Radiator design features

Internal filling of a heating radiator

The battery is a separate heating device that contains elements with internal channels for the movement of energy carriers. Heat is removed by convection, radiation and heat transfer.

Sectional types allow you to increase the heating area by adding elements. Panel installations cannot be changed in shape, which is taken into account when calculating and installing the system. The accompanying passport indicates the temperature criteria for the operation of the device, operating pressure parameters, and heat transfer.

Radiator section

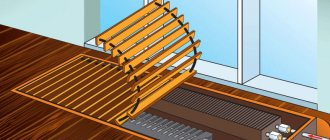

The cross-sectional structure of a heating battery consists of a metal pipeline in the form of combined horizontal collectors through which water passes. The channels are connected using small-diameter vertical tubes, and the entire system is housed in a housing made of cast iron, steel or aluminum. The separate sections are screwed together.

Radiators serve to heat the room, so the design of the devices affects the quality of heat exchange. The material of the heat exchanger and housing plays a role, so bimetallic options are used, including 2 types of materials.

Radiators must be able to be cleaned periodically, because... scale deposits on the inner surface reduce heat transfer.

Calculation of the number of battery sections.

For every square meter of area, 100 W of thermal power is required. Example, corner room, two windows and an area of 30 square meters. Power required (30 X 100) + 10% = 3300 W. We threw ten percent on the corner room. The same needs to be done for the first and last floors. We chose a radiator with a power of 170 watts per section. Thus, we will need 20 sections, 10 for each window. We take it with reserve. It’s better to ventilate once again in winter than to freeze. Our calculation is very approximate and is valid only for multi-storey residential buildings. If you are building your own separate house, then contact the designer. The specialist will make a calculation taking into account the thermal conductivity of your home.

Types of radiators by design

The power of a radiator depends on the area of its heat transfer.

The heating capacity of batteries depends on the exchange area, so the design is important.

The choice of form is influenced by factors:

- ceiling height and room area;

- maximum pressure in the heating line;

- duration of operation (long-term or periodic);

- boiler power, pipe material, characteristics of other devices in the system;

- chemical composition and physical properties of the energy carrier.

Radiators are selected in the form of sections, panels, plate and tubular types. The climate in the region and the required heating conditions, the presence of aggressive factors, and the cost of batteries influence.

Sectional radiators

Approximate calculation of the number of radiator sections based on the area of the room and the height of the ceilings.

Heat exchangers connect sections of the same type, which inside have 2–4 channels for water movement. Prefabricated elements are made of aluminum, steel, cast iron of various shapes and lengths. Heating of the room is coordinated by the number and size of sections.

Prefabricated batteries transfer heat by convection and radiation, operate economically, and are equipped with manual and automatic temperature controllers, taps, and valves. The products are inexpensive, and the ability to choose the center distance makes them popular for different buildings.

Disadvantages include the risk of leaks due to a sudden surge in pressure, difficulties with cleaning internal channels and external cleaning of the intersection space.

Tubular batteries

Design of tubular batteries.

The power depends on the diameter of the pipes. The cross-sectional design of the radiator includes 1 – 6 vertical collectors, which are connected by an upper and lower pipe; the coolant circulates unhindered. Heat transfer depends on the diameter of the pipes and the dimensions of the heat exchanger (0.3 - 3.0 m). The units can withstand pressures up to 20 atm.

Tubular batteries withstand pressure changes and hydraulic shocks. Smooth interior contours resist the accumulation of dirt and deposits. Welded joints do not leak. The appearance fits into various interiors. Radiators are available in all sizes and differ in body shape. The disadvantage is the high cost.

Panel models

Panel radiator with a corrugated surface

A panel radiator looks like two metal panels welded together. Inside the plates there are vertical channels for circulation of the energy carrier, and ribs are attached to the outside, which increase the heat transfer surface. The panels are arranged in 2 or 3 rows, the material is steel.

Advantages of the models:

- low inertia makes it possible to quickly respond to changes in external temperature;

- due to its lightness, massive fastenings are not required;

- compact devices can be placed in any part of the room;

- low price.

To heat the model, you need half as much water as a sectional battery. The disadvantage is that panel installations cannot withstand high pressure in the main line; purified energy carriers without dirt and impurities must be poured into the system. Poor quality painting of joints leads to corrosion and leaks.

Lamellar

The power of a plate radiator depends on the number of plates.

The operating principle of the radiator is convection exchange. The heat exchanger is a core with fixed fins made of thin metal. Inner tubes serve to transfer water. This type of radiator is installed in industrial and public buildings, multi-apartment buildings with a centralized main line.

The degree of heating is regulated by increasing the number of plates. Radiators effectively heat the room, but when the boiler is turned off, cooling occurs quickly. The coolant must be heated to a high temperature and pass under pressure.

Accessories for device installation

The quality of its operation depends on the parts that go on sale along with the radiator. Together with the device, two important components are offered: an air release valve and fasteners. For apartment buildings they are supplemented with a duct extension.

Mayevsky crane

Serves to remove air from the system . Helps get rid of gas locks and superheated steam. Thus, it allows you to reduce the pressure that has increased due to the long operation of the boiler. Mandatory for installations in closed type pipings supplemented with a circulation pump.

Reference. It is desirable to have a valve for draining water. It will serve the same purpose as the Mayevsky tap , affecting the liquid part.

Classification by material of manufacture

Radiators must last a long time and withstand various aggressive influences. In a multi-storey building, the operating conditions are not entirely suitable, since the coolant is not of high quality. Aluminum appliances are not installed in the apartment, because... The radiator is wearing out and will quickly fail.

Manufacturers take care of damage to the insides and protect the surface with polymers, but such options are expensive and are not always in demand. Bimetallic and steel installations are less damaged by corrosion. Cast iron batteries are suitable for centralized heating from the city branch.

Cast iron

Cast iron radiators take a long time to heat up, but they give off heat for a long time and retain it

. A heavy radiator consists of sections and is distinguished by powerful heat transfer. The device tolerates energy contamination, but limescale and scale accumulate on the insides. The units operate for a long time, sometimes they are removed, disassembled and cleaned under pressure to restore the original heat transfer.

At the same time as cleaning, the intersection gaskets are changed, which eventually fail. Cast iron batteries have an outdated design and are not installed in closed automatic heating systems. In apartments that are heated from the central branch, such batteries can withstand pressure changes and water hammer.

Aluminum

The aluminum radiator in the heating system efficiently releases energy and has a large area due to the impressive number of fins. Devices are produced that can withstand a pressure in the system of about 12 atm, and the pressure during pressure testing is at the level of 18 atm.

Sectional design options for an aluminum heating radiator:

- one-piece structures with cast sections;

- extruded type with elements connected mechanically;

- combined options.

The advantages of aluminum radiators include small dimensions, lightness, and large area. The disadvantage is the destruction of metal in an aqueous environment, especially in the presence of stray currents in the main line. The oxide film inside is damaged by an aggressive energy carrier; during the reaction, gas is released, which in a closed circuit leads to rupture of the battery.

Bimetal

Bimetallic and aluminum radiators do not differ in appearance, but there is a difference in technical indicators.

Bimetallic installations are of higher quality. The purpose and design of the radiator allows the device to operate under high pressure conditions and with the danger of water hammer.

Batteries are produced sectional or cast, and come in two types:

- made of aluminum and steel;

- made of aluminum and copper.

In bimetallic devices, contact of water with aluminum is not provided. This design improves thermal conductivity, reduces weight and increases strength. Radiators made of two metals can withstand pressure up to 100 atm, no corrosion is observed.

Installation is a big deal!

The quality of installation often depends on the components supplied with the radiator. Components have a big impact on the system, so it is important to install them correctly. To do this, it is recommended to invite a specialist .

Modern aluminum heating radiators are very popular. Such equipment can be seen both in city apartments and in offices. They are especially often installed by owners of private and country houses. The technical parameters of the batteries make them an excellent option for one-, two- and three-story buildings. The article discusses the device, characteristics, advantages and disadvantages, the main models of aluminum batteries, and also describes how to disassemble, assemble and wash an aluminum radiator.

Design and operating principle

The principle of operation of a radiator is that the heated energy carrier moves through a pipe system and enters the batteries, transfers heat, then moves along the return branch to the heating source. A radiator heats the air in a room using radiation and convection. Different types of devices have different ratios of thermal radiation and convection.

Steel and cast iron radiators heat the room by radiation, and plate and panel heaters transfer energy by convection due to the large total area of ribs and strips. The warm flow tends upward; in return, cold air is drawn in, which heats up.

Specifications

Aluminum heating radiators have technical characteristics that allow complex heating of rooms, transferring one half of the heat by radiation from the battery panel, and the second by convection air flows. One section of such radiators has the following indicators:

- depth – 70-110 millimeters;

- panel area – 0.5 m²;

- coolant capacity inside the battery – 0.4-0.6 liters;

- thermal power – 120 W;

- weight – maximum 2 kilograms;

- coolant temperature – 90 degrees.

Connecting the radiator yourself

Single-pipe and two-pipe radiator connection diagrams

In the multi-apartment sector, the batteries are mounted on one side of the room. The radiator is connected using several methods depending on the pipe layout.

Diagonal or cross connection is used. The underwater pipe is connected to one side of the battery at the top, and the outlet pipe is connected to the other side at the bottom. This scheme is relevant for installations with a large number of sections of considerable length.

The bottom connection involves connecting the inlet and outlet from the radiator from below to two pipes on both sides of the heat exchanger. The scheme is characterized by low efficiency, but this option cannot be avoided if the heat supply system is located in the floor.

What to look for when choosing

Let's find out what characteristics of a bimetallic radiator you need to study when purchasing.

- Operating pressure. A bimetallic sectional radiator must withstand a constant load of 15 atmospheres; for a centralized heating system, it is better to choose a device with a maximum operating pressure.

- The rated power of the section is needed to calculate their number.

- Dimensions. For standard window sills with a height of 80 cm, a model with a center distance of 500 mm is suitable.

- Thickness of steel inlays. The thicker the walls, the stronger the device and the longer it will last.

- Price. Bimetallic radiators cost at least 20% more than aluminum ones. If the price is lower, most likely it is a low quality “semi-bimetal”.

USEFUL INFORMATION: Multifunctional glass: what is it