How to cover radiators so that they fit perfectly into the overall design of the rooms and do not spoil their design? But with this calculation, of course, to avoid significant losses in the efficiency of radiators? This question arises quite often when completing renovations of an apartment or house. If cast iron radiators of an old model are installed in the heating system, but there is no desire to change them, since they function perfectly, then they can be disguised with decorative screens or grilles.

How to cover radiators

These devices, we repeat, must be made in such a way that they do not interfere with the flow of heat into the room. Therefore, if you plan to make them yourself, you need to carefully consider the design. In addition, such products can be ordered from a furniture workshop, taking measurements from the place where they are installed, or they can be immediately purchased ready-made in specialized stores.

It should be noted that you can choose a model of protective and decorative screen that will not only mask the unsightly appearance of cast iron products, but will even increase the circulation of warm air from the radiators towards the room.

To choose the right screen model, you need to understand the operating principle of heating radiators and some of the patterns of transfer of thermal energy into the room.

Functional purpose of the screen on the battery.

Screens, regardless of their material, are an excellent solution to several problems:

- Protection. Radiators, whether old or new, pose a health hazard to residents. The heated surface of the batteries can cause skin burns, and protruding parts that hit them can cause mechanical damage. In this regard, radiators pose a particular danger to children. Various types of screens for radiators reliably perform protective functions for the health of adults and children.

- Hygienic cleanliness. The complex accordion-shaped batteries have always been a hard-to-reach place where dust and dirt collect. Cleaning near radiators brings a lot of negative emotions, so the screen, protecting the battery from dust particles, will help ease the process.

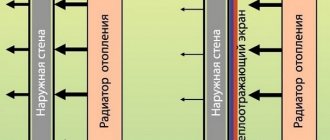

- Improving the convection qualities of radiators. Thanks to the fact that many screens designed for heating systems have cutouts, additional spaces and specially designed elements, it is possible to increase the overall convection of radiators. Often, a reflective screen is placed between the battery and the wall, and when heated, it increases heat transfer.

- Decorative solutions. Most often, screens for a heating system are installed in order to harmonize it with the interior. To hide the radiator and add missing elements to the decor, grilles are chosen of a non-standard type. Today there are an infinite number of options for making screens for radiators, differing in material, shape, decor and design, so there will be no problems with the choice.

Design of pipe joints with bases

When laying out the heating system, the openings for the inlet (outlet) of the heating pipes into the wall or floor are always made larger than the diameter of the pipeline, so there are gaps around the heat pipe where it passes through building structures, which even after sealing do not look aesthetically pleasing. The problem of designing such connections is very easily solved - for installation on joints, detachable ring and rectangular rosette covers made of plastic, metal or wood are available for sale, differing in size, color and design profile. Installing them in place is simple - the halves of the product are put on the pipe in a girth and fixed by snapping together; first, a drop of any glue is applied to the contact area of the ring with the base so that the product does not move along the pipe. These decorative ring covers for heating pipes are reusable products and can be removed for cleaning or installation in another location.

Advantages and disadvantages

Screens for radiators, as evidenced by the design developments in the photo, create home comfort and can become an important element of style. At the same time, decorative boxes and shields also perform a protective function, protecting radiators from the accumulation of dust and mechanical damage.

Installing a screen on cast iron batteries with high heating temperatures is an important measure to protect against burns. Enclosed niches under windows also reduce the risk of injury, especially in cases where there are children at home.

The choice of materials and designs depends not only on aesthetic taste, but also on requests for ease of maintaining cleanliness and energy saving.

Thus, respectable panels made of natural wood will inevitably lead to heat loss, while complex carved decor will make cleaning difficult. An open top and bottom will help reduce heat loss, but will make cleaning much more difficult.

Perforation is another prerequisite for the manufacture of decorative screens for batteries. Regardless of the material used, the main panel must have through cells that allow air to pass through. Design solutions can be different: lattice, wicker, blinds or cut-out patterns.

Masking box and panel structures are not airtight, and therefore it is important that they are easily removable, providing access to the batteries for cleanliness and emergency situations.

It is also possible to provide covers, as well as side and bottom panels, which can be opened or removed during the heating period in order to increase air circulation.

To reduce heat loss, the inner surface of the screens and the wall adjacent to the battery can be covered with a special rolled material - heat-reflecting polypropylene or aluminum-coated film.

Types and forms

In addition to different materials, radiator grilles come in different designs. All this together creates a huge number of options.

Flat screens. Most often used if the radiator is installed in a niche. In this case, the flat panel is attached to bars fixed around the perimeter of the niche. In addition, glass screens for batteries also have this shape, but are attached to special pins embedded in the wall. This type of decorative grille for heating radiators is also called “facades”.

Hanging screens. There are two types:

- With top cover. They are usually used on accordion-type batteries if the radiator protrudes beyond the window sill. The shape of the cover is made so that the grille holds onto the radiator without any problems.

- Without cover. Clings to the upper battery collector using hooks that are attached to the front panel.

Grate-box. From a heating point of view, this is far from the best option, since air circulation is difficult. Install if you need to cover the side parts of the radiator. These grilles can be made in the form of some kind of piece of furniture, most often a chest of drawers or a cabinet. If they can stand on their own, without support, they are also called attached.

There are also boxes that require fixing to the wall - they do not have legs. For better heat dissipation, a 3-5 cm wide gap is made under the lid and above the floor in the grille box. It is also a good idea to make a hole in the top lid.

These are only the main types of screens and grilles covering heating radiators. Fantasy is limitless, there are very interesting models, but they are most often made by craftsmen with their own hands.

Application nuances

When choosing thermal insulation, it is worth remembering that not everyone can reflect heat. In order for the indicator to be maximum, the foil must be thick enough. Most often, the insulation, its basis, is extruded polyethylene with a thick aluminum layer that retains maximum thermal energy. These include insulation materials Teplofol, Penofol, Alufol, and others.

Teplofol

Sheathing that can reflect is available in the form of mats, rolls, and pipe cylinders. If it is manufactured using testing technology, the thermal resistance characteristics must be indicated in the accompanying documents. If you foil the material, its range of applications will expand indefinitely. It's ideal for

For interior work, metallized polyethylene material, which is capable of reflecting heat, is ideal. When installing, you will need to leave a distance between the sheathing and the wall for ventilation. This will preserve the material and prevent moisture accumulation and mold growth. If this is external thermal insulation, you should choose mineral wool or polyethylene with metal

When laying, it is important that the material is joined, the cracks are taped with special tape. When the ceiling is insulated, mineral wool is used, a layer of air between it and the finish. To create such a structure, a sheathing of wooden blocks is installed, and a metal profile is also used.

For heating networks and small-diameter water mains, insulation without an air gap will be indispensable. If the pipe is large in diameter, a cushion between it and the casing is required; an exception to the rule is foiled mineral wool. When pipeline insulation is made of polyethylene, it is desirable that it be foil-coated on both sides. In order for heating radiators to operate at full capacity, they use a material that can effectively reflect heat. Cut the sheet to the size of the battery, place it between the wall and the heating device, the foil should be directed towards the room. Insulation is easy to install, but guarantees high efficiency of heaters, batteries, air heaters, increasing it by 30-35%.

battery thermal insulation

Types of decorative screens

According to their design features, screens are distinguished:

- flat, covering only the front part of the battery;

- wall-mounted with or without a lid;

- hanging boxes covering the battery on all sides.

If the battery protrudes above the wall, the best option for it would be a box or a hanging screen without a cover. The latter looks lighter and more relaxed and does not clutter up the space.

Boxes or models with a lid can also be used in an original and practical way in the form of a stand or cabinet, especially in the summer. During the heating season, it is better not to place objects on the lid so that they do not heat up and interfere with the free circulation of warm air.

If the radiator is located in a window sill niche, a flat hinged or mobile panel with legs will do. This design is an excellent decorative option that does not take up usable space.

Screens can be made of different materials - metal, wood, glass, plastic. There are also combined models containing glass and HDF, metal and wood, etc.

Metal screens

Metal gratings are made from steel or aluminum sheets with various perforations, which can be in the form of openwork ornaments and patterns or a regular mesh. A standard metal screen is usually inexpensive, but designs with original stainless steel perforations can cost significant amounts.

Metal grilles have excellent heat dissipation, are easy to clean and can be installed without any hassle. Moreover, such screens are not subject to deformation from prolonged exposure to high temperatures and do not change color.

Metal grilles look great against the background of minimalism, hi-tech, industrial, rustic styles, that is, interiors where there are steel accents.

Drywall

Drywall sheets are used to make a frame, the openings in which are filled with other material: plastic gratings, metal panels, MDF, HDF.

The screen itself is not made from gypsum plasterboard, since in case of leaks the structure will have to be completely destroyed.

Forging

These grilles are beautiful, but too lacy. Forging is often combined with a contrasting background, against which the elements will look brighter. Metal sheets provide better circulation.

Wooden screens

These grids are suitable for any type of battery. They are made from natural wood of various species - from beech or oak to more expensive and valuable varieties. Rattan models are especially popular. Graceful carved designs and the ability to cover the surface of the wood with a varnish and paint substance allow you to create exquisite decorative screens.

The main advantages of wooden structures are environmental safety, naturalness, excellent heat transfer and impeccable appearance. They will fit perfectly into an interior with wooden elements - from classic to avant-garde.

But it must also be said that the price of such gratings is considerable. Wooden screens can become deformed over time and require special care using wood products.

Screens made of HDF, MDF and combined

HDF and MDF are sheet materials of high and medium density. It is made by pressing small wood under the influence of heat and pressure. Such gratings are cheaper than models made of natural wood. Usually the box itself is made from sheets, and the screen is made from rattan or wooden mesh.

It is important to understand here that a dense mesh with a small number of holes will have poor heat transfer, so special attention should be paid to the choice of mesh screen.

Glass screens

Glass screens are rarely found in interiors, although they have high aesthetic capabilities. Such structures are made from tempered glass, the thickness of which is no more than 8 mm. Thanks to special processing, the glass is resistant to scratches and damage, and the rounded corners are absolutely safe.

Most often, glass screens are produced in the form of a single panel. Stained glass models are not cheap; acrylic glass is considered a more budget-friendly option. Such designs are simply impressive with their varied decorative design. All kinds of techniques reveal a wide potential of design possibilities, allowing you to create stunning patterns, designs, textures and stained glass windows.

Glass screens are easy to clean with regular window cleaner. They have good heat transfer, but in some cases in this category they may be inferior to screens made of other materials and with perforations.

Plastic as a screen material

Plastic does not have the same thermal conductivity as aluminum or steel. To increase the strength of the material, you need to increase its thickness, which further increases heat loss.

- Plastic screens are not installed in children's institutions.

- Because when heated, they begin to emit toxic fumes.

- These designs are recommended for non-residential premises and offices.

The big advantage of plastic screens is their resistance to wet environments, resistance to corrosion, and low weight of the structure. The price of such a grill is about 200 rubles.

The grille is selected with a minimum surface area and installed at a distance from the floor, and then it will not only decorate the room, but also preserve the microclimate of the room.

Bamboo and rattan

Completely natural materials are safe, have an unusual appearance, suitable for oriental design style. It is better to order inexpensive products from Chinese online stores.

Photos in the interior of the rooms

There are several ways to hide batteries in the interior; in this section we will look at the most popular and effective ones.

Kitchen

The kitchen is the ideal room in which all ways to hide batteries will become practical and convenient. If the room is small, then you can hide the radiator with the help of a beautiful tabletop or make a folding table, which will fold out when convenient.

Factories of metal-plastic structures offer a large selection of beautiful large-sized window sills that imitate stone, wood and other materials. A modern window sill does not break under weight, is not afraid of external factors, is easy to care for, wipe clean, is not afraid of scratches, and so on. You can hide any type of battery in this way, including cast iron.

In the photo, wooden boxes are used to disguise the radiators.

Hallway

For radiators in hallways, glass screens or wooden boxes are suitable. In a small room, covering the battery is only necessary from a practicality point of view. This could be a locker for storing shoes, or the battery will become a small coffee table where keys and other necessary items will be stored.

Bathroom

You can hide the pipes in the bathroom using a louvered door, plastic grilles or a cabinet with opening doors.

We hide heating radiators using wooden, glass or plastic screens.

In the photo, the radiators in the bathroom are hidden using a wooden box.

Bedroom and children's room

In the interior of a bedroom and children's room, batteries can be used as another place to relax, a tabletop for decorative elements or a workplace.

Living room

If the radiator is in a niche, then a wide window sill will help create a work area.

You can place souvenirs, vases or potted flowers on the constructed wooden box. You can also cover unsightly radiators in the living room with thick curtains.

The photo shows a modern living room. In order to hide the radiators, a wooden structure was installed, which also serves as a place for rest, storage and decoration.

Operating principle

If the insulation is foiled, it acquires an increased ability to repel condensation and retain heat, and each layer in it is responsible for certain functions:

- The first layer of material consists of glass, mineral fibers, foamed polyethylene, expanded polystyrene, which does not allow heat to go anywhere. It tends to reflect waves into the home, creating a favorable microclimate for living.

- The second is 7-15 mm foil, which can reflect the heat flow as much as possible. According to the laws of physics, the material, if foiled, accumulates up to 90-95% of thermal energy, the remaining 5-10% is retained by polyethylene fiber.

- The production process is simple: metal is soldered onto the material, joining it into a single whole, after which it gains the ability to reflect the body.

- Thermal insulation is available on one or two sides, which determines the range of uses. Insulation, in which one layer is aluminum, is used to insulate the inside of the room. If you foil the material on both sides, it can be used to insulate refrigeration units, heating mains, industrial buildings, and factory lines.

Instructions for DIY production and installation

Any of the materials considered can be used to make screens yourself. It is necessary to objectively assess your skills, take into account the availability of tools and the availability of components for sale.

Works according to a single algorithm:

- Choose a design based on a photo or sample.

- Measurements are taken of the radiator and installation location: height, width, depth of the niche.

- Make a sketch and, if possible, an accurate drawing of the screen.

- The instrument is being prepared.

- Purchase materials, including consumables (paint, fasteners).

- A frame is made and sheathed with the selected material.

- Finishing is carried out.

- Attach using the chosen method to the wall or floor.

You can inspect the model you like at a construction supermarket and then start making it yourself.

Glass or mirror screen

You will need:

- drill or screwdriver;

- hammer drill for drilling a wall for fasteners;

- glass drill bit.

- a glass cutter and a diamond block, if you are cutting the glass yourself.

Glass or mirror can be ordered according to the required sizes in stores or workshops, and the edges will be processed there. The price of glass (at least 6 mm) with a cut ranges from 1,000 to 2,000 rubles per square meter. Holders will cost from 1,000 rubles. per set. Additionally, holder brackets can be purchased.

They can be of different designs, but must hold the panel in a vertical position.

Self-production algorithm:

- The glass is cut to the required size, taking into account gaps for air circulation.

- Treat the edge with a diamond stone or fine sandpaper.

- Using a crown of the required diameter, drill a hole for the holder. The drill is set to minimum speed, and as you work, the drilling site is watered with water.

- Make markings to install the holders on the wall or floor.

- Drill a hole and attach the brackets.

- Install the glass on the holders.

Before drilling, try to perform the operation on an unnecessary piece of glass. Another no-drilling option involves using prefabricated brackets and nickel-plated posts. All materials can be purchased at any construction supermarket.

The surface can be covered with a tinted film of the same color or with a pattern.

Protective box made of MDF, HDF

Prepared:

- drill (screwdriver), hammer drill or impact drill for concrete walls;

- jigsaw;

- a hacksaw with fine teeth complete with a miter box;

- construction corner, ruler or tape measure;

- a set of screwdrivers of the required configuration;

Buy:

|

|

|

|

|

|

|

|

MDF panels can be replaced with laminate.

Sequence of work:

- Conduct final measurements of the opening.

- Make a drawing.

- The HDF panel is cut and cut to the required dimensions, it is advisable to maintain the symmetry of the pattern.

- Mark and cut off the frame bars.

- Using steel corners, assemble the frame.

- Hangers are attached for further installation.

- The top and sides are covered with MDF panels.

- Secure the perforated panel using self-tapping screws screwed into the corners.

- The box is finished with a decorative corner.

- Mark holes in the wall, drill and screw in screws on which the box will be hung.

- Place the screen in place.

If necessary, the entire structure can be removed in a few seconds.

Some of the purchased MDF screens have sufficient thickness and strength so as not to make a frame; then the panels are connected using furniture corners.

Steel screens are made using similar schemes.

Forged gratings

To work, in addition to the hammer drill, you will need an angle grinder, an arc welding machine, a protective mask and electrodes. Blanks for the grating are purchased at a construction supermarket. The price depends on the part configuration and size.

To obtain the grid:

- The frame is welded from a steel angle or profile pipe.

- Monograms and racks are welded.

- Clean the weld areas with a grinder.

- Paint the finished product.

- Attach the grille to the wall or floor.

Welding cannot be carried out indoors, since the gases released are toxic, and the smell does not disappear from the room for several days. Observe fire safety measures: protect flammable objects and the floor with screens, prepare a supply of water in case of fire.

Calculation of radiators for a room, taking into account the features of their connection and location

We must assume that since a site visitor is reading this article, he will be interested in calculating the required power of the heating radiator (number of sections - for collapsible models). Moreover, the final value also depends on the presence and type of decorative screen.

The required power of a heat exchange device installed in a room depends not only on the area of the room, but also on a number of other criteria. All this is taken into account in the calculator presented to the reader.

Below are some explanations on how to carry out the calculation.

Calculator for calculating the required power of a heating radiator

Go to calculations

Mounting features

Grilles on heating radiators must be mounted in such a way that you can easily and quickly access heating appliances and pipes. Periodically, at least twice a year, the heating system elements must be cleaned of dirt and dust, so access is necessary.

In addition, emergencies arise from time to time. In this case, a quick reaction is required and there is no time to unscrew the fasteners. Therefore, try to come up with a fastening system that allows you to remove the screen in one motion.

Attached and mounted

The easiest way is with mounted or attached screens. They are removed/retracted in seconds. But flat, covering radiators in niches and box screens that are attached to the wall are the most problematic. But even here everything is solved simply. You can secure the box to the wall using two strips: one on the box, the second on the wall. The whole secret is that the top edge of the planks is beveled (you can see it in the picture).

The one that is nailed to the wall has a slope towards the wall, the one on the frame has a slope towards the grating. When the box is installed in place, it turns out something like a lock.

Another option is to attach metal plates to one of the strips and magnets to the other. Or attach not a wooden plank to the wall, but a metal corner, for example.

In the case of flat screens, the solution may be the same - metal plates and magnets. Another option is hooks and loops. It is easy to implement, but not very convenient to use: while you get into loops, you have to suffer. There is also a difficult-to-install but convenient way: make a screen like a sliding door.

You can take the guides that are sold for furniture doors, install them, and insert the screens into the corresponding grooves. If you do not plan to actively use the niche near the battery, you can not install roller mechanisms, but it will be difficult to move them away. This method, by the way, can also be used for the box lattice. It can then be nailed “tightly” to the wall, and the front wall can be made movable.

Material of the outer skin of the frame

As a finishing material, you can use:

- eurolining,

- MDF panel,

- plastic,

- perforated metal plates (grids).

The most popular material for finishing boxes is (considered) gypsum plasterboard sheet (GPS). This is explained by the fact that in the future the surface of the gypsum plasterboard box can be decorated with facing tiles, film, wallpaper, or simply painted in any color at will or in accordance with the design project. Despite the fact that masking communications screens and boxes have a sufficient number advantages:

- Very low cost (if installed by yourself). They can be made from leftover material left over from repairs.

- Arbitrary sizes. This is especially true for hard-to-reach areas and non-standard pipe layouts.

- They also have a number of disadvantages:

- If an emergency occurs with a water supply (heating) pipe, to eliminate it you will need to remove the entire lining of the box.

- Restoring the cladding will require new (partially or completely) materials.

How to close batteries correctly - technical rules and tips.

Before closing the radiator, you need to take into account several technical nuances:

- Keep in mind that the heat transfer of a closed radiator is reduced in any case, no matter what masking method you choose. The main thing is that the change is not significant. Ideally, the decrease in air temperature in the room should be about 1-1.5 degrees.

- Before closing the battery, put it in order: blow it out, wash it (this is done at the end of the heating season) and paint it.

- Keep in mind that the denser the grille weave, the better it masks the radiator, but the worse it conducts heat. Therefore, when choosing a screen for a battery, try to look for a middle ground or rely on heat saving.

- To minimize heat loss, the screen can be placed on legs and a groove can be cut in the center.

- When closing the battery, it is very important not to block convective air flows, otherwise it will blow in the room and the windows will begin to fog up, which will ultimately lead to the appearance of mold on the walls. Ideally, the window sill visor should protrude no more than 30 mm above the radiator; the top and bottom of the radiator should be as open as possible.

- There should be a distance of at least 35-50 mm between the battery and the screen. There should be a gap of about 60-70 mm from the radiator to the floor and to the window sill.

- To resolve emergency situations, it is necessary to provide free access to the radiator. For example, the box grille can be removable, folding (see photo), opening on hinges or sliding out on profiles.

At a minimum, for trouble-free maintenance, the following must remain in good accessibility: pipe connections, valves, thermal head and threaded connections.

You can increase heat transfer by 20-25% by placing a heat-reflecting screen, for example, fumisol, on the wall behind the radiator. Often this is quite enough to completely compensate for the heat loss of a closed battery.

Principle of operation

To understand the principle of operation of such insulation, consider the main methods of transferring heat from one coating to another:

- thermal conductivity - the ability to conduct heat (solids);

- convection - heat transfer through the air due to different densities of cold and warm air currents;

- radiation - any body with a temperature above zero emits heat waves, which are absorbed by walls and ceilings (surfaces), converted into heat and transferred to the cold external environment. This exchange accounts for about 60-90% of heat loss.

Thus, heat loss is inevitable. It turns out that to create the effect of thermal insulation, it is necessary to minimize heat loss from radiation. But traditional TIMs are not able to protect a building from this type of heat transfer. And the optimal material was found - foil insulation, known for its reflective and low-emissivity properties.

Reflective thermal insulation works across all heat transfer processes: radiation, convection and conduction, inhibiting heat loss.