Home / Installation, repair, maintenance / Insulation / How is the ceiling insulated from the inside with penofol?

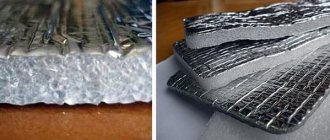

Ceilings can be insulated in a variety of ways. Very often, not only the ability of the selected insulation to retain heat in the room plays an important role, but also its thickness. This is especially relevant when the ceiling is insulated from the inside of the room. In this case, it is possible to insulate the ceiling with penofol - an insulation consisting of foamed polyethylene, covered on one or both sides with foil.

Varieties

Despite its apparent simplicity, it has several varieties that differ greatly in their characteristics:

- Type "A". This is the most common species. It is covered with a foil layer on only one side.

- Type "B". The foil coating is already on both sides of the material.

- Variety marked “C”. It will differ from the others by the presence of a self-adhesive coating on one side. This is a very useful feature during installation.

- The type of polyethylene foam, marked with the letters “ALP”, has a foil layer on both sides, but at the same time, one of the foil-covered sides is also protected by a film coating.

- Penofol types “R” and “M” have foil on only one side, but have a relief structure.

- Products marked “AIR” are used to create air ducts.

- Another type, marked with the word “NET”, is used for thermal insulation of heating mains, air ducts and pipelines.

The last four types are not used very often, but rather on a specialized basis. Therefore, you are unlikely to encounter them in everyday use. But polyethylene foam, designated by the letters “A”, “B” and “C”, can be found much more often, and is actively used for domestic purposes, among which the main thing will be the insulation of all kinds of surfaces.

The first type of this heat insulator is mainly used as an auxiliary material when creating a thermal cushion. It works well as a vapor barrier.

For complete heat conservation, a material with more significant characteristics is needed. It is best to create an independent layer of thermal insulation, use either polyethylene foam, marked with the letter “B”, or, a variety, marked “C”.

How to properly glue foil insulation

Instructions for use of stekloizol and folgoizol

Folgoizol and stekloizol grades K (FK and SK) are intended for the installation of the top layer of rolled carpet on roofs with various slopes and configurations of buildings located in climatic zones 2, 3 and 4.

Folgoizol and stekloizol grades G (FG and SG) are intended for the installation of a protective waterproofing coating for thermal insulation of pipelines.

Work on installing a roof or protective waterproofing must be carried out in accordance with current building codes and regulations (SNiP 3.04.01-87 Insulating and finishing coatings, VSN 32-81 “Instructions for waterproofing bridges and pipes on railways, highways and city roads”) .

The installation of a roof or protective insulation can be carried out on a pre-primed base by melting or liquefying (plasticizing) the binder layer, as well as gluing with hot or cold adhesives. The base surface for roofing or insulation must be properly prepared:

compacted and leveled; cleared. dust free. dried if necessary;

primed with a continuous layer without gaps or breaks.

Insulation and roofing work can be carried out from 60 ° to minus 30 ° C in the environment (with the use of hot mastics - at a temperature not lower than minus 20 ° C; when gluing the binder layer by liquefaction (plasticization) with the simultaneous laying of rolled carpet, liquefaction should be carried out at a temperature air not lower than 5 ° C).

When working in sub-zero temperatures, glass (foil) insulation must be heated to a temperature of at least 15 ° C within 20 hours, rewound and delivered to the place of installation in an insulated container.

Before sticking, roll materials must be marked at the place of installation; The layout of panels of rolled materials must ensure that their overlap is 100 mm. when sticking (on the roof ridge the overlap on the opposite slope should be 250 mm - when sticking panels across the slope and 1000 mm - when sticking along the slope).

Peculiarities

Due to the presence of a reflective foil layer, this type of insulation perfectly helps to conserve the existing heat in the room. In order for the effect to be significant, it is necessary to lay the insulation sheets end-to-end, gluing the seams with special, metallized tape.

With a foil surface, penofol should face the inside of the room. It will reflect the heat back inward.

This insulation will be most effective when creating an air gap on both sides of the laid material. To do this, on the insulated ceiling, it is necessary to build a sheathing in advance, to which the polyethylene foam will be attached. To press the material will be similar to the sheathing, only located on the outside.

It is impossible to attach polyethylene foam with an overlap. This method of fastening significantly reduces the efficiency of heat conservation and there is a risk of condensation flowing into the room, along the surface of the heat insulator.

As an independent insulation, foamed polyethylene is used quite rarely. You can combine it very effectively with other materials, such as polystyrene foam or polystyrene foam. But, you can use this type “C” insulation as a self-functioning heat insulator if the temperature does not drop to very low values.

Is it worth insulating a house with foil insulation?

This also helps to reduce external noise levels and get rid of drafts. The anti-corrosion properties of aluminum foil are useful in rooms with high humidity (baths, saunas) or when condensation occurs. Insulating the chimney, in particular with stone wool insulation, will help avoid unnecessary heat loss into the air.

Important positive qualities include low cost with a long service life - up to 50 years. The ability to install the insulator yourself without involving specialists is also appreciated.

The disadvantages of this material stem from its advantages: insulation with foil retains not only heat, but also moisture and odors. These side effects are most noticeable when you want to wrap the entire house in foil: floor, walls, ceiling. In this case, regular ventilation of the premises is recommended.

With maximum use of foil insulation, especially in rural areas, the cellular signal strength is likely to decrease, which can lead to frequent disconnections while talking or using the Internet. Placing the PC or the subscriber itself closer to the window will solve this problem.

Work procedure for insulation

In order to insulate the ceiling with penofol from the inside of the room, in the first pass, you can lay a thin layer of the same penofol, but of minimal thickness. It is attached with wooden slats, which will act as a sheathing or frame to secure the main insulation.

When the sheathing is completely ready, the main layer of insulation can be laid on it. You can fasten it either with a construction stapler or with exactly the same wooden slats as the first layer.

The efficiency of heat saving, in this case, will be much higher. Not only due to the double heat-saving design, but also due to the resulting air cushion. It is also necessary so that the air can move freely, taking with it excess moisture and preventing the formation of condensation.

On the outside of the sheathing, you can subsequently attach decorative trim parts, such as MDF panels, plastic lining, or wooden lining strips.

In what cases can foil insulation be used for the ceiling?

Insulators with a layer of foil are suitable for insulating residential and commercial premises in private houses or apartments. They are often used in complex insulation of a loggia or balcony.

The foil insulator itself is used only if there is a warm room above. It is ideal for insulating a basement, bathhouse, sauna, kitchen or bathroom. When insulating a ceiling under an unheated attic, its effectiveness has been proven only in combination with other heat insulators.

Density and thickness of mineral wool for ceiling insulation in a private wooden house

Nuances

All joints between individual sheets of insulation must be carefully taped with construction tape. If you don’t have it on hand, you can go over all the seams with silicone sealant. In any case, joints should not be left untreated.

It is advisable to avoid joints at corner connections between the ceiling surface and the walls. Do not allow the foil side of the heat insulator to come into contact with power supply wires and cables. Aluminum conducts electricity well, therefore, all places where the heat insulator comes into contact with wires must be carefully insulated.

Penofol cannot be glued overlapping. Condensation may flow along its edge, which will appear if moist air gets on the inner surface of the material.

Finally, about other use cases

Home craftsmen use insulation made from foamed polyethylene for a wide variety of purposes:

- protection of heating and hot water pipes from freezing;

- interior decoration of entrance door leaves;

- reflective screen glued to the outer wall behind the heating radiators;

- inexpensive thermal insulation of outbuildings - sheds, workshops, garages;

- exotic – shoe insoles made of 3 mm thin sheet insulation.

Polymer insulator "Penofol" is a material that deserves attention. If applied according to the instructions, it will serve as a good insulator. But do not try to save money and solve all thermal insulation problems using thin polyethylene alone; use other effective insulation materials.

Pros and cons of ceiling insulation

Penofol for the ceiling today is a popular material due to its versatility and easy installation. In addition, construction specialists value insulation for such parameters as:

- Light in weight, due to which the material can be worked at any height.

- To fix the insulation, no additional tools or devices are required.

- The coating is not water- and vapor-proof, incl. not subject to destruction under the influence of precipitation.

- Insulation performs several functions. So, when fixed to the ceiling, it prevents heat loss and absorbs noise. Often used in conjunction with other insulators to improve properties.

- When exposed to high temperatures, it does not release toxins. In the manufacturing process of the material, polyethylene and foil are used, which are used in food production.

- After installing the heat insulator, there is no significant loss of usable area. Because of this, penofol is often used in rooms with low ceilings.

- The material is sold in roll form, which makes the work much easier.

- The products are not subject to combustion and are resistant to rodents.

As for the disadvantages of insulation, there are few of them. Thus, these include a high price tag and the need to use secondary heat insulators to improve the properties of the first one. The second significant disadvantage is the use of glue as fasteners, which also increases the financial burden. Third, the material has a soft structure, so it cannot be used in rooms where you plan to wallpaper the ceiling.

Best answers

%username%:

Pat doesn't bother me at all, you have to come to terms with it

Roman Shved:

double-sided tape

Dmitry Dved:

There is a special adhesive foam like Penoplex in construction stores, but not Penoplex, it is specially made for this. The cylinders are red (more precisely the color cyan). I bought pistol cylinders with a capacity of 750-800g in Castorama. I don’t remember the name, it can be used as glue and foam. Dissolves with foam cleaner. The packaging indicates that before applying the foam it is worth spraying with water from a spray bottle. Water does not improve adhesion, but is a catalyst for hardening.

Vladimir Nikitin:

88 (such glue... ask the shoemakers)

Answers from experts

Grandfather Au:

ordinary food will not work - it is metal and if it can “reflect” some part of the radiation, then part of the convective flow will still heat it up, and since aluminum is an excellent conductor... Insulation is needed under the foil! The walls need to be insulated themselves, for example .termoplex /korund.php?table=korund

*:

Try to stick it with drool...

Marek Black:

You'd be better off insulating it with polystyrene foam from the outside. and the floor can be insulated. You talk to those who do this.

Evil Electrician:

I think you need to consult a construction store at the store or try installation

New:

First, prime it several times with bentonite, and then glue, but it’s better with a heat-insulating layer, even PVA, but there are some that are sold as self-adhesive on a heat-insulating backing.

Sergey Burmasov:

think about it, maybe galvanized iron, or better yet stainless steel, because foil is weak

Nina Ilyina:

oh, if the sticker is crooked, get a magnifying glass, with a focus like in ancient Greece they burned the fleet)

Albert Belkov:

I use Termoizol - foil on foam, it’s easy to work with: I insulate steel baths - they turn out no worse than cast iron ones, they are warm. And food grade can be glued onto cardboard with slots for hooks for easy insertion.

Yuri Martysyuk:

Buy penofol, they are sold in different thicknesses. It can be self-adhesive, but if not, try double-sided tape!

Chuck Kazemierczak:

If the foil is glued to the glass with egg yolk, then it will definitely stick to the concrete

Dmitry Nizyaev:

Double-sided tape. He then o? It will hold, but nothing more is required.

egor ag:

Why insulate at all? I've never done this. Insulation only retains heat, but does not generate it. And no insulation will keep the engine warm overnight. Moreover, the hood is not even the surface of the engine itself.

Doctor:

Bolts or rivets

Pavel Voronin:

why attach it at all, just put it in when you need to twist it and put it away

zheka-zloy:

narrow stripes and reinforced adhesive tape around the perimeter, see all this is fair... and the discarded material is used as a reflector for radiators in apartments (it is believed that it increases efficiency when heating in winter)))

kurt:

called FOLGOIZOL

Engineer:

If it’s more durable, then formos /produkciya/klej_adgezivy/klej_sprei-3m/80-scotch-weld/If you stick it and unstick it, then lenta-plus m/catalog/kley/49

kenny unknown:

The material is penofol, the trouble is that it will definitely melt in the collector area. It is glued with liquid nails from the installation company for products made of PVC and polystyrene.

What is it needed for

The main feature of penofol is the presence of a heat-reflecting screen. It is indispensable for insulation:

- walls and ceilings as part of multilayer enclosing structures;

- balconies and loggias;

- pitched roofs, attics and attics;

- utility rooms and outbuildings;

- greenhouses;

- heat-reflecting screen as part of a heated floor system;

- niches with an installed heating radiator;

- air conditioning systems for freezing units;

- pipes and lines with refrigerant or coolant within the permissible operating temperatures.

In addition to its thermal insulation and heat-reflecting properties, penofol has practically zero vapor permeability. It is used for effective and unique waterproofing properties as part of a roofing pie. H only from the inside of the attic or attic.

Covering all the advantages, penofol is ideal for arranging insulated heat-efficient rooms: greenhouses, incubators, vegetable stores, for protecting basements and semi-basements.

Thanks to the hermetic closed structure of polyethylene foam, penofol has good soundproofing properties. Basically, it absorbs shock sound and vibration well, but is less resistant to high-frequency sounds and noise.

As an underlay for flooring, as well as under a thin screed, it will absorb the sound of footsteps or impacts on the floor.

Floor insulation. Under the screed

When insulating floors, penofol is used as a substrate for all types of screeds, wet, semi-dry, dry, bulk or made with any sheet material, as well as as a substrate for all types of floor coverings.

This is facilitated by the high compressive strength of the material and the dynamic modulus of elasticity is much higher than that of any other insulation.

Floor insulation scheme

Polyethylene ensures the strength of air bubbles, which in turn provides uniform shock absorption to any distributed loads.

Taking into account the horizontal distribution of penofol, it is not necessary to attach it additionally to the base.

When installing a heated floor or fixing a reinforcing layer, any damage to the surface of the penofol should be minimized so as not to violate the integrity of the foil layer.

Balcony insulation

For insulating a balcony, penofol is an ideal thermal insulation material. In conditions of extremely limited space, it will be necessary to subtract only 20 mm from each fence in order to insulate the room with penofol, taking into account the required gap between the insulation and the finishing to form a closed air chamber.

Two installation options are used:

- Uniform laying of the material end-to-end over the entire insulated surface and installation of sheathing for further finishing on top of it;

- First, a sheathing made of 40x40 mm timber is attached, and then insulation is distributed in each cell, extending onto the sheathing elements.

Balcony insulation scheme

In both options, there is no need to use adhesives or a large number of fasteners. In the first case, the insulation will be securely pressed to the base by the sheathing, and in the second case, it is enough to attach the penofol under the very base with a stapler to the same sheathing.

The choice of the optimal option is determined based on the required load capacity of the sheathing and the weight of further finishing.

Description of material

Isolon thermal insulation consists of artificially foamed polyethylene, which has the form of small cells or pores. Increased thermal insulation characteristics are achieved thanks to the porous structure. Using it, various surfaces and entire structures are insulated and waterproofed. The finished material can be in the form of a sheet, tape, block or roll.

The main scope of application is hydro, sound and thermal insulation. It is also used in household tasks, as it has better characteristics compared to similar products. The special structure makes isolon a durable and wear-resistant material.

It is often used in conjunction with other insulators. For example, if the task is thermal insulation of the surface, it is combined with polystyrene foam or expanded polystyrene. This “pie” allows for high-quality insulation of walls, interfloor ceilings and loggias. It also serves as an insulating coating when screeding floors. It is also used in car production - it insulates bodies and protects metal parts from corrosion.

Types of glue for penoplex

There are three main types of glue based on their composition:

- mineral;

- polymeric;

- waterproofing.

Mineral:

Mineral-based adhesives include components of alabaster, gypsum, and cement. This solution should be mixed gradually, in small volumes. For indoor use, as a rule, a composition containing cement is used, and for external gluing of surfaces, solutions containing gypsum are used.

This glue takes quite a long time to set - 3-4 hours, which means that builders have the opportunity to remove the canvas or one side of it and re-glue it if the result is of poor quality. The coating must be removed carefully and correctly so as not to damage or tear it.

Mineral glue must be diluted. Many craftsmen consider this a disadvantage of the composition, since the work requires a construction mixer, with the help of which the mixture will become homogeneous and smooth.

A dry mineral adhesive mixture, which can be used to glue penoplex to concrete or metal, is available in bags of different sizes.

Polymeric:

This type of construction adhesive is an aerosol product that is sprayed from cans. This method is good for metal planes. These are quickly hardening substances, so surfaces coated with glue must be fastened immediately.

The main condition: the base for pasting must be well primed and then dried. Only in this way will the strength of the connection be maximized. This glue is not afraid of a humid environment or temperature fluctuations.

Waterproofing:

This class includes rubber, bitumen, and acrylic adhesives. They are a solvent-free mastic. This glue will harden for about 2-3 days, but then the insulation is unlikely to come off the concrete or metal coating.

When choosing what to glue penoplex with, pay attention to this method. The glue is used when working outside and inside the house. This composition best prevents moisture from entering and is not afraid of freezing. Mastic is used sparingly.

The most common adhesives for penoplex

Let's talk about six brands of adhesive solutions with which penoplex is best attached to any surface:

- "Moment"

It is better to choose the “Universal” brand - different types of insulation are installed on it. This glue holds well, firmly, for a long time. He is not afraid of moisture, low temperatures, or heat.

- Penoplex Fastfix

An excellent composition for laying thermal insulation on brick or concrete. Working with it is quick and easy. But such a product does not adhere firmly to a plane covered with foil, so do not use it to attach penoplex to surfaces made of Teflon, silicone, or polyethylene.

- Tytan ("Titan")

High-quality adhesive-sealant has high quality at low cost. In practice, builders more often choose the Professional Styro 753 brand. It adheres well to the surface and is resistant to high humidity.

- Master Termol (“Master Termol”)

The adhesive mixture is well suited for attaching penoplex, adheres firmly to cement and concrete, is frost-resistant and environmentally friendly. Its price is lower than other well-known brands, but it sticks just as well.

- ProfLine ZK-4

The content of certain substances in this composition is responsible for increasing the level of adhesion of materials to each other. It can even be used on walls covered with plaster. When completely hardened, it is resistant to destruction and precipitation.

6. Cerisit (“Ceresit”)

Allows you to fasten the foam sheet to a base made of concrete, metal, ceramics. Available in the form of construction foams, dry mixtures, adhesive solutions. High-quality glue with a low price.

How to glue penoplex to metal - instructions

Before gluing metal surfaces with penoplex, you must thoroughly clean them of debris, dust, and scrape off dirt particles. Then wipe the surface with a damp cloth and let dry.

After this, the metal must be treated with a primer using compounds that do not contain water. Due to the water-containing solution, a corrosion process may begin on the steel plane, and then the insulation will be damaged.

If the metal is cracked or chipped, apply several layers of primer to make the surface even and smooth.

Now we take the desired sheet of penoplex and lubricate the side without foil with glue. Wait 1-2 minutes until the composition is slightly absorbed into the surface of the insulation. Next, take the sheet in your hands and carefully apply it to the wall or floor. Carefully smooth out the thermal insulation sheet and look at the result. If the sheet lies unevenly, you have half a minute to correct it.

After this, firmly press the penoplex fragment to the working plane. It doesn’t matter what type of glue you use to hold the materials together, this rule always applies. The quality of the future connection of the insulation with any surface depends on the force applied.

How can you glue penofol to the floor?

In this case, the material is usually used as an additional layer. The main ones are polystyrene foam, expanded clay or expanded polystyrene under the screed. In addition to penofol and the main thermal insulation material, the work contractor must have on hand metal (or wooden) sheathing, tools for installation and plumbing work, an adhesive solution (or hardware), as well as wooden logs.

The following can be used as an adhesive solution:

- liquid Nails;

- Double-sided tape;

- polyurethane foam (applied in a thin layer).

- Before starting insulation work, it is necessary to level the floor using a concrete screed for this purpose. Lay a foam or expanded clay base.

- It is recommended to play the role of a wooden frame with lags impregnated with an antiseptic composition or use a metal frame. The products are laid on an insulating layer, and sheathing is placed on top of it.

Price

in the production of foil insulation on the Russian market :

- Jermaflex;

- Izolon;

- Penofol;

- Tepofol;

- Folgoizol;

- Ecofol.

| Firm | Characteristics | Price |

| Jermaflex | 1.2 m x 8 mm | 80 RUR/m² |

| Izolon | Type A, thickness from 2 to 10 mm, length 1 m | 140-260 RUR/m² |

| Penofol | Type A, thickness from 3 to 20 mm, length 36-12 m (the thicker, the shorter the meter) | 53-278 RUR/roll |

| Tepofol | Type A, thickness from 2 to 10 mm, length 2.5 m | 40-1200 RUR/roll |

| Folgoizol | Type A, thickness 10 mm, length 15 m | 1650 RUR/roll |

| Ecofol | Type A, thickness from 2 to 15 mm, length 25-10 m | 780-1030 RUR/roll |

Life time

Since foil insulation appeared relatively recently, it is not yet possible to determine the exact expiration date. However, after conducting experiments, we can say that the material does not lose its properties for 200 years.

The service life of the installed insulation depends on the adhesive used. If the adhesive composition has passed its expiration date, then you can re-install it with the same heat insulator.

There are a lot of insulation materials on the construction market. The choice is so wide that the question arises, which is better. To answer, you need to compare the characteristics of the thermal insulation material and the scope of application - street, living room, garage or agricultural building.