Among heating devices, the most common are heating radiators. The heating radiator design can be either sectional or panel. Such elements are made from different materials - it can be cast iron, steel, and alloys. Their appearance and aesthetics can currently be completely different, but heating radiators also differ in design features.

Radiator

Characteristics and types of heating radiators

The most common and well-known type of radiators are made of cast iron. They were quite common and were used in every home. They are very massive and are not suitable for a modern heating system and do not fit into a modern interior.

Cast iron radiators have a number of advantages: they can withstand pressure drops well, do not corrode and do not interact with elements emitted by the heating system.

- Radiators made of steel have thin walls, which means less heat transfer. This quality can be improved by purchasing a single panel steel radiator. Due to the increase in area, heat generation increases.

- The design of aluminum heating radiators harmonizes perfectly with modern design. It features a small and weightless design with good heat dissipation.

It is possible to manufacture radiators from aluminum with the addition of various impurities. If the cost is greatly reduced, then silicon is added to the composition. It significantly reduces the structure's ability to resist pressure.

Radiators of a higher price category contain zinc and titanium; they significantly increase resistance to third-party damage, increase corrosion resistance, and pressure resistance.

The design of bimetallic heating radiators are radiators that are made of two types of metal (copper and aluminum). The advantage of radiators is that they are better able to withstand sudden changes in pressure and are not subject to destruction under the influence of water.

They are easy to install on standard pipes. In combination with steel pipes and aluminum plates, the heat transfer process can be significantly increased.

Review of popular models

The market offers an impressive number of models of all types of convectors from various manufacturers. Moreover, domestic companies are actively operating in this area. For example, in the niche of inexpensive heating equipment they are traditional leaders.

So, if the buyer needs reliable, affordable wall-mounted devices, then he should buy the KSK-20 products, proven by time and a large number of users, which are produced by the famous Tolyatti plant. He has been making popular and inexpensive heating units for decades.

The KSK-20 convector is an efficient, reliable and inexpensive heating device

These convectors can cover the needs of all categories of users, as they come in different capacities, sizes, and configurations. For example, the length of the devices is in the range of 60-160 cm, and the weight starts from an insignificant 8 kg, which allows you to place the devices on any walls or partitions without the risk of damage.

The power of such heating equipment ranges from 0.4-2 kW, which allows you to heat both a small living room and a large industrial or commercial premises. High-quality steel is used for manufacturing, which ensures the device has a service life of at least 25 years.

Such convectors can be used in any heating systems, because they can withstand exposure temperatures of up to 150 °C and operating pressures of up to 10 atmospheres. The high-quality powder paint that covers all products protects the device from minor damage and gives it a modern, pleasing appearance.

The only minor drawback of the KSK-20 is the lack of brackets in the kit that are used to attach it to a wall or other vertical surface

Some buyers pay attention to the poverty of the color palette - heating equipment, most often, can only be purchased in traditional white or gray colors, so it does not always fit perfectly into the interior

If you need a more beautiful device, then you should turn to the product line of another domestic manufacturer - Techno. Thus, at his Moscow plant, various colors are used for decoration and products are decorated with various structural elements. For example, the Vita Bench KBZ model is in demand among buyers.

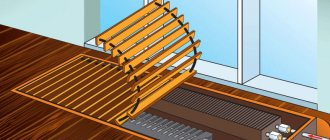

Its main feature is execution. The floor-standing unit is a bench, and the wooden elements can even be made from popular and valuable types of wood, which makes it a decoration.

At the same time, Vita Bench is a durable and efficient convector, which the manufacturer equips with a thermostatic valve. But the disadvantage of the presented model is the price - it is significantly higher than the KSK-20, which is similar in power.

Covectors can have decorative qualities and serve as decoration in hotels, offices, and homes.

In recent years, another Russian manufacturer of convectors has become known - Varmann. Reason: its products are distinguished by functionality, practicality, and high decorative qualities.

Thus, its line of built-in Qterm HK devices is equipped with air channels and tangential fans that allow air to be drawn only from the desired side. This function significantly increases efficiency and economy.

The fan speed is regulated by a microprocessor, and if necessary, the convector can be connected to a smart home system or using a control panel. The reason for this is simple - thermal power depends on the fan performance

High-quality materials used in manufacturing make it possible to withstand impressive pressure during the pressure testing period, reaching up to 16 atmospheres, and work stably with coolant heated to 90 °C.

The following article, dedicated to this interesting issue, will introduce you to guidelines for choosing a convector-type heater.

Heating radiator design

When planning a heating system, it is quite difficult to calculate the amount of heat required. You have a choice between a sectional battery system and a convector one.

When choosing a sectional radiator, it is possible to add additional sections or subtract them if necessary. When choosing a sectional radiator, it is possible to eliminate elements that have come out of order. The convector radiator system does not provide this opportunity.

- An important aspect when installing heating radiators is the interaxle distance.

- This is the distance between the inlet and outlet sections of the radiator displayed vertically.

- When replacing the radiator, this indicator must be taken into account.

- You need to purchase a radiator with an identical indicator.

- Otherwise it is necessary to change the heating system.

To prevent premature and unwanted clogging of the heating system, it is necessary to take into account the diameter of the pipe. The small diameter contributes to the formation of blockages.

The heating system functions by running hot water through it. And the water may contain various microelements, sand, rust, and other debris, which causes congestion.

This, in turn, can disrupt the functioning of the heating system or completely render it unusable.

Choosing a suitable sectional design of heating radiators presupposes good functioning of the heating system.

A few general questions

The technical design of radiators includes several parameters. This is the design option, the material from which they are made, and the performance specifications. Until recently, in our country, exclusively cast iron batteries, which are a domestic invention, were used to organize the water system. The rib design was invented by foundry engineer Franz Sangali. He also called the unusual heating device a battery.

Today on the market of heating units there are several types of radiators with different technical characteristics, so a competent assessment of each option is necessary. The technical device displays the operating capabilities of a particular model, determines the type and quality of the coolant used, the permissible operating pressure, the choice of connection system and installation features. Therefore, it makes sense to talk about all this in more detail.

https://www.youtube.com/watch?v=3BaaUUG4JZE

Methods of operation

The operating principle of heating radiators is extremely simple. Hot water moves through pipes to radiators to heat the room. In turn, the principle of heating using radiators is divided into two types.

In the first case, the process of heating the room occurs by heating the incoming cold air and converting it into warm air. This method is called converter.

- The next method of heating a room occurs by heating the air using a heated surface. The method of heating a room in this way is called radiator.

- The heating system can combine panel and convector heating radiators.

- In terms of room heating efficiency, convector heating is considered more efficient. It also has a minus; if you look at a cross-section of a convector radiator, you can understand that when heated, dust particles are released into the room along with the air. In turn, this factor adversely affects people’s well-being.

- A convector heating system is used in buildings in which another type of heating cannot be installed due to its size.

Regardless of the temperature to which the battery is heated, it will only release 60% by transferring heat to the room. The remaining percentage of heat is spent on heating the air using a converter method. This is how you can describe the system of operation of a radiator; to some extent, it is similar in principle to working with a heated floor.

Purpose of thermostat elements

All functional elements included in the thermostat include:

- thermal valve;

- thermal element;

- thermal sensitivity element;

- connector;

- transmission rod;

- spool valve;

- union type nut;

- compensator;

- fixation ring;

- scale.

The thermoelement has the form of an element that is equipped with a cylinder filled with a working composition that strongly reacts to any changes in temperature around, and its walls from the inside are made in compliance with corrugation technology. This mechanism is called a bellows.

When the temperature increases, the volume of the working medium also increases, which, in turn, causes the working rod to move and block the movement of the coolant. If the temperature drops, the volume of the working medium, on the contrary, decreases, thereby compressing the bellows itself. This leads to reverse movement of the rod, which opens the way for the coolant to the heating radiator. A similar cycle of compression and expansion in modern devices is repeated a huge number of times, which makes it possible to operate them for a very long time.

Installing a heating radiator with your own hands (step by step)

Before starting installation work, it is necessary to draw up a diagram of the heating system. The heating system diagram can be developed for a separate case, with the calculation of the advantageous position of the heating radiators for maximum heat transfer.

The most common method of installing radiators is one-sided. It is effectively used in multi-storey buildings. Radiators are installed to the general system using a one-way connection.

Two-way installation path. A heating pipe is connected to the radiator from above, and it comes out from the bottom of the radiator.

With a large number of sections and proper connection, sufficient heat will be released to heat the room.

There is also a third method of installing a radiator to a heating system; it is less effective compared to the two previously presented.

In this case, the pipe supplying and conducting hot water is mounted to the bottom of the radiator. This installation method can be considered effective for a heating system built into the floor.

Current system

Domestic and foreign cooling systems are overwhelmingly closed, where liquids are forced to move. Their main elements are:

- cooling radiator;

- pipes and connecting hoses;

- jacket (technological channels of the block);

- water pump;

- multi-blade fan;

- thermostat.

When the power plant is operating, the antifreeze located in the channels of the jacket receives heat from the engine. Then it moves through the existing channels to the radiator to cool, and returns back through other channels. The movement is aided by a pump located in the system, and cooling is facilitated by a large fan located behind the radiator. The work intensity is adjusted by a built-in thermostat and timely auto-start/auto-stop of the fan.

Topping up the required volume of antifreeze is carried out through a special neck in the radiator. This can also be done using an expansion tank. As a rule, modern systems fit about 6-12 liters of antifreeze. It can be replaced after it has been completely drained by unscrewing the cap on the block or at the bottom of the radiator tank.

Photo of heating radiators

Three-way valve

An unconventional device for regulating the temperature of heating devices is a three-way valve. It is placed at the connection between the bypass and the supply pipe that goes to the battery. In order for the valve to perform the function of stabilizing the heating level of the radiator, it must have a thermostatic head. If the temperature near the head rises above the required value, the supply of coolant to the battery stops, and the liquid flow moves through the bypass. When cooling occurs, the valve opens again and the radiator heats up. This adjustment method is suitable for single-pipe systems with vertical wiring.

Important! In homes with a central heating system, the coolant usually contains foreign particles that clog thermostats. Therefore, you can safely install manual taps or valves, as well as three-way valves in your apartment.

If you want to install automatic heat regulators, you must install filters in front of them, which will have to be cleaned regularly.

Aluminum and boiler with copper heat exchanger

Some installers are confident that aluminum batteries cannot be combined with a boiler that uses a copper heat exchanger. Indeed, aluminum and copper are considered an incompatible galvanic pair. If you connect these metals directly to each other, the copper will attract aluminum ions, as a result of which the aluminum structure will simply be destroyed quite quickly.

However, in heating systems it is simply impossible to imagine direct contact of the radiator with the copper coil of the boiler. Most often, polypropylene pipes are used to connect them. Since copper and aluminum do not come into contact, ion leakage is completely eliminated. The service life of the radiator will not change, regardless of the metal from which other elements of the heating system are made.