Comfortable living is ensured not only by the availability of utilities and the design of the premises. It is important to protect the house from heat loss, which is important during the cold season. Doors and windows are powerful sources of cold air entering the home. There are several ways to keep your room warm.

Replace doors with energy-saving designs. This is not cheap and involves related operations to design slopes, install platbands, etc. In many cases, it is possible to solve this problem in affordable ways without significant costs. One of the traditional insulation materials is felt door seal, which has both disadvantages and advantages.

Advantages of felt seals

Today, manufacturers offer a new generation of materials that are easy to install and affordable. The share of felt products is decreasing, but it is too early to abandon their use, since they have a number of special qualities:

- Wear resistance. Natural fibers can withstand significant physical stress without deteriorating.

- Life time. Unlike rubber and foam seals, felt does not contain volatile substances, the content of which steadily decreases during operation. This leads to destruction of the material and requires replacement. Felt seals do not lose their properties for many years.

- Soundproofing. The material absorbs vibrations. Both outside noise and the sounds of the door in contact with the frame are dampened.

- Environmental friendliness. Only natural raw materials are used in production. There is no release of substances harmful to health.

- Fire safety. The density of wool fibers and their quality are such that combustion is impossible under normal conditions.

Ready-made felt seal for doors

Manufacturers and prices

Today, every hardware store offers door insulation in a wide range. Each manufacturer provides its own thermal insulator options, which will differ in cost, type of filler and other characteristics.

You can buy high-quality door insulation from the following manufacturers:

- Aviora – price 150 rubles.

KIM TEC – price 76 rubles.

Ultima – price 130 rubles.

Self-adhesive insulating tape for door construction is a unique opportunity to eliminate heat loss and make the room cozy and comfortable. Today, the range of products under consideration is very wide, so you can choose your ideal insulation option. In addition to choosing a heat insulator, it is necessary to evaluate the complexity of the problem in order to understand which of the presented installation options is advisable to use in a particular case.

Foam rubber sealant for windows and pipes: can it be used?

Thermal insulator: comparison of insulation materials for walls

Insulation for ventilated facades: density of ventilated facades, which one is better

Insulation: types and characteristics, application, properties, what it is

Disadvantages of felt seals

Previously, felt was used everywhere as insulation and sealant. It was considered the best material for these purposes. Why is this method of protecting your home from the cold inferior? Despite the fact that the user qualities of felt are not in doubt, there are also disadvantages:

- Price. Production refers to traditional technologies with a centuries-old history. Felt is made from natural wool. During hydrothermal treatment, fibers are pressed into sheet or roll material. The cost of raw materials and labor create a price that is higher than synthetic fiber of similar size.

- Difficult to install. It is difficult to find a felt seal that satisfies most requirements on sale. All operations require an individual approach and qualifications. The range of felt materials is limited. You need to independently cut the strips of the required width and choose the method of fixation.

Rolled felt

- Attractive to moths and mice. Unlike microorganisms and mold, which do not live in felt, rodents and some types of insects like the material. Moths perceive felt as a food product, and mice insulate their minks with it.

Attention! When purchasing, you should carefully read the information about the product on the packaging or in accompanying documents. Natural felt is 100% wool. There are materials on sale with a similar name, but they cannot be considered as such. In cases where the percentage of natural fiber content is indicated in the composition, and even more so when it is absent there.

Eliminating gaps using a sealant

When choosing how to insulate a wooden entrance door, you should not ignore different types of sealing elements, but to determine the best one, it is better to consult with the seller. Seals are specially designed products whose function is to maximally fill the gaps and cracks between the door elements: the frame and the wooden leaf. In addition to thermal protection, the insulation serves as soundproofing for the entrance door to an apartment or house.

Installing a seal and sealing reduces the overall heat loss through a wooden door, solving the insulation issue by about 60%.

Types of felt seals

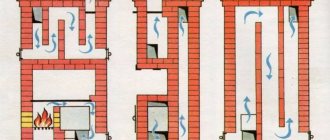

The production of the material is localized in regions that traditionally produce wool products. Classic technology is rooted in the distant past and has secrets. Not all developed countries know how to make felt. In Russia, production secrets have not been lost, and the products enjoy well-deserved respect. Despite the fact that the manufacturing process is traditional, the quality of the products is regulated by state standards. The consumer can choose the desired felt from the following types:

- GOST 288-72. Fine-wool technical felt. Inclusion of synthetic substances is allowed. Its main application is in technology. Gaskets and seals made of this material are used in mechanical engineering;

- GOST 6308-71. Semi-coarse technical felt. Excellent wear resistance. Used in mechanical engineering and in small quantities in construction;

- GOST 6418-81. Coarse wool technical felt. Used in many areas of economic activity. From mechanical engineering to construction;

- GOST 16221-79. This type of felt is called yurt. The name corresponds to the purpose of the material. Available in the form of rectangular cavities. There is no single standard. Allowed length is from 2 to 6 m, and width is from 1.4 to 2 m;

- Felt. It is used for technical purposes and in the production of household items and clothing. Expensive type of felt. Produced in thicknesses from 2 to 10 mm. Felt padding is made from old items such as hats or anti-shock layers removed from packaging and is used to transport fragile, valuable instruments and devices.

Automotive soundproofing felt

Any felt is used as a door seal. The minimum required thickness should be taken into account. The dynamic compression coefficient of felt is limited. For this reason, the difference in gap width should not exceed 2-3 mm. Otherwise, the door leaf rebate will not be airtight, the seal will be partial and the protection will not be effective.

Advice! If the width of the gap is uneven, you can pre-fill places with a large gap with pieces of felt of the required thickness. It is easy to cut lengthwise. After preliminary leveling, the finishing felt strip is installed. Another option involves installing a felt seal with the end side relative to the plane of the door. In this case, it is effective to form a roller.

When do you need to insulate?

Wood has low thermal conductivity, but the disadvantage of the material is its response to changes in humidity and temperature. The door block dries out, swells, warps and even cracks. There are three main reasons signaling the urgent need to insulate a wooden door in a country house:

- Formation of gaps between the frame and the ends of the opening walls . Initially, during installation work, all gaps are foamed. Foam is a good insulator, but over time it loses its properties. Destruction occurs faster on the street side if platbands are not installed. Foam deteriorates from exposure to the sun. Another cause of cracks is the misalignment of the bowl.

- Formation of gaps between the frame and the sash . The most common defect in a wooden entrance door occurs due to poor wood, poor-quality installation and long-term use. Often the owner himself becomes the culprit when he trims the swollen sash so that it closes better. After drying, the product decreases in size and a gap forms.

- Wear of insulation. Each thermal insulation material is selected taking into account operational requirements. If they were not initially followed, the incorrectly selected insulation loses its effectiveness. For example, mineral wool quickly cakes, and due to dampness it decreases in volume. Any old wooden door, as well as a thin leaf, needs to be insulated.

Insulation works

Immediately before insulating the door leaf and sealing the gaps, cracks, distortions, loosening, subsidence, and other visible door defects should be eliminated. The cracks are covered with wood putty, the gaps and distortion of the canvas are adjusted with awnings. On a wooden door, you can seal the holes for the screws for the hinges so as not to move them to a new place. An extreme measure to eliminate the loose closing of a wooden door or its distortion is the use of a plane.

Choosing a seal for any door is a serious matter, since different materials will behave differently:

- Foam rubber seals are usually made with one self-adhesive surface, and they are not reliable or durable. Their advantage is their cheapness;

- The rubber seal is a narrow strip with a sticky surface. The tape is sold without an adhesive surface, and then it can be glued with ordinary rubber glue, after first cleaning the work surface. The rubber seal can be nailed onto a wooden door with small nails;

- A felt seal in the form of a tape is nailed to the frame of a wooden door or glued to metal (plastic) with rubber cement. The thickness of the felt tape depends on the gap - if you need to make the tape thinner, it is cut with a carpenter's cutter;

- Sealing tape and plastic or silicone are much more elastic than rubber or felt; it does not compress well under the pressure of the fabric, so it will last longer. Both silicone and plastic do not crack due to frost, do not deform or stretch, and make hermetically sealed surface connections.

Sealing the door with felt

» alt=»»> The tape is fastened and placed around the perimeter of the frame without gaps, the length of the tape may be longer than necessary, but not less, so that you do not have to make an additional connection, which will reduce the tightness of the seam. The thickness of the tape is established with a piece of plasticine - it is glued to the frame, the door is closed, and after opening it you will see how thick the seal is needed.

Replacing the seal on the entrance door

Any tape seal must be attached if the thickness of the factory seal is no longer sufficient to prevent drafts, and combining decor with insulation is the most reliable measure.

Which insulation is better to choose?

To make an insulated wooden door with your own hands, you will need thermal insulation material, as well as material for the top decorative finish. The gaps are sealed with a sealant. When the question arises of how to insulate a wooden door in a private house, pay attention to the following materials:

- polystyrene foam as internal insulation for wooden entrance doors. The slabs can be sheathed on the side of the room.

- Foam rubber is considered the most common insulation material, which is covered with artificial leather on top. Porous material allows you to create a volume effect. Foam rubber loses over time and crumbles into crumbs.

- Mineral wool does not burn, has good thermal insulation properties, but quickly cakes. When exposed to dampness, it accumulates moisture. Under the weight it slides off a vertical surface.

- Foamed polyethylene - isolon has a structure similar to foam rubber. The material has better thermal insulation properties and a longer service life. Isolon does not tolerate long-term exposure to direct sunlight.

- Polyurethane foam is applied by spraying, firmly adheres to the wood, and penetrates into all cracks. The disadvantage is the impossibility of performing work without special equipment.

- Expanded polystyrene resembles polystyrene foam, but has improved characteristics. The material has self-extinguishing properties when exposed to open fire.

When choosing insulation for the doors of a wooden house, it is important to consider the thickness of the material. Thick layers will weigh down the sash and create an obstacle to normal closing. Thin is useless. You need to find a middle ground between these two parameters.

Types of seals for door frames

In addition to thermal insulation, you will need a sealant to seal the cracks around the perimeter of the canvas. It is a tape that differs in thickness and material:

- The foam strip is fixed using an adhesive base. The seal wears out quickly during the season.

- The silicone strip is resistant to dampness and elastic. Over time, it begins to stick and tear into pieces.

- The rubber seal for wooden doors will last for many years. The tape is resistant to wear, dampness, and mechanical stress.

- Thermoplastic is the best in terms of wear resistance, but is difficult to install.

- The polyurethane strip is glued due to the adhesive base. The characteristics are not inferior to a rubber seal.

Thermal insulation cannot be done without decorative finishing. Usually the insulation is covered with artificial leather. Fixed with furniture nails with a wide decorative head. On the inside, the canvas is sheathed with laminated MDF panels. Genuine leather trim looks beautiful, but the material is very expensive.

Criteria for choosing building materials

If you carry out insulation yourself, it is preferable to purchase a self-adhesive version. Craftsmen advise having foam rubber or felt available. Using them is not difficult. A sash equipped with this gasket can be closed without any effort. The sealing material – rubber is characterized by high wear resistance.

Soft rectangular, tubular rubber seals are also in demand. Their service life is 5-7 years. They protect the room from odors and extraneous noise. The thermoplastic-based profile is resistant to temperature changes.

Craftsmen focus on the choice of filler for insulating the sash and the space around the frame. This process must be conscious, as it is difficult to change them

When choosing, you need to pay attention to the thermal conductivity coefficient. It determines how the material will handle heat retention. For wooden products, thin fillers are a good option. The use of soft insulation greatly simplifies the work. Its advantage is that it covers the surface with a reserve and shrinks as much as necessary

It is important to measure the thickness and dimensions of individual structural elements with increased accuracy

How to insulate a wooden door?

The insulation of a wooden door begins with preparatory work :

- weakened hinges are secured with new elongated screws;

- if thick, heavy insulation is used, install an additional loop;

- eliminate box distortions and fabric defects;

- check the condition of the seal around the perimeter of the door frame at the junction with the walls;

- replace broken fittings: lock, handles, peephole, latch.

After all defects have been eliminated, installation of insulation on wooden entrance doors begins.

a vapor barrier necessary when insulating wooden doors? When arranging the installation seams of the door block - it is necessary. The gap between the box and the wall is sealed with foam. To prevent the thermal insulation from deteriorating, the seam is covered from the street with PSUL tape. From the room side, the foam is destroyed by vapors. For protection, the seam is sealed with vapor barrier tape. A vapor barrier may be required for the product if it is installed in a damp room and mineral wool serves as thermal insulation.

We insulate an iron door with foam panels

Typically, metal doors are made of sheet material, welded at the sides with corners, that is, they have voids inside that need to be filled from the inside for additional insulation.

The insulation technology is as follows:

- We take the dimensions of the door leaf (width and length) according to which we will cut out the fiberboard panel to cover the foam layer.

- We transfer the dimensions of the door leaf, the location and dimensions of the peephole and handle onto the fiberboard plywood, and cut out openings for them.

- We apply the panel to the door, checking that all the marks are correct.

Insulating an iron door with foam plastic

- Using a sharp knife, we cut out sheets of styrofoam to glue them to the inside of the door leaf. This insulation is glued using silicone, which is applied in a dense, uniform layer over the entire surface.

Advice! The thickness of the foam is determined by the size of the corner shelf.

- Now you can cover the foam with a fiberboard panel. We put a bit on the screwdriver and screw the fiberboard to the door leaf with self-tapping screws.

- The stiffening ribs of the metal door are made of a hollow tube; in winter it freezes and the effect of a “refrigerator” is obtained. To prevent this from happening, it is filled from the inside with polyurethane foam. To do this, a hole is made in the pipe with a drill, where foam is poured.

Attention! If you want to thoroughly insulate the wall, the cracks between the foam sheets can also be filled with polyurethane foam.

Installation of double doors

A good way to insulate your home is to install a double entry door. Due to the formation of an air space separating the room from the street, heat is retained. The disadvantage of this design is the reduction in space.

A threshold is set for the indoor unit. Insulation is additionally laid on the slopes between the doors. There are designs where two doors are hinged on one deep frame.

When insulating entrance doors, you must remember that moisture affects the canvas from the street side. Treatment with impregnation, painting with paint or varnish will help protect against dampness as much as possible. Drying oil creates good waterproofing.

Felt comes in rolls and sheets.

In one of the earlier articles, we introduced you to how to insulate a bathroom. Today we will talk about a very old, but, unfortunately, insulation made from natural sheep wool, which has lost its popularity - felt. This material is ideal for insulating doors, window and door frames, and the crowns of log houses. But if you want to completely isolate your house with it, you will encounter many problems, solutions for which are extremely difficult to find. “There are no hopeless situations,” said the notorious Baron Munchausen, but despite this, there is still no developed clear method for insulating walls with felt.

Sealing strips by door type

For each individual variety, its own seal was developed.

Input

Most often, entrance doors are finished with a dense material in the shape of a tube, inside of which there is a void. The significant thickness and bubble nature of the material create a reliable fit of the door to the frame. Read this article on how to choose reliable and warm doors for your home.

Of particular interest is the internal structure of these rubber bands for insulating doors. Thanks to the presence of internal pores, a multiple increase in the insulating effect is achieved. Most often, the entrance door seal has a self-adhesive base, which makes its installation very quick.

On the other hand, over time, the glue loses its characteristics, and the strips begin to lag around the perimeter. You can read about comprehensive door insulation.

Interior

The seal for interior doors is not assigned the function of protecting the room from outside cold, as in the previous case.

This allows you to make it more aesthetically pleasing by using more elastic and soft silicone instead of dense rubber. The installation method for these products may differ, which will be discussed below.

If you decide to change the doors during the renovation process, be sure to read this article.

Plastic

This group of materials is characterized by high speed of installation and dismantling. Grooves are usually applied to plastic doors along the line of contact with the frame, so the seals are given a special shape that follows the configuration of these grooves. Thanks to the presence of walls on the sides of the fixation point, the sealing strip receives additional protection from external aggressive influences. The seal for plastic doors is not afraid of moisture and temperature changes, so it can be used both outdoors and on interior doors without much difference. It is important to keep in mind that this rubber seal was designed specifically for plastic doors with grooves, so it is not recommended to seal other types of doors with it. In addition, different manufacturers complete their plastic doors with an individual seal: this should also be clarified when selecting a suitable material.

Glass

In the manufacture of seals for glass doors, silicone is used, equipped with a special profiled notch. When installing the strip, you must first wet the area where it will be placed: this will make the connection as strong as possible. Since the design of glass doors can be very different, therefore, a different seal is developed for each of them.

What kind of felt insulation for doors is there?

What a pity that this excellent, natural material with excellent characteristics is almost forgotten. Today, felt is used to insulate doors and window openings. In ordinary houses, this is where it ends, but if we are talking about wooden structures or a bathhouse from a log house (timber), then it is also used as inter-crown insulation and for caulking cracks. And probably no one even knows that felt insulation comes in different forms:

- technical fine-haired – manufactured in accordance with GOST No. 288-72;

- technical semi-coarse wool – manufactured in accordance with GOST No. 6308-71;

- technical coarse-haired – manufactured in accordance with GOST No. 6418-81;

- yurt - manufactured in accordance with GOST No. 16221-79;

- fert - made from the finest fibers of six rabbits and goats.

Felt insulation has a fairly low thermal conductivity, the coefficient is 0.03-0.07 W/m*K and depends on the density of the material. The latter varies in the range from 10 to 400 kg/m. cube

The material is produced both in panels and in rolls. The dimensions of the panels are 2000 x 2000 mm, rolls are up to 1800 mm wide and up to 200 m long. It is made from both natural and synthetic raw materials. Synthetics are already a trend of modernity; you shouldn’t take them seriously, but natural materials deserve attention.

This is a crown seal made of 15% felt.

Features of choosing door insulation

The reasons for heat loss are different: from misalignment of the door leaf and insufficient sealing, to insufficient quality of the material. If replacing the door is not included in the plans, then the only correct solution that will help save 25-30% of heat energy is door insulation, the nuances of which will be discussed.

In order to reliably insulate entrance or balcony doors, the following materials are used: mineral wool; honeycomb insulation; liquid insulation; foam propylene; felt insulation (including self-adhesive); polyurethane, anti-draft.

Nuances of installing door insulation

You will have to tinker with the insulation of a metal door.

Algorithm for installing insulation on a metal door:

- If the door is collapsible, it is unscrewed after first removing it from its hinges and dismantling the locks with handles. In the case of welded seams, they are separated using an angle grinder.

- Laying insulation into an empty box (if necessary, blowing it with polyurethane foam).

- Assembling the door frame.

In the case of a wooden door, first align the jamb and strengthen the hinges.

Stages of attaching insulation to a wooden door:

- The doors are removed from their hinges and the fittings are unscrewed.

- Lay the canvas on a flat surface, after which the insulation is attached to it with liquid nails or glue.

- The upholstery is strengthened while maintaining a 30 cm interval between nails.

Each material has design and installation criteria that help you choose the right insulation.

How to insulate a bathhouse door with felt

Most often, felt is used to insulate door and window frames, as well as for external door insulation. The fact that the material is environmentally friendly and that it breathes allows it to be used even in baths at high temperatures and humidity. Let's look at insulating a bathhouse door with felt from two angles. The first will be the insulation of the box.

This technique is applicable for both entrance doors and the entrance to the steam room. In both cases, insulation for felt doors is laid around the perimeter of the frame at the junction with the movable part. To do this you need:

- roll the felt into a small roll;

- on the side where the edge is visible, the roll is laid around the perimeter of the box;

- fastened with nails or a stapler.

No additional protection is needed. If you need to insulate the front door with felt, then you need to take the panel and secure it to the outside. Then, using furniture nails with beautiful caps, fasten the material you like (usually a leather substitute) over the insulation. The main thing is that the finish is resistant to atmospheric aggression.

A two-pipe heating scheme for a two-story house can be either vertical or horizontal. At the same time, there may also be several methods for laying out horizontal contours for each floor. Some of them: hitching, dead-end, collector.

Heating a country house is somewhat different from the main home. You can read about the best way to heat your dacha in winter in this article.

Description and characteristics

When thermally insulating an entrance door, various types of materials can be used. Each of them has its own thermal insulation qualities and installation methods.

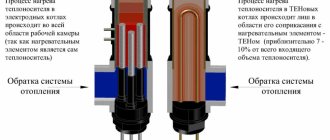

Honeycomb insulation

The material received this name due to the method of installing the filler into the canvas. This technology is very similar to the honeycomb layout.

The main material is corrugated cardboard. It is characterized by high rigidity, low weight and an affordable price.

This door insulation is obtained from the rock of silicate melts. It is characterized by a fibrous structure, as a result of which the resulting insulation has excellent heat and sound insulation properties. Mineral wool is not afraid of the influence of water, aggressive chemical substances and sudden temperature changes. Additional advantages of the material include environmental friendliness and low price.

But such insulation has a number of disadvantages, among which is the settling of mineral wool, which results in the formation of voids. But it is possible to eliminate this problem. To do this, it is necessary to install additional ribs that will keep the mineral wool from crawling.

You can see what self-adhesive insulation with foil looks like and how it is used in the photo in this article.

This information will help you understand how to use a seal for wooden doors.

You may also be interested in knowing which sealant is best to use for metal doors.

This door insulation material is characterized by low heat conductivity. In addition, polystyrene foam perfectly insulates from noise. The next advantage of insulation is its long service life. If you use the material correctly, it will not deteriorate and retain all its original properties.

In addition, one cannot but rejoice at the low price of the material. The disadvantages of polystyrene foam include its susceptibility to combustion. When burned, the heat insulator releases toxic components. But what are the thermal insulation properties of polystyrene foam and how they are determined is described in this article.

Foamed polyurethane

This product is classified as artificial, since its structure is made up of numerous balloons. Using rubber material, you can evenly and tightly fill the voids inside the entrance structure. The advantages of the material include resistance to the negative influence of environmental factors, light weight and environmental friendliness. But what is the price of sprayed polyurethane insulation polynor, you can find out by reading this article.

On the video, self-adhesive insulation for doors:

Where else is felt insulation used?

Felt-based linoleum - insulation and sound insulation.

In addition to the purposes described above, this material can be used for thermal insulation:

The methods, of course, are rarely used, but are still discussed on forums. Although felt for floor insulation is very often used as a backing for linoleum. When considering the hypothetical possibility of laying insulation under finishing materials, for example, insulating walls with foam plastic, you need to immediately eliminate possible problems:

- moisture – although the material does not absorb moisture well, it still happens;

- moth - you need to saturate the material with some means, but then you can forget about environmental friendliness;

- rodents will not miss the chance to steal soft bedding into their hole.

As you can see, using felt for wall insulation is quite problematic, and the price is high. It is sold by weight and costs from 200 rubles per kilo, depending on density. Such insulation will cost almost gold. Felt sealing is suitable for local thermal insulation, but even the technology has not been developed for insulating large areas. What to do in a situation where you don’t even have anyone to turn to for practical advice? You won’t find any practitioners on this issue on the forums during the day - only theorists and those are skeptical.

Insulating a house with felt is a harsh reality

Despite all the positive aspects of this material, comprehensive insulation of a house with felt is not possible for a number of reasons:

- it absorbs moisture;

- there are moths in it;

- mice feel great in it;

- it's too expensive;

- There is no methodology for such work.

You can talk about how to insulate a door with felt from two sides:

- insulation of the box (joints);

- comprehensive insulation on the outside.

This material is also used for caulking inter-crown cracks. In addition, felt insulation for the walls of wooden houses is used as a gasket between logs (beams) during the installation of the structure. It can be used both in pure form and as part of other materials (jute). It is better to abandon attempts to completely insulate the walls of any buildings from any materials. Yes, there is strong felt for yurts that has high insulating qualities, but it still won’t work. It is not designed to be enclosed by the body of the walls, because you are not going to insulate without finishing. Felt floor insulation is used quite widely, but only as a backing for linoleum. It is not used for laminate.

Insulation methods

Modern metal and wooden entrance structures are already on sale with thermal insulation. Another question is that the thickness or quality of the material is not enough to retain heat in the house (Chinese models mainly suffer from this). Also, preparatory work is required for custom-made items, which are initially produced only in the form of a canvas with a box.

In total there are 3 main options:

- end sealing;

- use of rollers;

- insulation for doors.

What is used for thermal insulation

The sealing of the ends and the rebate is used in any case if it does not fit tightly and air movement is felt. Even an insulated door without a seal will let in cold air and heat will begin to escape through it.

Rollers can be used both as an independent element and for upholstery with decorative or insulating materials.

Thermal insulating upholstery is applied on the inside, decorative on the outside or both. Depending on what material is used, the finishing method is chosen.

- foam;

- isolon;

- mineral wool;

- Styrofoam;

- expanded polystyrene.

- leather;

- vinyl;

- leatherette;

- leatherette, etc.

It is very easy to work with foam rubber - the finished sheets are attached to the panel and secured on top with strips. But the inexpensive material accumulates water, which creates cold bridges. In addition, mold can form under the foam rubber.

Izolon is structurally similar to foam rubber, but does not absorb water as actively and does not crumble during operation. They fasten it in the same way as foam rubber.

Mineral wool is more preferable for insulating a structure, but over time it will begin to clump and sag, gradually as if flowing down. It is advisable to first fill the beads on the inside in the form of small rectangular sections and then insert mineral wool plates into them. This will prevent loss of volume and will not create cavities.

Polystyrene foam and polystyrene foam are very light plates that hold their shape and have good thermal insulation properties, but when burned they emit extremely toxic substances.

Polystyrene foam and expanded polystyrene crumble heavily when cutting sheets. This can be avoided by using hot wire. Cutting work in this way is carried out outdoors or in a well-ventilated area.

How to insulate a door with a sealant

Let us repeat, this is a mandatory measure for any entrance element where there is a loose fit of the sash to the frame. The seal completely closes the gaps through which cold air passes through, strengthens the pressure and makes the closing process quieter. Structurally, it is a tape, one side of which is covered with an adhesive layer, and the other is made in the form of a rubber or foam pad.

The rubber seal is of better quality and lasts longer due to less damage and less compression. The service life of foam rubber rarely exceeds 2-3 years and this is due precisely to the soft structure of the foam rubber, which can come off and bend in some places.

Before you start gluing, you need to measure the perimeter - the width and height of the canvas and with this calculation, buy the required footage of the tape. Before purchasing tape, be sure to consider not only the perimeter of the box, but also the thickness of the rebate and slots.

For reference. The door ledge is a 3-5 cm thick strip that acts as a continuation of the door leaf and extends onto the frame itself.

The gluing process itself is very simple:

- degrease the places where it will stick;

- starting from the bottom, carefully separate the paper from the sticky layer in small sections and, pressing, fix the tape.

Today, with the advent of adhesive tape, it has become very easy to isolate cold bridges, whereas previously in the same places it was necessary to nail down pieces of leatherette folded in several layers with small nails.

For greater effect, you can glue soft tape to the edge of the box.

Sealing with special rollers

Insulating the front door with rollers allows you to perform 2 tasks at once - to close the cracks through which it leaks, and to decorate the panel. The cushion is a soft seal that is wrapped in upholstery material. The rollers are rolled in small portions and nailed on the inside.

Currently, this method is not as popular as it was in Soviet times, but it is an excellent way to seal entrance doors.

How to work with rollers

The upholstery process looks like this:

- prepare the material - the seal is wrapped in leatherette;

- from the inside they nail it with nails strictly along the edges of the canvas;

- in the lower part, make sure that the rollers protrude half a centimeter.