Today's heating equipment market offers a wide range of electric and gas boilers, but solid fuel units remain in demand. They are cheaper, allow heating large areas, operate autonomously, and fuel is available for them. In order for the device to work properly and remain safe, a chimney through the wall must be installed. How to do this correctly – we will consider further.

A chimney brought out through the wall Source dimohod.spb.ru

Main design components and principle of operation

A chimney is a structure used to eliminate exhaust gases after combustion of fuel to the outside. It is located vertically and has a cavity inside. The structure performs the following tasks:

- releasing toxic gases into the street (they are dangerous to humans);

- eliminating soot particles deposited on furniture and entering the body;

- removal of water vapor;

- fire prevention.

Before bringing the chimney through the wall , you should consider the principle of its operation. It lies in the physical properties of gases: when heated, their density becomes less, they become lighter and rise upward. As a result, the air in the firebox becomes thinner and fresh oxygen enters it. Good draft ensures constant combustion.

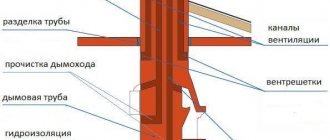

All chimney structures have the following components: a horizontal section (from the boiler to the wall), a vertical box, valves and inspection hatches (they are required for periodic cleaning of the walls from soot). At the top of the chimney, a cap is placed on the pipe to prevent precipitation from penetrating inside.

Components of a chimney Source dymoxody.ru

Principle of operation

The principle of operation of a chimney is based on the tendency of hot combustion products to rise upward. Hot gases expand, their density decreases, and they tend to “float” into a higher layer of the atmosphere with the same density. When the waste combustion products rise in the furnace, a vacuum is formed and fresh air is sucked in. Thrust ensures a continuous supply of oxygen to the fuel.

Many factors influence cravings:

- Chimney height.

- Cross-sectional area of the internal channel.

- Insulation of the channel.

- The location of the head relative to the top of the roof (ridge).

- Sufficient air supply.

Classification of chimney structures

Before installing a chimney pipe through a wall, you should consider the types of construction. By design, it can be single-walled or double-walled. The first option is made of sheet steel. It is inexpensive and suitable for installation in country houses and cottages. The disadvantage of the product is its short service life. For effective operation, the structure will have to be insulated.

Double-wall chimneys are sandwich systems that are recommended for installation in wooden houses. The chimney is multilayer and has low thermal conductivity, which is extremely important for highly flammable materials.

Depending on the material used to make the structure, there are:

- Brick . Often, their construction requires a foundation, and for proper laying, certain construction skills. This option is acceptable when building a fireplace in the house.

- Steel . Stainless steel material is cheap, but requires external thermal insulation. If this is not done, condensation will accumulate inside the pipes, which will affect the quality of traction. Moisture can also get into the firebox and extinguish the flame. It will be difficult to light the boiler again.

Steel chimney Source krovlyamoya.ru

- Asbestos-cement . Such products are heavy and fragile. A foundation is required for their installation. Under the influence of hot gases and moisture, such products deteriorate faster.

- Ceramic . Such a chimney can withstand temperatures of more than 100 degrees, but requires thermal insulation and careful operation. Installation of such pipes is difficult, and they are expensive.

- From sandwich pipes . The preferred option for building a chimney on the street. To produce the product, two pipes are taken, placed inside each other. There is a thermal insulation layer between them. The system is installed simply and quickly.

When choosing a material, not only its technical characteristics are taken into account, but also its decorative properties.

Fireplace in a wooden house

Recently, a country house is gradually turning into a full-fledged year-round home.

In any home, the main issue is heating. Owners of wooden buildings often prefer to use a fireplace with natural fire as a heater. However, when choosing this heating method, it is very important to remember safety rules, because the main material of the constructed home is easily combustible. A classic wood-burning fireplace has a closed firebox and a chimney pipe.

Such a stove is usually finished with natural stone or other heat-resistant materials

A classic wood-burning fireplace has a closed firebox and a chimney pipe. Such a stove is usually finished with natural stone or other heat-resistant materials.

When laying a fireplace, it is necessary to reduce the impact of house shrinkage on it as much as possible. First of all, this applies to the intersection of the chimney with floor beams and partitions. At these points, especially high-quality thermal insulation is needed to prevent fire.

General requirements for construction

Since you can remove the chimney correctly yourself, you should take into account the technological requirements. The cross-section of the smoke exhaust ducts depends on the power of the heating equipment. With lower parameters, draft will deteriorate and combustion products will be removed more slowly.

Placing the pipe inside the box Source petropech.ru

To create normal draft, it is better to use a round chimney. The number of bends should be reduced. The minimum allowed height of the structure is 5 m. If the roof covering is prone to ignition, then a spark arrestor is placed on it in the area of contact with the chimney.

High-quality ventilation is installed near the boiler. The length of the inner part is no more than 1 m, otherwise this area will quickly become clogged with soot and traction will deteriorate. The chimney is equipped with a reservoir to collect accumulated condensate and a window for maintenance. Do not make 90° bends.

DIY metal hood

Features of assembly and installation:

- All seams and joints must be treated with sealant;

- The structure is assembled from individual elements, starting from the bottom and up. The planting depth of the pipes must be at least half the outer diameter;

- For roofs made of flammable materials, it is necessary to install a spark arrester;

- The head is installed at a height of more than one meter above the roof;

- The joints must be secured with special clamps;

- Using brackets, the pipe or each turn after 1.5-2 meters is additionally fixed;

- A special nozzle is installed at the bottom. It is necessary to clean the hood from dirt and soot. The diameter of the nozzle hole should be at least 10-12 millimeters;

- To make it more convenient to drain condensate, the nozzle can be additionally equipped with a special cone;

- When installed on a flat roof, the hood should rise above it by at least 500-600 millimeters;

- It is advisable to avoid installing horizontal sections. If necessary, its length should not exceed one meter;

- Additionally, the roof and walls are treated with fire retardants.

Chimney installation - insulation

Chimney installation - insulation

Installation of a chimney from the facade

Installation of a chimney from the facade

Installation of a chimney on the second floor

Installation of a chimney on the second floor

Advantages and possible disadvantages

Before leading the pipe from the stove through the wall, you should consider the positive and negative aspects of the design. The following are its advantages:

- saving space indoors;

- the construction is not at the initial stage of construction of the building, but after its completion (this is the best option if it is necessary to reconstruct the house);

- ease of maintenance and repair;

- less construction work;

- ease of regulation of the chimney if necessary to change the draft force;

- high level of fire safety of the building and heating equipment;

Fire protection of a chimney Source krovlyaikrysha.ru

- there is no need to violate the integrity of the rafter system, there is no need to make holes in the ceiling or roof;

- optimal level of safety in terms of leakage of toxic gases.

However, this design also has disadvantages:

- requires mandatory thermal insulation;

- low efficiency (heat from them enters the atmosphere);

- at high altitudes, operation of the structure is difficult due to the large windage, so additional fastening is required;

- with a large number of bends, the rate of removal of combustion products decreases.

To prevent water from the slope from entering the chimney, it is necessary to install special ebbs. Sometimes the design can disrupt the exterior of the building.

Manufacturing

It just so happens that even with any degree of availability of different models of fireplaces in the store, we are interested in the question of how to make a metal fireplace with our own hands. Moreover, this interest is driven not only by the desire to save money. Here you can realize all your ideas about the location, shape and decoration of a living hearth. After all the work done, relax into a soft chair and listen to the crackling of firewood in the firebox with a feeling of satisfaction.

Before you start constructing a metal fireplace with your own hands, you need to familiarize yourself with a number of aspects that will not only help improve the efficiency of its operation, but are also necessary to ensure the required level of fire safety.

- The walls of the fireplace body become very hot when wood burns. By the way, this fact should be taken into account when choosing a room for installation. Under no circumstances should this be done in children's bedrooms. Closely located surfaces must be insulated on all sides, this applies to walls and floors.

- The chimney, which ensures the removal of combustion products, must be led through the roof to the street, therefore, despite the mobility of the fireplace, you should carefully consider its location.

A homemade fireplace can be made from any material: copper, iron, steel, cast iron. As a rule, iron fireplaces are cheaper in cost, but are inferior in performance to copper or cast iron ones. The thickness of the metal for the main firebox should be 3-5 mm. Having prepared the required number of sheets, as well as the corners for making the frame, you can begin to act.

To make it easier to start constructing a metal fireplace with your own hands, you need to prepare the necessary drawings, according to which the sheets will be cut and assembled. There are ready-made designs for different types of fireplaces, but you can use your own artistic skills. Moreover, there are no special requirements for the design, so modeling and drawings are made taking into account the required geometric shapes and sizes.

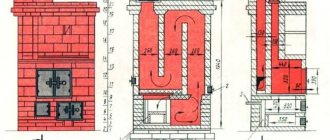

You need to start assembling with the fireplace stand. It performs a dual function: on the one hand, the stand insulates the firebox from the floor at a decent distance, and on the other, it provides access to cold air, which is necessary for combustion and is a coolant. The stand will be a rectangular frame that needs to be welded from corners and legs, providing an elevation of 15-20 cm above the floor. The resulting frame is sewn up with a sheet of iron.

The body is made of metal sheets in the shape of a parallelepiped. At the top there is a hole for the chimney. On the front side, hinges are welded to the wall and the door is installed. All these manipulations require skills in working with a welding machine. If the original appearance does not have aesthetics, then you should not forget about surface finishing, with which you can veil all the flaws.

The firebox must be divided into two parts, but not a blank wall is used as a partition, but a valve capable of adjusting the gap between the sections.

- One part will serve for direct combustion of wood.

- The second is used as a smoke collector before it enters the chimney.

Preparing for assembly

Before installing a stove in a country house with a pipe exiting through the wall, you need to prepare. Work requires special clothing and gloves. If you will be cutting metal products, it is advisable to wear safety glasses.

Selection of tools and materials

To complete the work, the following tools are required:

- drill, equipment for cutting material;

- heat-resistant sealant;

- riveter;

- clamps, dowels, corners;

- foil construction tape;

- screwdrivers;

- level, plumb;

- knife;

- ladder;

- When working with concrete walls, you will need a hammer drill.

Components for installing a chimney Source vse-postroim-sami.ru

The materials you will need are a steel pipe, with which the horizontal fragment is connected to the boiler. You also need a tee for connecting pipes, an elbow (with its help the structure is directed upward), and a support console. Brackets and dowels are used to mount products on the wall. The connection of several pipes is carried out using clamps. You also need thermal insulation material and a protective cap.

See also: Catalog of companies that specialize in the installation of fireplaces, stoves and utility networks.

Choosing a location

The house has central and side walls. The second is located on the side of the slopes and under the roof overhangs. Liquid gets onto this part when it rains (if the drainage system is not fixed). There is a small roof overhang above the central walls, so the risk of liquid entering from the roof is minimal.

It is better to mount the smoke exhaust structure on the front wall. Here it is taken into account that there should be no windows or balconies on it along the line of the chimney. If you have to install a pipe through an overhang, then high-quality fire protection is installed.

Choosing a location for the chimney outlet through the wall Source stroychik.ru

Calculation of chimney height

Since it is possible to correctly bring a chimney through a wall to the street in a wooden house only if technical requirements are met, the first parameter that is taken into account is the height of the structure. It depends on the number of floors of the house. If the height of the building does not exceed 5 m, then the minimum parameter for the height of the structure is 5 m. If this value is neglected, the structure in the house will smoke in the house, the draft will deteriorate, and the performance of the heating device will decrease.

If the pipe is too long, fuel consumption will increase. When the height of a building exceeds 10 m, the main reference point is its ridge: it should be 0.5 m below the chimney. This characteristic is affected by the cross-section of the pipes and the power of the heating equipment.

Chimney height Source vosaduly.ru

Pipe diameter calculation

The internal diameter of the structure must correspond to the dimensions of the pipe. Any narrowing of the internal volume of the pipe affects the formation of draft. The presented value is affected by the power of the equipment: the higher it is, the larger the internal diameter. You need to follow standard building rules:

| power, kWt | Internal section, cm | Minimum diameter, cm |

| up to 3.5 | 14×14 | 15,8 |

| 3,5-5,2 | 14×20 | 18,9 |

| 5,2-7 | 14×27 | 21,9 |

If we take into account all the technological features of installation, the structure will last for decades without significant problems.

Brick chimney

Despite the mass of new materials for making chimneys, brick still remains quite popular and in demand.

Let us remind you that:

- The pipe should be laid with a bandage, inside the house using lime or cement-lime mortar, and cement mortar is used above the roof.

- According to the “Rules for Pipe and Stove Works”, chimneys must be made of solid red brick, the seam no thicker than 10 mm. It is prohibited to plaster the inner surface of the pipe.

- Serious weight requires a foundation.

- Brickwork is destroyed by acid condensate, brick fragments can collapse inward and narrow the cross-section of the channel.

- Due to the roughness of the brick, soot accumulates inside the chimney pipe.

To reduce the negative aspects, the installation of a brick chimney is carried out as follows: an asbestos-cement pipe is inserted into the smoke channel and the space between it and the brick is filled with concrete. This event is called gilzovka.

Interfloor overlap

The figure below shows the passage of a chimney through a wooden ceiling. On the left is a passage device using 2 layers of asbestos, then the distance from the pipe to the wooden floor beam is 1 brick, that is, 250 mm. And on the right is shown an option without asbestos, in which case the distance from the chimney to the wooden floor beam should be no less than 1.5 bricks, that is, 380 mm.

Rice. 1. Cutting the chimney passage in the interfloor ceiling: 1 chimney; 2 wooden beam; 3 cutting with a thickness of one and a half bricks; 4 double layer of asbestos; 5 cutting the width of a brick with asbestos insulation.

Connection to a wooden wall.

Wall

- The wooden wall must be insulated from the chimney, the distance from the “smoke” to the tree must be at least 25 cm. If there is no asbestos insulation, then this distance must be at least 38 cm. This retreat can be closed with quarter-brick walls on the sides.

- In new log houses, it is customary to install a plank board attached to the wall on a sliding fit to compensate for the inevitable settlement of the log house. And the side closing wall should be adjacent to the quarter in this shield

- Holes are made in the side walls for air circulation. Up and down.

- Wooden setback floors are covered with one row of bricks, tiles or other fireproof materials.

A very important question: how to remove the chimney through the roof? A correctly organized chimney passage through the roof is shown in Fig. 2.

- When planning to bring the pipe through the ceiling, you should make sure that the distance between the outer surface of the brick pipe and the wooden rafters is regulated at least 130 mm.

- This space is filled with stone (basalt) wool, made without an organic binder.

- If the roof was installed from flammable materials, such as roofing felt, the distance should be doubled to 260 mm.

- In the place where it is planned to remove the chimney, the roof is covered with fireproof materials, for example slate, or better yet roofing steel, at a distance of at least 500 mm from the pipe and the pipes are carefully adjusted to fit the otter.

Rice. 2. passage through the roof

Pipe height above roof

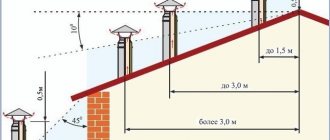

The figure below shows a general diagram of the height of the pipe above the pitched roof.

The height of the chimney above the roof is taken as follows:

- not less than 500 mm when located near the ridge of a pitched roof or in the case of a flat roof;

- not less than 500 mm above the ridge of the roof when the distance of the pipe axis is less than 1500 mm from the parapet or ridge;

- not lower than the ridge of the roof when the chimney axis exits from 1500 to 3000 mm from the ridge;

- not lower than an imaginary line drawn down from the ridge at an angle of 10° to the horizontal, when the chimney axis exits more than 3000 mm from the ridge.

Installation instructions

Now you should directly consider how to install a chimney through a wall. The technology may differ slightly depending on the material used to construct the building.

Brick base

If the walls are brick, then installation involves the following work:

- Determination of the exit area of the structure. It should not disturb the exterior of the house.

- Marking the wall. First, the installation location of the boiler is determined. Next, the height of the boiler and the outlet pipe is measured. At the same time, we must not forget about fire safety standards for organizing heating. The pipe outlet is marked in the required location. The parameters are checked several times.

- Making a hole. This requires a hammer drill. The hole is insulated with fireproof material. For concrete walls or brick structures, mounting foam and asbestos sheet are suitable.

- Box insert made of fire-resistant material.

Installation of otter and head

The procedure for installing a chimney, installing an otter and a cap:

- The otter's perimeter should be between 10 and 16 centimeters;

- The neck of the main pipe is installed on the otter;

- The cross-section of the neck must be equal to the diameter of the chimney;

- The head is made of brick or stainless steel;

- It can be of any shape and size;

- The chimney should rise above the roof by approximately 700-900 millimeters;

- Smoke ducts must be treated with a special solution after installation is completed.

Video description

How to pass a pipe through a wooden base is shown in this video:

- Making a hole for the box. At this stage, the diameter of the product is taken into account, as well as the space for the insulating material (basalt wool inserts).

- Pipe installation. An asbestos sheet is laid between its walls and the box. The element is displayed strictly at a right angle. Any deviation will impair the operation of the boiler.

- Attaching a protective screen outdoors. This is a steel plate fixed to the outside of the wall. It protects the wood from overheating and reduces the risk of fire.

Pipe protection with insulating material Source petropech.ru

- Tee installation. A vessel for collecting condensate is attached to its lower part.

- Installation of support. It is screwed to the wall or rests on the ground. Its task is to maintain the vertical part of the structure.

- Chimney connection. Condensation should not get into internal joints. Every meter the structure is fixed to the wall with brackets. During fastening, a building level is used to maintain the strictly vertical position of the pipe. The last clamp is installed under the roof.

Lastly, a protective fungus is put on the pipe.

Elements of modular systems

To draw up an installation diagram, purchase components and subsequent assembly, you need to understand what parts are used in a double-circuit chimney. We list the main elements, accompanied by photographs:

- straight sections of sandwich pipes 25, 50, 100 cm long;

- tees at 45, 90°;

- elbows 90, 45, 30 and 15 degrees;

- transitions from a single-wall pipe to a double-wall pipe - “start sandwich”;

- rotary gates (flaps);

- condensate collectors and various heads;

- ceiling passage units (abbreviated PPU);

- support platforms, brackets;

- fastenings – crimp clamps for guy wires;

- pitched roof sealing elements called master flash or “kryza”;

- end caps, skirts.

Note. Here is a partial list of chimney parts. There are direct channels with inspection and condensate drainage, floor stands, inspection hatches, and crosspieces.

Double-layer pipes are connected to other fragments using the socket-profile joining method. In a more accessible language, the connection is called “tenon-groove” or “male-male”, as you like. When manufacturing each shaped part (except for the end parts), a tenon is provided on one side and a groove on the other.

Scheme of installing a chimney along the outer wall of a country house

As an example, we suggest considering the assembly diagram of a wall-mounted sandwich chimney starting from the boiler:

- We connect a single-wall pipe to the output of the heat generator through a coupling, then mount the starting adapter onto the sandwich.

- We connect to the transition a straight section of a double-circuit pipe facing the street. There it is inserted into the tee.

- Below the tee we place an inspection section, then a support platform and a condensate collector. The structure is placed on a wall bracket.

- We rise from the tee in straight sections, fasten it to the wall every 2 meters with sliding brackets, and compress the joints of the elements with clamps.

- At the end of the chimney we install a cone without an umbrella (for a gas boiler), a simple cap or a deflector.

Comment. If a horizontal chimney duct crosses a wooden wall, you need to cut a square opening and install the PPU in accordance with fire safety requirements.

When you need to get around the roof overhang, we use 2 bends at 30 or 45 degrees. We secure the end of the chimney with guy ropes so that it does not sway in the wind, as was done above in the photo. Watch the video for professional installation of a sandwich pipe for a steel furnace:

Video description

You can see the chimney outlet through the wall in a bathhouse in this video:

- the upper part of the structure is located slightly above the roof ridge so that the smoke is blown away by the wind;

- there should be no other communications or wires near the box through which the pipe is inserted;

- Regardless of the material of the chimney, its horizontal part is inserted into the wall at a right angle.

Before making a chimney through a wall in a wooden house, you should treat it with an antiseptic and a liquid that increases its resistance to fire.

Types of fireplaces for a wooden house

The fact that the house is built from logs will not be an obstacle to installing a fireplace in it. However, it is necessary to take into account all the requirements, since there are safety rules according to which the device must be installed. Manufacturers now produce products of different shapes and from different materials, so the complexity of installation will depend on these factors. And also on where you decide to install the device.

Typically, experts classify fireplaces for a wooden house according to the type of construction, the type of material from which they are installed, and also the type of fuel it requires.

Types by type of construction:

Corner fireplaces - it’s already clear from the name that such structures are installed in the corner of the room. A corner fireplace in a wooden house looks quite stylish, but most importantly, it does not take up too much space.

Direct wall device - they, in turn, are divided into those that are built into the wall and those that are mounted near the wall. The advantage of built-in products is that they are used not only as a beautiful decorative element, but can also heat two adjacent rooms.

An isolated device looks quite interesting, as it can be of any shape, both round and rectangular. But what makes it exceptional is not its shape, but the fact that it can be installed even in the center of the room. The structure is always installed at a distance from the wall.

Types according to the material of manufacture

Cast iron. Standard products whose fireboxes are designed to run on wood are usually made of metal, namely cast iron. These stoves are installed in stone, wooden, artificial stone, and brick fireplaces. In addition, chimneys are attached to them, and if we talk about a wooden house, then the installation of cast iron fireplaces must be done using a closed firebox. Glass or steel is used for this purpose.

Brick. In a wooden house, a similar one is installed on a separate foundation. The structure consists of two parts - ordinary brick is used for masonry, at the request of the owner. But for finishing the firebox, only high-quality, refractory bricks are used. To design a chimney, you can choose two options - install a metal pipe or use brickwork.

Biofireplace or electric fireplace. This device is always made of steel, as well as fire-resistant glass.

According to the type of fuel consumption

For a wooden type of housing, the design should be selected most carefully. Most products that consume fuel openly are prohibited. Nowadays, you can even find open-type stoves that consume alternative fuel that does not pose a danger to life. They can even be installed without using a chimney.

- Classic, solid fuel design. They are heated with coal or wood. It can be installed in a house from a log house, but only on a separate foundation and with the obligatory condition of insulating the surfaces and ceilings that will be adjacent to the fireplace.

- An electric fireplace is rightfully considered the safest, since the likelihood of a fire due to this device is very low. Instead of using fire to heat the room, it uses electricity to warm the room. To make everything look as if it was a real fireplace with fire, manufacturers installed special lighting that imitates flames. The advantage of this type is that for their installation there is no need to build a separate foundation and chimney. It can be located on the second floor, the main thing is that the wiring is insensitive to voltage changes and is reliably insulated.

- Biofireplace is a fairly new type, they have only recently begun to be installed. Ideal for wooden houses, as it operates using a substance - ethanol. Inside the stove there is a special container for filling with ethanol, as well as a ceramic combustion system. The advantages of this type are that there is no ash, soot, or other sediment, and the fireplace does not produce emissions of harmful substances. The only negative is that it does not heat at all, it only performs a decorative function. They can be mounted on a wall, they can be suspended, floor-mounted or even table-mounted. It is not necessary to install a chimney.

- Gas - the inside is not ceramic, as in biofireplaces, but a gas combustion system. Natural gas is used as fuel and is installed in the same way as a classic one, including the chimney.

Selection of insulating materials

So , how to properly install a stove in a house with a chimney through the wall is already clear, so you need to consider the issue of insulating the outer part of the structure. If a sandwich system is used, then this procedure need not be carried out (except for the place where the element passes through the wall). The insulation must be fireproof. It is allowed to use the following materials:

- Stone wool. This is the best option for a wooden house. The material is easy to use, does not contain harmful substances, does not burn or smolder. Cotton wool not only does not burn, but also prevents the spread of open flames.

Insulation of structures on the street Source teplo.guru

- Asbestos. Many masters refuse to use it. The material contains toxic carcinogens. However, it has high insulating qualities and does not come into contact with humans in any way.

- Superpower. Modern insulation, which does not burn, provides good insulation. The disadvantage of the material is its high cost.

- Basalt cardboard. It is characterized by a long service life. The insulator is relatively cheap and resistant to high temperatures. The material contains no toxic substances, and its quality is better than mineral wool.

The insulated structure may not look very presentable, but this stage cannot be avoided. Without insulation, condensation will collect inside the structure. It will not only deteriorate moisture, but will also have a negative effect on the metal.

Chimney insulation

External insulation of the chimney is designed to eliminate the main enemy of the chimney - condensation, which forms in the cold season as a result of condensation of water vapor on the internal walls. Firewood contains a particularly large amount of moisture - up to 25% in dry wood and up to 60% in freshly cut wood. Coal does not contain vapors, but since the combustion process uses air from the living room, its humidity can reach 8–10%. Passing through a cold pipe at low speed, steam is deposited in the form of droplets on the inner walls and, mixing with soot, turns into a chemically active acid.

Insulating the chimney pipe avoids the formation of condensation on its internal walls

Three main methods of insulation are used:

- Plastering. The simplest and most accessible method that does not require special skills. It consists of applying several layers of slag-lime mortar to the chimney, which, when hardened, forms a strong protective “coat”. To strengthen the adhesion of the plaster to the masonry, use a metal mesh, securing it to the pipe with anchor nails. After applying 3-4 layers (with drying intervals), the insulated surface is covered with whitewash or lime. As practice has shown, such protection can reduce the heat transfer of a pipe by 20–25%. This method is fast and does not require large financial costs.

- Insulation using wooden boards. You will need boards 30–40 mm thick. A wooden frame is mounted around the entire chimney (from the otter to the cap) and completely sheathed with boards. The wood is protected from above with slate. The distance between the brickwork and the boards (5–7 cm) is filled with any non-flammable insulation - earth, sand or mineral wool. To prevent the insulation from spilling out, the gaps between the boards are covered with plastic film or puttied with sealant. This method is effective in regions of the steppe zone, where dry winds often blow and prolonged rains are rare.

- The third method requires certain expenses. It consists in the fact that the pipe walls are insulated with mineral wool, which is resistant to solar radiation. The best option is basalt wool, which has very low thermal conductivity. A layer of adhesive is applied to the chimney, to which basalt slabs are attached. For good adhesion, the entire insulation mass is fixed with plumbing tape and covered with reinforced polypropylene film. After the glue has completely dried, the cotton wool is covered with grainy facade paint using a painting mesh. Another option is siding or cladding with profiled metal sheets. This pipe insulation allows you to retain up to 50% of the heat inside the chimney duct. And, as a result, ensure the absence of condensation on the internal walls.

Fire safety rules

The distance from the brick wall to the chimney is 130 mm. If the structure is wooden, then this parameter increases to 260 mm. When pipes pass in close proximity to rafters or through flammable materials, these places must be insulated.

Fire protection of a chimney Source petropech.ru

When using solid fuel equipment, the chimney is equipped with a mesh metal spark arrester, regardless of the material from which the building is constructed. The cell size does not exceed 5*5 mm. In addition, there are other rules:

- the chimney head must be positioned correctly relative to the roof;

- to reduce moisture condensation, the temperature at the outlet of the structure should be 15°C higher than the dew point temperature (60°C);

- if the chimney height is less than 5 m, then the installation of an electrically driven smoke exhaust is required.

The outer wall is separated from the structure by an asbestos-cement sheet or basalt overlay.

What fuel to use

The main fuel for metal fireplaces is wood. The wood of deciduous trees (birch and ash) will quickly heat up the fireplace and the room where it is installed. And coniferous firewood (spruce or pine) will fill the room with the specific aroma of pine resin. However, it is not recommended to often burn a fireplace with pine wood, since the released resins quickly pollute the chimney and fireplace grate.

Sometimes peat pellets can be used in wood-burning fireplaces. But coal cannot be used as fuel. In addition to increased contamination of the room, it greatly heats up the working elements of the fireplace, which can lead to their deformation and damage to the fireplace.

In some cases, by modifying the design of the fireplace, natural gas can be used as a fuel source. But it must be remembered that the installation of gas equipment is possible only subject to prior approval of the project with gas services.

Errors in chimney installation

Since it is not always possible to correctly install a stove in a house and route the pipe through the wall, you should consider the most common installation mistakes in order to avoid them. Incorrect robot design is possible in the following cases:

- Insufficient amount of insulation at the junction of elements. In this case, the pipe will overheat.

- The presence of joints where they pass through a wall or roof overhang. Such installation increases the risk of fire in a capital structure.

For boilers with an open combustion chamber

For gas boilers with an atmospheric burner, a smoke channel is required that provides good draft - the removal of combustion products occurs due to the movement of air through the pipe. Therefore, it is made as straight as possible, preferably with smooth walls. There are two options:

- Bring it horizontally through the wall, then along the outer wall up to the required height. This option is also called an external chimney.

- Lead the pipe up from the boiler, go through all the floors, the roof, and lead it above the roofing material. If necessary, you can move the pipe further away from the wall by making two 45° elbows. It is better not to make 90° bends with this design.

Which option is better? An external chimney is easier to implement - with an outlet through the wall

It is only important to pass through the wall correctly (maintain a fire gap if the walls are flammable). But this option requires good insulation and high-quality fastening to the walls

And even under such conditions there is usually a lot of condensation. Therefore, the installation of a tee and a condensate collector at the outlet is mandatory.

Option for passing through the ceiling and insulation

In the case of a chimney outlet through the roof, there are at least two difficult points - passage through the first floor ceiling and through the roof. In these places, special passage units are installed. They provide the proper degree of fire safety.

Features of metal pipe assembly

If sandwich pipes or single-wall metal pipes are used, then the external chimney for a gas boiler is collected “by condensate”. That is, inserting the upper pipe inside the lower one. This is possible due to the presence of a corrugated edge on one side.

When assembling a chimney inside a building, the structure is assembled “according to the smoke.” In this case, it is more important that gases do not enter the room. Therefore, they unfold the pipes so that the upper element fits onto the already installed one.

Types of chimney assembly made of metal and sandwich pipes

There is a third option - to assemble two circuits in different ways: the external one for smoke, the internal one for condensate. For such an assembly, it is imperative to use sandwiches, since they are the only ones with two circuits. This is the best option, since the protection is complete, but the assembly is complicated.

Smoke pipes in the shaft (box)

To prevent communications from spoiling the interior, they are often “packed” into a shaft - a specially constructed box. Inside there are, as a rule, a chimney (or chimneys, if several devices are working), ventilation ducts, and there may be risers for water supply, heating, and sewerage. In any case, it is better to cover the chimney pipe with thermal insulation. If insulation can still not be used in a heated room, then in the attic (especially if it is cold), insulation must be mandatory. Use basalt wool with an operating temperature of at least 300°C.

The chimney can be hidden in the shaft

Insulation will have a positive effect on the temperature inside the chimneys, which will increase draft and reduce the amount of condensate. But do not forget that we are talking specifically about gas boilers, and their combustion products have a low temperature.

Video description

This video clearly shows an example of violation of the rules for installing a sandwich chimney:

- The position of the pipe is not observed. It is installed strictly vertically. When insulating main walls with foam plastic or mineral wool, long dowels are used to secure the chimney.

- There is no ebb on the side roof slope. In this case, precipitation can get on the insulation and impair its functions.

- Insufficient overall vertical height. This error leads to poor traction.

Problems arise when using low-quality insulating material. Cheap insulation shrinks over time, so there is a possibility of local overheating of some parts of the chimney.

Furnace piping

In rare cases, a room is heated by a stove due to convection currents. The very status of the device implies the most efficient use of released energy. Therefore, the heating system is supplied with a coolant, which can be water circulating through pipes or air moving under the influence of forced convection. Connecting the coolant channels to the furnace is called piping.

Some problems associated with the installation of a fireplace stove are concentrated in the incorrect installation of the main line. With water heating, circulation is provided by a pump or it is carried out due to natural convection. In the second case, it is important to maintain a certain slope of the line, since a reverse slope will lead to stagnation of liquid. In a closed heating system (case 1), the slope does not matter, but the system has strict requirements for tightness. Even a small amount of trapped air will stop circulation.

The water circuit with which the fireplace stove is equipped has an inlet and an outlet for connection to the main line. If they are not specifically marked, then you must remember that the hot water outlet is located below the cold water inlet.

Heating circuit connection diagram

Piping the air duct is not difficult, but laying the line under the panels or covering it with plasterboard is a labor-intensive process. A furnace that uses air as a coolant is equipped with a fan system that drives air through the main line. By adjusting the supply dampers, you can direct heat selectively to different rooms.

Good to know: Electric oven for making pizza at home

Expert advice

Before purchasing the necessary materials for arranging an external chimney, the power of the equipment is determined. It affects the diameter of the pipes. You can also use these expert tips:

- if the heating equipment is equipped with forced draft, then it is not necessary to increase the vertical section of the structure; it is enough to remove the horizontal pipe;

- a horizontal section that is too long helps slow down the smoke flow (the value should not exceed 1-1.5 m);

Rules for installing chimney pipes Source krovgid.com

Inspection openings are installed not only on the outer part of the structure, but also on the internal horizontal element.

Recommendations from professionals

To build a high-quality fireplace for heating rooms, you need to take into account certain features. The fire source must be installed in such a way as to minimize the likely risk of fire. There should be no flammable objects nearby; a fire extinguisher must be installed near the fireplace.

The following expert advice will help you build a fireplace correctly:

- The wall near the combustion chamber must be fireproof. Moreover, an additional layer of thermal insulation made of aluminum foil or other metal alloys is laid.

- The floor near the fireplace should be covered with non-combustible materials - metal, porcelain stoneware or stone. This will prevent fire caused by falling sparks.

- To protect the ceiling from elevated temperatures, partitions made of metal lathing and plasterboard are used.

- For the installation of a smoke exhaust duct, it is recommended to use a two-layer material.

A fireplace cannot always heat a building completely, since the bulk of the thermal energy is lost through the chimney. In this case, the best design may be a fireplace stove, which makes it possible not only to heat the house, but also to cook food. To heat the house, you can connect a water heating circuit.

Service life of the external chimney

The service life of the structure depends on the material of its manufacture and correct installation. When used correctly, ceramic pipes will perform their function for up to 40 years. A brick chimney can be used for more than 50 years. Stainless steel will have to be replaced after 15-20 years, but it all depends on the thickness of the metal. Galvanization has the shortest service life: up to 10 years.

The durability of the structure is affected by the heating temperature of the exhaust gases. A high-quality sandwich system will last up to 20 years. Structures last longer if heating equipment runs on gas or pellets.

Do it yourself or order it?

You can only make a brick chimney yourself or a structure from an insulated single-layer steel pipe. But laying smooth and beautiful walls of a brick pipe is more difficult than laying just a brick wall, and you must have the skills of an experienced mason. Single-layer pipes will have to be insulated; the quality of self-insulation is much worse than that of ready-made factory-made pipes.

You can independently install a chimney made of ceramics and sandwich pipes. It is impossible to manufacture elements of such chimneys on your own, but the industry produces many modules that allow you to assemble a pipeline of any design.

The question of whether to install a pipe yourself or hire a team of professionals is quite complicated. Installing a chimney is quite a complex job, and it is worth thinking about and carefully assessing your capabilities: is it possible to take prefabricated scaffolding or scaffolding of the appropriate height, will you have assistants, do you have the skills to install building structures, how do you react to height.

Briefly about the main thing...

Chimneys can be single- or double-walled. Based on the material of manufacture, metal, brick structures and structures made of sandwich pipes are distinguished. The last option is optimal for private houses. When installing a chimney, the rules for its placement in the room are observed. Its functionality, as well as the presence of draft in the heating equipment, depends on the correct determination of the diameter and height of the structure.

The installation technology through a wooden and brick wall is the same, but there are some nuances: wood is more susceptible to ignition and requires maximum protection. During installation, you must comply with fire regulations, and also take into account possible errors.

Ceramic chimneys for wooden buildings

Modern industry produces high-strength and fireproof modular chimneys from high-quality ceramic materials. They are a kind of constructs that are assembled locally from several elements.

ceramic chimney

Such a chimney may consist of multilayer material. Its inner surface is made of ceramic material, which is particularly resistant to heat and acids formed during the reactions of combustion products. Their internal surface is very smooth, which prevents the formation of soot and creates smooth and powerful traction. But such a chimney system has considerable weight and requires special skill during installation.

In addition to ordinary metal chimney pipes, usually made of stainless steel or cast iron, so-called “sandwich pipes”, which are a multilayer composition, have recently become popular.

The inner surface of such chimneys is made of stainless steel, then there is insulating material - and then a galvanized pipe. Together, this complex quite successfully performs its functions and is very easy to install. The smooth stainless steel surface inside gives even traction, preventing the formation of turbulence.

However, when choosing such a pipe, it is very important to remember that different heating devices have different combustion temperatures and, based on this, select the required thickness of the inner wall. When building a chimney for a boiler using gas, diesel fuel or pellets, it must be at least half a millimeter

Chimneys for bathhouses or fireplaces are usually equipped with an internal pipe of 0.8-1.0 mm, but for coal-fired stoves this figure should be at least a millimeter.

Just like ceramic chimneys, sandwich pipe chimneys have a modular design and are easily connected to each other. Thus, special elements are produced for passing through interfloor ceilings. But even in this case, it is necessary to ensure that the pipe joint is not located in the thickness of the ceiling.

4fec99b31024563e6e0e719edef4afc8.jpe

3b094557e69134ab5f56ab99027f2cec.jpe

Types of chimney systems for gas boilers

Today, for heating systems with a gas boiler, several types of chimneys are most often used. You can build any of them yourself, but you will need a diagram for assembly and recommendations from a specialist. We will try to help you in this matter!

Brick chimney

Brick chimney

Brick pipes have been installed for a long time, even before the advent of pipes made from new materials. But even now, some house owners have not given up on their construction, although, to be honest, such a chimney is complex in design and labor-intensive to install. In addition, building a brick chimney takes a lot of time and is expensive. It should also be noted that the brick version is inferior in technical characteristics to more modern systems, since due to its shape and rough inner surface it is often overgrown with soot, which slows down the removal of fuel combustion waste. You don't want to hire a chimney sweep in a couple of years, do you?

Ceramic chimney section

Requirements for coaxial chimneys of gas boilers

The coaxial chimney is significantly different from all other designs in all respects.

Coaxial chimney connection diagram.

It has a neat, compact appearance and a different shape from other chimney pipes - it does not rise to the roof, but is discharged through the wall.

... and coaxial

Despite its small size, the chimney has high operating efficiency due to its structure and coating on the inner walls

Condensation does not appear inside it, which is very important for the operation of heating systems running on gas fuel

Stainless steel sandwich chimney

This model is the most popular and in demand in recent years, as it has a number of undoubted advantages over other options. They have a large number of different transitions, tees and other parts made at different angles, which allows you to assemble structures of any complexity.

Stainless steel sandwich chimney

Chimneys made of stainless steel consist of three layers. The middle one is a heat-insulating one, which is made of mineral wool. This insulating layer can have different thicknesses - from five to ten centimeters. The choice of its thickness will depend on the location of the chimney pipe and the average winter temperatures of the region where the building is located. The correctly selected chimney pipe will determine whether condensate will collect in it, and therefore the proper operation of the entire system as a whole.

The stainless steel chimney has a perfectly flat inner surface, which allows the combustion products of the boiler to be easily removed. In addition, it has a mirrored outer surface, which contributes to the presentability of the overall appearance of the system.

Stainless steel chimney elements

Variety of chimney system parts

Whatever chimney (with the exception of a brick one) is installed, additional elements will be required for it, which are selected according to a pre-developed system assembly diagram. These include the following details:

- The connecting pipes that connect the pipe to the boiler are adapters.

- Pipes of various lengths.

- Pass-through pipes.

- An inspection tee with a fitting at the bottom through which condensate is removed.

- Cone-shaped tip.

- Bends.

Mistakes when choosing a chimney

Mistakes in the design, selection of materials and installation of the chimney pipe have a negative impact on the operation of the chimney.

The most common manifestations are:

- fire of building materials;

- destruction of chimney walls;

- drop in traction indicators.

The most common mistakes when selecting and creating a chimney:

- incorrectly selected pipe;

- using the wrong materials;

- violation of fire safety regulations.

Wrong choice of pipes usually causes poor-quality traction. Its strength is influenced by external aspects: precipitation, wind characteristics, and so on.

That is, it is important to ensure the influx of fresh air masses from the outside, for which you can install a separate air channel from the street, which can be regulated

Inaccuracies in pipe construction may include the following aspects:

- incorrect choice of section;

- low chimney height;

- there are deviations from a straight vertical line - the angle of the inclined parts is not allowed greater than forty-five degrees.

If we talk about the incorrect selection of materials, then in the case of mediocre characteristics of the brick for the chimney, it begins to collapse quite quickly, which causes the structure to freeze.

Not all stainless steel models are suitable for creating a chimney. It is better to use AISI 321 steel, which is most resistant to fire and acids, as well as physical impact. When using enameled pipes, you should select the appropriate models based on thermal characteristics, since often such pipes simply burn out for many.

Another common mistake is violating fire safety regulations.

The main mistakes in this case are:

- lack of fireproof cutting and filling with high-quality fireproof materials between pipes;

- poor-quality pipe lining, which causes it to overheat.

As you can see, creating a chimney for boilers of various types is not difficult even for an uninitiated person. But it will function efficiently only if a large number of different factors are taken into account.

In the next video you will find diagrams of chimneys for the boiler.