It is difficult to live without hot water in the house, and heating all rooms at the same time is much more convenient than a stove in one room, which can warm a maximum of two rooms.

Wood fired hot water boiler

A wood-fired hot water boiler will be a good option for a house located outside the city or a country cottage where the owners live most of the year.

There are different types of hot water boilers designed only for heating water or heating, and there are boilers with two circuits that will heat the house and provide hot water for household needs. Having considered several options for different types of wood-burning water heaters, you can easily decide which one is more in demand in your home.

Differences in the design of water heaters

The name “Titan” is popularly attached to such devices, although there are several manufacturers of wood-burning speakers.

In principle, titans have a similar design, but there are still a number of differences, based on this we will give a classification:

- in different models the firebox can be either separate or combined with a water tank

;

Note! This division allows the tank to be rotated, which is convenient in cases where it is necessary to make a connection in the bathroom. The tank can simply be turned in the desired direction.

- By the type of tank material, we can mention products made of cast iron, ordinary steel, stainless steel; enameled water heaters have also earned positive reviews. The firebox is made of steel or cast iron;

- in more modern models, a seat for installing a heating element may be provided

. If there is electricity at the dacha, then titanium will be able to work both from burning solid fuel and from the network. When equipping a structure with a heating element, the manufacturer most often equips it with a thermostat, which will allow you to automatically maintain the temperature of the water in the tank;

- Also, most manufacturers take into account the operating features of the products and make it possible to pour water from above. So if , then the tank can be filled with plain water;

- There are also gasified titans

, but this option from the point of view of autonomy is not the best option.

You can recognize which device is in front of you by the markings:

- the designation KVL LF indicates a boiler model with the possibility of using heating elements. Most likely, this model also has a thermostat to maintain a constant temperature;

- KVS - in this titanium model, the firebox and water tank are combined;

- the letters KVL indicate a separate firebox and water tank.

Where to buy a fireplace stove with a water heating circuit?

You can buy environmentally friendly equipment for heating your home in the KaminDom online store. Our catalog contains only the best models of stoves with a water heating system. They allow you to reduce the cost of purchasing fuel by 30%. The cost of certified products from well-known manufacturers varies over a wide price range. It may depend on the type of material used, external design and heating capabilities. Our specialists offer highly qualified installation and scheduled maintenance services for equipment. We have a favorable and affordable price for each fireplace stove with a water circuit.

More information about wood-burning water heaters

At first glance, such devices look like relics of the past, but it’s no joke - during the rampant electricity and gasification, it is proposed to use firewood for heating. But wood-burning titanium does not lose popularity, so it’s worth figuring out what the reason for this is

Reasons for popularity

There are several reasons for the popularity of wood-burning water heaters:

- versatility - literally any flammable substance can be used as fuel with the exception of coal. Not only firewood can be used, but also sawdust, shavings, combustible waste from a summer cottage and even paper;

Note! If you nevertheless load coal into the firebox, the metal can quickly burn out - the temperature will be too high.

- economical - literally 5-7 medium-sized logs are enough to heat the water in the tank. Although the water heater is inferior in heating time to its electric counterparts, the process still proceeds quickly;

- ease of installation;

- low cost. The price of a modern water heater is about 15,000 rubles. For this money, the buyer receives a steel tank of 86 liters, a cast-iron firebox with an ash pan, as well as a mixer and a shower head, that is, a complete set, except for a chimney. The full volume of the tank is guaranteed to heat up to 80ᵒC within 45 minutes;

- Some enterprising summer residents use old water heaters as room heaters. Instead of water, sand is poured into the tank and the heater is ready for use; it can easily heat a small house in the country.

There are, of course, some minor drawbacks. For example, during severe use, the tank may leak along the seam; the reason for this lies in the fact that it is not designed to withstand significant pressure. You can also note the small thickness of the metal of the tank - about 3 mm.

Design and principle of operation

Any wood-burning water heater operates on the same principle - fuel is burned in the firebox, and the resulting energy is used to heat the water in the tank. The firebox and tank can be separated (this leads to a slight slowdown in the water heating process) or placed in one cylindrical body.

To ensure that the heat generated during fuel combustion is used as efficiently as possible, a gas exhaust pipe passes through the entire titanium. Due to this, the water heats up faster.

As for the chimney, its diameter exceeds 100 mm (manufacturers often make the outlet hole 115 mm). Due to this, conventional sandwich chimneys can be used. In order not to bother with laying it through the ceiling and roof, you can simply lead the pipe through the wall and lift it to ensure good traction.

Titan shower wood-burning water heaters have another interesting feature - the mixer that comes included has only 1 input - for cold water. But hot water is supplied from the water heater tank.

Note! It is for this reason that it is impossible to replace the complete mixer with a conventional analogue that you like. After all, typical bathroom faucets have 2 inputs.

Features of operation and improvement of titanium

The key feature of a wood-burning country water heater is that it is not designed to withstand significant pressure. The manufacturer assumes that water will be poured into the tank manually, the maximum - the required pressure will be created by a container raised on the roof, or a country water supply, but the pressure in it is low.

Separately, it is worth dwelling on the modernization of the design; a small improvement with your own hands and ordinary titanium can be used, for example, for water. Moreover, this will not lead to significant costs.

The point of modernization is that the mixer is removed from the usual circuit, and water circulation is organized as in conventional electrical devices:

- cold water will enter the tank from the bottom, at the point where the mixer was previously installed;

- In order for the water to be drained without problems, you will need to install an air intake valve near the top fitting. If you try to drain the water without it, then the air simply will not replace the drained water and it will not be possible to drain all of it;

- a safety valve (to relieve excess pressure) is installed optionally. The fact is that if a tank raised to the attic is used as a source of water, then it will play the role of an expansion tank in the heating system and the pressure in the water heater tank will not exceed the norm;

- It can also be recommended to additionally insulate the titanium tank, but this is at the request of the owner.

Installation and connection of titanium

This stage is also performed without the help of specialists. First of all, you should take care of fire safety; after all, titanium heats up quite well, and a coal can always fall out of the firebox.

Several rules must be followed:

- The wood-burning water heater is installed only on a base made of non-combustible material. You can cover a section of the floor with asbestos slabs or build a small foundation of brick or concrete;

- the walls should be thermally insulated; any non-combustible materials, including asbestos boards, are suitable for this.

Connection instructions may look like this:

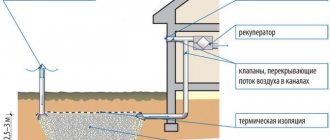

- there are 2 tanks on the roof of the shower - 1 with cold water, the 2nd with hot water (it can be lined with foam);

- the pump supplies cold water to both tanks from the well; it can also be supplied from the country water supply;

- then water from the insulated tank enters the titanium, heats up in it, and returns to the tank;

- From both tanks, supply pipes are connected to a conventional mixer in the shower; it is also possible to install pipes for other consumers.

Note! Thermal insulation of the tank allows you to maintain sufficient water temperature for at least a day.

Hot water boilers

Water-heating double-circuit wood-burning boiler

In addition to just water heating devices, in many cases a home also requires a heating boiler, which can be installed in combination with titanium or purchased a boiler with a built-in boiler.

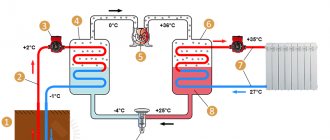

This diagram clearly shows how one boiler can perform two functions and provide a house with heat and heated water.

Boiler design and operation diagram

Boiler design

In this case, the diagram clearly shows the boiler built into the boiler body. This heating device has a labyrinth system for the passage of heated air - this is a firebox where fuel and three horizontal plates are placed, between which hot gases pass. By staying longer in the boiler, they give off heat more significantly and, before going out into the chimney, they manage to warm the water for heating and the boiler for using the heated water for domestic purposes.

The boiler runs on wood, but there are models that run on gas, pellets or diesel fuel. The last option requires a little modernization: a burner is installed in the bottom door. A device operating on wood can be converted to use another fuel even after its installation, but for this you should invite a specialist. The diagram clearly shows changes in the design after reworking the boiler.

The efficiency of a boiler arranged in this way reaches 87-92%. In addition to the design itself, the fairly thick walls of the combustion chamber also contribute to high heat transfer - their thickness is half a centimeter. Such models are equipped with pump activation thermostats, a cooling circuit and a thermometer.

Cleaning the boiler and maintaining it during its operation is extremely simple; an accessory for cleaning it is usually included with the device.

Installing a boiler is no different from installing titanium - this must be done while observing safety precautions. The size of the chimney pipe will depend on the boiler model - its diameter can be determined by the pipe coming out of the boiler. The chimney is discharged through the roof and waterproofing must be installed around the head. The head should rise above the roof according to the same principle as discussed above.

Design and operating principle

Perhaps to the modern generation a wood-burning heater seems like a curiosity, but our parents remember well what it is. Previously, the wood-burning column was called titanium. Structurally, a wood-burning boiler is a large water tank. Its capacity in a wood-burning column may vary. The capacity varies from 80 and 200 liters. Options for wood-burning heaters with greater productivity can be easily manufactured to order. Under the water tank of the titanium shower is a firebox for wood. This is where the whole process takes place. At the top of the wood boiler there is a shower outlet. Through it, hot water flows into the mixer, which is located below. The presence of pressure is not necessary for the entire process. Water under its own pressure can drain and fill the bathroom from a wood-burning boiler, and cold water can easily be unscrewed from the well.

The best quality is considered to be a wood-burning heater with a stainless steel tank. Such a wood-burning column better resists corrosion and temperature. The firebox of a wood-burning heater can be joint or separate. The difference is that in the second version of the wood boiler, the water tank can rotate around its axis. This means that it will be easier to place such a column in any room, since the firebox can be turned towards the door. Also, such a product is easier to maintain. If the combustion chamber of the boiler needs maintenance, this can easily be done separately. The tank is also easy to repair if it starts to leak.

Advice! Choose a wood-burning stove with a cast-iron firebox. Its walls do not burn out as quickly as sheet material, so it lasts longer. It also retains heat longer.

Types of wood stoves by material of manufacture

Wood-burning stoves, while still remaining an excellent source of heat, fit well into modern heating systems for private households. Wood-burning stoves can be divided according to the material of manufacture into the following main groups:

- brick (stone);

- cast iron;

- steel.

Brick wood stoves

Brick kilns are the most durable and expensive to build. A good stove is not cheap, and it is not easy to find an experienced installation technician. To build such a stove, fireclay and refractory red bricks are used, as when laying a wood-burning fireplace, special mastics for masonry, cast iron doors, grates, and valves for the chimney pipe. A brick oven takes a long time to heat up, but also retains heat in the room for a long time.

Cast iron wood stoves

Cast iron stoves are usually used as an additional heat source. Manufacturers create not only heat sources from cast iron, but also beautiful products that fit perfectly into the interior of any home. Heated cast iron retains heat excellently, and the presence of a hob allows you to cook food or heat water for domestic needs.

Metal wood stove

A metal wood stove can quickly raise a room's temperature using minimal fuel, but the thin steel they're made of doesn't allow the heat to last long. The simplest type of metal stove is the well-known “potbelly stove,” which is often used to heat small country houses or garages.

As mentioned above, the stove itself only heats the room in which it is located. In order to transfer heat to other rooms, there are two ways - organizing air heating with an air duct system, or water heating from a stove with a heat exchanger, piping and heating radiators. Air heating is easier to install, but has a number of disadvantages, which together outweigh the use of a traditional water heating circuit.

The disadvantages of air heating include:

- installation of air ducts through which warm air is distributed must be carried out at the stage of building a house, since they are quite bulky;

- the need to install fans with a flow rate regulator, which improve air circulation but produce noise. Installing a furnace with fans in the basement of the house can solve this problem.

- The need to install additional air filters to prevent dust transfer.

The advantage of air heating, which at the same time is also a disadvantage, is low inertia. That is, the rooms begin to warm up immediately after the stove is lit, but they also cool down quickly.

Another advantage of air heating is the absence of heating radiators. Air ducts, as a rule, are hidden under the ceiling of the building, and the space under the windows remains free.

In most cases, owners of houses with stove heating opt for a water heating circuit for a private home, so we will analyze this option in detail.

Advantages and disadvantages

The main and undeniable advantage of a wood-burning heater is fuel. Not only firewood is suitable, but also anything that can burn without emitting toxic smoke. For example, if you have old tires without a cord lying around your dacha house, you can cut them into pieces and put them to use. Heating of water with them will occur faster, because they burn well and generate enough heat. Another positive point is the ease of integration into the existing water supply system. The shower column is also easy to connect to a storage tank, which can be located on the roof to create pressure.

If there is an electricity supply to the house, then you can additionally install a heating element in the wood-burning water heater, which will heat the water when you are too lazy to carry firewood. True, in the latter, titanium heats up many times faster than an electric boiler with a smaller volume of liquid. The device is completely independent and autonomous, so no interruptions in the network or water can prevent you from enjoying hot water. Another positive point is the relatively low cost of even the “top design”.

Disadvantages include the lack of automation. If you do not take into account models with a heating element and a thermostat, then titanium cannot be left and gone. It will either go out or, conversely, begin to boil if a second stack of firewood has been made. In the cold season, when the device is not planned to be used, the water must be drained. If it freezes and expands inside, this will lead to failure of the entire structure. For some, the disadvantage will also be the need to constantly clean up waste combustion products.

Advantages and disadvantages of the oven

Pros:

- fast water heating;

- simple installation and dismantling;

- efficiency;

- low cost;

- possibility to make it yourself.

Minuses:

- the heater cannot be automated; the water temperature will have to be controlled using a thermometer;

- the heater should be located at a distance of several meters from the pool;

- it must not be left unattended;

- requires constant attention of the “stoker”;

- It is imperative to adhere to safety precautions when working with fire;

- the boiler requires maintenance in the form of removing ash, cleaning from burning and periodic painting with special enamel.

Possible applications

A wood-burning heater can be used in the most unusual and interesting ways. The most obvious application is in the bathroom or outdoor shower. If in the summer you like to install an inflatable pool at your dacha or have a self-made structure, then such a wood-burning boiler can be used as a heater. To do this, you just need to bring a hose to the entry point, connect the pump to it, and throw the other end into the pool. Light the titanium and turn on the circuit and add firewood. The water from the pool will flow into the boiler, warm up and return back. In a short time it will be possible to warm up a large amount of water.

Thanks to the firebox in a wood boiler, energy is transferred not only to the water, but also to the environment. This means that with the right layout and choice of location, it is possible to organize heating of additional rooms. For example, a wood-burning boiler can be mounted into the wall so that the firebox opens into one room, and the shower is located directly in the bathroom. Due to the fact that the firewood will be stored in one room, it will also be warm due to the firebox and the heated tank.

Possible improvement methods

Despite the simplicity of the principle of operation, such a water heater is very convenient to use, but requires a number of modifications. First of all, at the outlet of the chimney from the tank, you need to drill a through hole and insert a pin with a damper disk into it. At the same time, the disk does not have a rigid attachment to the stud, because the damper must be periodically disassembled to clean the chimney.

To service and repair the heater, it will need to be disconnected from the piping, so it is recommended to install “American” type connections made of brass on the threaded pipes of the tank. The lower pipe is connected directly to the water supply system through a shut-off valve. Also in this place you can make a drain outlet with a tap and a fitting for connecting a flexible hose. On the upper branch pipe it is necessary to provide a free outlet with a ball valve to allow air to leak in when draining water from the tank. A standard safety group is installed behind the outlet - an excess pressure relief valve for water heaters. Next, a shut-off valve is packed behind the group.

If the water heater is located outdoors, it will not be superfluous to provide thermal insulation to the tank. It is quite easy to do with ordinary basalt wool. You will need a wide piece of steel reinforcing mesh, rolled into a ring to form a gap from the tank walls of about 50–70 mm. The insulation is attached to the mesh with thin wire, then the resulting casing is wrapped around the water heater and tightened with wire clamps.

Installation process

If you are thinking about buying a wood boiler, it is good to know how to install it correctly once it has been delivered. To do this, it is necessary to determine the purposes of its use, as described above. Tools for installing a wood boiler you will need:

- gas or adjustable wrench;

- level;

- perforator;

- roulette;

- fastening consumables;

- Bulgarian;

- metal fittings;

- marking tool.

The first step before installing a wood boiler is to prepare a place for it. With a boiler tank capacity of 200 liters, the total weight with a fully filled flask can exceed 300 kg. This means that the base for the wood boiler must be strong enough. Also, the wood boiler should not be tilted, as if it falls, it can cause serious injury or death. In the room where the wood boiler will be installed, a square area with a minimum size of 1 m 2 is marked. Using a grinder, the contour is determined and a 15-20 cm deepening is made. A concrete solution is prepared from cement.

Stands made of brick or stone are placed inside the prepared recess to a height of 5 cm. The rods are evenly laid out on them. They can be twisted with tying wire to form a lattice. The concrete mixture is poured on top and compacted well. To ensure that it fills all the cavities, you can pierce it with a piece of reinforcement so that air bubbles rise to the surface. Using a spatula, the surface is leveled and usually brought to a horizontal level. The site for the wood boiler will gain full strength within two weeks.

Note! Such surface preparation will be needed if the floor in the room is leaky or if you plan to install a wood-burning heater with a large tank volume.

A sheet of galvanized metal or thick foil is mounted on the walls around the wood column. They will serve as reflectors that will prevent surfaces from overheating. The wood-burning column is placed in its place and secured to the prepared base using bolts and dowels. A chimney outlet is drawn. If there is a stove channel nearby, then you can take it directly there. But at the same time, everything needs to be calculated well so that there is no backdraft. The water supply is made, the mixer and the shower tube are fixed in place. Make sure that all threaded connections are tightly wound with tow. This is important so that boiling water from the wood boiler does not leak out.

Manufacturing and lining of the firebox

The most difficult task in producing a homemade Titan is rolling the steel sheet into a cylinder. With a significant thickness of the metal, this is not so easy to do; the parts must be welded without stress, because when exposed to high temperatures, the strength characteristics of the weld are greatly reduced.

Initially, you should select the expected internal diameter of the firebox in the range of 50–70 cm and cut two disks to this size . According to the diameter, the circumference is calculated, and a strip is cut out of it from the sheet, from which the walls of the combustion block will be formed. The height of the firebox, as already mentioned, is selected according to the volume of the tank: about 5 kW of heat is consumed to heat every 50 liters of water, which corresponds to approximately 1 kg of dry firewood. Thus, for a 200-liter heater, the firebox should freely accommodate 4 kg of firewood without taking into account the volume of the ash pan. The higher and narrower the heating column, the more efficient the heat transfer occurs, but the stability of the Titan decreases.

The cut steel sheet is laid horizontally, and two disks are installed vertically on its short edge. One is placed parallel to the long edge with a slight indentation - this disk forms the bottom of the combustion block. The second disk is installed parallel to the first with a distance of 20–25 cm from it - this is how a partition is formed between the firebox and the ash pan. You can immediately cut an opening in the partition, the size of which is 40–50 mm smaller than the existing grate.

Two disks act as a rigid mandrel for rolling the cylinder. First, they are welded to the strip on both sides with tacks 10–15 mm long, carefully monitoring the perpendicularity of the installation. Next, the metal is driven over the discs with a sledgehammer; if the metal thickness is more than 5 mm, heating with a propane torch may be required. When the two parts to be welded are pressed tightly, the perpendicularity of the disks is checked, after which the welding seam continues for another 10–15 mm and so on until it goes completely around the circumference. When the seam is completed to its full length, it is covered with another one: the electrode is drawn without separation with heating and surfacing of a wide area, the weld pool is displaced in a zigzag. After welding the discs to the wall, a longitudinal seam is welded on the outside.

When the firebox body is assembled, it is lined from the inside with fireclay bricks without any binder in the seams; the thickness of the lining is about 50–70 mm. To accurately adjust the stones to the size of the firebox, they are first placed vertically on a flat surface in a cylindrical well, the internal diameter of which is approximately equal to the diameter of the firebox . In this case, the bricks are located closely on the inside and with the most uniform indentation from each other on the outside, diverging in rays.

The distance between adjacent stones at the most extreme points must be divided in half and the bevels of the resulting size removed with a diamond wheel, achieving a wedge-shaped shape. After this, the bricks are installed against the walls of the firebox from the inside; if necessary, they are adjusted to each other using an angle grinder. The stability of the lining can be ensured with the help of a steel strip rolled into a ring and installed from the inside. After lining the walls, a grate is placed inside.

Do-it-yourself wood-burning heater

The design of a wood-burning heater is quite simple, so you can make it yourself at home. This will require skills in working with a welding machine, as well as other power tools. You will need the following materials and tools to make a wood-burning stove:

- Bulgarian;

- roulette;

- welding machine;

- marking tool;

- metal pipe ½”;

- metal couplings with ½” internal thread;

- grate;

- a ready-made tank or two gas cylinders;

- chimney pipe;

- Sheet steel.

The first step in making a wood-burning boiler is making the tank. You need to take two gas cylinders, unscrew the locking mechanisms and let them stand for several days in the fresh air. Using a grinder, the bottom of one and the other product is cut off. This results in two forecastle tanks for the future wood-burning boiler. Now a hole is made at the end in the middle of each element through which the chimney pipe in the future wood-burning boiler will pass. Two parts of the cylinders are welded together to form a tank. A piece of pipe is placed inside so that it protrudes slightly from above. The seams are well welded using a welding machine.

A hole with a diameter of 15 mm is drilled in the upper part of the cylinder for a wood boiler. A coupling with a ½” internal thread is welded onto it. This will be the outlet for the shower pipe. Another hole is made just below the middle of the cylinder. A tee is mounted to it, through which cold water will be supplied, and a mixer for the wood-burning boiler will also be attached there. The shower pipe is fixed into a coupling fixed at the top and part of it is lowered to the mixer so that it also contains hot water.

The firebox for a wood boiler is made from sheet metal. It can be made square. Height is approximately 50 cm. The bottom of the firebox for the wood-burning column is covered with a sheet of metal. The grate bars are fixed at a height of 20 cm from it. A round hole is made in the upper part of the firebox, which will serve as a mounting hole for the prepared tank. Legs made of reinforcement are attached to the bottom of the firebox for the wood column. A tank is placed on top and boiled around the perimeter. The next step is to secure the doors and install them in place.

This version of the wood-burning column design is provided as a basis. You can vary the materials, the main thing is that the basic principle of assembly is clear. Below you can watch a video of another boiler option. Having a wood-burning heater in your dacha is an excellent solution that will help you out in any circumstances and will allow you not only to always be clean, but also not to freeze on cold nights.

How the wood-burning "Titan" works

There is nothing tricky about how Titan works. This is an ordinary wood-burning stove, the lid and chimney of which have a water jacket. To facilitate the maintenance and assembly of a home-made structure, it is recommended to make the product modular.

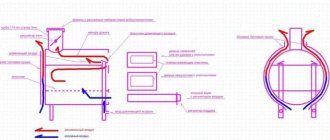

Wood-burning water heater structure: 1 - firebox; 2 - ash pan door; 3 - combustion door; 4 — cold water supply pipe; 5 - water tank; 6 — hot water intake pipe; 7 - chimney

The combustion block is a cylinder without a cover, divided into a combustion chamber and an ash pan by a massive grate. To reduce unnecessary heat loss and extend the service life of the metal, the inside of the firebox is lined with fireclay bricks. Apart from the ash pan doors and the firebox with a specially shaped porch, there is nothing remarkable in the design of the combustion unit.

Hot gases, rising through the chimney, give off heat to the water inside the tank, while heating occurs mainly in the lower zone, which forces the liquid to circulate and mix. To ensure heat transfer is as efficient as possible, the chimney pipe is equipped with radiator fins. It is also important to maintain the tightness of the tank without slowing down the transfer of heat from the combustion chamber. For this reason, the tank is welded as a solid container, which is “put on” on top of the firebox glass to form a double rebate around the perimeter.

Laying out the oven from bricks

If you have some practical experience in building brick stoves, try building a large sauna stove with your own hands. We offer a stove-heater option with dimensions of 102 x 129 cm, equipped with a 170-liter tank and designed to heat a bathhouse with an area of 12 m².

To build the stove shown in the drawing, prepare a set of materials:

- solid clay brick (red) – 580 pcs.;

- fireclay stone grade ША-8 – 80 pcs.;

- cast iron grates measuring 30 x 25 cm - 2 grates;

- main door for loading firewood – 210 x 250 mm;

- ash chamber door – 14 x 25 cm;

- smoke damper – 320 x 450 mm;

- heater door – 51 x 42 cm;

- steel pipe with a diameter of 57 x 4 mm - 6.3 m;

- iron strip with a cross section of 40 x 5 mm - 2 m;

- the same, size 80 x 10 mm - 2.5 m;

- basalt cardboard, roofing felt.

Note. The list did not include the brick required for the construction of the chimney, cement, clay and sand for mixing the mortar.

Also, before construction, you need to weld a tank-boiler with dimensions of 102 x 77 x 25 cm from sheet steel grade St20 with a thickness of at least 3 mm. We will not outline the technology for installing a reinforced concrete foundation, preparing mortar and stove masonry - it is described in detail in the instructions for constructing a fireplace.

Let's move on to building the furnace according to the presented procedures:

- The zero and first rows are laid in a continuous line. Tiers 2 and 3 form an ash pit, and a blower door is installed.

- Row No. 4, covering the door, is the bottom of the fuel chamber, partially lined with fire-resistant stones with a gap of 5 mm from red bricks. Trimming is done, a grate and a loading door are inserted.

- When laying tiers 5-9, the walls of the firebox are built. On the 10th row, cells are prepared for pipes, cut into pieces 1050 mm long. These parts are placed in nests and sealed with basalt cardboard, and a water container is installed.

- From the 11th to the 20th tier, the furnace walls are built around the tank. On the 20th row, the end of the boiler is covered with two steel strips L = 35 cm.

- The heater door is installed on the 21st row, and the laying of the outer walls continues according to the scheme up to the 26th tier. On top of the door we place 2 strips 650 mm long.

- On the 27th row, the stove overlap begins to form. Cutouts are made for laying large strips 120 cm long. Bricks of the 28th tier cover the cavity of the heater, leaving a chimney opening.

- The flue valve is installed on the 28th row, tiers 29-32 finally form the stove vault and the transition to the chimney.

Six jumpers in the form of Ø57 mm pipes serve as supports for the future array of stones and at the same time serve as convective air heaters in the sauna. After 2-3 days, when the solution has dried thoroughly, you need to eliminate the defects, load the heater and begin test lighting. For a detailed description of the masonry in rows, see the next video:

Making a steel stove-stove

The construction of a homemade sauna stove with a built-in heater and water tank is shown in the drawing. The design is quite simple - the body of the heat generator, made of an iron pipe, is divided into 4 compartments - an ash chamber, a firebox, a heater and a water heating tank. At the bottom of the firebox there are grates, between the remaining sections there are metal partitions crossed by a chimney.

The following materials will be used to manufacture the heater:

- pipe with a diameter of 400-500 mm;

- sheet metal 3 and 5 mm thick for partitions;

- fittings or corners for the grate;

- pipe Ø10-15 cm for the chimney.

Advice. For the body, it is advisable to find a thin-walled pipe (3-5 mm), since standard rolled metal with a wall thickness of 8-10 mm will be too heavy. The height of the stove can be adjusted due to the size of the heater, tank and firebox.

The procedure for assembling a heat generator with an integrated tank:

- Align the ends of the pipe with a grinder, cut openings for loading hatches and doors. Treat sharp edges.

- Place the cut pieces of metal on the doors - clean the edges, weld the handles and hinges.

- Make round partitions with holes for the flue. Make the firebox vault from 5 mm thick steel, the remaining covers from 3 mm sheets.

- Weld the grates from reinforcement Ø12-18 mm or angles No. 4-4.5.

- Mount all workpieces according to the drawing. Clean the welding seams and check for permeability using kerosene.

Equip the tank located on top with a convenient lid, cut a fitting into the bottom of the container and install a drain valve. It is better to reinforce the junction of the chimney and the firebox roof with stiffening ribs made of metal triangles, since this place burns out first. How to properly make such a stove, see the latest video:

Installation and use rules

The wood-burning water heater must be installed on a solid, non-combustible base. The fireproof substrate should protrude 15 cm in each direction from the column profile and at least 50 cm from the side of the combustion door. The column should be installed no closer than 15 cm to walls with non-combustible coating and no closer than 50 cm to flammable finishing.

Titanium can only be ignited when completely filled. In this case, an air pocket is formed in the part of the tank located above the hot water intake pipe, which acts as a damper in case the liquid boils. The procedure for preparing the tank for operation is as follows:

- The firebox is being ignited.

- The ash pan door is kept open until the flame engulfs the entire volume of fuel.

- After the fuel is ignited, the ash pan closes. The damper regulates the air supply so that the chimney outlet is only noticeably warm.

- If the characteristic noise of boiling water appears in the tank, the blower damper closes completely.

- After complete combustion of the fuel, the chimney damper is closed.

published

PS And remember, just by changing your consumption, we are changing the world together! © econet