Almost every owner of a private home thinks about ways to save energy resources, and the most effective of them is home insulation.

Proper ceiling insulation will help you significantly reduce energy costs for heating and create a comfortable atmosphere in your home. There are several methods for insulating the ceiling of a house, each of which is quite simple. In this article you will learn how to properly insulate a ceiling and what materials are needed for this.

Insulation materials

Thanks to the rapid development of technology, modern insulation materials have many advantages over their predecessors. They are durable, reliable, and easy to use.

The main insulation materials are mineral wool, glass wool, polystyrene foam, expanded clay and extruded polystyrene foam. Some of these materials are more suitable for external ceiling insulation, such as glass wool, mineral wool and expanded clay, while others are more convenient to use for interior work.

Mineral wool and other fibrous insulation materials are highly valued because they are absolutely non-flammable, environmentally friendly, and have good vapor permeability, which allows the ceiling to “breathe.”

At the same time, these materials must be protected from exposure to dampness, since then they lose their beneficial properties. High humidity negatively affects the sound and thermal insulation of materials, reduces their stability and leads to fiber shrinkage. To avoid this, it is necessary to use vapor barrier protection - that is, polyethylene film.

The same applies to expanded clay: its thermal insulation characteristics can completely disappear at high humidity, so the use of a vapor barrier is considered a prerequisite.

Cellular materials, which include polystyrene foam and expanded polystyrene, have very low moisture absorption, are lightweight and inexpensive, but at the same time require additional reinforcing materials, easily catch fire, and are damaged by rodents. Such materials are better suited for insulating the ceiling of a private house indoors.

Slab insulation

It is this type of insulation that is most popular among other thermal insulation options. This is due to its availability, versatility and ease of installation.

Mineral wool

Depending on the raw materials used, basalt (stone), slag and glass wool are distinguished. Thermal conductivity, regardless of the type, is almost the same (from 0.035 to 0.048 W/mK). There is a significant difference in density, fire resistance, environmental friendliness and water resistance.

The lower the thermal conductivity coefficient, the better!

- Glass wool . Retains working properties at temperatures up to +450°C, weight of one cubic meter is 130 kg. It is absolutely non-flammable (doesn’t even smolder), doesn’t cake, dampens vibration well and absorbs noise. Disadvantages: absorbs moisture, including steam; once sufficiently saturated, it thickens and loses all useful qualities (it is impossible to dry); difficult to install (brittle, crumble, causes skin irritation after contact). Modern glass wool-based insulation is more environmentally friendly and comfortable to use. Price – 2500 rubles per m3.

- Basalt (stone) wool . The heat-resistant material (up to +700°C) is almost twice as heavy as glass wool (a cubic meter weighs 220 kg). It is relatively moisture resistant, if it gets a little wet it does not lose its properties, it is environmentally friendly, and does not cause skin irritation during installation. The main disadvantage is the price - about 1000 rubles per 0.15 m3.

- Slag . The most dense insulation, the mass of m3 is 400 kg. It retains its performance characteristics at temperatures up to +250°C; if heated to 300°C, it begins to melt. It is elastic, fits well on curved surfaces, and if the standards of use are observed, it will last more than 50 years. Cannot be used inside residential premises or on metal floors with high humidity.

Tips from our specialist on choosing mineral wool and proper installation:

Slab polystyrene

Foam plastic is a lightweight, affordable and cheap insulation material, durable enough for use on any ceilings, completely moisture resistant, easy to install and has low thermal conductivity (0.04 W/mK).

But there are three significant drawbacks that make the use of polystyrene foam in residential premises undesirable. Polystyrene foam practically does not allow air to pass through (vapor permeability 0.05 mg), it is flammable and toxic.

Cost from 2000 rubles per 1m3.

Penoplex

An improved version of regular foam, often called extruded polystyrene foam. Its porous structure resembles polyurethane foam, with the difference that the cells in it are much smaller - they are almost invisible. Penoplex does not crumble, it is much denser and more elastic than ordinary foamed polystyrene, but is not without all its disadvantages. Thermal conductivity is about 0.03 W/mK, the price per cubic meter is 4,500 rubles.

Ceiling insulation techniques

You can make the thermal insulation of the ceiling in your house yourself; for this you do not need special equipment or professional skills. Although there are many ways to insulate ceilings, they are all divided into two types - internal insulation and external insulation. For internal thermal insulation, it is recommended to use vapor-permeable insulation; in addition, the insulated ceiling should be covered with finishing material, for example, plastic or plasterboard.

For external, or external, insulation, the insulating material is placed above the ceilings. This eliminates the need to construct a suspended ceiling, and besides, external work is much easier to carry out than internal work.

Internal ceiling insulation

If the house has concrete ceilings, the easiest way to insulate is to attach sheets of foam plastic. Such sheets are simply glued to the cleaned ceiling surface with special glue.

Since the outer side of these sheets can be very decorative, no additional finishing of the ceiling is needed; the most important thing is to glue the material carefully so that the glue does not protrude on the outside of the foam. Of course, thermal insulation in this way has less effect than insulation with other materials, but it is the lightest and cheapest.

But concrete ceilings in private homes are quite rare, so it’s worth familiarizing yourself with another thermal insulation method.

It is necessary to take into account that internal insulation of the ceiling of a private house will make the ceiling a little lower, so this method is not very suitable for low houses. So, if you decide to do thermal insulation from the inside, you first need to attach frame structures to the ceiling on which the suspended ceiling will be attached. The frame can be made of boards or aluminum profiles.

After this, the thermal insulation process begins. The best insulation in this situation is mineral wool slabs, which are glued to the ceiling between the profiles. Tile adhesive is ideal here - it quickly and reliably attaches the material to the surface, but you can also use fastening dowels.

When laying mineral insulation, it is worth considering that it cannot be compressed, since this will reduce its thermal insulation characteristics. You just need to lay the material tightly, leaving no voids.

Having filled all the space between the profiles, you can cover the frame with finishing materials - plastic, plasterboard or others. This insulation method is very effective; heat in the room will be retained for a long time.

Surface preparation

Before installing the insulation, care should be taken to waterproof it on the floor side. You can treat the ceiling with special waterproofing solutions that have become commercially available recently. They penetrate deeply into concrete structures and reliably protect against moisture.

Procedure:

- The ceiling must first be cleaned and washed.

- Particular attention should be paid to seams and cracks. If necessary, the cracks must be repaired and a filler, for example, fine gravel, must be added to the solution.

- The waterproofing solution is applied to the dampened surface of the ceiling using a brush; additional conditions for working with them can be read in the instructions.

Effective insulation of a private house

For external insulation, you can use different materials - mineral insulation, expanded clay, polystyrene foam, polystyrene foam and even sawdust or straw. Of course, the last two types of materials are now practically not used due to their impracticality, but all the others are excellent heat insulators.

When choosing insulation, you need to take into account not only their cost, but also other characteristics. First of all, pay attention to the weight of the material, because a thick layer of heat insulation will put a lot of pressure on the floors.

In cold regions, it is recommended to choose lighter materials that are laid in two, three, or even four layers. But in areas with a mild climate, the insulation layer on the ceiling may not be very thick, therefore, the material can be chosen heavier.

Regardless of what material you choose, the initial stage of work is always the same. First, the entire ceiling is cleared of debris and foreign objects. Between the beam ceilings it is necessary to lay a layer of vapor-proof film or glassine.

These materials need to be cut into strips of such width that after laying them between the beams there is a margin of several centimeters. The edges of the film are secured with a stapler to the walls and beams.

What to look for when choosing insulation

Experts recommend assessing insulation based on three factors:

- Density. The indicator is expressed in kg/m3.

- Coefficient of thermal conductivity. Marking I - lambda. The best products are those with an I index of 0.03-0.06.

- Price. You should know that expensive products may have additional sound and waterproofing qualities. The cost is also affected by the use of natural materials, treatment with impregnations against water and fire.

What else you need to pay attention to:

- light weight;

- resistance to mold, mildew, and insect damage;

- heat resistance;

- moisture resistance and resistance to hot steam.

Insulation materials differ according to their physical characteristics. Solid, fibrous, and sprayed product options are available for sale.

Thermal insulation with mineral wool

If the insulation of the ceiling of the house is done with mineral wool, then the next stage consists of laying insulation blocks between the beams. For northern regions, it is recommended to lay cotton wool in several layers - this will make the thermal insulation more effective. Having densely filled the space between the ceilings, lay the last layer so that it covers the beams well.

This way you will avoid even the slightest heat leakage through wooden floors. The top of the insulation is covered with another layer of plastic film.

In cases where a living space is equipped in the attic or is simply used frequently, it is necessary to lay a plank floor, but if the attic is rarely used, a few wide boards across the entire room will suffice. This method perfectly retains heat throughout the house for a very long time.

Two options for ceiling insulation

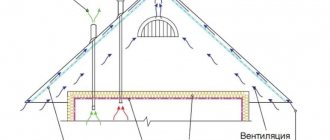

The ceiling is insulated if there is a non-residential attic above it, which is not equipped with thermal insulation.

It is not used as a living space in winter, therefore, there is no need to lay a layer of insulation on the slopes. Often this is just a warehouse for equipment or a room for drying mushrooms/berries.

The non-residential attic itself plays the role of an air chamber, preventing the movement of heat waves both inside and outside the building. However, to dry the wooden elements of the frame structure, roofing, and metal fastening parts, a cold attic is usually equipped with effective ventilation.

Ventilate it naturally, i.e. regular ventilation without the use of any mechanisms. The system operates without coercion. Air moves due to the temperature difference with pressure outside and inside the attic.

The air flow enters the attic space through the dormer windows in the summer and the gaps framing them in the winter, when a rarefaction of air is formed inside. It is removed spontaneously, replaced by a new portion coming from the street.

For building structures, constant air circulation is really necessary. But along with continuously moving air masses, heat is blown out of the attic. As a result, instead of saving it to save energy resources, additional costs are incurred.

How to deal with them? Be sure to insulate! Insulation is carried out in two standard ways:

- Installation of thermal insulation along the ceiling from above. Those. From the attic side, slabs of foamed polymers, mineral wool are placed on the reinforced concrete floor or between wooden joists, expanded clay or folk remedies (sawdust, dry leaves, etc.) are poured in.

- Installation of slab insulation from inside the premises. Simply put, fastening insulating boards from the premises to the lower plane of the ceiling.

In both cases, the insulation layer increases around the perimeter, i.e. along the line of connection between the ceiling and the adjacent wall. Reinforcement is required here due to increased heat loss. A vapor barrier membrane is placed between the wall, ceiling and insulating layer.

Why is it not waterproofing that is used in the formation of a heat-insulating pie over the ceiling? Yes, because it is necessary to protect it, first of all, from steam penetrating from living quarters, and not from atmospheric water flowing from above.

It is the fumes emitted during breathing by us, our pets and house plants, as well as those formed during the cooking process, during hygiene procedures that can harm the thermal insulation system. But the roof above must protect it from water.

By the way, when laying all types of insulation from the side of a cold attic, they are not covered with either vapor or waterproofing on top. This allows the materials to dry out spontaneously when the attic space is ventilated.

Under no circumstances should insulation materials get wet or wet under a practically sealed insulating film. Together with moisture, they lose their insulating properties. Wet thermal insulation preserves almost nothing, but it can rot, and mold will spread to wooden elements.

The vapor barrier under the insulation, laid from the attic side, is arranged in the form of a trough: with the edges of the panel extending onto the walls. So it will prevent the insulation from getting wet not only from steam moving upward from the side of the premises, but also from the walls that absorb atmospheric moisture.

It is permissible not to use a vapor barrier layer only when extruded polystyrene boards are used as thermal insulation. They have virtually no pores capable of absorbing and retaining moisture.

Moreover, this is allowed only above rooms with stable “dry” operating conditions. Above bathrooms, showers, and swimming pools, a vapor barrier layer is installed in combination with extruded polystyrene as usual. Since there is a possibility of moisture penetration between the joints of the slabs.

Thermal insulation with expanded clay

This method of insulation is more suitable where heat loss is not very large and the insulation layer can be of small thickness. Although expanded clay is a lightweight material, too much insulation layer puts a lot of pressure on the ceiling.

After laying the plastic film, the entire space between the ceilings is covered with crushed clay, onto which expanded clay is poured. For greater thermal insulation density, it is worth using expanded clay of fine and coarse fractions. It is necessary to fill the expanded clay very carefully so that there are no voids left.

Then the surface is leveled and a cement-sand screed is applied to protect the insulation layer from damage. Again, if you plan to use the attic space frequently, you should lay the floor from boards or other materials.

Thermal insulation with polystyrene foam or polystyrene foam

The method of thermal insulation using polystyrene foam boards is also very effective and easy to implement.

External insulation of ceilings in a private house with such material is carried out quite quickly and without special devices. All you need is the material itself, a sharp knife, polyurethane foam and glassine. The foam sheets should be no thinner than 50 millimeters, otherwise the thermal insulation will not be good enough.

A layer of glassine or other waterproofing is laid between the floor beams, securing its ends to the wooden floors using a stapler. Now the foam boards are cut so that they fit tightly between the beams, and all remaining cracks are filled with polyurethane foam.

Waterproofing is again laid on the top layer so that the insulation is reliably protected from moisture. Insulation is done in the same way using polystyrene foam, only it costs much more.

The entire thermal insulation structure must completely cover the floor beams, then insulating the ceiling will have the greatest effect. As in other cases, after laying the insulating material, it is necessary to lay the floor on top. To prevent the foam from breaking under the weight of a person, a metal mesh is used as reinforcement, and the layer of cement screed should not be less than five centimeters.

As you can see, insulating ceilings is not a complicated process at all; any home owner can cope with this task on their own. If each stage is performed efficiently and the entire building is insulated at the same time, then you will ensure comfort and warmth in your home for many years.

Contents: [hide]

- Features of insulation from the inside

- Insulation using drywall

- Using sawdust

Many city residents spend a lot of time at their summer cottages. Some live there permanently.

After all, fresh air and a rural climate have a positive effect on overall well-being and mood. However, in winter, some homeowners experience loss of heat energy in private homes. Therefore, they insulate walls, floors, facades and ceilings.

Roof insulation diagram from the inside.

Insulating the ceiling from the outside and inside can significantly reduce heat losses.

Thus, you can achieve a comfortable temperature in the house if you insulate a certain area.

In addition, this procedure allows you to save money on energy resources. After all, heated air leaves the room through the ceiling. Therefore, it is so important to choose the right quality insulation and carry out construction work.

Installation technology

Ceiling insulation can be carried out from the inside and outside.

From the inside

Insulation from the inside can be done using two technologies:

- with lathing;

- without sheathing.

With lathing. A coniferous beam or a metal profile is attached to the ceiling, regardless of whether it is wooden or reinforced concrete. Insulation is installed between the cells. A vapor barrier film (type B) is stretched over the heat-insulating layer. A counter-lattice is placed under the sheathing. The process ends with fastening the sheathing.

If a suspended or suspended ceiling is planned, then vapor barrier is the last stage of insulation work.

Without sheathing. The option of attaching insulating mats and slabs without lathing is used when painting the ceiling or gluing wallpaper. In this case, the insulation is first glued to the ceiling with glue, then additionally fixed with special dowels with a large head or a special washer.

The process is completed by gluing the reinforcing mesh and puttying the surface of the insulated ceiling. The operations are described in detail in the works: “Insulation of the ceiling with mineral wool” and “Insulation of the ceiling with polystyrene foam”.

Outside

When insulating the ceiling from the outside according to SNiP, all operations are performed in the following sequence:

- roofing material or polyethylene film is laid on the ceiling for vapor barrier. In this case, it will be correct to place the rolled materials on the beams (beams) and on the walls;

- fill or lay insulation material;

- cover the insulation with a vapor barrier membrane (type A or AM);

- lay a flooring over the beams or insulation for walking in the attic space.

You can learn more about the technology in the work “Ceiling insulation with expanded clay.”

Features of insulation from the inside

If previously wooden houses were insulated using readily available materials, modern manufacturers offer a number of special means. Insulation materials are made from synthetic or natural fibers.

In any case, you should pay attention to the pile of the fabric. It must be dense to provide reliable thermal insulation. You can even insulate a private house or apartment with your own hands.

Wooden floor insulation scheme.

Insulation of ceilings from the inside should not interfere with ventilation throughout the room. During installation, the layers should be laid in such a way that a sealed cavity is formed. For these purposes, the seams are taped with construction tape.

In such cases, humidity and condensation will not form. This thermal insulation is relevant for private houses. You can insulate the surface in a similar way in baths or saunas.

Mineral wool is often chosen for insulation and thermal insulation of ceilings. This material is environmentally friendly and safe.

In addition, it is beneficial from an economic point of view. Mineral wool can be laid either in one layer or in several. The material is sold in the form of bulk rolls.

Polystyrene foam is perfect for ceiling insulation. This construction product is resistant to moisture and dampness.

It does not dampen or rot. The material is durable and does not lose its physical properties. It is not difficult to insulate the surface yourself using this product.

Return to contents

The use of plasterboard allows you to achieve a smooth ceiling surface. To insulate the surface you will need:

Insulation scheme for a wooden ceiling.

- metal scissors;

- roulette;

- drywall;

- insulation (mineral wool, fiberglass, etc.);

- ceiling profile;

- self-tapping screws;

- screwdriver;

- building level;

- stapler;

- polyethylene film.

At the initial stage, it is necessary to attach plastic film to the ceiling. To do this, you can use a construction stapler.

This work is necessary to prevent moisture from entering the coating. The procedure is especially relevant for private wooden houses. If precipitation gets on wooden beams, then after some time they will rot.

Using slats, a base for the insulation is made.

For example, you can insulate the ceiling from the inside using mineral wool and plasterboard. The insulation has a soft, pliable structure. Therefore, it is easy to install even at distant intervals.

However, when working with it, it is recommended to arm yourself with gloves and a mask so that small particles do not eat into the skin. When laying the material, we must not forget about the tightness of the canvas. Use adhesive tape or tape to seal the butt seams.

In order for the insulation to retain its technical properties for a long time, it must be carefully attached to the base of the ceiling from the inside. To do this, you need to glue another layer of plastic film.

This can be done using a stapler or tape. Thus, a dense, water-repellent barrier is formed that will provide the room with heat for a long time. This procedure is necessary for the reliability of drywall and other finishing materials.

Using plasterboard, you can sheathe the ceiling from the inside of the room. For this procedure, the sheets are cut to the required sizes. The frame is made using special profiles.

To ensure that it matches the size of the ceiling, it is recommended to draw a diagram and make markings in advance. The width of the drywall must be taken into account. After all the manipulations, the ceiling tiles are attached.

In addition to using drywall, you can choose special plastic panels.

The work stages will be similar. The main thing is to distribute the insulation correctly and evenly. In addition, the surface can be insulated from the outside.

For example, in a private house, this procedure can be done in the attic or attic floor. To do this, cover the entire space with sheets of foam plastic. It is recommended to treat the places where the material is connected with polyurethane foam.

Return to contents

Insulating the ceiling with sawdust is a method that has been used for a long time. The advantage of this method is minimal financial costs. However, the material also has disadvantages.

Sawdust is not fire safe. Similar construction work is done in private homes. Insulation occurs from the attic side.

To do this, the floor in the attic must be thoroughly coated with liquid clay. It should fill all the cracks and gaps.

Sand is evenly sprinkled on top of the clay surface. To avoid the sawdust being eaten by mice, you need to make a solution (mix carbide and slaked lime). The resulting mixture is also poured onto the surface.

Sawdust must be poured onto the floor and distributed evenly.

The insulation layer varies between 20-25 cm. To avoid fire hazards, a thin layer of treated slag is poured onto the surface. To make it comfortable to walk in the attic, you can lay boards on top of the layers.

There are different materials and construction options for ceiling insulation. It is necessary to choose the appropriate products for a particular home and follow all installation rules. Only in this case will a comfortable temperature regime be maintained throughout the building.

Insufficient insulation of ceilings and attics, through which heat is actively lost from the room, is called by professionals one of the most popular mistakes of self-taught builders. The same reason underlies the increased humidity in the room.

The condensation formed in the contact zone of warm air with the cold plane of the ceiling changes the microclimate of the entire house. Stuffiness, damp walls and even the appearance of mold are the consequences of an illiterate approach to insulation, along with the problem of rapid cooling of the air in the room. High-quality insulation of the ceiling from the inside in a private house is one of the components of a comfortable microclimate and rational expenditure of funds for heating a country house, city cottage or summer house.

What's the problem?

Why do you need a suspended ceiling with sound insulation and insulation? Do these factors really need to be given any special attention? (see Stretch ceilings with sound insulation - structure and principle of sound absorption)

There are two possible reasons for this:

- If you live on the top floor and have a cold attic overhead, a lot of heat will be lost through the ceiling. Remember: warm air rushes upward. An insufficiently thick expanded clay bedding will cause the room to dry out quickly .

- Noisy neighbors upstairs often make you dream of improving sound insulation. In this sense, modern panel high-rise buildings, where thin linoleum is laid directly on concrete, are a mockery of normal sleep and silence in the apartment. When you hear any knocking or coughing through two ceilings, this is, to put it politely, not encouraging.

A special case

Under certain circumstances, a stretch ceiling can effectively serve as a resonator. Do you remember how a drum sounds after a seemingly light blow to one of its membranes? The sound is clearly audible near the opposite side of the instrument (see Stretch ceilings with photo printing - an original decorative element).

A similar effect is observed with ceilings: soundproofing of a stretch ceiling is required because after its installation, suddenly every sound from the room above becomes audible.

Sometimes the ceiling surface can become a resonator with an area of several square meters

Please note: the situation described is the exception rather than the rule. Typically, a suspended ceiling, on the contrary, improves the sound insulation of the ceiling, creating an additional barrier to acoustic vibrations.

Materials for ceiling insulation

Building materials stores offer an assortment of insulation materials. Main types:

- mineral wool, produced in glass wool, slag wool and stone wool varieties;

- rolled foil polyethylene foam;

- foam boards of various thicknesses;

- polyplex or polystyrene, also available in the form of slabs;

- loose expanded clay.

Among the methods that are used less and less, but have the right to exist, sawdust can be noted.

The refusal of professionals to use this method, which was recently popular, is understandable. To protect against rodents and moisture, the material must first be thoroughly prepared, mixed with clay and lime, moistened, dried, and loosened. Against the background of these hassles, the advantage of cheapness fades, inclining the master to choose less demanding foam or polyplex.

Combining materials is allowed: the toxicity of mineral wool makes us think about an additional barrier against the gases it emits. This can be served by a dense but thin layer of foamed polyethylene on a foil base.

Popular materials for ceiling insulation: mineral wool, expanded clay, sawdust and polystyrene foam

Mineral wool

Mineral wool is considered an economical insulation material. The main forms of release are mats from 10 cm thick and rolls from 5 cm thick.

It is used for both external and internal insulation, but has significant restrictions on use.

Without additional waterproofing, the use of this material in rooms with high humidity is not recommended. When saturated with water, mineral wool does not perform basic heat-protective functions. Insulation of the ceiling in the bathroom from the inside with mineral wool mats will have to be carried out in several stages, first fixing the base material, and then covering it with film, glassine or foil.

However, waterproofing in such rooms will also be required for other types of materials if the main floor is made of wood. This precaution will prevent condensation from forming directly on supporting structures and wood sheathing.

When working with any type of mineral wool, precautions must be taken.

Toxic and allergic-causing material must be handled using gloves and a tight suit; contact with skin is not allowed. A protective mask or respirator and goggles must be used. The advantage that distinguishes mineral wool from other popular insulation materials is its resistance to fire and rodent activity, which is an important advantage in the private sector.

When working with mineral wool, safety precautions must be observed.

Polystyrene foam and polystyrene foam

Polystyrene foam is more environmentally friendly and easier to use.

Waterproofing with this insulation technique is not required, and the small thickness allows this material to be used in rooms with low ceilings. Insulating the basement ceiling from the inside with foam boards will only take a few hours. The plates are easy to cut, and they can be attached with glue without building the sheathing.

Polystyrene is a direct relative of foam plastic, a denser and less friable material.

The price of such insulation is slightly higher than others, but its advantages are difficult to overestimate. Zero moisture absorption allows it to be used in any type of premises without worrying about waterproofing. The thickness of extruded polystyrene sheets is 1-10 cm.

Such a large assortment allows the use of polyplex for insulation of floors, walls, ceilings, and external communications. Manufacturers, as a rule, ensure ease of installation by cutting grooves along the edges of the plates in advance. This makes it possible to secure the material without gaps, providing maximum insulation.

When insulating from the inside, polyplex is attached to supporting structures or between them

The surface of polystyrene boards is quite smooth. Insulating the ceiling with polystyrene foam from the inside allows you to immediately begin finishing by simply filling the surface.

Ceiling in the apartment

Insulation of ceilings in an apartment may be necessary only in one case - if it is on the top floor. And it doesn’t even make much difference whether the house has an attic or not. Even if there is, it is still not heated. Unless, in this case, the likelihood of your ceiling getting wet if the roof leaks is reduced.

- But it also happens that after a good rainfall or melting snow, the ceiling in your apartment is wet. And where there is dampness, it is cold - and such a nuisance, alas, is not uncommon, especially in old houses.

If the ceiling is constantly wet, then the fungus will not take long to appear.

- And if this does happen, you shouldn’t despair. Simply, before insulating the ceiling in an apartment, you need to perform a number of manipulations. Of course, if a fungus appears, you must first get rid of it, and our website has detailed articles on this topic. But if it hasn’t come to this, then the main thing that needs to be done is to block the moisture.

- To do this, you will need a waterproofing repair compound such as Aquastop, Kalmastop, Gidroizol. These are penetrating soils that can not only block incoming moisture, but also displace existing moisture from the thickness of concrete.

Repair compounds for ceiling waterproofing

- These compositions are effective even in cases where there are cracks in the slabs (see How to repair a crack in the ceiling, real recommendations) opened up to three millimeters. At the same time, the structure being processed does not have to be dry. If there is a seam on the ceiling formed by the joint of the plates, and it is large enough, you will need a joint compound, which, when crystallized, forms an insurmountable barrier for water.

Advice! After treating the seams and corner joints of the ceiling, they can be strengthened by gluing self-adhesive fiberglass insulating tape around their perimeter.

Fiberglass Insulating Tape

Having finished processing the joints, you can begin applying waterproofing primer over the entire ceiling area. We insulate the ceiling after the coating layer has dried. If you have waterproofed it using the technology we described above, your ceiling is now safe.

You can decorate it in any way convenient for you. But you still need to install the insulation, and this requires a frame. If the height of the room is quite low, and you don’t want to take away another 12-15 cm, it’s worth considering options for frameless insulation.

Thermal insulation plaster

And here is your first idea on how to insulate the ceiling on the top floor. One of the frameless options for insulation, not only of the ceiling, but also of the walls, is warm plaster.

What is it:

- These are dry mixtures composed of porous fillers and plasticizing additives. The binder base of mixtures used for interior work is the same gypsum.

- Different types of heat-insulating plasters differ from each other only in the type of filler. Depending on the manufacturer, the following can serve as filler: granulated expanded clay, expanded polystyrene, foam glass or silicon, vermiculite or perlite expanded sand.

- Cheaper options use sawdust, but this is not the best option for an apartment. We will not dwell on the properties of each type of warm plaster. Let's just say that they all have good adhesion to various surfaces, are resistant to dampness and mold, and have a low thermal conductivity coefficient.

Such plasters are universal and can be used not only on facades, but also indoors

- For residential premises, it is best to use plasters with fillers of natural origin. They are applied to the wall without prior leveling, in one layer. In this case, there is no need to install reinforcing mesh. Some of the thermal insulating plasters do not even require finishing.

- For example: foam glass mixtures. They are so plastic that they even allow you to create a relief on the surface of a ceiling or wall, or form decorative elements similar to stucco. Such plaster itself, due to the coarse filler, creates a coating with an interesting texture.

- Naturally, this material is the most expensive compared to other warm compounds. On the other hand, the thermal conductivity coefficient of foam glass-based plaster is 30-40% lower than that of mineral wool.

Aluminum panel with foam glass coating

By the way, foam glass can also be used in suspended ceilings. There are aluminum acoustic panels coated with foam glass.

They are very light, rigid, and have excellent sound insulation. The panels come in various formats and can be used not only for suspended ceilings, but also for wall cladding.

Cork agglomerate

Cork is not only very beautiful, but also retains heat well

How and how to insulate the ceiling in order to do without leveling and installing the frame, and even better - without finishing? We offer another, environmentally friendly option for ceiling insulation.

Cork in ceiling design

- This is the covering of its surface with cork agglomerate. The cork is not at all afraid of moisture, it is very light, and can be mounted either with glue or on lathing. The installation method will depend on which coating you prefer: roll or in the form of slabs.

- This material is made from the bark of a certain type of oak tree called cork. White agglomerate is used as decorative coatings for walls and ceilings.

- It is obtained by molding and pressing granules in an organic binder: gelatin, coal-stone pitch, resins. Polymers are not used in the production of cork coverings.

Insulation of ceilings and walls with cork

- A huge advantage of this material is its varied texture and colors, the possibility of painting, drawing, or stenciling. Cork covering perfectly hides small unevenness and defects in the ceiling, so it does not require preliminary leveling of the surface.

- The only condition for gluing cork is a cement base. That is, if there was previously a plaster screed on the ceiling, it will have to be removed. From figures and elements cut from cork of different colors, you can create appliqués, panels, and entire paintings on the ceiling.

- We talk about the ceiling because it is the topic of our conversation. Naturally, everything we talk about is also relevant for other surfaces. Cork coverings are used even more often for finishing floors and walls.

- By the way, cork flooring, designed for installation with glue, can also be used for the ceiling. It is glued either to the base ceiling or to the surface of the slab insulation, as shown in the photo below.

Cork flooring option: adhesive flooring

And if you need to decorate and insulate the entire apartment, why is the ceiling worse than the floor or walls? Cork is often used in the design of the entire room.

Cork is hypoallergenic, so cork flooring is ideal for children's rooms and bedrooms. Such a room will not only be warm, but also perfectly insulated from noise. Why don’t you decorate your apartment like this?

Wood does not like drafts, so the ceiling sheathed with it must be insulated

Needless to say, all materials mounted on the frame are good when it is necessary to insulate the ceiling. And this is not only cork or solid wood, but also any sheet and modular options: plasterboard, MDF panels, even plastic - because insulation can be placed inside the structure.

Eco panels and foam tiles

How can you insulate the ceiling in order to also create a design worthy of decorating the interior of the living room? Continuing the topic of decorative materials, which are excellent insulation, we cannot help but mention eco-friendly panels. This is a relatively new material that has a three-dimensional surface, for which it received 3D status.

Variety of 3D panels

- The three-dimensional surface of volumetric panels is perceived differently, depending on the lighting. By using an eco panel for ceiling cladding, you can insulate the ceiling and get a chic design. Just look at this variety! Shown here are options that already have a finished finish, and those that can be painted.

- Eco panels are produced from natural raw materials of plant origin: dissolved cellulose, crushed bamboo, reed, straw, or the same cork. The binder is organic resins. Due to this, this material is referred to with the prefix “eco”.

- Such panels are mounted using glue - everything is very simple. To ensure that the ceilings in all rooms do not look the same, you can use panels with different textures, or you can use your own insulation option in each room.

Fiberglass tiles are also an excellent thermal insulator.

You can also use small-format MDF panels mounted on glue and polystyrene foam or fiberglass tiles to obtain a beautiful and insulated ceiling. The latter, however, is more often installed on a frame, using a cassette ceiling system. However, additional insulation can be installed in such a structure.

Insulation works

Ceilings separating rooms of different types require additional heat, steam or waterproofing. In a multi-storey building, overlap between residential tiers is rarely required.

The exception is hollow blocks with open voids. The type of roof of a building determines the optimal insulation method. Ceiling insulation from the inside is suitable both for the upper floors of buildings with a flat roof, and for rooms not adjacent to it, but requiring additional thermal insulation.

A gable roof is primarily insulated from the inside, but the ceiling between the cold attic and the living floors also needs a thermal insulation layer. The main stages of insulation work are similar, regardless of the type of material chosen.

The waterproofing is attached with a reflector inside the room and glued with tape

From the attic

For insulation using this method, any of the insulation materials, even bulk ones, are suitable. The only condition for full and long-term operation is the installation of walkways that do not allow the material to be compressed. Craftsmen do not recommend mineral wool for external use due to the high risk of dampness.

- The attic floor is cleared of furniture and other items.

- A vapor barrier is laid on the floor with allowances for the walls.

- If necessary, a sheathing is installed to define the space between the ceiling and the attic floor. It should be at least 0.5 cm greater than the thickness of the insulation.

- The space between the beams or grating is covered with vapor barriers and covered or covered with insulation. Basalt or expanded clay is poured in a layer of 2-2.5 cm. Sheet or roll insulation is laid close to the beams, if possible without gaps between them and the sheets themselves.

- A vapor barrier is again placed on top. Film or foil that prevents the insulation from becoming damp can be joined with ordinary tape.

- The floor is covered with a gap from the insulation.

Insulating the ceiling from the attic side

Bulk insulation

Bulk insulation is made from polymers, wood derivatives, cellulose, clay rocks, resin and even stone. For obvious reasons, it is possible to insulate the ceiling with bulk materials only from the attic side, and for some types, for example, ecowool, a compressor will be required. The main positive quality of bulk thermal insulation is its high penetrating ability. The weak point is considered to be shrinkage, which is characteristic of all insulation materials of this group.

Expanded clay

The most common and relatively inexpensive bulk insulation. For its manufacture, ordinary baked clay is used. The result is a lightweight (about 400 kg per m3), moisture-resistant product. Depending on the size of the fraction, expanded clay is produced in the form of crushed stone, sand or gravel. In terms of thermal insulation properties, they are the same - the difference is in size and density.

Note! Expanded clay is resistant to moisture, absorbs it very slowly, but once saturated, it releases it even more slowly, which affects its thermal insulation properties.

Expanded clay costs significantly less than other bulk insulation materials of synthetic origin or ecowool, and has relatively low thermal conductivity (from 0.9 to 0.17 W/mK). It does not harbor rodents, does not grow mold, is chemically neutral, durable and does not contain toxins. When laying, you can mix it with sawdust, but then it is necessary to increase the insulation layer, since sawdust has greater thermal conductivity. The price of expanded clay is 2000 rubles per m3 or 150 rubles per bag (30 kg).

Indoors

How to insulate a ceiling from the inside in a particular case depends on the type of material chosen. Polystyrene foam does not require mandatory installation of the sheathing, as it adheres well to glue and mastic.

The strength of other technologies is ensured by the suspended structure. For wet rooms it should be a metal profile, for the rest you can get by with a wooden one. It will not be possible to insulate the ceiling from the inside without subsequent decorative finishing.

- The profile is mounted taking into account the dimensions of the insulation.

- Glassine or film is used as a waterproofing material.

- The insulation is installed without gaps.

- The second layer of waterproofing is also sealed tightly. When using foil material, it is placed with a reflector inside the room.

- The grid that secures the insulation is also used as a support for the decorative finishing of the ceiling.

Insulation of the ceiling from the inside with mineral wool

Insulation is a painstaking and responsible job, the quality of which will determine the atmosphere in the house for many years. Studying instructions and recommendations is the key to success. If you doubt your own abilities, it is better to entrust this work to a professional team.