020 Stylish roof roofing

Images published on our website are taken from open sources. If you are the author of the image, please contact us via the contact form and we will try to quickly resolve this issue.

The principle of installing a chimney in a mine

In modern houses, they try to hide all utilities and other structures that spoil the interior. In order for the chimney to look neat, it is covered in a special shaft. You can also hide non-aesthetic communications there: water pipes, sewer risers, ventilation ducts.

The chimney at the level of the unheated attic is covered with heat-insulating material. The best material is considered to be basalt wool, which can withstand high temperatures up to 300 degrees. It is durable and does not emit harmful substances into the atmosphere.

When the chimney is insulated, draft significantly improves, condensation formation decreases, and the efficiency of gas equipment increases. Thus, the cost of high-quality insulation of the chimney will pay off due to its durability and fuel economy.

Advantages and disadvantages of coaxial chimneys

Such systems for supplying air and removing combustion products have now gained wide popularity. This is easily explained by the many advantages of such a scheme:

First of all, the advantage is that the air necessary for the combustion of “blue fuel” is taken not from the room, but from the street. This circumstance greatly simplifies the organization of general ventilation - no calculations are required for additional inflow, there is no need to resort to frequent ventilation or organize other ways of air supply from the street

This is especially important for those cases when the boiler is installed in the “living area” of a house or apartment, for example, in the kitchen. In frosty weather there will be no unnecessary influx of cold into the premises. In principle, combustion products cannot enter the room - they are immediately discharged from the closed chamber to the street. The air taken from the street receives very noticeable heating from the internal pipe, through which waste products flow in a counter flow

And this is important for uniform and complete combustion of gas, for maximum boiler efficiency. In addition, complete combustion of gas ensures minimal emissions of substances that can cause air pollution. On the contrary, combustion products are effectively cooled, which significantly increases the fire safety of the system. The likelihood of ignition of soot particles, which can accumulate in the pipe over time, is sharply reduced. And at the outlet the gases no longer have a dangerous temperature. The outer surface of the coaxial pipe does not heat up to too high temperatures. And this is a big “plus” in the sense that the requirements for organizing safe passage through walls (floors, roofs) are significantly reduced. No other type of chimney, including sandwich pipes, allows such “liberty”.

Even through a wooden wall, you can lay a coaxial chimney without cutting out a huge window for a fireproof penetration.

- Installation of a coaxial combustion product exhaust system will not involve large-scale construction and installation work, as usually happens when installing “classic” vertical chimneys.

- The installation itself is quite simple and intuitive. Any kit is always accompanied by detailed instructions. So in many cases it is quite possible to carry out the installation work yourself.

- There is a wide range of coaxial chimney kits on sale, and therefore it is possible to select the desired system for a boiler of a certain model. As a rule, it is purchased immediately along with the heating equipment. And for any system, the assortment includes the necessary additional parts - tees, 90 or 45 degree bends, condensate collectors, inspection chambers, cuffs, clamps, fasteners, etc. That is, there are no problems with acquisition.

The main disadvantage of coaxial chimneys is the abundant formation of condensation, which is inevitable at the border of distinctly hot and cold gas flows. And as a result, ice freezes at the tip in severe frosts. And this, in turn, is fraught with failure not only of the combustion product removal system itself, but even of the heating unit.

In severe frosts, despite the very hot exhaust, ice build-up may form on the pipe of the coaxial chimney. This phenomenon must be combated so as not to “ruin” the entire system.

This drawback is often attributed to the fact that coaxial chimneys were originally developed for European countries with much more benign climatic conditions than in Russia. In an effort to increase the efficiency of boilers, designers tried to reduce to a minimum the possible diameter of the internal pipe for gas removal, which led to a shift in the dew point inside the air duct and heavy freezing of the condensate that fell.

Additional insulation of the outer section of the outer pipe of a coaxial chimney is a simple and effective means of combating icing.

The second, but very conditional, disadvantage is the high cost of high-quality coaxial chimneys. But there is something to argue with here. Firstly, the price still doesn’t look scary compared to the overall costs of the heating system. And secondly, if you add considerable savings on construction and installation work, then it becomes ridiculous to talk about cost in general. And this is without taking into account the other advantages of the coaxial system.

How the design works

Air masses from the street enter inside through a larger diameter pipe. Passing through the external channel, they absorb heat from the internal channel, which serves to remove exhaust gases. The movement of air of different quality and temperature occurs in different directions. It enters the combustion chamber already hot, no additional energy is wasted on heating it, which significantly increases efficiency. At the same time, gas consumption per unit time decreases, making heating equipment much more economical.

Heating from the inside, the air from the outer channel simultaneously cools it, preventing overheating. This feature, firstly, ensures a long service life, and secondly, makes it possible to install it even in a wooden house without any additional protection: in good condition it is not at all fire hazardous. But nevertheless, it is often additionally thermally insulated with basalt insulation, as this significantly improves traction and efficiency.

Chimney freezing

Quite often, owners of boiler equipment wonder why the coaxial pipe freezes. In this case, the boiler room may even stop functioning

In order to avoid such a nuisance, it is important when connecting the boiler to try not to ignore the manufacturer’s advice. It is necessary to observe the length of the pipe, its location and slope

The presence of a fan will free the chamber from combustion products; it will provide rarefaction, which is necessary to suck in new air.

Coaxial kits also differ in the material of manufacture, as well as in design, so some of them may freeze, while others function normally. If the vertical coaxial pipe is frozen, the problem can be partially solved by removing the plugs that are located in the upper part of the boiler. In this case, the flue gases will go outside, and the air will come from the room.

The plug should be installed in its original place as soon as the ice melts. After all, the boiler will not be able to operate in this mode all the time. Unit breakdown is inevitable if airborne particles such as kitchen dust and soot get into the equipment. When icing does not happen so often, this method can be used, but if freezing occurs regularly, you should purchase an anti-ice kit.

Options for assembling a metal chimney system

There are certain rules that apply to the assembly of a chimney from single-wall metal and sandwich pipes.

The part of the chimney that is installed outside is designed “for condensate”. The corrugated edge on one side of the pipe allows the top pipe to be inserted inside the bottom pipe.

The chimney that runs inside the building must be assembled “according to the smoke”: the upper pipe is put on the lower one. This way you can protect the room from dangerous flue gases.

An ideal option for assembling sandwich pipes: the upper circuit is assembled through “condensate”, and the inner circuit “through smoke”. This is quite difficult to do, but there is a 100% guarantee that the joints will not allow gases to pass through and condensate will not leak.

Installation specifics

Correct design and installation of a standard coaxial chimney system involves taking into account the dimensions of the structure. Vertical structures are installed where it is impossible to install an outlet channel through the wall. For example, the chimney can go directly onto a small busy street or be located near a window. Naturally, this is unacceptable, although in some cases it is possible to install pipes at a certain angle.

It is worth choosing a coaxial chimney based on the data from the technical data sheet. The connection between the chimney and the boiler must be made using a tee or elbow. Each structural element must be fastened so that there is no obstacle to the removal of exhaust gases.

Based on where the outlet pipe will be located, certain components are selected. If the pipe is at the top, then there should be no problems with the installation of the chimney. If it is located on the side, then the structure is brought into a vertical position using special brackets.

Advice from professionals

Reliable connection of pipes will be ensured by transition units. All joints must be covered with sealant and a protective casing.

In order for gas equipment to be accepted for warranty by the service center, it is necessary to install the recommended coaxial chimney system for the selected boiler.

You should not neglect the help of specialists and carry out the installation yourself without the proper experience.

Incorrect calculation leads to a change in outlet temperature and increased condensation formation. As a result, ice accumulates on the tip. It is mandatory to install metal shields in wooden rooms.

Protective units increase the cost of the structure, while increasing its performance. When installing vertically, a valve is always installed to increase draft and a condensate collection kit is installed.

Horizontal systems are additionally equipped with an anti-icing module, wind protection and a diaphragm.

Important installation requirements

To install a heating boiler with a closed combustion chamber, the installation of an autonomous heating system is required. Such a system can be used in individual construction, in city apartments or industrial premises.

If you decide to use a coaxial chimney, you must adhere to certain safety and installation rules and regulations. They will allow you to properly and reliably perform the smoke removal system and protect the room from exhaust gases.

Rules for installing a coaxial chimney:

- The maximum length of the vertical outlet pipe of a coaxial chimney should be around 3 meters. Sometimes longer chimneys are found. For example, it is possible to connect coaxial chimneys 4–5 meters long to Ferolli (floor-standing) boilers.

- The pipe is discharged to the street horizontally through the wall near which the boiler is located in the room. The length of the horizontal section is no more than 1 meter.

- If forced draft is installed using fans, there is no need for a vertical section of the system.

- The chimney outlet is located at a height of two or more meters above the ground and at least 1.5 m relative to the location of the boiler (above it).

- The chimney outlet must be located at a distance of half a meter from any window (side or top), door or ventilation grill.

- The outlet location of the coaxial chimney pipe under the window is not recommended. But if necessary, the location of the window above the chimney should be more than 1 meter.

- To drain condensate, when installing a coaxial chimney, it is necessary to ensure a certain slope of the pipe.

It should be noted here that disputes about the need and correctness of setting the slope of the pipe are a topic that is interpreted quite controversially and is vigorously discussed on many construction forums and websites. At first glance, such a simple matter, it requires a sensible approach and careful clarification of all the nuances. The main controversy arises over the side of the chimney. It is necessary to understand this issue in detail and note some of the nuances of installing a horizontal coaxial chimney.

Conditions for using asbestos-cement pipes

An economical chimney option is asbestos-cement pipes, but they have many disadvantages and limitations.

The walls of an asbestos-cement pipe are porous, so the chimney quickly becomes dirty. In addition, pipes made of layered material can be installed at a distance of no less than 0.5 m from the gas boiler pipe.

Several rules to follow when using asbestos-cement pipes:

- install the chimney only vertically;

- carefully seal the joints;

- make the pipe high enough and well insulated.

When sealing joints, hydrophobic compounds are added to the solution, and the dried cement mortar is also coated with a special sealant. Additionally, the joints are secured with clamps. Only after completing these measures can we say that the requirements for the gas boiler pipe have been met.

What material

A chimney for a gas boiler in a private house can be made from different materials. The main requirement is resistance to chemically aggressive substances, inability to pass gases. Traditionally, several materials are used. Let's talk in more detail about the advantages and disadvantages, as well as the assembly features of each of them.

Brick chimney

Today this is no longer the most popular type of chimney. It turns out to be heavy and requires a foundation at high altitudes. In addition, laying a brick chimney takes a lot of time.

However, this type of chimney has a number of negative qualities. First, its inner walls are not smooth, which contributes to the accumulation of soot and impairs traction. Secondly, brick is hygroscopic. Therefore, the condensate flowing down the walls is absorbed, which contributes to rapid destruction.

Construction of a brick chimney for a gas boiler with a metal sleeve insert

To solve these problems, a smooth pipe of suitable diameter is inserted inside the brick chimney. This is usually a stainless steel or asbestos pipe. When building such a combined chimney, attention must be paid to the following things:

- The joints of the liner pipe must be made airtight. If these are ordinary or sandwich pipes made of stainless steel, everything happens as standard - we collect the chimney using condensate. If the liner is made of asbestos-cement pipes, you will have to take care of the tightness of the joints. Moreover, covering the joint with cement is not an option. Such a connection is not sealed in any way - condensation will be absorbed. We will have to come up with sealed clamps and use hydrophobic (water-repellent) compounds. Moreover, they must also be chemically resistant. As an option, you can consider coating the joints with heat-resistant sealants with an operating temperature of about 200°C.

- To ensure that condensation forms as little as possible, it is better to insulate the pipes (even inside a brick casing). To do this, it is advisable to use insulation that is not afraid of getting wet.

- A condensate collector must be attached to the liner pipe below. Access to it must be free.

If you make a chimney for a gas boiler according to these rules, then even with abundant condensation it will be easy to deal with.

Stainless steel - single wall pipes and sandwich

Modern gas boilers are designed so that the temperature of the flue gases at the outlet is not very high. Therefore, condensation always forms. With good draft, most of it flies into the pipe; with good insulation, the remaining part evaporates. So it turns out that liquid is not always present in the condensate collector. But condensate itself is formed when the gas boiler is running all the time. Sometimes in larger quantities, sometimes in smaller quantities. In this regard, the requirements for stainless steel for a chimney are high: it must withstand prolonged contact with caustic substances. These requirements are mainly met by food grade stainless steel. Yes, it costs a lot, but only it will serve for years.

Sandwich pipe structure

Now let’s talk about whether to make a chimney for a gas boiler from a single-wall pipe or from sandwich pipes. In order for condensation to form in minimal quantities, it is desirable that the chimney does not cool down. That is, it needs to be insulated. And although the sandwich chimney has a lining made of insulation, when laying it externally (on the street) it is also better to insulate it - it will last longer, the draft will be better. But in this option, less insulation will be required - one layer, whereas a regular pipe may have to be wrapped in two or even three layers. So the costs of installing a chimney from a single-wall stainless pipe and sandwiches will be comparable. It’s just that in the first case you will have to use more insulation, and in the second less.

If we talk about reliability, then sandwich chimneys are more reliable, if only because they consist of two layers of metal. By the way, if you are insulating the chimney, the outer pipes can be made of galvanized steel - they do not come into contact with condensate, the temperatures are low, and the appearance is not important, since everything will be wrapped in insulation.

Ceramic chimneys

Ceramic chimneys are good for everyone: they are durable, reliable, and tolerate contact with aggressive substances well. But they have two significant drawbacks. First, they are expensive. Secondly, they have a lot of weight, so when installing a high chimney they require a foundation. And this is an additional expense to the already considerable amount. But the service life of such a chimney is calculated in decades.

Ceramic chimney

Asbestos cement pipes

This was once the most popular type of material in the construction of chimneys for a gas boiler in a private house. The material, of course, is porous, has rough walls, and its cross-section is not ideal (not round, but rather oval). But this is perhaps the cheapest option.

To avoid the appearance of such stains, the connections must be made absolutely sealed.

When using asbestos-cement pipes for the chimney of a gas boiler, you must:

- Make it as straight as possible, trying to make the joints even.

- Seal the joints. As has already been said, simply covering it with cement is not an option. A tight connection is required. Several solutions to the problem are the use of hydrophobic additives in the mortar, coating the dried cement mortar with sealant, and the use of sealed clamps.

- To reduce the amount of condensate, make the pipe high and insulate it well.

In general, nothing new, all the same rules as for the materials described above, but the hassle of joints is added. So, as a result, the price of a chimney made from asbestos pipes is almost the same as that made from stainless steel.