Of all the heating equipment that is used today in everyday life, solid fuel boilers have been known for a long time. Due to the simplicity of their design and operating principle, and the availability of fuel, units of this type have become widespread. Today, for many residents of private houses in rural areas, such equipment has become a kind of “lifesaver.” The constantly rising price of household gas and difficulties in obtaining permits for the installation of a gas autonomous heater contribute to the fact that today, at a minimum, solid fuel boilers have not lost their demand among the population living near forested areas as a source of firewood.

Solid fuel heating boilers: on the left - mounted and operating, on the right - without connection to the circuit, at the installation stage.

Today, there are two options to solve the problem of autonomous heating using solid fuel: buy a ready-made factory product or make a solid fuel boiler with your own hands. The cost of a modern high-tech heating unit is quite high, but the price range is wide - from 3 to several tens of thousands of rubles, which makes the device accessible to a wide range of consumers.

If you have certain technical training, you can assemble a solid fuel boiler yourself, using diagrams and recommendations for making models of these devices, which are the most popular for DIY installation.

The main function of a heat exchanger for a boiler

In the heat exchanger, water is heated, which circulates in the system and transfers heat to the radiators.

Gas and air are supplied to the boiler burner for combustion. The gas burns, releasing heat, and the combustion products are discharged outside. The heat source in this case is a stationary element.

The coolant - water or antifreeze - enters the heat exchanger. This is a device that provides heat exchange between two environments with different temperatures. The latter is located in the combustion chamber above the burner. Water, moving through the heat exchanger, is heated and supplied to the heating pipes. Most often, the device takes the form of a set of plates or tubes. The larger its working surface, the better and faster the water heats up.

Simple long burning boiler drawing

In Fig. Figure 1 shows a drawing of a simple boiler with a bottom firebox. Low-carbon steel sheets are used to manufacture the rectangular body and heat exchanger. The heat exchanger is designed as a “water jacket”. The heat transfer coefficient (efficiency) is increased due to the design of the protrusions inside the boiler, which reflect the flame and the heating gas.

Rice. 1 Boiler with a “water jacket”

In Fig. Figure 2 shows a combined heat exchanger of the “water jacket” type (2), formed around the combustion chamber plus a slot register (3) made of steel sheet. Combustion products exit through the smoke pipe (1). Solid fuel (5) burns at the bottom of the chamber. Below it is the air supply regulator (8).

Rice. 2 Boiler with slot register

Top combustion boiler

The camera drawing is shown in Fig. 3. A cylinder-shaped boiler is made from pipes of different diameters. Air is supplied through a moving pipe that extends upward to release the firebox when fuel needs to be loaded. When burned, it begins to decrease in volume and with it the pipe also falls smoothly downwards under the weight of its weight. Uniform fuel supply is achieved using a disk welded to the base of the pipe.

The heat exchanger is designed as a “water jacket” that envelops the combustion chamber. The air is heated in the upper part of the boiler.

Rice. 3. Top combustion boiler

Material of manufacture

The heat exchanger for the boiler is made from durable materials that conduct heat well, are not prone to corrosion and are sufficiently resistant to pressure. Since the cost of the material also has to be taken into account, the choice is limited.

Steel

A steel heat exchanger is cheaper in price, but less durable.

This is the most affordable material. Steel is very strong, but can be processed well. The price is low. The advantage of this option is resistance to high temperatures. Steel is plastic and does not crack when heated, and does not deform even in areas in contact with the burner.

A steel heat exchanger for a solid fuel or gas boiler is prone to corrosion. Water inside the tubes and combustion products in the boiler chamber have a destructive effect on the material. This affects durability. The steel model weighs a lot, which leads to additional fuel consumption for heating the element itself.

The stainless steel heat exchanger is resistant to corrosion and lasts for at least 50 years.

Cast iron

The material is much more resistant to corrosion than steel, and is not afraid of rust and the action of acid anhydrides. The service life reaches 50 years. However, cast iron is a brittle alloy and can crack under the influence of temperature. To avoid damage, the cast iron tubular heat exchanger must be washed: if ordinary water is used, then once a year; if antifreeze - then once every 2 years; if distilled liquid - once every 4 years.

The weight of a cast iron element is even greater, so more fuel and time have to be spent on heating.

Copper

Copper is a noble metal that is not susceptible to any type of corrosion. It is chemically inert and tolerates pressure well. Copper conducts heat better, so less fuel is required to heat the element itself and the flowing liquid. The weight of the copper model is small, the dimensions are compact with a very developed working surface.

The disadvantage is the high price. Also, the copper heat exchanger is too sensitive to heating to high temperatures. More often found in boilers from foreign manufacturers.

Copper

Cast iron

Step-by-step production of a solid fuel boiler. Subtleties and nuances

You will not be able to make the most economical homemade solid fuel boiler, but you can create a heating apparatus that is quite suitable for heating and hot water supply. The fact is that the assembly of industrial products is carried out on high-precision industrial equipment from specially selected materials in compliance with technological parameters. Each factory boiler model is based on accurate thermal calculations. The possibilities of working at home are incomparably more modest than in industrial conditions, therefore, when choosing a model to be manufactured, one must proceed from existing realities, including one’s personal potential as an installer.

Tools and materials

Having a drawing and specification of the heating unit, you can determine the list of necessary tools. Whether you want to make a large boiler or plan to assemble a small solid fuel heating device for your dacha with your own hands, the list of accessories will be approximately the same.

Tool kit for self-production of a solid fuel heating unit

*

To work you will need the following tools and accessories:

- welding machine;

- small grinder with cutting and grinding discs (safety glasses);

- electric drill with metal drills;

- gas keys No. 1, 2;

- hammer;

- a set of open-end or ring wrenches and screwdrivers;

- pliers;

- 90 degree square

The main material in production is steel, the thickness of which for the boiler must be at least 5 mm, for grates - from 7 mm.

In addition, you will need:

- steel corner 50x50 - for the boiler frame;

- sheet stainless steel - if there is a storage tank in the design;

- thick-walled steel pipes with a diameter of 32-50 mm - for the manufacture of a coil heat exchanger.

A complete list of materials and their consumption is prepared in advance on the basis of technical drawings.

Manufacturing of the housing and heat exchanger

The boiler body, which often acts as a combustion chamber, is the basis of the entire structure. To reduce the deformation of the walls under the influence of high temperature, the enclosing structures of the firebox are made in two layers with a backfill between the layers of dry sifted sand, which plays the role of a geometry fixator. The outer and inner shells of the firebox are made of frames, which also increases the rigidity of the structure. In addition, to increase the strength of the combustion chamber wall, the outside can be sheathed with a steel angle or profile in the form of stiffening ribs.

Manufacturing a solid fuel boiler body by welding sheet steel blanks

On the front wall, using a grinder or a gas cutter, according to the drawing, two openings are cut out - for the hopper door and the ash pit.

Advice! Before cutting sheet steel, it is necessary to make fine markings of future openings with small diameter holes (3-4 mm) in the corners of the holes - this will allow cutting with greater accuracy.

After finishing cutting the sheet steel blanks and the profile for the housing, you can begin to create a heat exchanger. We use cut water pipes, which are connected by welding into a single sealed circuit. The main task is to create a sealed flow fragment of maximum length to increase the heating area of the pipe.

This video shows how to make a heat exchanger, correctly position the pipes and perform welding.

Assembly

Once all structural elements are ready, assembly begins, which is best done at the site where the unit is installed - sometimes the dimensions and weight of the finished device do not allow it to be moved from the assembly site to its final location.

Most often, the boiler is installed on a specially constructed concrete foundation with the unit fastened by welding to embedded parts - anchors. Installation begins with the installation of the frame, after which it is equipped with components and cladding sheets. All welded joints are made with chamfering and weld processing - slag removal and grinding.

Note: After assembling the housing, a thorough visual check of its tightness is performed, based on the results of which additional welding of the seams is performed.

Grate bars (steel grate) and a heat exchanger are installed in the finished housing, which is connected by welding to the heating circuit. During installation of the coil, it is important to fulfill the design angle of its inclination, otherwise obstacles will be created to the natural circulation of the coolant in the circuit.

The body of a solid fuel boiler at the stage of installing external stiffeners

Important! It is better to entrust the manufacture of a storage tank from stainless steel with its insertion into the circuit to professionals, since working with this material requires special equipment and practical skills.

Upon completion of assembly, the boiler is painted with two layers of heat-resistant paint with preliminary surface preparation to protect it from corrosion.

Heat-resistant paint Ecoterra for covering surfaces operating at high temperatures

A self-made heating boiler is durable and easy to maintain, which consists of periodically cleaning the firebox from ash and maintaining the chimney.

Classification of heat exchangers

Primary heat exchanger for the heating circuit in the form of a coil with plates

Gas boilers can perform several functions. The main thing is heating the home. However, dual-circuit models also heat water for various household needs: from washing dishes to the bathroom. It is on this basis that heat exchangers are distinguished.

Primary

Serves the heating system. It is a pipe with a fairly large diameter, bent in the form of a coil in one plane. To increase the working surface of the device, plates of different sizes are placed here.

The primary heat exchanger is subject to the highest loads. From the outside it is affected by combustion products - soot, dirt, acid anhydrides, from the inside - by salts dissolved in the coolant. To reduce wear, the part is coated with paint and treated with anti-corrosion compounds.

The best option is a heat exchanger made of stainless steel or copper, since it is not subject to rust and is not afraid of salt deposits.

Secondary

Secondary heat exchanger for hot water supply

This heat exchanger heats the liquid for hot water supply. Its heating temperature is lower, but it is not worth heating water for domestic needs above +60 C. Most often, this is a plate design: it is assembled from many plates with extruded passages through which tap water circulates. Multi-pass models are more effective, since within one plate the liquid changes direction several times, that is, it stays in it longer and warms up better. It is made from steel, copper, aluminum.

Bithermal

When clogged, bithermal heat exchangers must be replaced with new ones.

They consist of 2 pipes inserted into each other. The coolant moves through the inner one, and water for hot water flows through the outer one. The heating fluid is heated in the combustion chamber and partially transfers heat to water for domestic needs.

The design is much cheaper. But although the water here heats up faster, its volume is limited. In addition, the bithermic heat exchanger is very sensitive to water quality and gets dirty much faster. Cleaning the device is not enough. To prevent rapid clogging and failure, it is necessary to install water filters at the inlet.

It is not possible to clean a combined heat exchanger like a regular separate one. If there are large salt deposits or clogging, the element will have to be replaced.

What do you need for work?

First of all, the workshop, that is, the place where you will manufacture the main components and assemble the unit. In addition, you will need a fairly extensive list of tools, which can safely include:

- welding mask, gaiters and overalls;

- household inverter welding machine and electrodes;

- circular saw with a set of discs for cutting metal;

- electric drill with a set of metal drills;

- tape measure, squares, building level.

To assemble a solid fuel boiler, you will need the following materials:

- steel sheets with a thickness of 5 mm;

- metal corners;

- cast iron grate;

- steel water pipes of various diameters;

- doors for the ash and combustion chamber;

- stove-type throttle valves.

Before you begin manufacturing the elements and components of the boiler, you need to perform structural calculations, decide on a circuit diagram and draw a drawing of the boiler, not forgetting to indicate all its structural components and their main parameters.

Smoke exhaust of a solid fuel boiler: inside and outside the building

And most importantly: observe safety precautions both during the work process and in relation to the quality of the solid fuel boiler. The slightest mistake on your part can cause serious problems, incl. increased risk of fire.

Criterias of choice

The main parameter of a heat exchanger is its power.

When choosing a device, the purpose is taken into account - in this case it is heating the coolant, and the type of medium - steam, water, antifreeze. A gas boiler usually works with water, but there are exceptions.

Other selection criteria:

- Coolant temperature at the inlet and outlet - it is necessary to calculate how much heat the consumer should receive. Based on these data, the heat exchanger power is calculated.

- Allowable pressure losses - the water pressure decreases as it passes through the heat exchanger. If it falls too low, it will not be possible to create a column of hot water of sufficient height.

- The maximum operating temperature on the burner reaches 600–700 C. A cast iron and steel heat exchanger can withstand this temperature; copper heat exchangers can withstand this temperature with some difficulty. The aluminum model must not be used.

- Maximum operating pressure – does not limit the choice of design or material.

Dimensions are a significant parameter. With the same efficiency, a shell-and-tube heat exchanger occupies an area 3–4 times larger than a plate heat exchanger.

How to connect heating equipment

The efficiency of homemade wood-burning equipment is ensured by good natural draft from the chimney. In order for the working draft to be sufficient, the pipe must have a height of at least 5 - 6 m, and the diameter of the pipe in the boiler body must be approximately 150 mm in diameter. To simplify ignition in the combustion chamber, bypassing the heat exchanger, a direct draft channel with a handle and a damper is made on the outer side wall.

During operation, an important role is played by the correct piping of the heating device. When operating a gravity heating system, which does not require electricity, there will be no problems. And yet, it is better if, when accelerating the boiler, in order to avoid the formation of condensation on the internal walls of the firebox, cold water from the system does not get into the jacket.

Condensation, mixing with ash, settles on the surface and forms a black coating that is difficult to clean off. Therefore, it will be better if you make a bypass at the coolant outlet from the unit with a three-way thermostatic valve set to 55 or 60 degrees. In this case, the coolant circulates in a small circle, up to a heating temperature of 60⁰. The thermostat will then begin adding cold water from the system.

If the heating system in a private house operates with a pump, then there is a danger that the boiler will boil if the electricity is turned off. To protect it, you need to take a number of measures:

- Install a safety valve into the water jacket, which will release steam when the pressure is exceeded.

- For further operation of the pump, an uninterruptible power supply and a diesel power plant will be required. The battery can only work for a short time, so you can’t do without an electric generator.

- To ensure natural circulation of water from the tank to the boiler and prevent boiling, you will need to install a heat storage tank. It will keep the house warm after the wood burns.

Correct operation

The heat exchanger is washed depending on the water hardness.

Transportation, installation and operation of the heat exchanger device are described in detail in the instructions:

- The heat exchanger is placed in the apparatus so that it has easy access for inspection and repair.

- Start-up is performed at stable pressure and temperature. Do not increase the temperature faster than 10 degrees per minute or increase the pressure more than 10 bar per hour.

- When filled with water, the air valves and valves behind the heat exchanger remain open. After the pump starts, they are closed. In this way, stable pressure is achieved.

- You need to change the heating parameters smoothly. The slower this happens, the longer the seals and the heat exchanger itself will last.

- The device needs to be cleaned periodically. The plate is cleaned directly in the frame, then the plates are removed and washed. Another method is possible: first removing and then cleaning the plates. It is not recommended to clean shell-and-tube machines. In case of complex blockages, the technician installs a plug.

- Before restarting, check the condition of all gaskets. Pressure and temperature are set as at 1st start.

To avoid salt deposits, a filter is placed on the water pipe in front of the boiler entrance.

Useful tips for making a TT boiler

Alloy Steel Pipe for Boiler

You can significantly reduce the cost of building a unit if you take a seamless steel pipe of grade 20.

Before installing the boiler in the place designated for this unit, carry out the first kindling outside, equipping the boiler with a temporary chimney. This way you will be convinced of the reliability of the design and will see whether the case has been assembled correctly. If you use a gas cylinder as the main chamber, then keep in mind that such a unit will provide you with combustion for 10-12 hours due to the small amount of fuel supplied. So, the small volume of the propane tank will decrease after cutting off the lid and ash pan. To increase the volume and ensure longer burning time, it is necessary to use two cylinders. Then the volume of the combustion chamber will definitely be enough to heat a large room, and there will be no need to add firewood every 4-5 hours. In order for the ash pan door to close tightly, preventing air from entering, it must be well sealed. To do this, lay an asbestos cord around the perimeter of the door.

If you make an additional door in the boiler, which allows you to “reload” fuel without removing the lid, it also needs to be tightly sealed using an asbestos cord.

For the operation of a TT boiler, the diagram of which we attach below, any solid fuel is suitable:

- hard and brown coal;

- anthracite;

- firewood;

- wood pellets;

- briquettes;

- sawdust;

- slates with peat.

There are no specific instructions on the quality of fuel - any will do. But keep in mind that with high fuel moisture, the boiler will not provide a high efficiency.

Possible faults

Steel products are subject to corrosion and must be replaced.

Most problems require the intervention of specialists. Some can be eliminated by the user:

- Reduced pressure - if caused by contamination, it is enough to clean the heat exchanger. If the connection to the network is incorrect, you need to check the connection with the drawing in the instructions.

- Reduced efficiency - in case of mechanical contamination, the device is washed. If the reason is the accumulation of oil or substandard gases, additional devices are installed to remove them.

- Leakage - most often caused by decomposition of seals. They are being replaced.

- Mixing of working media - occurs when plates or tubes corrode. The plates can be partially replaced, but a new shell-and-tube heat exchanger will have to be installed.

While the warranty is valid, it is prohibited to open the heat exchanger yourself and carry out any repairs.

Popular manufacturers

Cast iron heat exchanger for Beleto floor-standing boiler

Heat exchangers are produced by many manufacturers. The most popular companies in 2022 were the following.

Navien

The largest Korean manufacturer. It produces products intended for household boilers. The advantage is resistance to low water quality and water hammer. The device is perfectly adapted to poor operating conditions.

Baxi

Italian manufacturer. Presents on the market wall-mounted and floor-mounted condensing boilers with a cast iron heat exchanger, as well as electric heaters.

The company makes primary heat exchangers from copper and brass. For secondary plates, stainless steel is used. This increases the cost of the products, but ensures maximum durability.

And others

There are other worthy manufacturers on the market:

- Fondital Victoria Compact is an Italian company. Offers high performance bithermic copper heat exchangers.

- Beleto is a well-known Russian plant that produces a variety of gas equipment. Manufactures steel, cast iron and copper heat exchangers of various types.

- Ariston - offers aluminum and copper heat exchangers. The materials are insensitive to corrosion, and the manufacturing technology guarantees their strength.

If there is a need to increase the efficiency of the boiler when replacing the device, consult a specialist to calculate the required parameters.

Choosing the type of solid fuel boiler

How to understand which boiler will be optimal for servicing a particular heating system? Obviously, you need to decide on the type of fuel, the required power of the unit and the features of its design, installation process and subsequent operation, as well as the features of the connected heating system.

Homemade solid fuel boiler

Among the materials that can be used as solid fuel, the most widely used are:

- coal;

- peat briquettes;

- pellets;

- firewood;

- sawdust and other combustible production waste.

Types of solid fuel for heating boilers in the photo

Peat briquettes Firewood for solid fuel boilers Charcoal for solid fuel heating boilers Fuel pellets for heating boilers Wood briquettes for solid fuel boilers Eurofirewood (fuel briquettes for a picnic) Briquettes from recycled waste Wood sawdust for heating boilers

In order to increase the profitability and efficiency of the heating system, it is possible to manufacture a universal unit that can work with various types of fuel.

The choice of the type and design of the heating boiler directly depends on what fuel you are going to use, the required performance of the heating system, as well as the place where it will be installed. The following modifications of solid fuel heating units are suitable for self-production:

- Classic

Equipped with a steel or cast iron heat exchanger, they can be used for both heating and hot water supply. The efficiency of such boilers is about 85%.

Classic solid fuel boiler

- Pyrolysis

They ensure separate combustion of fuel and the volatile gases released, thereby significantly increasing the efficiency and, consequently, the cost-effectiveness of the heating system.

Diagram of a solid fuel pyrolysis boiler

- Pellet

The efficiency of this type of heating boiler reaches 90%. Their main advantage is the high degree of automation of work processes, and the disadvantage is the complexity of the design.

Operating principle of a pellet boiler

- Long burning

They are able to operate continuously throughout the entire heating season, requiring fuel loading once every few days, which distinguishes them from classic solid fuel boilers.

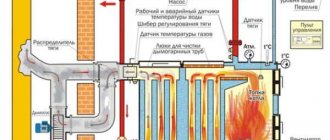

Layout of a long-burning solid fuel boiler