Author: Yuriy Fedorovich Kolesnikov, thermal power engineer

There is no shortage of available solid fuel in Russia and is not expected. A stove with a water circuit costs much less than a boiler: prices for domestic heating stoves with a water circuit start at 16,000 rubles; The average cost of such a stove across models is approx. 40,000 rub. A more or less decent boiler for the same thermal output costs three to five times more. Firewood in remote regions is often free - foresters will only be happy if someone removes the dead wood. Wood fuel is environmentally friendly: the growth time of a tree until it is suitable for use corresponds to the time of natural climate cycles, and when burning wood, exactly as much carbon dioxide is released as the tree removed to build itself. If you burn with fossil fuels, then nature “digests” the total emissions of greenhouse gases from many house stoves, dispersed over a large area and extended over time, much easier and faster than a salvo from a thermal power plant of the same power.

Building a brick or making a metal stove is quite a tricky business, but it does not require a machine park or production conditions. See, for example, video project of a brick stove with a water heating circuit for a private house:

We make wiring for a water heating system

The best option for a bathhouse would be a stove, into which a specially prepared water boiler is obviously installed, even at the construction stage.

In this case, the furnace acquires its own specific design features, which significantly increases the efficiency of the entire system and its compactness. Installation of such a furnace has the highest heat transfer efficiency

Heating of premises using the stove method ranks next in terms of efficiency after gas heating. The reality is that gas lines do not go everywhere, so you have to heat with wood. A conventional wood-burning stove has one serious drawback: heating efficiency is achieved only in the nearest room, and even then, not entirely evenly.

We can highlight the following nuances of using a wood-burning stove:

- Rooms located far away either remain cold or have to be additionally heated with electricity. In addition, often there is simply nothing to power powerful electric heaters. Since there is a maximum of 3.5 kW per outlet, and the power of the device exceeds 7 kW, three-phase power is required.

- In the absence of a thermal curtain, the windows constantly sweat and become covered with frost.

The solution to this problem will be to distribute the heating network from the stove throughout the premises, and install radiators for water heating under the windows. You will need to do a minimum of work: connect the stove to the water heating boiler, and make the appropriate high-quality wiring.

The simplest heating scheme will be a single-pipe one, with natural circulation of coolant. It is also called a gravitational system - in it, depending on the temperature, the liquid, increasing and decreasing in volume, circulates throughout the system.

A more detailed diagram of the furnace boiler looks like this:

- From the heat exchanger, the circuit rises upward - thus creating an accelerating manifold. An open type expansion tank is installed at its end. It is necessary to collect excess coolant due to expansion, where excess air from the heating system enters it.

- Next, the main circuit throughout the house goes back from the expansion tank to the heat exchanger, giving off all the heat to the radiators.

So that in a stove with a boiler for heating a house, circulating water can always move along the contour, there must be a slight slope along its entire length. To achieve the best circulation in it, the final part of the circuit should be as low as possible.

Scheme of water heating of a two-story wood-burning house

Combined heating system for a private house

A boiler is installed in the firebox, two pipes are connected to it - one supplies hot water, which is sent through the expansion tank into the system, the other returns water back to the register. Thus, water circulates in the system due to the force of gravitational law.

Often, small but powerful pumps are installed for good circulation. Such a pump is usually installed on a water return pipe (return); this method is especially effective when a large room is heated, which allows you to maintain the temperature in all parts of the system almost the same.

Scheme of a stove with a water circuit

Connecting the stove to the water circuit will significantly increase the efficiency of the installation, which is achieved through better heat distribution throughout the house without increasing combustion power. A detailed diagram will be very helpful in this matter.

When forming this type of system, the boiler under water is installed in the center of the furnace, as close as possible to the firebox or directly above it. Cold water is supplied through the lower pipe, which, having passed through the entire circuit, is heated, and from above, under the pressure of the flow movement, is sent back through the pipes.

Air flow pattern

The heat exchange compartment can be installed in one of two types. The single-chamber model is a straight tank formed by a boiler or flat box. The tubular version involves movement along pipe channels placed one above the other.

The second method is of great value, since due to the small volume of the filled space, the water flow constantly moves through the pipes. You should take hollow guides with a diameter of at least 5 cm so that the water inside does not boil.

Regardless of the choice, the dimensions of the furnace directly depend on how many caps of the heat exchange section there will be, as well as what additional sections need to be built in.

Stoves in houses

Creation stories

In the history of the creation of home brick stoves, the masters and developers I.V. Kuznetsov, Grum-Grzhimailo, I.S. Podgorodnikov are especially famous. Kuznetsov is the author of 150 developments that have been translated into reality.

Kuznetsov stoves with water heating have become especially popular. They are recognized not only in post-Soviet countries, but also abroad.

Chimneys

Classic stoves in houses complete with hobs, despite the differences in design, have one feature that unites them - the natural draft of the chimney.

This feature has a direct impact on the efficient operation of the furnace. Without natural draft, the stove will not be able to work; even modern solid fuel boilers need it.

Heating boiler assembly

In order not to look for any special materials to assemble a water tank, you should consider cast iron heating radiators as an alternative. They are the most reliable, as they can easily withstand high temperatures inside the oven. The unit must be disassembled into its component parts and washed with a solution of hydrochloric acid to remove scale and residual products of former water heating.

Then the sections are connected using asbestos cord, previously soaked in drying oil, as a seal. It is wound onto the joints and carefully knocked down the structure along with the cast iron nipples. Leave the holes free, on one side - the top and bottom. The supply and return pipes will be laid there. Thus, the heat exchanger for the furnace is ready.

Requirements

When equipping your heating installation with a water jacket yourself, you need to know some simple rules:

- To create a coil, you can use steel pipes or sheet steel with a thickness of at least 5 mm. Thinner metal can quickly burn out due to high temperatures in the firebox.

- The internal diameter of the pipe (or sheet steel structure) should not be less than 40 mm, otherwise the water in the coil will boil almost instantly, which can lead to mechanical damage not only to the water jacket, but also to the masonry.

- A gap of 1.5 - 2 cm is required between the coil and the masonry for thermal expansion of the steel. Failure to comply with this rule will certainly lead to the destruction of the masonry.

It should be understood that the shape of the heat exchanger also matters.

Manufacturing technology of a water circuit for a brick kiln

A well-placed brick stove with a water heating boiler is a heat accumulator, that is, in addition to heating the coolant for distribution into the heating system, the structure itself heats up and transfers heat to the rooms. When equipped with a hob, the device will eliminate the problem of preparing meals in areas with interruptions in the supply of gas and electricity.

Other advantages include the uniformity of heat supply and maintaining the temperature of the water coolant until the fire in the firebox goes out. But even after the end of combustion, the device releases thermal energy for a long time, maintaining a comfortable temperature in the house.

- the heat exchanger built into the firebox will not work due to the reduced volume;

- if the cold coolant moves particularly intensively, the efficiency of the device decreases and soot accumulates;

- non-compliance with the technology of integrating heat exchangers into the smoke duct leads to a decrease in throughput and the entry of carbon monoxide into the room;

- When embedding a heat exchanger into the masonry, you need to ensure that there is space left for the device to expand when heated, otherwise the masonry will become loose;

- inaccurate calculations of the power of the heat exchanger built into the chimney will lead to a decrease in the temperature of the flue gases and the formation of condensation, which leads to rapid wear of system parts.

You can reduce the risk of error by using ready-made factory devices or entrusting the job to craftsmen who have experience in constructing a heating system with a water circuit from a furnace.

Types of heat exchangers and areas for their placement in a brick stove

Heat exchangers are classified according to the type of material from which they are made:

- Cast iron. The heat-resistant material is suitable for arranging boilers, but does not tolerate temperature changes. If a cast iron heat exchanger is being formed, you cannot add cold water to it during the heating process - the metal will burst.

- Copper. Durable material with high thermal conductivity. It cannot be used in furnaces due to heating - the melting point of copper is +1083 C, the firebox warms up to +1400 C.

- Steel. The material is suitable only if it has high heat-resistant properties and a wall thickness of 5 mm or more. It is recommended to choose seamless pipes with anti-corrosion treatment.

- Stainless steel. Durable material practically does not rust, lasts a long time and has good thermal conductivity. The best steel grade is AISI 3040.

Material for making a heat exchanger with your own hands

It is most practical to use sheet steel or pipe. Nuances of doing the job:

- Sheet steel is selected with a thickness of up to 5 mm, 2 holes are cut in the sheet itself for a pipe with a cross-section of 50 mm - this is for the supply and return circulation pipelines of the coolant. The steel structure is placed inside the firebox so that it fits the walls and ceiling, and is supplemented with outlet openings (sides) for loading firewood and releasing gases. The internal gap must be at least 30 mm so that the liquid for supply to the heating network does not boil. The heat exchanger should be positioned so that the supply pipe is at the highest point; this is necessary to eliminate the risk of vapor locks and prevent water hammer in pipelines and radiators.

- If the heat exchanger is made from a pipe, then it is also placed in the firebox. A round pipe with a cross-section of up to 50 mm or a profile pipe with a rectangular cross-section of 40x60 mm or 60x60 mm is suitable. The parts are welded into a structure according to the calculated dimensions, there is only one rule - place the heat exchanger so that it does not interfere with the loading of fuel or block the grate and smoke exhaust channels.

When making pipe elements in the form of a flat register, the heat exchanger is installed in the chimney channels. This is not the best option, because there is little heat in this zone and you need to take a larger cross-section pipe. It is prohibited to install such parts into a finished furnace; they will overload the structure - all calculations and loads are performed only at the design stage and installation of the furnace.

Rules for calculating heat exchanger parameters and power

The standard formula is this: 1 kW of heat is required per 10 m2 of heated area. When applying calculations to a heat exchanger, you should know that up to 10 kW of thermal energy is removed from one 1 m2 device. If you make wood heating with a water circuit, then up to 6 kW of heat per hour is removed from 1 m2 of heat exchanger, for a coal stove up to 10 kW/hour.

For example, for a house with a heat demand of 15 kW/hour, the calculation is carried out as follows: S=Q/Qy, where 15/6=2.5 m2, and S is the area of the house, Q is the required thermal energy, Qy is the amount of heat released heat. An example is given for a heat exchanger made of sheet steel. In this case, the total area of the heat exchanger that comes into contact with the hot air of the firebox is 2.5 m2.

DIY masonry

Kuznetsov's heating and cooking stove with a corner shield or other design when performing the main stage of work is divided into several operations. Let's look at them in more detail.

Order

Description of the masonry

Regardless of what kind of structure we are building, the order of the Kuznetsov heating and cooking stove with a stove bench or a simple heating structure, the basic scheme does not change. Only the dimensions of the oven change. The remaining basic rules do not change:

- The bricks of the common channel coming out from the chambers of the 1st tier near the second layer of the bell chamber are laid on the edge and the masonry is done in a quarter of a brick. This increases the length of the combustion compartment;

- at the level of 2/3 of the height of the structure or on the 17-18th row - the first tier of caps is overlapped;

- In the inner sides there are special grooves on both sides for igniting firewood, with the size of one side being 60 mm. Such holes are made at the level of 21 rows. This will make it easier to clean chimneys if they are clogged.

The work is carried out according to a certain scheme.

| Row No. | Description of work |

| 1 | This is the basis of the entire system, so we lay it out solid, without voids or cracks. It is important to maintain the correct position of the bricks in all planes. Seam thickness – 5-7 mm. The corners should be laid out taking into account the diagonal dimensions. The structure must have precise dimensions and the correct configuration. Therefore, you will have to chip off and adjust the bricks to size. For this row you will need to prepare 20 ceramic parts. |

| 2 | We begin to form a chamber for collecting ash and organizing additional draft when lighting firewood, as well as the lower tier of 1 bell. On the outer sides we lay 2 halves without mortar and move them out of the row. These will be grooves for cleaning the ash pan after finishing the masonry and removing construction debris. On the front side we install and prop up the blower door with a stack of bricks. For this row we soak 14 bricks. |

| 3 | We securely fasten the blower door on this row and the stack of bricks can be removed. The laying is carried out according to the order scheme. |

| 4 | We lay out the back and side walls of the furnace combustion chamber from fireclay bricks. 2 ceramic parts are placed on top of the door; they should be slightly bent at an angle and protrude above the door. On the inside, in this place, we place 2 fire-resistant parts similar to the outside ones. To create a thermal gap, leave a small gap between the outer and inner layers of 5-7 mm. To do this, we do not place a solution between them, but a layer of combustible material of sufficient thickness. When the heating device dries, the material will burn, and the gap will compensate for deformations from different temperatures. |

| 5 | We begin to form the combustion chamber. To do this, all parts of the front part are cut at an angle. The space between them will be used for laying the grate; it should fall freely into the prepared groove, so we make a cavity with a small margin of 5-7 mm, taking into account the creation of a thermal gap between the grate and the bricks. Immediately behind the combustion compartment, at the location of the lower hood, we begin to lay out a vertical channel measuring 100-120 mm. It connects the caps together. We fill the gaps up to the grate with sand. |

| 6 | We begin to install the firebox door. We leave a temperature gap between the brick and the metal. To do this, we wrap the door hinge with fireproof material of the required thickness and install it in place. For the inner row, you will need to lay 3 fireclay parts in the place where the door is installed. |

| 7 | We make a dry seam on the back side. To do this, on the left side we leave a gap between the rows, up to 30 mm thick. Exhaust gases from the firebox will escape into it and provide additional draft in the firebox. |

| 8 | The laying is carried out according to the order scheme. |

| 9 | The walls of the firebox are closed. The formation of a channel for the removal of gases into the chimney begins. We carry out the laying according to the diagram. On this row, the top of the door is repositioned with a wound asbestos cord to seal the seam. |

| 10 | We cover the arch of the firebox with asbestos sheets and lay ceramic bricks on them without mortar. We lay out the cavity for laying the hob. To fasten it, we cut grooves 10-15 mm wide from the inside of the bricks. The fireclay brick is cut at an angle and laid out according to the ordering pattern. A cord made of fire-resistant material is placed in the grooves. On top we place a hob made of cast iron or thick heat-resistant steel. |

| 11 | According to the diagram, we lay out the roof of the cooking chamber, and install a tray for its door. |

| 12,13,14 | We continue to lay out the cooking chamber in order. |

| 15 | We begin to close the cooking chamber. To do this, we lay out its arch from red brick on a fixed steel plate. |

| 16 | According to the drawing, steel guides are laid out, on which we lay bricks, leaving marked ventilation ducts. On the bricks specified for installation of ventilation valves, we make samples for them. We install summer valves that will regulate the operation of the stove during the warm period. |

| 17 | The surface of the cooking compartment is lined with ceramic parts. |

| 18 | We form the top cap. We install 2 halves without solution, which will serve as channels for cleaning it. The rest of the work is carried out according to the scheme. |

| 19-26 | Executed according to plan. |

| 27 | We begin to prepare the base for laying continuous rows. |

| 28 | We make grooves in the bricks to install the chimney damper. The rest form the structure of the furnace. We install the damper. |

When laying out subsequent rows, the Kuznetsov stove diagram is used. A channel is left in the center for the passage of gases and the pipe is led to the roof.

Our Kuznetsov dome stove is ready. It remains to do a few preparatory work and it can be put into operation.

Types of mini-ovens

Mini-ovens are divided into several main subgroups. Let us analyze the main classification in detail.

Steel

The most affordable and popular material in the production of stoves. The main advantage is the low price and the ability to make it yourself. Homemade products will not be able to compare with industrial designs in appearance.

But in terms of performance, a home craftsman can make a design better than an industrial one. To do this, it is enough to weld several convection pipes and cover the surface of the walls with fireclay bricks.

The advantages include the low weight and mobility of steel appliances. They do not require a separate foundation, and in the summer you can equip a kitchen outside.

Cast iron

Cast iron units are the best option for small spaces. According to its properties, the material can accumulate and gradually release heat after fuel combustion.

Such devices can be easily taken out and set up as a summer kitchen in the warmer months, but you will need to find help. This design can weigh at least 25 kg.

An additionally installed container for heating water will add comfort to your small home. But cast iron is very sensitive to shocks and sudden loads.

Especially in a heated state, a slight impact can cause cracks to form. A massive and heavy structure will require an additional foundation, especially when installed on a floor made of fire-hazardous materials.

Brick

Brick mini-stoves are not very suitable for heating a dacha. Small premises in the country mean their use only in the warm season. Therefore, long breaks in operation and the stove being in an unheated, damp room are possible.

Such a stove becomes damp and begins to smoke. It will be necessary to carry out repair work and cover up all the cracks and seams between the bricks. But if there is enough space for construction and you plan to live permanently in a small garden house, there is no better option.

Such a unit can be retrofitted with a water heating tank, hob and oven. The stone accumulates heat well. The room will be heated for a long time after the firewood has burned out.

- Electric infrared stoves (quartz or halogen) allow you to quickly heat a room, but when turned off, the room instantly cools down.

- Gas burners built into metal or brick stoves are preferable to electric ones. But you will need to equip the system with automation and constantly refill gas cylinders.

- Solid fuel stoves are the best option. A homemade steel stove running on available fuel will not require large costs for the production and procurement of fuel. By spending a little more money on the purchase, you can purchase combined units that can operate on several types of fuel.

Furnace calculation

To make a reliable Kuznetsov stove for a 2-story house or for a small garden house, you will need to perform simple calculations

But if it is important to determine the exact power of the stove for your home, it is better to entrust such work to professionals

For example, let's calculate for a small, one-story house, with an area of 35 m2, a volume of 77 m3, with 1 window and door

To calculate, it is important to know the formula and several basic coefficients. We will need to multiply the volume with the sum of the coefficients of the thermal insulation layer (1.2) and the glass window (1.2) and add the coefficient of the material of the wooden door (1.5)

We substitute the data and perform the calculations: 77*(1.2+1.2)+1.5. We round the result up, we get the required furnace power of 21 kW.

To determine the dimensions of the furnace themselves, several proportions are observed:

- Based on the volume of the room, the area of the firebox opening is determined. They should be calculated in a ratio of 50-70 to 1;

- The depth of the combustion compartment is determined in a ratio of 1 to 2.

Advantages and disadvantages

Designs with a built-in heat exchanger have many advantages:

- The system is energy efficient and economical. Brickwork will not require serious financial investments, the costs for pipes and radiators will be in any case, and the heat exchanger is an order of magnitude cheaper than ready-made boilers. When operating a stove, the cost of heating the house will be several thousand rubles for the purchase of firewood for the winter period.

- The design of a brick stove hides unsightly elements; if desired, a fireplace or decor can be added to the system.

- Heating of the room does not depend on the location of the structure; radiators can be installed anywhere

- A brick stove takes a long time to cool down; the water circuit will remain hot for several hours after the wood burns out.

Some publications list the advantages of the water circuit system as the possibility of installing it in a ready-made furnace, which is possible in principle, but in practice this option is associated with a large number of problems that have to be solved.

Disassembling and subsequent reassembly of the stove is the most necessary thing that will have to be done. The cost of correcting an incorrectly installed register is comparable to the cost of a new stove, so contact professionals for such work.

The disadvantage of this design is a continuation of its advantages; in order to make a stove with heat exchangers yourself, experience is required, both in laying bricks and in installing heating systems. If experience comes with age and the amount of material studied, then when building a furnace with a water circuit, its disadvantages should be taken into account:

The fireplace is a fire hazard; it is necessary to take measures to prevent fire from reaching flammable objects; The stove takes up a significant area of the house, design the rooms in advance, include a large heating system in the design of the room; The temperature near the stove will always be higher than in the rest of the room; The heating process of the oven cannot be stopped instantly. If you are using a closed loop system with a circulation pump, turning off the electricity (even briefly for a few minutes) and stopping the pump will cause the water in the heat exchanger to boil. To avoid this, provide a combined system for water movement in the circuit. If the heating system is not used regularly, the water must be drained, which leads to premature wear of the entire structure. Otherwise, the water will freeze, which will lead to the destruction of the entire complex of devices. You cannot light the stove without water in the circuit.

This will lead to the destruction of the register and the reconstruction of the stove in order to use the stove in the summer without “turning on” the battery using the original design of the installation of heat exchangers. There is a risk of carbon monoxide poisoning, as with all solid fuel heating products, special attention must be paid to the correct manufacture of the chimney.

Making a heating system in your home based on a stove with a heat exchanger and batteries is an economically viable solution, but the design and construction must be approached competently, taking into account all the nuances of the work.

Varieties for different purposes

Igor Kuznetsov and his team have created a large number of universal and specialized models. Some are intended only for heating rooms, others are supplemented with elements for cooking or heating water. Fireplaces are a separate area.

Drawings of options tested in practice are collected on the inventor's website. For convenience, the structures are assigned alphanumeric designations.

Heating

Kuznetsov’s heating stove for a two-story house allows you to save on fuel

Various configuration options for domes make it possible to construct structures for heating one- and two-story houses.

Heating models are abbreviated as OIK (heating models by I. Kuznetsov). You can find options with a firebox located inside the room or in the utility room.

For variety and to give the desired qualities, there are stoves supplemented with warm beds (OIK -6 bed. AND OIK 19 bed.) and seats (OIK-7s).

Some products have built-in ovens. In this case, the letter D is added to the code designation, for example, OIK-5D.

Heating stoves also include stoves with a built-in fireplace.

Models RTIC (Russian heated heater by I. Kuznetsov) are needed for heating large rooms. They are massive and need a strong foundation.

Options with fireplace

Model with fireplace

Fireplaces, in addition to their heating function, serve as interior decoration. In this case, the firebox is open, the fire can be observed visually. The stoves are equipped with a firebox for conventional heating, which can be located on the facade, on the right, left side, or behind.

For construction, they choose an option in which it is convenient to service the stove from a utility room or hallway - you do not have to carry firewood into the living room. Working with waste (ash) also does not imply inevitable dirt in the room when cleaning the ash pan and the vent from the hallway.

Options for OIK-K have been developed with couches, built-in ovens and a corner fireplace.

Boilers

To organize a water heating circuit, options have been developed with the designation KIK (I. Kuznetsov boiler). A steel heat exchanger is built into the second dome. Water circulates through the system due to an electric pump.

Models are designed for power of 16, 17, 34 and 64 kW. The first option (16 kW) is equipped with a hob.

Heating and cooking

Heating and cooking model - a structure that completely exhausts the fuel resource

Universal heating and cooking stoves are designed for homes with year-round occupancy. The model has built-in hobs and ovens, shelves for heating food and water.

The firebox can be located on the front or side, which allows you to choose an option for any interior design.

Installation of a bed is available as an option. For large rooms, elongated fireboxes are made, which allows the use of large-caliber firewood. They burn longer and you will have to add fuel less often.

For the bath

I. Kuznetsov singled out sauna stoves as a separate area. There are three varieties: BIC, BIC BC and BIC PC. The abbreviation BIC corresponds to the purpose, and additional symbols indicate that the structure is equipped with a fireplace.

For different layouts, models are chosen that differ in the location of the firebox and fireplace - in the steam room, relaxation room or in the dressing room.

About the heat exchanger

When building a brick stove with a water heating boiler with your own hands, you should take into account many factors and calculate the project as a whole. Any type of materials and structures have their advantages and disadvantages.

There are several ways to install a water register in a furnace:

- Inside the hearth;

- In the chimney;

- In the body of the stove, next to the hearth.

Depending on the location, choose the material for the heat exchanger and its shape:

- Copper - effective due to the high thermal conductivity of the metal, but due to the low melting point of copper, constant circulation of water in the system is necessary;

- Steel - heat-resistant steel with a wall thickness of 4-5 mm is used for boilers. For long service life of steel structures, it is not recommended to drain water from them.

- Stainless steel is expensive, but the most suitable material for a boiler. The only disadvantages include the complexity of manufacturing.

When choosing the type of material and installation location of the heat exchanger, it is worth remembering that by placing the water circuit in the fireplace, in the summer the entire system will heat up; to avoid this, you will have to remove separate batteries to remove excess heat.

When installing a heat exchanger in the chimney, additional dampers are added to the stove design, which do not heat the boiler during summer operation of the stove. It should be taken into account that the heat exchanger must be larger in volume than when built into the fireplace. In addition, the boiler should not reduce the throughput of the smoke channels.

Calculation of power and dimensions

For normal heating of the room, it is necessary to correctly calculate the register area and its power. For a brick kiln, an approximate calculation is sufficient; it is impossible to make an exact one, due to many factors and variables.

It is known from practice that heating 10 m2 of space requires 1-1.5 kW of energy. From one square meter of heat exchanger you can get 5-10 kW. To determine the register power more accurately, you need to consider:

- Location of the coil in the furnace;

- Type of fuel - wood, coal. When burned, wood produces less thermal energy.

- Approximate temperature in the hearth and location of the heat exchanger;

- Average water temperature throughout the entire circuit;

- The heat transfer coefficient of the material from which the coil is made.

As the fuel burns, the power of the heat exchanger will decrease, so it is better to increase the calculated coil area by 10-15%.

Design

There are many types of heating brick stoves. They can perform only the function of heating the room or combine heating and cooking. There are also combination stoves with several fireboxes.

The principle of operation of a brick oven, regardless of its design, is the rapid accumulation of heat during combustion and its long-term release by the walls of the oven for several hours or even days. The stove material is ceramic brick, a good heat accumulator.

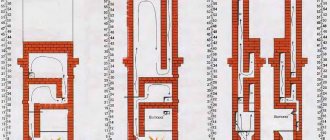

To increase the volume of heated brick, the smoke channels in the furnace are made extended, placing them along the walls. Hot smoke, passing through them, heats the brick and by the time it leaves the chimney it has a safe temperature. In addition to increasing efficiency, this design feature of brick kilns reduces the risk of overheating and roof fires.

A little theory

Traditional home stoves with hobs, “Dutch” and “Swedish”, despite their design differences, are united by one common feature. It affects the efficiency of these heating appliances - this is the natural draft of the chimney. Without draft, none of the majority of known stoves will function; solid fuel boilers are not far behind in this regard.

Let’s make a reservation: none, except Kuznetsov’s, because only the brainchild of Igor Vladimirovich does not require natural traction for its work.

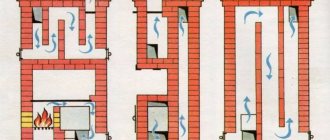

The secret of efficient operation, which distinguishes Kuznetsov’s two-bell furnaces from all others, lies in the principle of free flow of gases, which does not require additional external energy.

This theory is described in great detail and in an accessible way in articles posted by the inventor on the pages of his own web resource www.stove.ru. There are also publicly available designs of furnaces that have already been put into operation. We will look at the theory briefly, comparing the traditional method of burning solid fuels with the processes occurring in a bell furnace. So, in a conventional or duct stove of the “Dutch” type, the movement of air and combustion products is due to the presence of draft in the chimney pipe.

Natural craving is an external factor that acts depending on:

- height difference between the entrance to the ash pit and the upper section of the pipe;

- differences in temperatures of outside air and flue gases;

- wind load.

That is, the draft is present even when the heater is inactive, as long as the damper is open. In the operating mode of the furnace, the draft increases many times, the speed of the gases increases sharply. As a result, a lot of air enters the firebox, the combustion temperature drops, and the efficiency of wood burning decreases. By limiting the access of air with a damper, we force the fuel to smolder with a lack of oxygen, which is also not the optimal mode for extracting thermal energy from wood.

A proper stove with high efficiency should remove maximum heat from combustion products so that it does not fly out into the chimney. In practice, this is not so easy to implement and here's why:

- when the damper is open, hot gases quickly move through the brick channels, not having time to transfer heat to the walls;

- if the damper is closed, the flow speed will decrease, but the material of the channels is not able to absorb all the generated heat and transfer it into the room, so some of the energy still flies out into the pipe.

For these reasons, the efficiency of use of almost all existing furnaces rarely reaches 60%. Kuznetsov's developments successfully solved both problems; the efficiency of fuel combustion and the efficiency of using the released heat are about 80%. Not every boiler operating on solid fuels can produce such an indicator. I.V. Kuznetsov outlined the basics of designing furnaces in accordance with the principle of free flow of gases, which we will consider below.

Tips for use

Each owner of a solid fuel stove will need these instructions:

- In the fall, we carry out a preventive inspection and eliminate all faults. To fill the cracks and seams between the bricks, we use a solution of fireclay or red clay or seal them with sealant;

- maintain a sufficient level of traction. Before burning wood, be sure to open all the dampers and the ash pan and bring a lit splinter to the firebox door. If the flame draws into the stove, you can light the fire;

- Do not forget the rule for determining the amount of thrust by the color of the flame. At the slightest sign of a clogged chimney, we clean it immediately;

- It is prohibited to use firewood with a humidity level of more than 20%;

- Even in severe frost, it is recommended to heat the stove in the morning and evening. Heated brick walls of chimney ducts reduce the efficiency of stoves. The difference between the temperature of the exhaust gases and the walls of the chimney decreases, and less heat enters the room. But this rule does not apply to Kuznetsov stoves with a 2-bell system.

Calculation of basic parameters

In order to correctly build a Kuznetsov furnace, it is necessary to strictly follow the diagram developed by specialists. Craftsmen who have extensive experience in the construction of such furnaces recommend that before starting major masonry, practice laying it “dry” if you are doing this for the first time.

If the stove is being built during the construction of the house itself, then it is necessary to draw up the project in such a way that it can heat several rooms at once.

The foundation for the stove must be of high quality and must have a waterproofing layer. It is also necessary to take into account that the foundation of the house should not go into the base for the stove. This structure must have its own foundation, which shrinks on its own.

The concrete base should be approximately 10 centimeters larger than the size of the stove on all sides. The degree of its depth will depend on the height of the structure and the soil composition where the furnace will be built. Typically the depth of the pit is from 40 to 60 centimeters. A sand cushion is placed at the bottom for waterproofing and a layer of crushed stone to strengthen the building. To form the side walls, formwork from boards is installed.

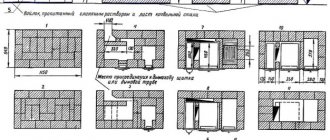

Layout diagram of the bell-type furnace OVIK-9

- The oven (OVIK-9) has a cooking chamber with 2 burners and steel lockable doors.

- It is equipped with a separate exhaust duct, which allows you to regulate the temperature inside the locked niche.

- It can be used as an oven, so metal runners for baking sheets are built into the walls.

- The two-bell stove can be used in “summer” and “winter” mode.

Therefore, in the summer you can only cook with it. Heating and cooking stove Kuznetsov OVIK-9

The depth of the firebox is 450x470 mm with a dry seam to expand the brick by 2–3 cm. If the firebox needs a large size of 510x530 mm, then the back wall is laid out not in ½ brick, as shown in the order, but in ¼ brick.

Formation of the second level

How to make a brick oven for a wood-burning home with your own hands

Continue laying in the usual way, the fence plate is fixed on one side with mortar. In the 19th row, it is necessary to install a brick in the center of the smoke collector, which will become a column under the roof of the stove. You need to leave a gap one brick wide behind the stove. They work on the same principle up to level 21.

Don't forget about the hood

Now they block the channel that leads to the pipe, the smoke will come out of the sinus, which was left in the lower part. In the next row, a steel plate is installed on the front walls of the oven. You can also use the factory rim with a door for this, which will greatly simplify the further construction of the steam collector.

At this stage they make a hood; ¼ brick will be enough. They continue laying up to the 24th row, and already on it it is necessary to lay out a step and attach the steam collector to the chimney, and make the channel closed. In the 27th, a fence plate is installed, and in the 28th, the structure is covered with a brick roof. At the next level, a pipe with a diameter of one brick is attached. The bell furnace is ready.

Water heating device

The water circuits, heated by the fuel, heat the installation, the smoke channels and the walls of the heating unit heat up. Batteries are connected to the heater, which become warm during the combustion of fuel in the firebox. The heated unit provides heat to the room until the walls have completely cooled down.

Elements:

- bake;

- a heat exchanger located inside, around the device in the form of a coil;

- water circuits located around the perimeter of the room.

Device structure

A heating installation that heats water circuits is more affordable when compared with other air heating equipment.

Water circulation diagram in the circuit

The heating system is built according to the scheme of natural coolant circulation through water circuits. The device is installed in the center of the room, supply pipes connected to the main heating center are placed in a circle.

The device will effectively heat the room and provide a comfortable temperature. It is not profitable to equip houses consisting of several tiers with a long-burning device. You will have to install a large stove, attaching many radiators, this is expensive and ineffective.

A standard installation with connected radiators consists of:

- heat exchanger;

- metal circuit pipeline;

- radiators, thick pipes;

- expansion tank.

With a one-time supply of fuel, the equipment will heat the house for twelve hours.

Oven – brick or metal

What material is best to build a long-term heating device from? Most often they choose a brick or metal structure.

Brick takes longer to heat up, but the heat transfer is longer. Long-burning steel equipment, on the contrary, heats up quickly and cools down in a short period of time.

Brick firebox

The brick installation is heavy, it must be capital, with a foundation and additional fastenings. It is better to install during the construction of the house.

If you plan to live in the house permanently, a brick oven is suitable. The heating device is expensive and difficult to install, however, it has a high efficiency.

A budget metal stove with connected water radiators. The structures are short-lived, but are suitable for irregular heating of the air in the house.

Metal unit

The choice depends on the wishes of the owner of the living space; if you want to build a heating system for a long time, it is better to choose a brick structure.

Pipes – stainless steel or metal-plastic

If structures with water circuits are used, you can choose steel, metal-plastic or polypropylene pipes.

Metal-plastic pipes are popular. However, if you are not sure that the temperature of the heated water will not exceed 95 degrees Celsius, it is better to install heat-resistant stainless steel pipes.

Heat dissipation - radiators or register

The slow flow of heat into the circuits ensures long-term heating of the room; you need to connect the correct heat exchangers for the installed main device.

Heat exchanger selection

The radiator looks like a battery, the register is a pipe connection. The radiator fits into the interior. The register is suitable for heating a private country house. They are more often found in villages and villages, where the issue of aesthetics is not important, the main thing is financial benefit and simplicity of design.

If the equipment is installed correctly, according to a pre-designed scheme, both heat exchangers will provide heat to the house.

Selecting a heat exchanger for the furnace

Most often they are made of steel, cast iron, copper. The copper heat exchanger is of high quality, but the price is too high. And it’s difficult to solder the device yourself.

Cast iron has better characteristics than steel. Making a heat exchanger with your own hands is difficult. If you take a finished battery, when the fuel burns in the firebox, the seal located between the sections will gradually burn out. This increases the risk of water leakage into the firebox and will significantly reduce the efficiency of the stove. It is difficult to clean soot from the inside of a cast iron battery.

A steel coil or a sheet metal jacket is the most advantageous option. The structure is easy to assemble by connecting several elements.