Most country property owners use natural gas for heating. But this energy carrier is an explosive substance, posing a threat to residents and the building itself. Before equipping gas boiler rooms, you need to familiarize yourself with the official requirements. This guarantees safety when using gas-powered equipment.

Gas workers will not issue permits if the installation is carried out with violations.

We recommend reading: Documents required when connecting gas

Rules and regulations for the installation of boilers operating on gas fuel

Such boilers are installed according to a design that reflects all safety standards, determines the installation location and fire-safe distances to the structural elements of the building.

Before the start of construction and installation work, the design documentation is agreed upon with the relevant regulatory agencies, which also check it for compliance with state standards.

Installation of the boiler is carried out only by a specialized organization that has a license to carry out such work. After completion of installation work, the boiler is put into operation by a commission consisting of representatives of the customer, the design organization of the installation company, city gas, architecture, capital construction, SES and the fire department. Thus, the owner must also know the requirements for the location of gas boiler equipment in order to correctly prepare technical specifications for the design.

Wall-mounted

Boiler diagram on the wall

Requirements for rooms where it is planned to install a wall-mounted heating unit are primarily aimed at protecting building structures from fire. In this option, the owner will have to pay special attention to the wall on which they plan to mount the device; it must be able to withstand the weight of the structure and be fire resistant.

Basic room requirements for wall-mounted units:

- The volume of the room for a gas boiler is over 7.51 m3.

- The presence of powerful natural ventilation; the room should have a window unit with a window and a door with an opening for air intake - 0.02 m2.

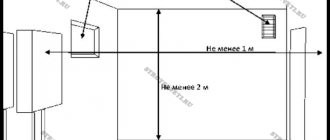

- Maximum distances to the building enclosing elements: floor - 80 cm, ceiling - 45 cm, walls on the sides - 20 cm, from the body to the rear wall - 40 mm, from the front of the unit to the door - 100 cm.

- The placement wall is covered with fire-resistant material made of steel sheet with a thickness of more than 3 mm.

- Thermally insulate the adjacent side surfaces of walls and furniture.

Floor-standing

For these models, more attention needs to be paid to the floor structure, since such structures are heavy, and heat losses from the body mainly flow to the flooring underneath.

Therefore, in the area of the boiler unit, a base is made of non-combustible material, with reinforcement capable of supporting the entire structure of the heating system, with a boiler and an indirect heating boiler.

Room standards for installing a gas boiler with floor installation:

- Free access to the working elements of the boiler unit.

- The minimum area for placing one unit is at least 4 m2, while no more than 2 devices are allowed in the room.

- The height of the room is 2.20 m.

- Supply and exhaust ventilation, windows at the rate of 0.3 m2 per 10.0 m3 of room volume, door with an opening of 0.8 m.

- The gap between the door and the front of the unit is 1 m.

- The walls and floor are made of non-combustible materials.

Regulations and design documentation

Absolutely all requirements for the installation of gas boilers are freely available in the following building codes and regulations:

- SNiP 31-02-2001;

- SNiP 2.04.08-87;

- SNiP 41-01-2003;

- SNiP 21-01-97;

- SNiP 2.04.01-85.

Further, data and figures taken from the relevant SNiPs are used.

1. You need to start by submitting an application for approval of technical conditions. The presence of this document gives the applicant the right to begin installation and connection of heating equipment to the central gas main. The application is submitted to the gas service, where it is reviewed by specialists within thirty calendar days.

To speed up the receipt of the above document and avoid possible delays, the application must indicate the estimated average daily volume of natural gas that will be required to meet heating needs. This figure is calculated individually according to the standards given in the first of the listed SNiPs.

- For a domestic gas boiler with a hot water supply circuit and used in central Russia, fuel consumption is 7-12 m3/day.

- A gas stove for cooking consumes 0.5 m³/day.

- The use of a flow-through gas heater (gas water heater) consumes 0.5 m³/day.

For a number of reasons, after the gas service has reviewed the application for permission to connect, it may be refused. At the same time, the responsible body is obliged to issue the owner of a private house a document that officially indicates all the reasons for the refusal. After they are eliminated, the application is resubmitted.

2. The next step after receiving technical specifications is an even longer but necessary process - creating a project. The main part of this document is a plan diagram, which indicates the location of the boiler, metering equipment, gas pipelines, as well as all connection points.

An appropriate specialist is always involved in drawing up the project. He must have permission to do this work. It will not be possible to develop a project on your own. In any case, the gas service will not accept for consideration a document prepared by a non-specialist.

After drawing up the project, it must be submitted for approval. This is done by the gas service department that controls gas supply in a specific locality or area. As a rule, it takes up to 90 days to approve the project, and only after receiving a positive response can work on arranging the boiler room and installing the heating unit begin.

The following documents must be attached along with the project and the application for its consideration:

- technical passport (available with the equipment);

- official operating instructions (a copy is possible);

- certificates;

- a document confirming the compliance of specific equipment with safety requirements.

It is also recommended to consult with a specialist drafting the project. He will provide the most up-to-date information on these issues, talk about possible innovations, changes in legislation and common pitfalls. This knowledge is guaranteed to save you a lot of time and nerves.

Approval of the project, just like receiving specifications, may result in refusal. At the same time, the owner is given an order indicating errors, shortcomings or inconsistencies that need to be eliminated. After corrections, the application is submitted and reviewed again.

Basic requirements for premises for placing gas boilers

The fire safety of the room is ensured due to the fire resistance of the walls and floor, as well as reliable triple natural air circulation.

The minimum volumes of premises depend on the thermal power of the units:

- Up to 30.0 kW - 7.5 m3;

- from 30.0 to 60.0 kW - 13.5 m3;

- over 60 kW - 15 m3.

For units with a power of more than 60 kW, for each additional kW, 0.2 m3 of volume is added, for example, for a gas boiler with a power of 150 kW, the volume of the furnace room should be equal to:

150-60 = 90 x 0.2 + 15 = 33 m2.

To the kitchen

This room today is most suitable for installing gas boilers, especially the wall-mounted version. Many users try to close the boiler from public view, so they install it either in a special box or cover it with a decorative panel.

The boiler in the kitchen can also be beautifully placed

In order for the gas service not to impose a ban on such an installation, you need to know and follow the rules for placing boilers in the kitchen.

According to the main parameters: ceiling height, minimum area and the presence of triple air circulation, the requirements for kitchens are similar to other furnace rooms.

There are also some peculiarities, given that the kitchen may have other gas-using equipment, for example, a gas stove and a water heater, their number is limited to no more than 2, so the owner will have to choose what to leave.

To the apartment

Installing a gas heating boiler in an apartment is much more difficult, especially in a multi-storey building with access to central heating. The owner needs to be very motivated to obtain permission from the local administration for such an installation.

Next, you will need to obtain specifications from all engineering services: city gas, heating network and house balance holder. Next, according to the general scheme, the project is carried out, approved by the architectural department of the local administration, and the boiler is installed by a specialized organization.

The rules allow the installation of boilers in multi-apartment residential buildings no higher than 3 floors and a power of up to 30 kW. In kitchens integrated into the living room, the installation of closed-type units is allowed.

All these actions will become impossible if the premises for installing a gas boiler in the apartment do not meet the general requirements. The most difficult thing will be to make a through hole in the wall to connect the chimney.

To a private house

In a private home, there are more opportunities for the safe installation of gas heating equipment. In accordance with current regulations, gas equipment may only be located in rooms with good natural ventilation.

They can be located:

- On the 1st floor.

- In basements or basements.

- In the attic.

- In the kitchen units up to 35 kW.

- Thermal power up to 150 kW - on any floor, in an individual building.

- Thermal power from 150 to 350 kW - in extensions.

To the boiler room

A boiler room attached or equipped inside a house is built from fire-resistant building materials. The interior finishing is also heat-resistant.

A gas boiler room must have:

- Custom foundation and concrete floor covered with ceramic tiles.

- Adjacent to a blank solid wall of an object.

- Be at a distance of 1 m from the window and door.

- Have natural ventilation with three air changes per hour.

- Have an opening window with a glazing area of 0.03 m2 per 1 m3 of combustion volume.

- The ceiling height is more than 2.2 meters.

- Have a separate power supply with devices: sockets, switches, automatic machines.

- For power below 30 kW, the volume of the combustion chamber must be more than 7.5 m3, and for 30-60 kW - more than 13.5 m3.

- Air intake for the gas combustion process must be carried out through a coaxial chimney, a window, and ventilation holes.

Normative base

Installation of equipment is preceded by measures to adapt the premises in accordance with current requirements. They are set out in detail in the Technical Conditions issued by Oblgaz or Gorgaz. This is relevant for organizing heating using liquefied or natural gas. But usually, in the latter case, they neglect to issue an official permit, which can lead to a serious fine and a ban on the use of the existing heat supply system.

The document regulating the requirements for the premises for the installation of gas heating boilers is developed on the basis of the following regulations:

Studying these documents can take a lot of time. In fact, about 20% of their content is devoted to the organization of domestic heat supply using gas boilers. To avoid wasting time, we recommend that you familiarize yourself with useful excerpts from regulations.

Room standards for a boiler unit with an open combustion chamber

Such a boiler must be installed in a separate room that complies with SNIP standards. Installation in bathrooms and toilets is prohibited.

Special requirements for these modifications of boilers are due to the fact that they take combustion air directly from rooms that should not be residential.

Therefore, in addition to the general requirements for installing boilers, the following are added:

- The need for a separate furnace door with access to the street.

- Air intake must not be carried out from internal rooms.

- Exhaust ventilation and flue ducts must comply with the parameters specified by the manufacturer in the technical documentation for the boiler and its installation design.

Main characteristics

This combination - gas and wood - should be given careful attention, because gas has high explosive characteristics, moreover, during the combustion process itself, the parts of the heating structure heat up, which also adds a certain level of risk.

Important elements of the house that need to be taken into account when choosing such heating are:

- Floor material. As a rule, the floor is made of boards, plywood or OSB, which are laid over the foundation beams. Such a base is quite movable, which eliminates the possibility of installing a water-based underfloor heating system, because it must be mounted with a screed.

- Insulation of walls and windows. Basically, such surfaces are made of logs or beams, which have a high level of thermal insulation. The coldest place is considered to be the opening, both window and door. That is why heating of a wooden house should be centralized in such places.

It is also important to note that a large amount of heat is also lost through the roofing areas, so the surface of the floor and attic should also be carefully insulated.

Moreover, a material such as wood has good flexibility, which allows the entire system of pipes and air vents to be installed without much interference.

Room standards for a boiler with a closed firebox

The regulatory requirements for installing a gas unit with a closed firebox are not so demanding. This is due to the reliable smoke exhaust system of these modifications.

Scheme with a closed firebox

In them, exhaust boiler gases are removed from a closed combustion space into a coaxial pipe. Through it, directly from the street, a forced supply of fresh air is performed to ensure complete combustion of the fuel.

In this regard, modifications of boilers with a power of up to 60 kW can be installed in any non-residential premises that meet the following requirements:

- The height of the room is not lower than 2.2 m;

- total volume - over 7.5 m3;

- reliable supply ventilation;

- walls and floors made of durable fire-hazardous materials.

Types of heating of wooden houses

To keep a log house cool in summer and warm and cozy in winter, it is important to choose the right heating options based on modern heating systems

Electric heating

Heating a wooden house using electric heating guarantees residents ease of control of appliances and the absence of harmful emissions. In addition, there is no need to build a separate boiler room and chimney.

The electrical system has virtually no shortcomings, but it can be affected by external factors in the form of constantly increasing resource costs and imperfect operation of electrical networks with frequent voltage drops. To protect yourself from such problems, you can stock up on a generator, but in this case the issue of saving becomes moot.

If electric water heating is used, the risk lies in the coolant, which can leak or freeze if the equipment is not used correctly.

Electric heating is provided by:

- heaters (mounted, floor, built-in - such as underfloor heating);

- radiators equipped with individual heating elements;

- radiator heating circuit, the “heart” of which is considered to be a heating electric boiler.

Gas heating

Gas heating in a wooden house is an easy-to-maintain and fairly effective method that provides high efficiency, but at the same time requires increased attention to safety precautions. This is especially true for wooden structures in which it is planned to install a gas boiler.

In addition, not all suburban settlements are supplied with gas, which is also a problem that can be solved by installing a special container on the site for storing imported gas - a gas holder or purchasing cylinders, but this will significantly increase costs.

Solid fuel

Solid fuel equipment is considered the best option for heating those houses that do not have access to a gas pipeline and where there is questionable operation of electrical networks.

Such heating is effective and less expensive than an electric unit, and is also attractive due to the low price of the equipment and the ability to install all the elements yourself. Modern models of solid fuel boilers include components and parts that improve their efficiency: for example, an automatic machine for dosed supply of coal into the boiler.

For normal operation of the unit, it must be installed on the ground floor or in a specially built boiler room.

The raw materials for heating this type of boiler are coal, peat, firewood, sawdust or pellets. The device becomes very hot during operation, which increases the risk of fire.

To ensure safety, it is important that the boiler room is lined with non-combustible material. In addition, it is necessary to take care of the premises intended for storing raw materials

Pechnoe

Stove heating in a wooden house provides warmth and comfort. The most commonly used stoves are the Swedish type, which combine not only heat transfer functions, but are also equipped with a hob and oven. If desired, such a stove is complemented with a fireplace and sleeping places are arranged against its wall.

The disadvantage of stove heating is the likelihood of poisoning by combustion or ignition products. In addition, the stove can heat a house with an area of no more than 100 square meters using wood or coal. m.

Liquid fuel

Oil boilers are also particularly popular in areas where other heating options are not possible.

Diesel fuel (diesel fuel) is used as the main raw material. The advantage of this type of heating is considered to be the low cost of raw materials, and the main disadvantage is the possibility of carbon monoxide poisoning, the occurrence of fires if safety precautions are not followed, and the need to equip special premises.

Infrared

Considering the difficulties with popular heating systems, an innovative and efficient heating scheme based on infrared radiation was developed.

The principle of operation of this equipment is the operation of heating elements that radiate thermal energy on the surface of a wooden house (furniture, walls, ceilings, floors), which, when heated, release heat into the air. At the same time, warm air rises and mixes with cold air, which avoids overheating and saves up to 70% of energy.

Sometimes combined types of heating are used, when several types are used simultaneously. This can be heating with an electric boiler, the functions of which, in the event of a power outage, begin to be performed by a solid fuel unit.

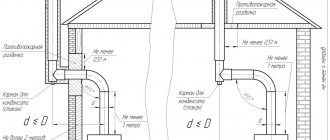

Requirements for the chimney device

The safety of a gas boiler is directly related to the correct installation of the smoke ventilation system, which must exhaust all exhaust gases into the atmosphere.

The following requirements apply to chimney installation:

- The chimney should not have more than 3 turns.

- The diameter of the flue must match the size specified by the boiler manufacturer.

- The edge of the pipe is placed 500 mm above the roof ridge.

- The hole for the passage of the chimney through the building structures of the task is made larger than the diameter of the pipe, the gaps between them are filled with fireproof material, especially in the area of wooden nodes.

- The smoke exhaust system must have a condensate drain at the bottom of the pipe and a deflector at the top.

Stove heating device in a private house: design of modern stoves

The main structural elements in a stove heating device for a private house are: foundation, trenches, ash chamber, firebox, smoke channels (smoke circuits), chimneys.

The foundation is the base of the stove, which takes on the loads from the stove and chimneys. This structural element must be reliable, since the safety of the structure in use depends on its strength. Correct placement of the stove foundation requires its location to be separate from the foundation of the house. The minimum gap between them is 3 cm, which is filled with sand.

First of all, they dig a well, which is then filled with small fragments of stone or baked brick, after which everything is carefully compacted. In this way, a pillow is prepared for the foundation. Then liquid cement mortar is poured into the pit. Laying a brick or stone foundation is done with bandaging of the seams. The last layer of cement mortar is carefully leveled.

After erecting the foundation, they begin to construct such a structural element of the furnace as shale. They are rows of brickwork that raise the oven on top of the foundation. To install the slates, two or three rows of brickwork are made. The bottom of the furnace is thus also involved in heat transfer.

An element of the design of heating furnaces, such as a blower, or ash chamber, serves to supply air to the firebox and to accumulate the ash coming from it. A special grate in the form of cast iron or steel rods is installed between the firebox and the ash chamber. While the stove is operating, the chamber door should be open, and at the end of the fire it should be closed to avoid rapid cooling of the air inside the stove.

The firebox in heating stoves is a furnace chamber in which fuel is burned - wood and coal. A special hole is installed in the upper part of the firebox to remove flue gas. The dimensions of the chamber are selected in such a way that it is possible to load into the furnace the amount of fuel necessary to heat the furnace.

At the bottom of the firebox, slopes to the grate are arranged, ensuring the free movement of ash into the ash pit. To prevent coals and ash from falling out of the combustion chamber, its door is installed above the grate by one row of brickwork. You can extend the life of the firebox by lining it with refractory bricks.

The operating principle of a stove heating system in a private home is based on heat intake through smoke channels, or smoke circulations. They can be positioned both vertically and horizontally, as well as rise and fall. How efficiently a stove operates depends on the size of the smoke ducts and their location.

The flue gas, passing through the channel, gives off energy in the form of heat to the walls, which heat the furnace. In order to increase heat transfer, smoke channels are designed in such a way that they are long and often change direction.

The smoke ducts of a modern stove heating of a private house can have a cross-section of 13 x 13, 13 x 26, 26 x 26 cm, their walls are made smooth (they are not plastered, since if the plaster is destroyed, the channels may become clogged). Access to the smoke circuits for cleaning them from soot is provided through special doors.

To obtain draft that helps remove gases from burned fuel, a chimney is installed, which is placed outside the house - on the roof. Most often it is made with a round cross-section, since gas movement in pipes with corners is somewhat difficult. In addition, round pipes are easier to clean. Ceramic or asbestos-cement pipes are used as the material for their manufacture.

Features of energy supply

The power supply of a gas boiler unit must be of two types: a separate power line from the subscriber panel and an emergency power supply, from batteries or a backup line. In addition, the boiler room power supply circuit must fulfill the following conditions:

- Mandatory installation of a boiler grounding system.

- Connecting the unit through a voltage stabilizer or uninterruptible power supply.

- The socket for the heating device must be located nearby in order to connect directly.

- The use of carriers is not permitted.

Wall backing material

The main requirement in finishing walls, floors and ceilings is fire protection. For this purpose, a special substrate is used for a gas boiler in a wooden house. It should not support the combustion process and protect the walls from temperature effects.

Recommended backing material:

- Basalt wool. A layer with a thickness of 50 mm or more is installed on a rigid base (metal sheet). The density of wool is maximum.

- Basalt fireproof sheets. In the event of an open flame, they will protect the wooden surface of the walls from thermal effects.

It is prohibited to use polymeric materials – polypropylene, foam. For floor-standing models, special attention is paid to preparing the floor surface. It is leveled and fire-resistant material is installed. In this case, basalt wool is not recommended, as it will shrink under the weight of the boiler. The solution is to install basalt sheets.

Fire safety

The combustion area must be kept clean, and there must be sufficient artificial lighting inside the room to provide good illumination for work and public areas. Storage of any flammable materials in such premises is prohibited. When pipes freeze, they can only be heated with steam or hot water. The use of open flame is prohibited.

Special requirements are imposed on the operation and maintenance of smoke ventilation systems; they must be checked and cleaned periodically:

- Every year in August – cleaning of smoke channels from soot contaminants and checking draft.

- Quarterly - cleaning of brick chimneys.

- The integrity of the ventilation ducts is inspected annually.

The entrance doors of the furnace room must open outwards. Windows - must have easily removable packages. At the entrance of the gas pipeline in the combustion chamber, a protective electromagnetic valve, a fire alarm and indoor gas sensors are installed.

How do heating radiators work in private homes: operating principle

Heating radiators in a private home are devices that transfer heat into the room from the coolant. The degree of its heat transfer ability depends on the area of the heating surface of the device. The open pipeline serves as an additional heating surface.

In European countries, the most common is the so-called gentle heating, since conventional heating systems dry the air in the room and also electrify it. As the heating radiator operates, dust settles on it, which then rises with the warm air. It begins to decompose into substances, some of which are quite harmful to human health.

By using gentle heating, this problem can be solved. In this case, the temperature of the heated surface should not exceed 45 °C. Taking into account the operating principle of heating radiators, additional fins are installed on them, which make it possible to increase the area of heating devices.

Typically, heating devices are installed in wall niches under windows, placed along the walls in 1-2 rows; sometimes they are covered from above using decorative panels. However, in the vast majority of cases, devices are placed directly on the walls under the windows. The length of heating devices is no more than 75% of the length of the window opening, and they are not mounted on internal walls.

Depending on the method of heat transfer, type of heating surface, material, and the magnitude of thermal inertia, several types of heating devices are distinguished: convective, radiation, convective-radiation. All devices can be either with a smooth or ribbed heating surface.

Heating devices include finned tubes. Many narrow fins allow you to increase the heating surface area. Install the pipes, forming several rows. These heating devices are low cost and compact. They are easy to install.

The operating principle of a heating radiator is based on combining the operating principles of convector and radiant heating devices. According to its design, it can be sectional or panel, made of metal.

In Russia, sectional cast iron radiators are most widespread. They consist of single- or multi-channel sections and have channels of ellipsoidal or round cross-section. The sections are connected to each other using nipples with rubber, paronite or cardboard gaskets.

In order to prevent an increase in hydraulic pressure, an expansion tank (damper) is used. It not only serves as a container for excess water that occurs after it is heated, but also replenishes the lack of liquid when cooling the water. Expansion tanks can be either open or closed. In private homes, the latter are mainly used.

A heat pipe is used to supply and remove coolant from heating devices. It consists of liners, risers, mains and horizontal branches. The water heating boiler and the riser are connected to each other using a main line, and the connections act as connecting elements between the risers and heating devices. The riser is a pipe connecting the connections to the main line.

Choosing a location for a gas boiler

The choice of such a location can be carried out by a specialized organization during the development of a gas boiler installation project. The owner must only agree with the design organization on the preferred location from the possible options:

- In the kitchen;

- in the basement or attic;

- in non-residential premises, for example, in a garage and workshop;

- in an extension to a residential building.

Thus, simply taking and placing a gas boiler in the house will not work. It will be necessary to fulfill all the numerous requirements of the boiler installation project, SNIP, gas, fire and sanitary safety regulations.

Only then will the owner of such a heating device be able to obtain permission to operate it.

Boiler power calculation

When the type of heating unit is selected, you should decide on its power. If desired, you can order a thermal engineering calculation that allows you to determine heat loss in the premises. Based on this figure, they begin to select the boiler power.

You don’t have to make calculations, but use the standards obtained experimentally, according to which 1 kW of boiler power is required for 10 “squares” of area. To this result should be added a reserve of productivity for various losses.

For example, to supply heat to an apartment with an area of 60 square meters, you need a 6 kW device. If you plan to heat the water, add 50% and get 9 kW of power, and in case of abnormally cold weather another 20-30%. The final result is 12 kW.

But this is a calculation for central Russia. If the settlement is located to the north, the productivity of the unit should be further increased. The specific value depends on the degree of insulation of the house. For a panel or brick high-rise building this will be 50% or more.

The boiler must have sufficient power to ensure comfort in the apartment, so you should not save on it. The difference in cost will not be big. If you purchase an automated boiler, there will be no excess gas consumption, since such models of units are the most economical.

The process of obtaining permission related to whether it is possible to install a gas boiler in an apartment is quite complex, costly and time-consuming. But all the effort is worth it, since it is much better to live at a comfortable indoor temperature. At the same time, you will have to pay less for individual heating than for centralized heating.

Step-by-step experience of self-gasification of a house in the Moscow region: initial stage

Everything that is written below is the personal experience of a FORUMHOUSE member with the nickname Alex347, and we are talking about the Moscow region. Input data:

- The house will be connected to the gas main in 2022.

- The house stands on a plot of 12 acres in the DPK - a dacha consumer cooperative.

- The area of the two-story frame house is 144 square meters. m.

- The volume of the boiler room for gas heating ( important ) is at least 15 cubic meters. m.

- The main gas pipe runs 1.5 meters from the site boundary at a depth of 1500 mm.

- The distance of the main line for introducing the pipe into the house is 30 m.

Alex347

Friends! I think my experience will be useful to you. I myself went through all the stages of connecting gas to the house and would like to tell you about them. I did everything myself, slowly. It could have been faster, but I had time. For money, they offered to do everything “turnkey”, but I decided to act without intermediaries. So, from the very beginning. What I had:

- Ownership of land and house.

- BTI passport.

- The house was assigned a postal address.

- Geodesy, which was done by the company for 13 thousand rubles. The site plan shows the house, communications - water and electricity supply and sewerage pipes.

- Geodesy is needed for the project.

- Written consent of the head of the dacha-consumer cooperative for gasification of the house.

In addition, the house must have:

- Exhaust ventilation. The diameter of the pipe is at least 15 cm.

- Window in the boiler room.

- The gap between the floor and the door to the boiler room is at least 30 mm, for ventilation of the room.

A protocol was issued for ventilation from the company recommended by the main gas supplier. It took 4 thousand rubles.

- Grounding, because The gas boiler has electrical components.

A protocol was also required for grounding. The asking price is 4 thousand rubles.

The house has a gas boiler and a gas stove and radiators.

Alex347

Important point! You will often have to take time off from work to meet people from gas and installation services. Or, someone must be in the house at all times.

Is it possible to install gas equipment yourself?

The possibility of installing the boiler yourself is quite possible, but to carry out this process you need to familiarize yourself with a number of special documentation, SNiPs, conclude an agreement for gas supply, develop a project, approve it and obtain permission to carry out the work. Going through all the necessary stages is a rather labor-intensive process that involves spending a lot of time, and let’s be honest, nerves. Special authorities have a specific attitude towards people who want to do the installation themselves.

It must be taken into account that even a small deviation from regulatory documents can not only cause a fine when checking the gas service, but also cause irreparable harm to the house, as well as the health of its inhabitants. Therefore, in the case of a gas boiler, it is better to entrust the work to specialists.