Every owner of a private home faces roof insulation work. Those who are doing this work for the first time will face a long process of becoming familiar with different technologies and studying the properties of modern materials. The task of roof insulation is to create a cake from insulation and waterproofing films. Regardless of the type of roof structure, the durability and efficiency of insulation is determined by the correct choice of materials and compliance with the sequence of laying each layer of the roofing cake.

Characteristics and properties of the material

Mineral wool consists of randomly oriented fibers tightly compressed into flat mats or rolls. The air contained in the space between the fibers serves as a heat insulator. The material is used for insulation of various building structures:

- floors and ceilings;

- walls;

- roofs.

Mineral wool is not subject to drafts, it is not afraid of heat and frost. The material also has good sound-proofing and vibration-proofing properties, which helps protect living spaces not only from the cold, but also from street noise.

Mineral wool does not burn on its own and prevents the spread of fire. This makes it an excellent material for thermal insulation of interfloor ceilings, walls and roofs. Basalt wool is used to insulate places where chimneys pass through ceilings and walls. When heated to high temperatures, no harmful substances are released, as happens with thermal insulation based on foamed plastics.

The material does not serve as a breeding ground for the development of mold, mildew and various microorganisms

What is a roofing cake for an attic roof?

Structurally, all roofs are divided into two main types:

- “cold” - do not involve installation in the attic of residential premises, the roofing cake does not include thermal insulation;

- “warm” - immediately or subsequently focused on exploiting the space under the attic as residential or utility.

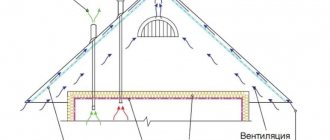

Regardless of the design and architecture, for every house the roof is one of the most important functional protective and decorative elements. It protects the building from external atmospheric factors and various mechanical influences, and also prevents the outflow of heat from the building during the cold season. Heat always tends upward, and if it is not contained, heat loss through the roof alone can reach 35%, and this is a significant overexpenditure of energy resources and operating funds. To minimize heat loss, and, consequently, costs, specialized thermal insulation materials must be used during construction or reconstruction. The difference is that in the case of a cold attic, the floor is insulated, and when arranging a residential attic, both the floor and the roof slopes are insulated. When insulating the floor of a cold attic, the maximum possible layer is laid in it to prevent heat loss. In the ceiling of a warm attic, a smaller layer of thermal insulation is laid, mainly to increase acoustic comfort, while the main “line of defense” is precisely in the slopes. The attic roofing pie consists of several functional layers.

- Vapor barrier - prevents steam released as a result of vital activity from entering subsequent layers of the roof. Even impermeable films with taped joints do not guarantee absolute tightness and retain the bulk of fumes, but some amount still gets inside.

- Thermal insulation is the main functional layer formed from a specialized thermal insulation material. It prevents the outflow of warm air in cold times, overheating of the under-roof space in the hot season, and also provides acoustic comfort, which is no less important for residential premises. The thickness of the insulation is selected based on the standards for thermal resistance of enclosing structures for a specific region of residence and type of thermal insulation. For the bulk of the regions and most materials, a layer of 200 mm is considered the minimum, for the southern regions - from 150 mm.

- Waterproofing – protective membranes laid on top of insulation under the final roofing covering are also called windproof membranes. Vapor-permeable membranes prevent moisture from entering from outside, prevent convective heat transfer (weathering) and release steam from the insulation. It is removed by ventilation of the under-roof space. The use of impermeable films as waterproofing and wind protection is gradually disappearing, since their use requires the construction of two ventilation gaps: between the insulation and the film, and between the film and the roofing. Whereas the membranes are laid directly on the insulation without a gap, which simplifies installation.

The key to the energy efficiency of the design and long years of operation is dry insulation, since when moistened it does not lose its thermal insulation properties. The insulation is maintained in its original condition thanks to a vapor barrier that traps the bulk of vapors from the inside and waterproofing that prevents it from getting wet from the outside.

Advantages and disadvantages

Choosing mineral wool as thermal insulation for a pitched roof gives the home owner the following advantages:

- excellent insulation;

- long service life;

- resistance to biological factors: mold, microorganisms, pests;

- fire resistance and ability to withstand high heat;

- the breathability of mineral wool helps to establish proper circulation of air masses, improving living conditions in residential premises;

mineral wool has a long service life.

The material also has a number of disadvantages

- when installing slabs or rolls of mineral wool, especially glass wool, harmful dust is generated, this requires the use of personal protective equipment;

- the high hygroscopicity of mineral wool and its loss of thermal insulation qualities when wet requires special attention to the vapor and waterproofing of the insulation system;

- the high specific gravity compared to foam plastic or penoplex leads to the need to strengthen the rafter system.

In general, when insulating residential buildings, the arguments of environmental friendliness and fire safety take precedence over the shortcomings of the material. An important reason to choose mineral wool is its affordable price.

Types of mineral wool for insulation

Modern manufacturers offer three types of mineral wool:

- basalt, or stone;

- glass;

- slag.

Slag wool is produced from metallurgical waste, has average thermal insulation parameters and is not environmentally friendly. It is not used in residential buildings.

Basalt

Basalt wool is made from specially processed rocks; it is the most natural material of all insulation materials. Stone wool fibers are short and stiff. This determines its high specific gravity and greater strength than glass wool. Basalt wool is used to insulate floors and flat roofs under cement screed. It is also perfect for thermal insulation of pitched roofs. Supplied mainly in slabs.

Glass wool

Glass wool is a product of recycled glass and glass production waste. Glass wool fibers are long and elastic, this determines its physical and mechanical properties. The material turns out to be lighter and more elastic; when placed between the rafters, it easily compresses, and when expanded, it returns to its shape, holding well into the spacer. Along with its low specific gravity, this makes glass wool an excellent insulation material for pitched roofs. The main disadvantage of glass wool is its high hygroscopicity. When wet, it loses most of its thermal insulation properties. Therefore, when choosing glass wool, special attention must be paid to vapor and waterproofing.

Glass wool is one of the types of mineral wool

Summing up

You can handle roof thermal insulation using mineral wool yourself if you have experience in carpentry. Before implementing the task, you need to select the material. If you have limited finances, you can get by with cheap glass wool. But experts recommend choosing basalt (stone) wool. It is easy to install and has positive characteristics. It is imperative to install hydro- and vapor barriers on the gable roof. When insulation work is done correctly, the materials will have a long service life, and the home will become warm and cozy.

Criterias of choice

The main criterion for choosing insulation is its thermal conductivity coefficient. The lower it is, the better the material retains heat. The coefficient value should not go beyond 0.033 – 0.044 W/(m*K).

In addition, you need to take into account such parameters as:

- Density. The load-bearing capacity of the rafter system must allow the required amount of insulation to be placed.

- Vapor permeability, or the ability of a material to remove water vapor without allowing moisture to accumulate on the surface or in the mass of the insulation. The value must be at least 0.7 mg/m*h*Pa.

- Life time. The manufacturer must guarantee the preservation of all working qualities for at least 15 years.

- Environmentally friendly. When making thermal insulation, substances harmful to health or the environment must not be used. The material itself should not emit such substances during operation.

- Manufacturer's reputation. Well-known brands value their reputation and strictly adhere to manufacturing technology and quality control procedures. Insulation is purchased once every few decades, so there is no point in saving money by purchasing products from a little-known manufacturer.

It is also important to consider its purpose when choosing a model.

Leading manufacturers optimize the properties of a particular model for various applications. So, there are special types of mineral wool for floors, walls, flat roofs, and ventilated facades. Basalt wool slabs for pitched roofs are equipped on the sides with 2 cm wide inserts of reduced density and increased elasticity, for better fixation between the rafters.

How to insulate a ventilated flat roof

Knowing how to properly insulate the roof of a house from the inside with mineral wool will help preserve warm air and reduce the cost of heating the room. For this purpose, layers of mineral wool are laid between the rafters and then secured with ropes and metal staples using a gun to avoid shedding. Glass wool is elastic and is able to stay between the rafters on its own. Basalt wool is more rigid, and to secure it it is necessary to construct a lath.

The thickness of the material is selected depending on the climate of the geographical area in which the house is located. If winters are severe, the layer should be thicker; the panels can be laid in several rows. Mineral wool fibers repel water well, but moisture can accumulate in the voids between them. In the case when more than 2% of its own mass accumulates water in the insulation, its efficiency is halved. To avoid this phenomenon, the insulation strips are protected by a vapor barrier film, which is stretched over the top layer of mineral wool.

Nuances of calculating the thickness of mineral wool

In addition to the thickness of the mineral wool layer, you should also choose its density. When insulating an already constructed building, the rafter system must withstand the additional weight of insulation, vapor barrier and sheathing. Therefore, too dense wool (90-120 kg/m3), used for flat roofs and floors under screed, will not be suitable in this case. It is also not worth choosing models with a density below 50 kg/m3 - they are prone to shrinkage under the influence of gravity for many years. If you choose denser and less elastic basalt wool, you will have to worry about constructing a retaining sheathing.

The thickness of the mineral wool insulation layer is determined in several ways. A complete thermal calculation is carried out taking into account

- roof thickness,

- thermal conductivity coefficients of all materials making up roofing structures,

- their total thermal resistance,

- thermal balance of the building.

- a number of other factors.

Only a specially trained civil engineer can do such work. Manufacturers of mineral wool offer simplified calculation methods on their portals, based on the climate zone and the design of the roofing.

Approximate formulas make it possible to determine the layer thickness with sufficient accuracy. In addition, most models are available in fixed thicknesses: 50 and 100 mm. The results of the most accurate calculation will still have to be rounded to multiples.

It is recommended to add 50mm to the design thickness in case of extreme weather conditions.

Advice from professionals

There are standards SNiP II-3-79, which provide formulas for calculating the thickness and density of thermal insulation for insulating the attic and other structural elements of the building. Professionals recommend using them before starting work.

Attic insulation will be effective if it complies with SNiP standards

In addition to the above formulas, they take into account the climate of the area, the specific heating of the building, the material of the floor and roof. At the same time as the ceiling in the attic, communications are insulated. The pipes are wrapped with mineral wool, and on top with foil-foamed polyethylene foam. You can use special sleeves or shaped shells to insulate the pipeline.

Thermal insulation of pitched roof with mineral wool

In order to create a comfortable microclimate in the house and minimize heat loss through the roof, certain preparatory work should be carried out. In addition to the roof itself, it is also necessary to insulate the ceiling of the last floor. After choosing the manufacturer, density, layer thickness and mineral wool model, it is time to calculate the amount of materials. You should not purchase it strictly according to the roof area, especially if it has a complex shape, it has turrets, bay windows, and roof windows. It is better to make a reserve of 5-10% for cutting losses. Otherwise, you can end up in a situation where on Sunday evening there are not enough three mats to finish insulating the roof. If you save the receipt, then the unused material can then be returned to the hardware store.

Before starting work on insulating the roof with mineral wool from the inside, it will be useful to read the instructions for all materials used and apply them in accordance with the manufacturer’s recommendations.

Preparatory work

At the preparation stage, the following operations must be performed:

- carefully inspect the entire rafter system; if parts with traces of mold or rot are found, replace them;

- eliminate all possible roof leaks;

- treat wooden parts with antiseptic and fireproof impregnation;

- check all system components located in the attic: electrical wiring, heating, water supply.

Materials and tools

For work you will need:

- insulation;

- vapor barrier membrane;

- boards or slats 20 mm thick for sheathing;

- Double-sided tape;

- synthetic twine;

- screws and nails;

- antiseptic and fireproof impregnation and means of its application;

- screwdriver;

- hand carpentry tools;

- tape measure, level, ruler;

- a set of thick work clothes and shoes;

- personal protective equipment: gloves, goggles, respirator.

To insulate the roof with mineral wool you will need a screwdriver

Material installation stages

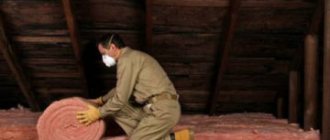

After the necessary preparation has been completed and the materials have been brought into the attic, it is time for the main operations. They are performed in the following sequence:

- To ensure that the vapor barrier does not touch the roof, drive nails into the rafters and stretch synthetic twine between them in a zigzag pattern.

- Roll out the vapor barrier film along the rafters and staple it. The smooth side should face the inside of the attic. Tape the joints of the panels with double-sided adhesive tape.

- Lay insulation mats between the rafters. The mats should fit in with some effort, without any gap. Where it has formed, the cracks must be filled with trimmings.

- Roll out and staple the second layer of vapor barrier along the rafters. Tape the joints of the canvases with an overlap of 10-15 cm.

- Sew up the insulation with slats or boards 20 mm thick.

If you plan to use the room as an insulated attic, use plywood, OSB or gypsum boards instead of slats or boards. They can be used for final finishing.

Safety precautions

Mineral wool, especially glass wool, becomes a source of harmful dust during installation. If inhaled or enters the gastrointestinal tract, it can cause serious diseases of the respiratory system and other body systems. If such dust gets on the skin or mucous membranes, irritation occurs and severe allergic reactions are possible. Therefore, when working with mineral wool, you should follow the safety requirements:

- use personal protective equipment: gloves, goggles, respirator;

- work clothes, shoes and hats must be made of thick fabric, have tightly fastened cuffs and do not leave exposed skin;

- When cutting mineral wool, you should use freshly sharpened, sharp knives or scissors;

- Ventilation of the attic should be organized to prevent the accumulation of hazardous dust in the air;

- At the end of the shift, you should take off your work clothes, thoroughly wash your hands and face with cold water and take a shower.

In addition to the danger from harmful dust, we should not forget about the general safety rules:

- work only with working tools;

- do not work from random supports, use inventory scaffolds and stepladders;

- before starting work, check power tools and extension cords for mechanical damage and integrity of insulation;

- When working at height, use a safety belt secured to a reliable support.

Timely and high-quality insulation of a pitched roof will help create comfortable conditions in the house and save significant amounts on heating. Mineral wool has established itself as one of the most popular materials for roof insulation. The technology does not require special skills, high qualifications or the use of expensive equipment. You can insulate the roof with your own hands.