Professional installation, high-quality materials and a well-thought-out design of heating communications do not guarantee heat in the house if the heating system does not have a small part for bleeding air. The problem of airy cold radiators is familiar to both residents of multi-storey buildings and the owners of a private mansion. To avoid this, an air valve is installed for the heating system.

Types of air vents and their installation locations

Air vents are manual and automatic. Manual air vents or Mayevsky taps are small in size. They are usually installed on the end of the heating radiator. The Mayevsky tap is adjusted using a wrench, a screwdriver, or even manually. Since the faucet is small, its performance is low, so it is used only for local elimination of air locks in the heating system.

Air vents for the heating system are of two types: manual (Mayevsky tap) and automatic (work without human intervention).

The second type of air vents - automatic - operate without human intervention. They are installed both vertically and horizontally. They have high performance, but are quite sensitive to contaminants in water, so they are installed together with filters on both supply and return pipelines.

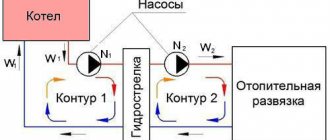

Automatic air vents are installed in closed heating systems along the pipeline line at different points. Then air is released from each group of devices separately. A multi-stage deaeration system is considered the most effective. With proper laying and proper installation of pipes (at the required slope), removing air through air vents will be simple and hassle-free. Removing air from heating pipes is associated with an increase in coolant flow, as well as an increase in pressure in them. A drop in water pressure indicates a violation of the tightness of the system, and temperature changes indicate the presence of air in the heating radiators.

Air valves and radiator fittings

Almost all modern radiators provide the possibility of installing Mayevsky manual valves for air discharge. Some manufacturers even complete their products with them. If desired, instead of a manual air vent, you can install an automatic one, but in practice it does not look very presentable.

Recently, laying heating lines below floor level and using radiators with bottom connections has become increasingly popular. Then there remains a small gap between the battery and the floor, where it is not always possible to place any fittings. For this case, there is a special connection headset with built-in taps, shown in the picture (left):

On the right is a headset for the bottom connection of a conventional radiator with side plugs; it also has valves plus the ability to connect a thermal head. Such solutions look very aesthetically pleasing, but will require maximum financial costs. More information about the headset is shown in the video:

Why is an air lock in the radiator dangerous?

If there is air in the battery, nothing good will come from it.

Excess air is an obstacle to the normal functioning of the system. It can also cause corrosion on the walls of the radiator. If a circulation pump is installed in the circuit. an air lock can also disrupt its operation. When the system is functioning correctly, the plain bearings on the shaft of the pump unit are constantly in the water. And if there is air, a “dry friction” effect occurs, which negatively affects the sliding rings and can damage the shaft

Therefore, it is important to know how to remove air from your home heating system. Timely measures will help prevent damage to the heating network

What problems can an air vent solve?

When moving along the circuit, the coolant chooses the path of least resistance, and since the airy areas are a serious obstacle to the passage of heated water from the boiler, the batteries with accumulations of air mass remain cold or only partially warm up. In addition to the fact that this phenomenon worsens the quality of heating, it also has a detrimental effect on the performance of all elements connected to the circuit.

If the heating system does not use a valve on the heating radiator to bleed air, then the owner can expect the following troubles:

- failure of the boiler as a result of overheating of the heat exchanger;

- corrosion of heating devices;

- low radiator temperature when the boiler is operating at peak performance;

- the risk of defrosting an individual radiator or an entire circuit in severe frosts;

- sudden pressure surges in the circuit, leading to leaks and damage to the integrity of heating devices.

It is worth understanding that air in the circuit is a serious nuisance. You can find out how to get rid of air in the circuit in our article “How to properly bleed air from a heating radiator?” It has different physical properties from water - when heated, it expands more and faster. This leads to serious emergency situations.

Knowing how to properly ventilate the heating system, the owner will protect himself from unnecessary hassle and costs, and will take the level of reliability of the heating circuit to a new level.

Bleeding air through the plug

If there are no taps on the heating devices, a problem such as an air lock in the home heating system becomes much more complicated. You will need to unscrew one of the plugs.

For these purposes, you should prepare a large adjustable wrench. You need to place a container under the plug. Next, the key grabs the plug and turns it very carefully. It is unacceptable to completely unscrew the plug, since there may be high pressure in the heating system, the coolant will go straight into the room with high pressure, and it will be problematic to cope with the current situation

That is why the plug should be turned with extreme caution. It is advisable to first turn off all available equipment in the room and close window and door openings tightly. While turning the plug, you need to listen

If a slight hissing noise appears, do not turn the plug any further. At this moment you need to stop and put the key aside. Now you should wait until the excess air from the heating device gradually but completely leaves the system. It is very simple to determine that the plug in the heating system has come out - liquid will begin to leak from under the plug. Then, using a large adjustable wrench, you need to smoothly and carefully return the plug to its original position.

Tips and tricks

As you know, the more complex the equipment, the higher its cost, while such a device is less reliable. Therefore, in order for the hydrofloor to work properly, you need to buy and install high-quality components.

Today there is a huge range of kits for installing water floors on the market. When choosing, you should carefully read their characteristics and features.

You can use a mechanically driven device, which is reasonably priced. In addition, the operation has been proven by many years of practice, so it rarely breaks down. Devices with a sulfur drive are more expensive, and there are more elements that can fail in this design.

When choosing a device for bleeding air, experts recommend paying attention to Mayevsky taps - they are reliable, durable and do not need adjustment.

Automatic devices have a more complex design and are more expensive. In addition, they become unusable when dirty.

As you can see, air locks lead to malfunctions, but this problem is easy to solve. The main thing is to bleed the air from the pipeline in time, and this must be done correctly and regularly.

Types of air vents

Valves for removing air locks are automatic and manual. The second type of air vents includes Mayevsky taps. They are used not only to remove air, but also to start it up in order to drain the coolant from the system.

Mayevsky crane

This device is made of brass and has a simple but reliable design. The main parts of the Mayevsky crane are the body and the screw. All valve parts are located as closely as possible to each other, so that the coolant cannot escape outside. Open the tap using a special key, screwdriver or hand.

Before removing air from the heating system, it is necessary to prepare a container for the coolant and tools. Step-by-step instructions for removing air pockets using a Mayevsky crane:

- If the heating system operates using a circulation pump, it should be turned off while the air is being vented.

- Using a wrench, screwdriver or hand, turn the tap 1 turn counterclockwise. You will immediately hear the hiss of air escaping from the radiator.

- As soon as the coolant begins to flow out, it means that the air lock has been removed, the Mayevsky valve is closed back.

Automatic air vent

Automatic air vent VALTEC VT.502

This device independently removes air from the heating system. Installs either vertically or horizontally. Consists of a brass body, float, release valve and articulated arm. To prevent coolant from leaking through it, the air vent is equipped with a protective cap.

Note! Automatic devices are sensitive to impurities contained in water. For long-term operation, cleaning filters are additionally installed in the heating system.

The operating principle is as follows: if there is no air in the chamber, then the outlet valve is closed. As it moves in, the float lowers. Once the chamber is completely filled, the exhaust valve opens and the air is discharged outside. The float then closes the outlet valve again.

Air separator

This device consists of a metal body, an air vent, a drain valve and a tube with a mesh. Unlike conventional air vents, the separator itself removes air from the water. As the coolant passes through the mesh, it swirls, causing air bubbles to form. As a result, they rise to the top, and the gases are removed through the air vent. In addition to air, the separator separates sand, rust and other impurities. Remove sludge through a drain valve located outside at the bottom of the housing.

Installation recommendations

Regardless of the type of automatic air intake for heating, you need to ensure that the exhaust cap faces up during installation. Bleed valves in systems are usually installed after ball valves or shut-off valves. An exception to the rule is the boiler safety group: secondary intermediate fittings are not used in this case.

Thanks to the shut-off check valve, it becomes possible to carry out maintenance or replacement of the air vent without emptying the entire heating system. Therefore, having such a device is very convenient. Only wrenches are suitable for installing an automatic bleeder: they, unlike adjustable ones, allow you to measure the effort required to screw the fastener. During installation work, it is not recommended to hold the device by the body to avoid damage. For these purposes, the design provides a hexagon at the bottom of the cylindrical chamber.

What are air vents and what are they for?

Many owners of radiator systems have encountered a situation where, with hot pipes, some parts of the radiator do not heat well or are generally cold; similar problems arise with insulation with water floors. The main reason for this phenomenon is the presence of air in the pipes, which rises and impedes the movement of the coolant.

If in an open circuit air bubbles are sent to an unclosed expansion tank located on high floors of a building or attic, and bleeding is not so important, then in a closed system an air bleeder for the heating system is vital on all circuits and individual heat exchange devices.

When plugs interfere with the operation of the system, manual or automatic heating drain valves are used to remove accumulated air. One of the simplest devices is a regular valve installed at the top point of heating radiators. To bleed air from the batteries, open the valve and wait for the moment when the stream stops flowing jerkily along with the air - in radiators without air, the water flow will be uniform.

In individual heating lines of private houses, instead of ordinary valves, special locks are installed on the radiators, which function automatically or are manually adjusted. With their help, they remove not only air from devices in which gas formation occurs, but also, when necessary, oxygen from water, which causes accelerated corrosion of metal fittings.

Rice. 2 Air vent for venting air from the heating system - design

How the device works

An air valve (or several) is installed in the heating system, in places where air bubbles are most likely to accumulate. This prevents the formation of a large traffic jam and the heating operates uninterruptedly.

Mayevsky crane

Such devices are named after the name of their developer. The Mayevsky tap has a thread and dimensions for a pipe with a diameter of 15 mm or 20 mm. It's structured simply:

- There are 2 through holes made in the body of the valve body, which in the open position of the Mayevsky tap communicate with the heating system.

- These holes are closed by a threaded screw with a conical tip.

- Air is released through a small (2 mm) hole directed upward.

In order to bleed air from the system, unscrew the screw 1.5-2 turns. The air escapes with a whistle as the communications are under pressure. The end of the air plug exit is characterized by a drop in pressure and the appearance of water.

Note! The Mayevsky crane is a simple and reliable device for bleeding off air accumulations. It does not clog or break because it has no moving parts. Its design is simple and reliable.

On the market you can find several varieties of the Mayevsky tap, which are identical in design, but differ in the way they regulate the shut-off screw. There are:

- with a convenient handle for unscrewing by hand;

- with a regular head for a flat screwdriver;

- with a square head for a special key.

For an adult, the principle of unscrewing the locking screw does not matter. However, in a house where there are children, it is safer to use devices that should be unscrewed with a special tool. By unscrewing a regular tap with a comfortable handle, a child can be scalded by boiling water.

Automatic crane

The automatic air release valve is designed on the principle of a float chamber, the design includes:

- vertical housing with a diameter of 15 mm;

- float inside the housing;

- a spring valve with a cover, which is connected and adjusted by a float.

The automatic air valve for the heating system operates without human intervention. In normal condition, when there is no air in the system, the float is pressed by the pressure of the liquid filler to the valve cover. The lid is tightly closed.

As air accumulates in the valve body, the float moves down. As soon as it drops to a critical level, the spring valve opens and bleeds air out. Under the pressure of the carrier in the system, the space is again filled with liquid. The float rises, closing the spring valve cover.

When there is no coolant in the communications, the float lies at the bottom of the valve. As the system fills, air comes out of the tap in a continuous stream until the coolant reaches the float.

Note! A small amount of air is constantly present under the automatic faucet lid. This is the norm and does not affect work in any way.

The following configurations of automatic air valves for heating are distinguished:

- with vertical air discharge;

- with side air discharge (through a special jet);

- with bottom connection;

- with corner connection.

For an amateur, the design features of an automatic crane do not matter. However, for a professional there is a difference in choosing between devices.

- a device with a jet and a side hole is more reliable in operation than an automatic valve with vertical air discharge;

- a bottom-mounted valve traps air bubbles more effectively than a side-mounted valve.

If the design of the Mayevsky crane has not undergone changes for many years, the design of automatic valves is constantly being improved and supplemented.

Manufacturers offer automatic valves with additional devices:

- with a membrane to protect against water hammer;

- with a shut-off valve for easy dismantling of the device during the heating season;

- mini valves.

Note! The disadvantage of an automatic valve is its rapid contamination. Scale and debris clog the internal, moving parts of the device. This leads to a weakening of its efficiency or complete failure.

Automatic heating air valves require frequent inspection and cleaning. The undoubted advantages of these devices include the ability to install them in hard-to-reach places.

Causes and consequences of air locks in a closed heating system with forced circulation

The reasons are the same as for an open system, plus:

- A loose circulation pump impeller can “grab” air during operation;

- If hot water is supplied to the expansion tank from above, then air can enter the system through cracks or breaks in the tank membrane.

An air lock in a closed circuit will lead to increased pressure in the system and activation of the safety valve. The valve will bleed water over and over again until the boiler burns out or the heating pipes rupture. Therefore, security requirements for closed systems are much stricter. In particular, for air release, the closed circuit is equipped not only with manual Mayevsky valves, but also with automatic air vents. One of these automatic valves is included in the safety group. The group is placed on the water supply, immediately after the boiler.

Important! A leaky pipeline or radiator cannot cause an air lock. A working system, whether closed or open, is under pressure

The air will never go towards higher pressure - this contradicts all the laws of physics.

Features of installing an air vent in a private house

You will need a wrench for installation.

An air vent designed for heating communications in a private home must be installed strictly in a vertical position. For installation work you will need a threaded tee, FUM tape, and an open-end wrench.

The installation process is carried out in stages:

- Tee fastening. You will need a piece of pipe onto which a tee is fixed by soldering, glue or simple shrinkage.

- Preliminary check of the location of the vent at the highest point of the equipment. The device connection must have an upward direction.

- Installing the shut-off valve on the hexagon of the device using an open-end wrench.

- Connect the automatic air vent so that the protective cap with nipple faces upward.

- Screw the cap tightly to prevent debris from accumulating.

- Checking the tilt of the device (for radiator models). The battery section with the drain rises slightly.

After installation, the devices do not need to be adjusted - they will bleed air automatically.

Features of a multi-stage scheme

The multi-stage deaeration scheme provides for the installation of automatic devices along the entire line. Connecting the vents in this way allows you to locally and simultaneously remove air pockets. The automatic device is placed in the zone of rotation, formation of a loop. To extend the service life of the valve, an additional filter is installed. Once assembled, the system operates with the radiator hot at the bottom but cold at the top.

In two-story houses, installation of diverter devices must be carried out on the top floor.

A corner, straight or radiator vent is suitable for the heating main of an apartment building or private building. The automatic device is simple, reliable and maintainable. After installing it, the owner does not have to waste time monitoring the system and manually bleeding air.

Air removal methods

There are heating systems with forced and natural circulation of coolant. In the first case, the liquid flows using a circulation pump, and in the second, due to a certain inclination of the pipes and the pressure in them.

Natural circulation systems

An expansion tank is used to remove air from this type of system. It is installed at its highest point. Most of the air is independently removed through it when the coolant is heated. If air pockets still remain, many experts recommend increasing the amount of fluid in the system by opening the air vents. Thus, the coolant itself will displace the air from the network with movement and pressure.

Forced circulation systems

In systems with a circulation pump, pipes and radiators are located level and without slope. Air vents are used to remove air from them. They are always mounted at the bends and at its highest points, since this is where the accumulation of gases occurs.

Note! If it is not possible to remove air from the system using air vents, then it is necessary to drain all the coolant and refill it. The coolant must be poured into the system slowly, as rapid filling will cause air bubbles to form.

At the same time, you need to remove air from radiators and other elements. The longer the system, the longer it takes to fill it with coolant. If a heated floor is connected to the heating network, then the installation of air vents is mandatory, since the pipes are often located at different heights. You also need to constantly monitor the amount of coolant in the system to exclude the possibility of air getting into it

It is necessary to pour the coolant into the system slowly, since rapid filling causes air bubbles to form. At the same time, you need to remove air from radiators and other elements. The longer the system, the longer it takes to fill it with coolant. If a heated floor is connected to the heating network, then the installation of air vents is mandatory, since the pipes are often located at different heights. You also need to constantly monitor the amount of coolant in the system to exclude the possibility of air getting into it.

What to do if the air vent does not work

Air vent malfunctions often occur when air is not released from the system. This happens because the drain hole becomes clogged with scale. From time to time it needs to be freed from scale and rust.

To do this, unscrew it, first closing it off from the environment with shut-off valves and draining the water from the repair section of the pipeline

Next, the valve is removed, disassembled, and the needle is carefully cleaned. After cleaning is completed, seal the housing parts and reinstall them

In order to prevent clogging of the automatic vent, experts recommend installing a Valtek filter to purify network water. For dismountable structures, there is often a leak through the seal between the body and the head.

It is almost impossible to replace it, since such seals are not sold in the retail chain, so if such a problem occurs, it is better to use fum tape or silicone sealant. The cause of the leak may be a misalignment of the float; it is easy to fix it yourself.

Thus, we can summarize that the air vent is a mandatory element of any heating system, both central and individual, its installation is in accordance with the current rules. Automatic air vents are used to continuously remove air pockets without operator intervention.

Why does air appear in the heating system?

Many of our compatriots are familiar with the concept of “air jams”. This phenomenon is remembered at the beginning of the heating season, when heat is allowed into houses, but in apartments on the upper floors the radiators often do not heat up or only heat up in the lower part, and are absolutely cold in the upper part. Where does air come from in pipelines? There can be several reasons for airing:

- carrying out repair work (assembly, disassembly of the pipeline), during which the appearance of air is inevitable;

- non-compliance during installation with the magnitude and direction of the slope of pipelines;

- low pressure in the water supply. the water level drops, and the resulting voids are filled with air;

- when water is heated, bubbles of air contained in it are released and rise to the upper part of the pipeline, creating air jams there;

- the heating system is not filled correctly: after a summer period of inactivity, the pipes should be filled with water not quickly, but slowly, while simultaneously bleeding air from the heating system;

- unsatisfactorily sealed pipeline joints through which coolant leaks. Leaks in these places are hardly noticeable, since the hot water immediately evaporates. It is through loose seams that air is sucked into the system;

- malfunction of air intake devices;

- connecting a water “warm floor” to a heating system, the pipes of which are located at different heights during installation.

Causes of air

The logical question is: how does air get into the heating system if it is completely sealed?

There can be many reasons for this phenomenon:

- High blood pressure. Water contains not only magnesium and calcium, but also oxygen. The volume of oxygen depends on the pressure level in the system. As pressure increases, the concentration of oxygen in water increases.

- Violation of requirements for pipe slopes during installation work.

- Incorrect filling of the pipeline, leading to air congestion. Water should be supplied slowly while air is pumped out of the batteries, right? otherwise, the formation of bubbles is inevitable, which causes airing of the heating system. The general rule is: the more branches a system has, the slower its filling should occur.

- Diffusion. This phenomenon is a process during which the ability of molecules of one substance to penetrate between the molecules of another is realized. In the described case, we mean the penetration of oxygen molecules between the molecules of polypropylene or polyethylene. To prevent diffusion, special coatings are applied to the pipe material.

- Insufficient connection density between system elements.

- Faulty or missing air vents.

- Carrying out repair work during which depressurization occurred.

- Corrosive processes leading to violation of the tightness of equipment.

The above factors do not exhaust the reasons that cause air in the heating system, but they are the most common.

Heating air vent

Design, principle of operation of the air vent

But in addition to radiators, situations often arise when it is necessary to expel an air lock from the heating system in the pipes. To do this, it is necessary to install air vents in certain sections of the pipeline. Their design is in many ways similar to the Mayevsky automatic cranes described. However, there are significant differences - they are designed for the largest volume of air released and are installed not horizontally, but vertically.

In order to remove the resulting air lock from the heating system, you first need to install air vents in the right places:

- At the highest point of the highway. For an open system, this is only possible if a sealed expansion tank is installed on the return pipe;

- In collector heating - on each comb;

- For tee wiring - before each branching node of the main line.

After installation, it is necessary to correctly set the pressure value at which the air vent will operate. To remove an air lock from the heating system, coolant is pumped into the pipes until the air vent on the return line operates.

When removing an air lock in an autonomous heating system, you need to reduce the temperature of the coolant to a minimum. This will reduce the volume of water and will help resolve the problem more effectively.

In combination with the functional qualities of Mayevsky taps, this makes it possible to effectively break through any plug in the heating

It is important that the response parameters of the devices do not exceed the critical pressure value. Otherwise, the security of the system may be at risk

The video shows an example of venting a heating radiator:

How to choose an air vent: expert advice

- The Mayevsky crane works effectively only in a place where air naturally accumulates. It cannot independently capture air bubbles in the passing flow, since it is not equipped with an air chamber. When installing a tap into a water supply system, it is additionally worth installing an air chamber. To do this, just install the pipe.

- It is worth paying attention to trusted manufacturers. You should not trust Chinese products: with a low price and attractive appearance, such devices do not last long and cannot be repaired.

- When purchasing a device, do not neglect designs with an additional cut-off device, which will allow you to remove the faucet at any time without turning off the system.

Before purchasing, it is better to study the tables with characteristics provided by heating equipment manufacturers.

Why are there taps on radiators?

Each heating device is a separate element of the system that requires adjustment and periodic maintenance. If you control the coolant flow through the batteries depending on the heat demand, you can achieve good results in terms of energy savings. That is, radiator valves and heating taps are designed to solve the following problems:

- Complete isolation of the heating device from the system.

- Restriction of coolant flow through the battery.

- Change in coolant flow depending on external conditions.

- Bleeding air from the radiator and piping network.

There are many situations in which it is difficult to do without disconnecting the battery. For example, properly working central heating in the middle of spring, when it’s already warm outside, but it’s just hot in the apartment. Another case is the need to remove a heating device for the purpose of replacement, flushing or repair. In the absence of shut-off valves, carrying out any action with the radiator becomes problematic.

Valves are also installed on batteries in retro style

Restriction of the flowing coolant is carried out in order to balance individual heating in a private house or apartment

No matter what type of heating system you have, without balancing with valves, the first radiators will always receive more water than the last ones. Limiting the coolant flow at the beginning of the network and thereby balancing all devices with each other is the task of the control radiator fittings

Automatic control of the flow of incoming coolant is a way to save energy used to heat the house. If each tap on the heating radiator maintains the set air temperature in the room by controlling the flow of water through the radiator, then in general the system will consume only the required amount of heat, no more. And this is a considerable saving.

Well, the problem of air release when filling the system or during operation is also solved by special air valves installed on all modern radiators. Below is a list of types of shut-off and control valves, listed in the same order as the tasks they solve:

- Half-turn ball valves in straight and angle versions. Made from brass, bronze or polypropylene with a metal insert.

- Balancing valves for radiators – straight and angular.

- Regulating valves with thermal heads (thermostatic valves).

- Air drain valves – automatic and manual.

For reference. Some home craftsmen use three-way mixing valves to connect heating appliances. But such a solution is unreasonably expensive and is rarely used in practice.

Now we should consider in detail which taps are best installed on radiators in various conditions and circumstances. Some options are clearly shown in the video:

Ball

Sewage flooding is especially likely in high-rise buildings, where several apartments are located on one vertical pipe. Even one plastic bag may be enough to clog the riser, and then yes, not finding its way, will rush back, splashing out of all the drain holes. This situation is especially likely in old houses, where the pipes are covered on the inside with thick crusts of deposits.

The risk of backflow of waste water is especially high in apartments on the ground floor. Often at night in such apartments it is necessary to plug the drains with rags, plugs and other improvised plugs. But if valves are installed on the first floors, water can break through on the second floor. Up to the third floors, the pressure is usually not enough, and if it is strong enough, it will simply destroy the blockage and the water will go into the pipe.

So, it’s worth installing a check valve if:

- Your apartment is located on the first or second floor.

- You live in an individual home: a cottage, a dacha, a private house.

- The house was built a long time ago and there has been no major repair of the sewer system or replacement of risers.

- According to neighbors, there are frequent cases of sewer blockages in the house.

Automatic vent valve for heating system

A heating system with a liquid coolant uses a number of specialized elements to ensure reliability and efficiency of its operation. These include an air valve (separator) for heating. A device for releasing air from the heating system makes it possible to remove gases accumulated in the pipeline and radiators.

When an air plug forms in the pipeline, it tends to the highest point of the radiator or the heating circuit as a whole. If an automatic air release valve is installed in this place, the coolant from its internal chamber is displaced by gases.

When the liquid is displaced, the float moves down and opens the valve, as a result of which gases are released from the heating pipeline, and the chamber is again filled with coolant.

The valve for automatically releasing air from the heating system becomes silted over time and becomes overgrown with scale. This leads to jamming of the mechanism, loss of tightness of the valve - moisture begins to seep through it. Such a device requires replacement - automatic air vents cannot be repaired.

The number of automatic air vents depends on the characteristics of the heating system.

- Device required for installation:

- as part of the safety group of the boiler unit at the outlet pipe of the water jacket, where the coolant is heated to the maximum temperature;

- at the highest point of vertical risers - this is where gaseous substances rise and accumulate;

- on the distribution manifolds of underfloor heating so that air can be vented from the circuits;

- on U-shaped loops made of polymer pipes, which are installed to compensate for the thermal expansion of the pipeline.

Selection principles

Air valves for the heating system can be part of a safety group or a manifold kit for a heated floor, supplied with heating appliances.

The car air vent is selected taking into account its operating parameters (maximum permissible temperature and pressure), they must correspond to the characteristics of the heating system. Based on their design, they are divided into straight and angular devices, horizontal and vertical.

- Mayevsky cranes differ in the way they unscrew the working screw:

- with a rod head for a special key (the inconvenience is that the key may not be at hand at the right time);

- with a non-removable handle (cannot be used in places accessible to young children to avoid the risk of burns from heated coolant;

- with a slot for a flat-head screwdriver (the most convenient and safest option).

To equip your heating system with a reliable air release valve, it is recommended to choose products from well-known brands. You should avoid cheap products made from fragile silumin that imitates brass.

Why is air in a heating system dangerous?

Air dissolved in the coolant gradually damages steel pipes and radiators and elements of the boiler unit. The corrosive activity of air, which was first dissolved in water and then released during heating, significantly exceeds that of atmospheric air due to the increased oxygen content.

Gases accumulated in the pipeline not only provoke or accelerate corrosion of metal elements, but also form air locks that prevent the heating system from functioning fully: Due to gas locks, the circulation of the coolant worsens; in serious cases, the movement of liquid through the pipes can be completely blocked. In such a situation, heating devices quickly cool down. Air pockets act as a heat insulator, and if gases have accumulated in the upper part of the battery, it warms up worse and transfers less thermal energy to the room. If there are air pockets, the movement of the coolant along the heating circuit is accompanied by loud gurgling sounds and murmurs, which disrupts the acoustic comfort in the house.

Circulation pumps are not designed for pumping gases; when working with air-filled coolant, the bearing and impeller of the pump unit wear out much faster. Special air exhaust devices help solve problems associated with airing the heating system

It is important to choose the right valves for bleeding air and correctly determine the location of these elements.

https://youtube.com/watch?v=Q4LOLnuFOoc

Components of equipment

It is worth taking a closer look at the parts of the system that were mentioned above.

Disassembled crane

The operating principle is described in the air release instructions. The design of the Mayevsky crane is easier to study using this drawing. Such a miniature product is installed instead of a plug in the upper part of the collector comb. There is a carving in the central part. A screw is screwed in there, pressing the plastic seal.

To ensure the tightness of the connection, a rubber ring is used. All listed parts are included as standard with the product. No additional consumables are required for installation and operation.

The use of automated devices greatly simplifies the task. Without careful user control and additional settings, they are able to perform their functions over a long service life.

Automatic gas vent

Here is a schematic diagram of one of the devices in this category:

- The node (1) creates a rigid fastening of the rod (2) to the inside of the body with the desired angle. They regulate the opening level of the exhaust valve.

- During operation, air accumulates in the upper part. The float goes down. In a certain position, it will open the shut-off device, which will release the gas out.

- Next, the float rises to its original position, and the cycle repeats again.

- A soft seal (4) is installed in the lower part, ensuring the tightness of the connection.

Separator The following device performs similar functions more effectively:

- Here is an example of a flow separator. It is installed at the top point in the pipeline section using threaded connections (4, 5).

- A mesh (3) is fixed in the central part. When a stream of water passes through such a structure, air bubbles are released from it (2).

- They rush upward. The same unit is installed in this part as in the automatic gas vent. When the float drops below a certain level, the draft will open the valve (1) to release air to the outside.

- The cell sizes and other mesh parameters are selected so as not to create unnecessary obstacles to the movement of the coolant. However, this design traps rust particles (6). They accumulate at the bottom (7). There is a screw-on cap that can be opened to remove contaminants when performing routine maintenance.

Removing mechanical impurities reduces the load on different parts of the heating system. If you install a simple filter on the main water supply line, clogging of radiator ducts and boiler heat exchangers will be prevented. This will also extend the life of the valve jets of automatic air vents.

Balancing valve

The design of a valve for regulating heating differs from a conventional ball valve in that it can smoothly close the flow area in a few turns. Moreover, after balancing, the position of the valve can be fixed so that no one accidentally violates the settings. This type of control valves is installed at the outlet of the radiator, as shown in the diagram:

Shown here is the connection to a two-pipe horizontal system, most common in private houses and apartments with individual heating. By the way, the principle of installing fittings with a single-pipe scheme remains the same. A regular ball valve is installed on the supply line, and an adjustment valve is installed on the return line. In the case when a two-story house has a system with vertical risers, the installation diagram of the accompanying fittings looks like this:

The principle of product selection is the same as in the previous section

Straight or angular design is accepted depending on the layout of equipment and pipelines; it is also important to use American designs during assembly

Pay special attention to the quality of casting and the thickness of the brass walls of the fittings. If you have networks made of polypropylene pipes, do not rush to buy PPR taps; it is better to install adapters and reliable metal products

Advice. Balancing valves are installed on all radiators, except for the very last one, located at the dead end of the branch. It is enough to install simple ball valves on the connections to it.

Ways to combat system airiness

To remove air accumulated in heating pipes, special devices are used - air vents. They must be installed on each radiator. including steel, at the outlet of heating devices or at the highest points of the circuit, where released oxygen is concentrated.

You can find various modifications of such fittings on the market; the most common are devices made in Italy and Germany. With the same purpose, two fundamentally different types are distinguished.

Handheld devices

Mayevsky valves, or manual air vents, are used to discharge accumulated air in the circuit. They have a fairly simple design and consist of a screw that covers a needle-shaped hole in a brass body.

All parts of the device fit tightly and when closed do not allow coolant to pass through. Gases are released through a hole located in the side of the housing. Recently, fittings with metric threads have become more popular, which greatly simplifies their production. In various designs, adjustment can be made in several ways:

- unscrew with a screwdriver;

- open using a special square ICMA key;

- turn away with your hands.

Most often, manual taps are installed on radiators, screwed into the top hole. Such fittings are selected depending on the diameter.

Often these devices are installed on other devices. They are attached to heated towel rails using a tee. In two-story houses with top supply, all appliances located on the top floor must be equipped with Mayevsky taps.

After filling the system or before the heating season, it is necessary to bleed off the accumulated air. To do this, turn the hand tap counterclockwise and the oxygen leaves the device. Usually one turn is enough, but if a large volume of gases has accumulated, you can tighten the valve another half turn. It needs to be shut off when water begins to come out instead of gases. In systems with forced circulation, the pump is first turned off, and after a few minutes the accumulated gases are released. When the pump is running, it is impossible to collect all the air at the location where the valve is attached and the plug will not be removed.

Sometimes there are manual air vents not with a needle rod, but with a metal ball that blocks the hole for releasing oxygen. The design of the body may also differ, allowing installation of the crane both straight and at an angle.

Automatic valve

The operation of air vents, which operate automatically, is based on the float-valve principle. A float is installed in the brass body, connected by means of a lever to the outlet valve. The float constantly floats in the water, while the valve is closed. If air accumulates, the float lowers and opens the valve. The gas escapes into the atmosphere through a narrow opening between the float and the body.

Then the reverse process occurs. As air escapes, the housing is filled with coolant and the float rises, closing the valve. If the air vent breaks down, there is no leakage of liquid due to the presence of locking caps in the design. An automatic air vent is installed in the system through a special shut-off valve, which closes when the device is removed. This allows repair work to be carried out without draining water or releasing pressure.

https://youtube.com/watch?v=8PSjHc4kPcI

Such devices are installed at the highest points of the system and are located vertically. Most often they are installed in such critical places:

- on a heating boiler;

- at the top point of the riser;

- on collectors;

- on air separators.

Wider use is hampered by the low quality of process water. Small particles floating in the liquid clog the air vent and the equipment stops working. A fundamental change has been made to the design of AFRISO fittings:

- increased hole size;

- the outlet channel is located in the middle of the float.

This design allows the air vent to work more efficiently and regardless of the quality of the coolant, and its maintenance and cleaning have also been greatly simplified.

How to remove an air lock

Ideally, gases rise to the highest points of the circuit, where air vents are installed, and are released from there by valves operating in manual or automatic mode. In practice, errors in pipeline design or installation lead to the formation of air pockets in hard-to-reach places.

To remove such a plug, you need to find its location - by the murmur of coolant flowing through the air-filled area, by the relatively low temperature of the pipe or radiator, by the ringing sound when tapping the pipes.

Increasing the coolant temperature and/or pressure in the system will help remove the plug from the autonomous heating system. To apply pressure, it is necessary to open the make-up valve and the drain valve closest to the air lock (in the direction of flow). The water entering the system increases the pressure and causes the plug to move forward. After making sure that the plug has come out through the valve (it stops hissing), the system is returned to normal operating mode.

Removing an air lock from the heating system

In more complex cases, they are affected not only by pressure, but also by temperature. The coolant must not be heated above the maximum permissible values, so as not to damage the heating system.

Important! Regular formation of a plug in the same place indicates miscalculations in the project or incorrect installation. It is recommended to install an air vent in the problem area by cutting a tee into the pipeline

How does a heating air valve work and how to choose it?

Professional installation, high-quality materials and a well-thought-out design of heating communications do not guarantee heat in the house if the heating system does not have a small part for bleeding air. The problem of airy cold radiators is familiar to both residents of multi-storey buildings and the owners of a private mansion. To avoid this, an air valve is installed for the heating system.