In today's realities, an open-type expansion tank for heating has long and irrevocably lost the competition of a more modern and efficient closed tank.

Nevertheless, obsolete equipment is actively used. And in a number of situations it even has some advantages over technologically advanced membrane tanks.

In this material we will analyze its purpose and design features, and also get acquainted with the operating principle and rules for calculating this type of tank.

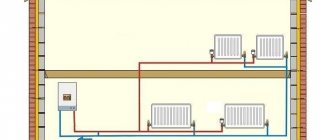

Features of a heating system with an expansion tank

The heating system can be closed or open. The choice of location of the expansion tank depends on the type.

Open systems have long been outdated and at this time they can only be found in old buildings. Here the expansion tank is an open top tank. The bottom of the container is equipped with a threaded connection to which pipes are connected.

- The membrane system is equipped with a tank with a closed top.

- By design, it is a sealed capsule, inside of which there is a membrane made of durable rubber.

- This device can be installed anywhere.

It must be taken into account that it cannot be placed close to the circulation pump. Otherwise, it is likely that pressure surges will occur throughout the heating system.

How to make a calculation?

As mentioned above, any expansion tank used for open heating is characterized by simplicity of design and manufacture. And calculating the dimensions of such a product is no more complicated.

For this purpose, you can use formulas or a method that involves approximate calculation of the working volume of the tank.

An example of using a formula to calculate the required tank volume. Based on the actual volume of water circulating in the circuit, only its increase when heated to a certain temperature is calculated, rounding up. Then add the result obtained to the volume of coolant in the heating system and add an arbitrary number of liters “in reserve”

In reality, to determine the required capacity of the tank, the owners of a small country house use formulas extremely rarely. Most often, the approximate volume of the expansion tank is calculated, to which any number of liters can be added for insurance.

Reason: in the case of open tanks, the extra volume does not significantly affect the cost, and in some cases does not lead to an increase in price at all.

As a result, the entire calculation of capacity comes down to determining 10% of the volume of the entire coolant, which should be its minimum value for the expansion tank.

The easiest way to do this is at the time of designing and creating a heating system, when all the parameters of radiators, pipes and other structural elements are known or can be easily found out by taking measurements. And then simply adding up the volumes of all components.

Although open expansion tanks and the systems for which they are intended have long since become obsolete, their availability and, most importantly, high autonomy make them in demand in conditions that are far from ideal. For example, if there is a problem with stable electricity supplies or the owners of the premises do not live there permanently

If the source data is unknown, then the most practical method of calculation is experimental. Why do you need to drain all the water from the system and then refill it with coolant?

In this case, measurements must be made, which can be done using a meter or using containers of known volume. After that, all that remains is to find out the required 10% of the coolant volume, which serves as a guideline when making or purchasing a tank.

Open type

Open type expansion tanks are installed at the highest point of the system. Often the location of the tank is chosen to be in the attic.

In addition to the fact that the device prevents the expansion of the coolant in the pipes, it also serves to prevent boiling of the coolant, and also replenishes its reserves in cases of leaks.

What it is?

Thanks to artificial heating of premises for various purposes, it is possible to compensate for heat losses and maintain the specified temperature values. Thermal comfort conditions for living require the operation of an open or closed heating system. Any type of heat supply network has undeniable advantages and certain disadvantages that must be taken into account when choosing a scheme.

Advantages and disadvantages

An open system is based on thermodynamic laws. Its main advantages include:

- energy independence;

- natural circulation of coolant;

- ease of maintenance;

- silent operation;

- minimum equipment;

- high level of reliability;

- ease of self-installation.

Significant disadvantages include bulkiness, the risk of cavitation, which destroys system elements, and low efficiency. Among other things, the operation of an open heating network requires strict control of the coolant level, as well as the impossibility of using antifreeze.

Differences from a closed system

Autonomous heating systems have a number of significant differences from a closed heating network. Features and main differences must be taken into account when choosing the optimal heating option for a room.

| Options | Open | Closed |

| Connection with the atmosphere | Permanent | Absent |

| Storage tank | Spacious round or rectangular tank with drain pipe | Double-chamber with membrane, designed for maximum pressure |

| Installation location | At the highest point of the mounted system | Not of fundamental importance |

In conditions of centralized heating (apartments), an open system is based on supplying hot water directly to the taps. The heat carrier first undergoes additional deaeration and mandatory cleaning, and after use it is discharged into the sewer.

Circulation

The tank can be installed in systems with natural or forced circulation.

- With natural circulation, the device should be built into the main line, thanks to which it will additionally serve as an air collector;

- With forced circulation, the device is connected to the return pipe so that the water does not boil in the system.

Open or closed system. What's better?

Closed and open types of heating differ in parameters and functionality, as well as other characteristics. In each specific case, the scheme is chosen strictly individually. The open version of the system is more suitable for organizing heating in small buildings, including country houses or private households. Given the simplicity of the circuit, such a system has a high level of reliability and does not require the constant use of expensive electricity.

The design of a closed-type heating system is characterized by the complexity of installation, as well as operational features, including the need to provide electrical power. However, this option becomes the most optimal for organizing year-round and most reliable heating in multi-storey buildings or large country cottages with a high-power dedicated power supply line.

It is important to see the following: open heating systems are not capable of competently regulating the temperature in rooms due to their limitations. With closed pump systems, all this can be achieved.

Connection system

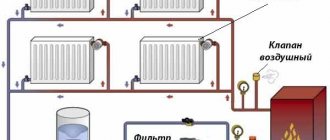

Essentially, an open-type expansion tank is a container with four pipe outlets:

- Circulating;

- Expansion;

- Overflow;

- Signal purpose.

The heating system is connected to an expansion pipe located on top of the tank. An overflow is needed to drain water into the sewer when the tank overflows.

At the bottom there is a signal pipe with a locking device. Circulation is necessary to permanently maintain the overall temperature, in order to avoid freezing of the coolant in the tank.

Using a pump in an open system

Installing pumping equipment ensures uniform heat distribution across all radiators, minimizing problems with insufficient pipe diameters and non-compliance with slopes. The addition of a pump is especially in demand in conditions of excessive length of pipelines. It is advisable to install the circulation pump between the water heating boiler and the expansion tank.

Minuses

Recently, such products are not used in heating systems, as they have many disadvantages. Among them the following can be noted:

- Cannot withstand high pressure;

- The design is quite bulky and has large dimensions;

- Air penetrates into the open system along with the coolant, which has a negative effect on the surface of the metal elements, which causes pockets of corrosion to appear - corrosion will soon form on them;

- Such a device must be installed at the highest point of the system, which incurs additional costs.

Operating principle of the device

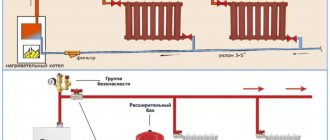

The expansion tank is part of the simplest heating systems that work according to the laws of physics. When liquid moves through pipes and radiators by gravity, the energy for this is provided by the pressure difference.

In order not to disrupt the natural heat exchange and water circulation, the expansion tank should be installed at the highest point of the entire heating system, while the boiler should be the lowest. We talked in more detail about installing and connecting the tank in this article.

Otherwise, the presence of a tank will not give the desired effect. This will not protect against increased pressure, water hammer and subsequent breakdowns.

An important advantage of open expansion tanks is their availability. For example, a tank can be made even from scrap materials, which are sufficient in summer cottages and in the utility rooms of private houses. Any metal or plastic container of the required size can become an expansion container, as evidenced by the photo

When the coolant is cold, the tank itself does not take any part in the operation of the heating system.

Everything changes when the liquid heats up to significant temperatures and creates excess pressure in pipes and radiators, since in such situations its excess is actively created and squeezed into the expansion tank. Where it remains until the coolant cools down, after which it again flows by gravity into the pipes and radiators, the boiler.

The described procedure is performed cyclically, that is, throughout the entire period of operation of the tank.

Due to the fact that the heating system is open, like the tank itself, compensation for the effects of expansion cannot be carried out without human intervention.

The reason is that the coolant, being in direct contact with the air, evaporates, and the more it heats up, the more active this procedure occurs.

As a result, the user has to regularly monitor the available water level. And top it up as needed.

The specified operation is performed using a bucket or other container with water. This is unpleasant, so the system can be automated by organizing the supply of water from a water supply system, from any one: local or centralized.

You should know that geometric shapes and precise calculations in the case of an open expansion tank are absolutely unimportant. The main condition for effective operation is placement at the highest point of the system and the presence of a sufficient volume of container up to the overflow pipe

In addition, using additional equipment, the described procedure can be made completely autonomous.

But in this case, the most important advantages of all open tanks and heating systems are lost:

- cheapness;

- complete autonomy , that is, independence from the performance, serviceability and presence of any engineering systems in the room.

All processes in an open tank occur according to the natural cycle, without the help of pumps and other equipment.

As a result, in order for the expansion tank to be guaranteed to be useful, the dimensions of the system itself must be moderate, that is, it should not be used for heating cottages and buildings whose area exceeds 100 m².

The optimal location for expansion tanks is warm attics. Since the highest point of the system is guaranteed to be there, and this solution also allows you to hide a structure with low aesthetic properties away from eyes

If this rule is ignored, this can lead to significant financial losses, since a number of alterations will have to be made to ensure the efficiency of the tank and the entire system as a whole.

In addition, height should be limited. Since it is very problematic to achieve the expected result when trying to heat more than a two-story building in this way.

Closed type

The membrane expansion tank does not have all the disadvantages inherent in the system described above.

However, installing it requires some additions and rules:

- Requires a pressure gauge;

- A device for manual pressure adjustment is required, otherwise the pressure may exceed all standard tolerances;

- The tank should be installed as close to the boiler as possible and with a connection to the return pipe. This is necessary to prevent the water from boiling.

You should not ignore the reliability of the fasteners, since during operation the weight of the expansion tank can increase significantly.

Tank Installation Guide

Fastening the expansion tank

Fastening the expansion tank

The first stage is preparation for work. In accordance with the general scheme, first, to install the tank, you need to disconnect the heating boiler from the power supply, shut off the water supply to the boiler, and then drain the liquid from the radiators. Additionally, you can open the so-called. Mayevsky taps, thanks to this, more efficient and faster drainage of water will be ensured.

Mayevsky crane

Prepare your expansion tank for installation and further use. If you plan to use polypropylene pipes to connect system elements, prepare a special soldering iron to fasten them together. You will also need standard elements such as corners, couplings, etc. As for fittings, it is best to use “American”. Such a fitting will allow you to easily remove the container in the future for maintenance and repair work.

American fitting with internal thread

The American fitting consists of 2 main elements. The first part of such a fitting must be attached to the thread on the expansion tank. The second part is attached to the first. A polypropylene pipe is soldered to the second part. Before screwing the fitting to the expansion tank, wrap a sealant around the threaded connection (flax is usually used) and additionally apply a little special sealing paste. Screw on the first part of the American fitting using a regular gas wrench.

The second stage is laying polypropylene pipes. Make sure that all water has been drained from the system and proceed to install the pipes. Where the tee will be installed, the pipe is cut using special scissors. Solder the tee and a pipe to it. Next you need to solder the stopcock. Thanks to it, it will be possible to repair the tank in the future without the need to remove water from the system. Solder the polypropylene pipes so that the last of them can later be connected to the expansion tank.

Installation of polypropylene pipes

The third stage is connecting the expansion tank. You need to screw the American to the container. After this, feel free to proceed with placing the tank in the location chosen for it. It is best to install the tank in a corner, on a flat floor, in such a place that you can freely access the tank in the future for repairs, etc.

The fourth stage is checking and replacing filters and cartridges. Before you run coolant into the pipes, thoroughly rinse the cleaning filter with water. Remove it first. At the same time, replace the main filter cartridge. It is installed directly after the pump.

The fifth stage is preparing and launching the system. Once all the elements are in place and the required connections have been made, you can begin preparing the tank for use. Restore water supply. Let the batteries fill with liquid until the pressure level in them increases to approximately 1.3 kPa. Next, you need to bleed the air from the pipelines, turn off the Mayevsky taps and start the heating equipment to warm up the rooms.

Tank installation

Recommendations for bleeding air and optimal pressure values were given earlier. If the pressure level rises above 1.1 kPa (this is the value that was set when setting up the tank), excess water will flow into the tank. When the pressure level decreases, the coolant will flow into the batteries. This will ensure normal operation of the heating system.

Thus, there is nothing super complicated about installing an element called an expansion tank. Follow the instructions in everything, remember the main recommendations and everything will be at its best. Happy work!

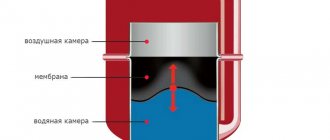

Design Features

By design, the expansion tank is a metal container of a flat or cylindrical shape. The inside of the tank is divided into zones by means of a rubber membrane.

One zone contains compressed gas or air.

- In the non-working position, the entire volume of the container is filled with gas.

- Before starting the system, the pressure in the tank must be the same as that of the entire heating system.

- After the temperature rises, water enters a separate zone, and in the part where the gas is located, the pressure increases to the value created in the entire system.

If there is a sufficient amount of coolant, the gas pressure requires careful monitoring. For this purpose, a special compressor is installed that maintains a certain pressure. It turns out that the main element in the tank is the membrane.

Plastic tank

Here you just take a plastic container. A 10-40 liter canister or a regular 10 or 12 liter bucket can serve as a tank. A more preferable option would be a rectangular base.

For it you should purchase a threaded fitting with a thread for two bends and a rubber washer according to the diameter of the fitting, as well as two nuts for the diameter and pitch of the thread of the bends.

Then one of the ends of the fitting is heated over an open fire with a blowtorch, gas cutter or gas stove, and with this heated fitting, the bottom of the canister, bucket or some other container intended for the expansion tank is burned. After this, you should cut off the top of the product and burn three holes using a nail heated over an open fire. These holes are made in a triangle and serve to attach the tank to the wall.

Now you should equip the bottom of the product with a fitting. For this purpose, a nut is screwed onto the drive, and it itself is inserted into the hole. From the inside of the tank container, put a rubber sealing washer on the thread of the outlet and screw on the second nut, tightening it tightly. The purpose of this second nut is to tightly fix the rubber to the bottom part with emphasis on the second nut located on the outside.

The last stage of work is to mount the container higher, somewhere under the ceiling. For this, dowels or self-tapping screws are used. They are inserted into holes pre-burnt with a hot nail or drilled in plastic. This mounting method is suitable for mounting a 5-liter container, but for its 10-liter sample, you will need to build a shelf.

Membrane types

There are two types of membranes:

- Diaphragm, often such an element cannot be replaced with anything if it fails. This type is used more often in small-volume tanks;

- The balloon is easily replaced if it malfunctions. The coolant in such a membrane does not have contact directly with the surface of the container, because of this the service life of the product is significantly extended.

Is it possible to make open systems from polypropylene?

A gravity-flow heating system made of polypropylene pipes is one of the affordable and easy-to-install options. Reinforced polypropylene pipes have an operating temperature within 70°C and peak performance at 95°C. An analogue of steel and cast iron structures is distinguished by its ability to withstand pressures of 20 Bar and above, and also has high thermal insulation, anti-corrosion resistance and hygiene. If the installation rules are followed, the system can last 50 years.

As you understand, PPR pipes can be used to make open heating systems, but from an aesthetic point of view, steel pipes will look better in the house. They can always be restored to a civilized appearance, while polypropylene pipes will become less presentable over the years.

DIY connection

A closed type system is more common, so it is better to familiarize yourself with the process of connecting the tank, just this option.

- First you need to decide on the capacity. It should be about a tenth of the total volume of the coolant.

- Make correct technical calculations. Particular attention should be paid to the overall volume of the heating system.

- Disconnect the boiler from the heating source. Shut off the coolant supply using the valve to connect the expansion tank.

- Completely empty the circuit of liquid.

- To connect the container to the system, you will need a special soldering iron, fasteners, and a set of tees and fittings.

It is recommended to install the tank in a place with the lowest pressure. But you need to calculate so that the expansion tank does not interfere. Despite the ease of installation, it is advisable to entrust the connection of the expansion tank and boiler to a specialist.

An expansion tank of a simple design is not that difficult to install yourself. This procedure does not require special skills or special tools.

However, it is necessary to strictly follow the recommendations relating to the characteristics of the heating system in which installation work is carried out.

Installation of membrane device

A hydraulic accumulator of this type is installed where there is a minimum probability of coolant turbulence, since a pump is used for normal circulation of water flow along the circuit.

Correct container position

When connecting the expansion tank to a closed heating system, be sure to take into account the location of the air chamber of the device.

The rubber membrane periodically stretches and then contracts. Due to this impact, microcracks appear on it over time, which gradually increase. After this, the membrane has to be replaced with a new one.

If the air chamber of such a tank remains at the bottom during installation, the pressure on the membrane will increase due to gravitational influence. Cracks will appear faster and repairs will be needed sooner.

It makes more sense to install the expansion tank in such a way that the compartment filled with air remains on top. This will extend the life of the device.

Features of choosing an installation location

There are a number of requirements that must be taken into account when installing a membrane expansion tank:

- It cannot be placed close to the wall.

- The device should be freely accessible for regular maintenance and necessary repairs.

- The wall-hung tank should not be positioned too high.

- A shut-off valve should be placed between the tank and the heating pipes, which will allow you to remove the device without completely draining the coolant from the system.

- When installing on a wall, the pipes connected to the expansion tank must also be attached to the wall in order to remove possible additional load from the tank pipe.

For a membrane device, the most suitable connection point is the return section of the line between the circulation pump and the boiler. Theoretically, it is possible to install an expansion tank on the supply pipe, but high water temperatures will negatively affect the integrity of the membrane and its service life.

When using solid fuel equipment, such placement is also dangerous because steam can enter the container due to overheating. This will seriously disrupt the operation of the membrane and may even damage it.

In addition to the shut-off valve and the “American” connection, it is recommended to install an additional tee and tap when connecting, which will allow you to empty the expansion tank before disconnecting.

Setting up the device before use

Before installation or immediately after it, it is necessary to correctly configure the expansion tank, otherwise called an expansion tank. This is not difficult to do, but first you need to find out what pressure should be in the heating system. Let's say an acceptable value is 1.5 bar.

Now you need to measure the pressure inside the air part of the membrane tank. It should be less by about 0.2-0.3 bar. Measurements are carried out with a pressure gauge with a suitable gradation through the nipple connection, which is located on the tank body. If necessary, air is pumped into the compartment or excess air is vented.

The technical documentation usually indicates the operating pressure, which is set by the manufacturer at the factory. But practice shows that this is not always true. During storage and transportation, some air may escape from the compartment. You must take your own measurements.

If the pressure in the tank is not set correctly, this can lead to air leakage through the air removal device. This phenomenon causes a gradual cooling of the coolant in the tank. There is no need to pre-fill the membrane tank with coolant; simply fill the system.

Tank as additional capacity

Modern models of heating boilers are often already equipped with a built-in expansion tank. However, its characteristics do not always correspond to the requirements of a specific heating system. If the built-in tank is too small, you need to install an additional tank.

It will ensure normal coolant pressure in the system. This addition will also be relevant if the heating circuit configuration changes. For example, when a gravity system is converted into a circulation pump and the old pipes are left behind.

This is true for any systems with a significant volume of coolant, for example, in a two- or three-story cottage or where, in addition to radiators, there is a heated floor. If a boiler with a small built-in membrane tank is used, installing another tank is almost inevitable.

An expansion tank will also be appropriate when using an indirect heating boiler. A relief valve, similar to that installed on electric boilers, will not be effective here; an expansomat is an adequate way out of the situation.

Photo of connecting the expansion tank to the heating system

How to turn an open system into a closed system

An open expansion tank promotes natural evaporation of the coolant and its saturation with oxygen from the air masses. To get rid of these problems and extend the life of the system, it is enough to perform a simple conversion of an open heating circuit into a closed one. In this case, the principle of circulation can be preserved, and the water will move due to its physical properties, but the best option would be to purchase and install a circulation pump.

The main stages of modernization are as follows:

- dismantling and replacing an open expansion tank;

- setting up a security group;

- installation of the expansion machine.

The standard safety group is represented by a pressure gauge, safety fittings, and an automatic air vent. After the alteration, it becomes possible to increase the length of the line and change the connection diagram, increase heat transfer and regulate the heating level of radiator batteries in an individual mode.

Operating rules

Despite the simplicity of the expansion tank design, this equipment still requires attention. It will reliably perform its functions only if all operating rules are followed. These include the following:

- Every six months the expansion tank should be carefully inspected for damage. These may include various dents, traces of corrosion and smudges. If you discover any of these phenomena, you must immediately understand the causes and eliminate them,

- with the same frequency, it is necessary to check the pressure in the gas compartment with that which is expected in accordance with the design parameters. To carry out this procedure, it is necessary to disconnect the expansion tank from the heating system, drain all the water from it, and then connect the pressure gauge to the nipple-gas cavity. In the event that the pressure is below the required parameter, it should be increased by pumping air using a compressor, connecting the latter to the same nipple,

- It is also necessary to check the condition of the membrane once every six months - if, of course, we are talking about a closed expansion tank. If any defects are detected - for example, the rubber element is deformed, cracked or simply leaks air - the bulb must be replaced with a new one,

- If the expansion tank is used seasonally, that is, with long breaks, then when you stop using it, you must remove all water from the tank and keep the equipment in a dry place. Otherwise, corrosion processes are likely to occur.

Safety precautions

In addition to maintaining the tank itself, it is important to pay attention to how safely it is used. There are several rules that must be strictly followed:

- if the equipment has visible damage - dents, deformations, etc. - it is prohibited to operate it,

- it is also prohibited to make any changes to the shape of the tank or its design,

- If the equipment needs repairs, then you need to call specialists with the appropriate skills. If it is necessary to replace any parts, you should use only “original” components,

- During operation, constant monitoring of pressure and temperature in the tank is necessary. Exceeding both is unacceptable.

- if it becomes necessary to dismantle parts of the structure that are under pressure, this is done only after disconnecting the expansion tank from the system, draining the water from it and reducing the pressure to atmospheric level,

- The tank capacity, as a rule, is made of materials that are not very resistant to various influences. Therefore, for use in the heating system, you should choose a high-quality coolant - for example, distilled water,

- When installing an open-type tank, it is necessary to select an installation location that will accurately support the weight of the equipment filled with water to the maximum. The floor in this area of the room must be very durable.

If all operating and safety rules are followed, the use of an expansion tank will be extremely beneficial. Based on the information received today, you will certainly be able to independently make the best choice and not get confused in the variety of equipment presented on the modern market.

It is quite possible that this article will be useful not only to you, but also to your friends. Therefore, share it with them on social networks and come back for a portion of new knowledge, of which there is still a lot, very much on this portal. Good luck to you, and see you again!

Equipment selection

To summarize, we can say the following: for an open heating system, take the appropriate type of expansion tank; for a closed one, this rule also applies. In general, you can even make an open tank with your own hands, there is nothing complicated there. The most important thing is to follow the placement rule described above.

Regarding the purchase of closed-type tanks, it is worth immediately warning: in appearance they are very similar to hydraulic accumulators for a water supply system. But these are different types of equipment, they are not interchangeable. Refer to the markings on the product; they indicate the permissible temperatures and pressures. For the expansion tank it is 120 degrees and 3 Bar, and for the hydraulic accumulator it is 70 degrees and 10 Bar.

Another criterion for choosing an expansion tank is its required volume. After all, it is important that the required amount of coolant fits into it. Calculating this indicator is not so simple, although, in principle, there are various online services for carrying out this operation.

But any program can fail, so it is still better to carry out calculations manually. To do this, you need to calculate how much water enters the entire heating system during operation of the latter. That is, you need to consider the following:

- the amount of liquid in the heating boiler tank. This indicator is taken from the technical data sheet of the equipment,

- the amount of coolant in all lines. To do this, you need to find the cross-sectional area of each section of the pipeline (using the formula for the area of a circle), and then multiply the resulting number by the length of the same section,

- the amount of liquid in each radiator connected to the heating system. This indicator is also taken from the technical data sheet of the product.

After all the calculations have been made, the resulting numbers are added up, and then 10% of the amount is calculated. This will be the required volume of the expansion tank.