Autonomous heating and hot water supply from your own boiler is the most preferable option for ensuring the temperature and climate conditions of a private home.

An important point is the optimal selection of heating equipment that provides comfort and coziness in the home and allows you to use resources economically.

A good option is the Baxi Eco Four 24 F gas boiler, which has a good set of parameters and high build quality.

Among other representatives of equipment of this class, these devices are distinguished by high performance at an average price range.

Let's take a closer look at this unit.

Description Baxi Eco Four 24 F

The brainchild of the Italian company Baxi, part of the BDR Thermea industrial group, the double-circuit wall-mounted gas boiler Baxi Eco Four 24 F is a 4th generation model.

The unit has the ability to simultaneously organize heating and circulation of coolant in the heating system and supply hot water for domestic needs . Continuous modulation (change of parameters) of the flame is carried out depending on external conditions, according to the signal from the external temperature sensor.

The case has a large and convenient LCD display that allows you to see all the displayed readings of the self-diagnosis system or current settings.

Experts and users note the high quality of assembly; all components are made either exclusively for this model or are samples from well-known European companies.

teplomex.ru

The mounted double-circuit gas heating boiler Baxi Eco Four 24 F , which we will review today, is one of the highest quality in the range of wall-mounted water heating units from this Italian manufacturer.

In order to verify this in more detail, we need to compare the technical characteristics of the Baxi EcoFor 24 F and prices, study the model’s operating instructions (passport), reviews from owners and specialists. In addition, we will pay attention not only to the advantages of the boiler, but also to its disadvantages, analyzing its main breakdowns, malfunctions and errors, as well as ways to eliminate them.

Baxi Eco Four boiler: operating instructions, features

The “Baxi Eco Four” series of gas boilers is a reliable wall-mounted gas heating device of the fourth generation in the “family” of Baxi brand boilers. The boiler of this series is distinguished by good build quality and the components and spare parts used. We look at the photo of the Baxi Eco Four 24F gas boiler.

Boiler Baxi Eco Four 24 F

The Italian company markets several modifications of Baxi Eco Four boilers: double-circuit and single-circuit, with an open and closed combustion chamber. In addition to all this, today the devices are produced in two types of power: 24 kW and 14 kW. Let's see what models the manufacturer offers us.

1. Double-circuit gas boilers (heating and hot water):

— Eco Four 24F; — Eco Four 24.

2. Single-circuit gas boilers (for heating only):

— Eco Four 1.24F; — Eco Four 1.24; — Eco Four 1.14F; — Eco Four 1.14.

The number in the abbreviation indicates the power of the device in kW, and the letter “F” means that the boiler is turbocharged, with a closed combustion chamber.

Baxi Eco Four 24F: installation of a double-circuit gas boiler

The most popular, judging by the reviews of owners and specialists, is the Baxi Eco Four 24 F model. This is a two-circuit mounted forced draft heating device with a power of 24 kW, capable of heating a private house with an area of up to 200-220 m2. It consists of several main elements characteristic of a modern wall-mounted gas boiler:

— two heat exchangers (copper for heating, stainless steel for hot water supply); — Grundfos two-speed circulation pump with automatic air vent; — Italian gas valve SIT 845; — Polidoro gas burner with stainless tips; — Honeywell electronic board; — brass three-way valve with electric servo drive; — expansion membrane tank with a volume of 6 liters.

As we can see, all the main elements of the Baksi Eco For 24 F gas boiler are produced by well-known companies, world leaders in their industry. In addition, all internal parts are made of brass: hydraulic group, supply pipes and gas part. The boilers are adapted to Russian frosts and are able to function even at very low gas pressure.

Design and principle of operation of the Baxi Eco Four boiler

The gas burner of the boiler has stainless steel nozzles and smooth flame modulation with smooth electronic ignition, as on all budget units from this manufacturer.

A specially developed system for automatically regulating air supply to the device is protected by a patent. Functions, control and safety

As with all models of fourth-generation Baksi boilers, on the front side of the wall-mounted unit “Eco Four 24 F” there is a control panel with an LCD display, which displays and sets settings and parameters, temperature in the heating circuit and DHW. In addition, error codes appear on it when malfunctions or malfunctions occur during the operation of the boiler.

The heating circuit of the Baxi Eco Four boiler can operate in two modes:

- traditional (30-85 °C); — warm floor (30-45 °C).

Like the boilers of the “Main Four” series, all “Baxi Eco Four” devices incorporate weather-dependent automation that helps the boiler operate depending on the temperature outside the window. All you need to do is buy an outdoor temperature sensor, install and connect it to the boiler.

Buying and connecting a room thermostat will also help save money, because the operation of the boiler, in this case, will depend on the set air temperature in the house or apartment.

Baxi Eco Four boiler control panel

“Baxi Eco Four 24 F” boilers are equipped with modern safety elements: a pneumatic relay (draft sensor) is activated when there is insufficient draft in the chimney, when the pressure in the heating system is low, a special pressure switch is activated, and when there is excess pressure, a 3 bar safety valve .

There are flame control sensors, temperature sensors on the heating circuit and running water, and a pressure gauge. The energy-saving circulation pump "Grundfos UP 15-50" automatically turns on once a day to prevent the three-way valve from blocking or jamming. This function is very useful when the heating device is idle for a long time and not used.

Also, the boilers of this series are equipped with a modern self-diagnosis system: the device itself periodically tests the operation and reports any problems on the LCD display. It is also possible to connect to bottled gas by first changing the gas injectors for liquefied gas.

Baxi Eco Four 24 F: technical characteristics of a gas boiler

The smoke removal system of the Eco For boiler is designed for a coaxial pipe with a diameter of 60/100 mm. When purchasing an adapter for separating chimney channels, it is possible to install aluminum pipes with a diameter of 80 mm. An atmospheric boiler with an open combustion chamber does not have a fan, and the diameter of its chimney pipe is 120 mm.

Heating and gas are connected to fittings with a thread diameter of 3/4′, the DHW circuit is 1/2′. The device has compact dimensions of 730/400/299 mm. The productivity of the boiler's hot water supply circuit is about 14 l/min, which is quite enough for the simultaneous operation of two water supply points: the kitchen and the bathroom. These and other technical characteristics are described in the table.

Baxi Eco Four 24F: technical characteristics of the boiler

Errors in the gas boiler Baxi Eco Four

E01 - the burner does not ignite. E02 - overheat protection sensor is triggered. E03 - traction pressure switch is faulty. E05 - the temperature sensor of the heating system circuit has tripped. E06 - malfunction of the temperature sensor of the DHW circuit. E10 - insufficient pressure in the heating system. E25/26 - there is no circulation in the heating system due to the pump being blocked. E35 - false flame. E96 - insufficient voltage in the electrical network.

Advantages of the Baxi Eco Four 24F gas boiler:

— European assembly; — two heat exchangers; — good quality of components and main components; — modern security system; — the ability to connect a room thermostat and an outdoor temperature sensor; — a network of service centers throughout the country.

Disadvantages of the Baxi Eco Four 24 F gas boiler:

— high price from 37,000 rubles; — expensive spare parts; — small volume of expansion tank 6 liters; — the electronic board is sensitive to power surges.

Today we left a review on the popular double-circuit wall-mounted heating boiler model - Baxi Eco Four 24 F , technical characteristics, device according to the operating instructions. Reviews from owners and specialists are quite contradictory, but the undoubted advantage of the EcoFor series devices is the presence in them of two separate heat exchangers, a brass hydraulic group and a Grundfos brand pump. Let's watch the video.

Model features

The double-circuit boiler Baxi Eco Four 24 F (Baxi Ecofor 24 F) has a closed (turbocharged) combustion chamber. This is evidenced by the presence of the letter “F” in the name. There is a separate heat exchanger, the primary one (for heating the heating system coolant) is made of copper, the secondary one is plate-type, made of stainless steel.

The boiler power is 24 kW, which allows servicing an area of 240 m2. (in practice, it is recommended to calculate the capabilities of the unit for 200-220 m2).

The hydraulic group, gas part and all supply pipes are made of brass, resistant to corrosion or other external influences.

What functions does it have?

The boiler functionality includes the following features:

- Heating and organizing the circulation of coolant (HC) in the heating system of the house.

- Heating and supply to hot domestic water distribution points.

- Providing control over the activities of the main components using a self-diagnosis system.

- Setting operating modes, adjusting heating and hot water parameters.

- The heating circuit can be used both for an open system and for underfloor heating with limited air temperature.

- It is possible to connect external temperature sensors (weather-compensated automation) and room temperature sensors (thermostat).

NOTE! To maintain the three-way valve in working condition and eliminate the possibility of it jamming and blocking, once a day the pump is started, pumping water through the valve and setting the structure in motion.

Accessories for temperature control

The latest self-diagnosis system, with errors displayed on the LCD display, allows for precise adjustment of the boiler’s thermal processes.

An electronic chip using primary sensors will analyze the condition of the boiler for compliance with the established temperature conditions and adjust the operation.

The electronic system is able to remember the latest failures. The temperature regime in the house and the heating level of the hot water supply can be set directly on the remote control unit.

Outdoor temperature sensor

When an outside temperature sensor is connected to the unit, the weather-compensating automation integrated into the electronic board of the device is activated.

The boiler will independently regulate the temperature in the supply pipe according to the specified control schedule. In this option, the internal thermal regime will correspond to maximum comfort and efficiency, since real atmospheric conditions will be taken into account.

The outdoor temperature sensor modifies the temperature regime of the supply coolant in the heating system in accordance with the outside air temperature outside. The device is designed to maintain a constant sanitary regime in the house.

The group use of external and internal air temperature sensors in the electronic control board implements self-adaptation of the equipment. In this way, the temperature relationship adjustment curve will be calculated automatically.

Room programmable thermostat

Such a thermostat is designed to guarantee a stable temperature in the house. It operates on the principle of turning off the equipment when the required ambient temperature is reached and turning on when it drops. Thus, a simple and safe means of regulating climatic conditions in the house is implemented.

The simplest adjustment system can save up to 15% of gas fuel used for heating needs. This is achieved by maintaining the temperature conditions more accurately and reducing the number of unit turns on/off.

The use of such devices is mandatory according to EU requirements and domestic standards for the operation of gas equipment.

Technical characteristics

Let's look at the boiler parameters, presented for convenience in table form:

| Characteristics | Meaning |

| Power | 24 kW |

| Heated area | 240 m2 |

| Dimensions | 730 : 400 : 299 mm |

| Weight | 33 kg |

| Power consumption | 10.6 kW |

| Efficiency | 92,9 % |

| Gas consumption | 2.73 m3/h |

| Exhaust temperature | 30-80° |

| DHW temperature | 35-60° |

| Allowable pressure | 19.1 bar |

| Chimney | Coaxial 60/100 mm |

| Power supply | 230 V, 50 Hz |

Price range

The cost of Baxi boilers with a capacity of 24 kW ranges from 32 thousand rubles. up to 41 thousand rubles. depending on the specific model.

The price does not include installation and delivery. You will also have to spend money on a chimney, which is not included with the equipment.

The total cost will be approximately 10% higher, which should be taken into account and prepared in advance.

Advantages and disadvantages of the model

The advantages of Baxi Eco Four 24 F boilers include::

- High quality manufacturing and assembly.

- Compliance with all certification requirements and standards.

- The boilers have been adapted to Russian conditions and are capable of operating at low gas and water pressures, with fluctuations in power supply voltage.

- It has its own security system.

- Possibility of connecting an external temperature sensor and a room thermostat.

- The design contains two heat exchangers.

- To solve emerging problems, there is a network of service organizations.

Disadvantages are considered:

- Relative high cost of units and components.

- The volume of expansion tanks is only 6 liters.

- The control board is sensitive to changes (especially surges) in the mains voltage.

IMPORTANT! Both advantages and disadvantages are common to all devices of this type and apply not only to this model.

RU User Manual Dear Customer...

Page 2

- Image

- Text

66

926.237.1 - RU

User Guide

Dear buyer!

We are confident that the product you purchase will meet all your requirements. Acquisition

one of the BAXI

meets your expectations: good performance, simplicity and ease of use.

Save this manual and refer to it if any problem arises. In this manual

You will find useful information to help you use your product correctly and efficiently.

Packaging elements (plastic bags, polystyrene, etc.) must be kept away from children, because they represent

constitute a potential source of danger.

Although we have prepared this guide with great care, there may be some inaccuracies in it. If you

If you notice them, we ask you to report them so that we can correct these inaccuracies in the future.

On BAXI

CE marked. The boilers meet the requirements

set out in the following standards:

— Gas standard 90/396/CEE

— Productivity standard 92/42/CEE

— Electromagnetic compatibility regulation 2004/108/CEE

— Low voltage regulation 2006/95/CEE

1.

Preparing for installation………………………………………………………………………………….

67

2.

Preparation for the first launch………………………………………………………………………………………..

67

3.

Starting the boiler……………………………………………………………………………………………………………..

68

4.

Regulation of room temperature and hot sanitary water temperature..………….

69

5.

Description of the button (Summer – Winter – Heating only – Off)

69

6.

Filling the system………………………………………………………………………………….

70

7.

Turning off the boiler…………………………………………………………………………………………

70

8.

Converting the boiler to another type of gas………………………………………………………………………………….

70

9.

Shutdown for a long period. Frost protection (heating circuit)…………….

71

10.

Security system: indicators and operation………………………………………………………………

71

11.

Care instructions…..………………………………………………………………………………….

71

12.

General information………………………………………………………………………………………..

72

13.

Checks before installing the boiler…………………………………………………………………………………

72

14.

Installation of the boiler.……………….…………………………………………………………………………………………

73

15.

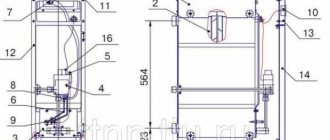

Boiler dimensions…………………………………………………………………………………………..

74

16.

Installation of chimney and air duct……………………………………..………………………..

75

17.

Connecting to power supply………………………………………………………………………..

79

18.

Connecting the room thermostat.……………………………………………………………..

79

19.

Converting the boiler to another type of gas and pressure settings………………………………………….

80

20.

Displaying the parameters of the electronic board on the boiler display……………………………………………

81

21.

Setting parameters……………………………………………………………………………….…..

82

22.

Control devices and safety devices……………………………………

83

23.

Location of the ignition electrode and flame sensor electrode……………………………

84

24.

Exhaust gas control…………………………………………………………………………………

84

25.

Flow/pressure characteristics…………………………………………………………………………………..

84

26.

Connecting the outdoor temperature sensor……………………………………………………..

85

27.

Connecting an external boiler………………………………………………………………………………………

85

28.

Annual maintenance……………………….……………………………………………………………

86

29.

Cleaning the cold water filter…………………………………………………………………………………………..

87

30.

Cleaning limescale deposits in the DHW circuit………………………………………………………..

87

31.

Dismantling the secondary heat exchanger……………………………………………………………….

87

32.

Functional diagrams…………………………………………………………………………………..

88-91

33.

Electrical connection diagrams…………………………………………………………………………………………

92-95

34.

Extract from EC norms and regulations for gas boilers…………………………………………………………………….

96

35.

Technical data …………………………………………………………………………………….

98

content

User Guide

MANUAL FOR TECHNICAL STAFF

Baxi Company ( BAXI SpA

) is one of the European leaders in the production of heating boilers and

high-tech heating systems. The company has certificates of the international quality system and organization

production CSQ in the field of environmental protection (ISO 14001); product quality control (ISO 9001) and safety

(OHSAS 18001). This confirms Baxi's strategic focus on health and safety.

own employees, user trust in the manufactured product and environmental protection. The company is constantly

is committed to improving all the above aspects to satisfy the wishes of its customers

His device

The boiler design consists of the following components:

- Primary and secondary independent heat exchangers.

- Circulation pump with automatic air removal and two-speed operation (Grundfos).

- Burner with stainless steel tips (Polidoro).

- Three-way valve with servo drive.

- Expansion tank 6 l.

- Control board (Honeywell).

The operation of the installation is to heat the coolant by forced passage through the heat exchanger. The hot heating agent in the three-way valve is mixed with the colder return flow in a given proportion and receives the desired temperature, after which it is sent to the heating circuit.

Water enters the boiler and is heated to a set temperature in a secondary heat exchanger. All operations are constantly monitored by a self-diagnosis system, which, if a problem is detected, displays a message in the form of an error code.

Safety

For the safe operation of the boiler unit, it is equipped with primary sensors that monitor important parameters of the boiler operation, signal possible failures, and send a signal to the control board, which makes decisions to leave the Main boiler in operation or turn it off in an emergency.

Basic safety equipment:

- working LCD display with LED backlight, push-button control and light indication of operating cycle characteristics;

- diagnostic system on a chip, with signal output to the control board;

- ionization control of the torch in the furnace;

- anti-blocking of the electric pump;

- anti-blocking three-way electrovalve with servomotor;

- primary coolant temperature sensor in the heating circuit;

- primary sensor for vacuum in the combustion chamber;

- pressure switch for gas line pressure;

- safety relief valve in the heating circuit, pressure protection above 3 bar;

- antifreeze protection in heating and hot water systems.

For which rooms is it best suited?

Double-circuit gas boilers are optimally suited for heating and hot water supply of private houses of the corresponding size. The use of these units in industrial or public buildings is impractical due to inappropriate working conditions and lack of proper maintenance.

Often such boilers are purchased with a view to the future and for the time being operated as single-circuit installations (only for heating premises). This approach is completely justified, since when the opportunity arises, you will only need to connect the appropriate pipelines, and the difference in cost is not too noticeable.

Often, users purchase Baxi Eco Four 24F boilers to organize heating of apartments with a much smaller area than intended by the design, expecting to obtain a large margin of safety.

Expectations are not always met, since operation in abnormal mode is just as harmful to the unit components as overload.

Startup instructions

After delivery and unpacking of the boiler, installation is carried out in the designated place and the corresponding pipelines are connected. These procedures can be performed either independently or by service center employees.

Then the following steps are performed:

- Open all heating system taps (input and output), while the boiler is disconnected from the power supply.

- The pressure in the expansion tank should be 0.5 At.

- Open the tap and fill the heating system to 1.5 At (green sector on the pressure gauge).

- Turn off the tap and bleed the air in heating devices (radiators, convectors, etc.). Because of this, the pressure will drop. Repeat the procedure until all air has been removed and the pressure is slightly above 1.

- Remove the cover and unscrew the screw of the plastic panel, opening access to the circulation pump. It has its own screw with which air is removed.

- If air escapes, the pressure in the system will drop, so it must be checked and, if necessary, raised to 1.

- Without putting on the lid, turn on the boiler in heating mode for 1 minute at temperatures up to 50°. The circulation pump will turn on. Various errors may appear on the display. This is normal, as there is residual air in the system that prevents the sensors from correctly displaying the situation.

- After a minute, turn off the boiler and open the pump screw again. Air will escape in noticeable quantities.

- Repeat the starting procedure in the same mode for 1 minute and bleed the air again. Repeat until the air is completely removed.

- After this, leave the pump screw unscrewed a quarter or half a turn to remove air independently.

- Switch the boiler to “summer” mode and check whether hot water comes from the tap. If this does not happen, and the burner started for a few seconds and turned off, you should turn off the boiler and turn the power plug over in the socket. The boiler is phase dependent and will not work correctly if the plug is not oriented correctly in the socket.

After correct connection, you should mark with a marker the position of the plug in the socket, so that later you can immediately turn on the installation without error..

Preparation for installation, Preparation for first start-up

Page 3

- Image

- Text

67

926.237.1 - RU

User Guide

The boiler is designed to heat water no higher than the boiling point at atmospheric pressure. It connects to the system

heating and hot water preparation system in accordance with its characteristics and power. The boiler must

installed by a qualified technician.

Before installing the boiler you must:

a) Check that the boiler is configured to work with this type of gas. This information is provided on the packaging and on the factory

boiler nameplate.

b) Make sure that there is sufficient draft in the chimney, there are no narrowings, and there is no entry of foreign products

combustion, unless the chimney is specially designed to serve several

devices.

c) When connecting a smoke exhaust pipe to an existing chimney, check that the chimney is completely clean,

because When the boiler is operating, soot particles can come off the walls of the chimney and block the exit of combustion products, thereby creating

the most dangerous situation.

d) In addition, in order to maintain the warranty on the device and to maintain its proper functioning,

The following precautions must be taken:

1. DHW circuit:

1.1.

if the water hardness is higher than 20º F (where 1º F = 10 mg CaCO3 per 1 liter of water), a polyphosphate filter should be installed

a dispenser or similar water softening system that complies with current regulations.

1.2.

Thoroughly rinse the equipment after installation and before use.

2. heating circuit

2.1. new equipment

Before installing the boiler, the heating equipment must be pre-cleaned to remove possible

deposits or contamination (pieces of sheathing, solders, etc.), using for this purpose substances available in free

sale. Substances used to clean equipment must not contain concentrated acid

or alkalis, which can corrode metal and damage plastic and rubber parts of equipment (e.g.

SENTINEL X300 or X400 and FERNOX Rigeneratore for heating equipment). When using cleansers

substances must strictly follow the instructions for their use.

2.2. Operated equipment:

Before installing the boiler, the heating equipment must first be cleaned of dirt and deposits,

using commercially available substances (see paragraph 2.1)

To protect equipment from scale, it is necessary to use inhibitor substances such as SENTINEL X100 and

FERNOX Protettivo for heating equipment. When using these substances, you must strictly follow

instructions for their use.

We remind you that the presence of deposits in heating equipment leads to problems in the operation of the boiler (overheating,

burner noise, etc.)

If these recommendations are not followed, the device will be removed from warranty service.

1. preparation for installation

The first start-up of the boiler must be carried out by a qualified specialist. You need to make sure the following:

a) The boiler parameters for power supply, water and gas correspond to the existing power, water and gas supply systems.

b) Installation was carried out in accordance with current regulations.

c) The device is correctly connected to power and ground.

If the above requirements are not met, the manufacturer's warranty becomes invalid. Before the first start

Remove the cellophane protective film from the boiler. To avoid damaging painted surfaces during washing and cleaning

surfaces, do not use hard tools or abrasive cleaners.

The device should not be used by children, people with physical or mental problems, or without sufficient

experience and knowledge, except when they use the services of a person responsible for their safety, do so

under supervision or according to the instructions intended for the device..

2. preparation for the first launch

Gas boiler operating instructions

There are no fundamental requirements for the operation of boilers. All possible situations are provided by the manufacturers and are displayed in the form of corresponding error codes.

The user is only required to respond in a timely manner to their occurrence, eliminating the problems that arise independently or with the participation of an invited specialist.

In addition, once a year it is necessary to carry out maintenance of the installation, clean the boiler of soot or scale, and perform other necessary work. This is done by the employees of the service organization; it is not recommended to do such things on your own.

Download instructions You can download instructions

here

.

Basic faults and troubleshooting methods

The occurrence of any problems is immediately displayed on the unit display based on a signal from the corresponding sensor.

Error codes:

- E01 . Burner failure. Check the presence of gas, clean the nozzles.

- E02 . Overheat. Check the presence of water, rinse the heat exchanger from scale.

- E03 . Fan failure. Check its condition and replace if necessary.

- E05 . Exhaust temperature sensor failure or short circuit.

- E06 . Failure or short circuit of the DHW sensor.

- E10 . Coolant pressure has dropped. The appearance of a leak, destruction of the heat exchanger.

- E25-26 . Circulation pump blocked or sensor failure.

- E35 . False signal about the presence of flame. Occurs when the control board is not grounded or the sensor is incorrectly positioned.

- E96 . Low power supply voltage.

NOTE! There are other codes that you should read carefully in your user manual.

Filling the system

Page 6

- Image

- Text

70

926.237.1 - RU

User Guide

To turn off the boiler, you must turn off the power supply to the device. When the mode switch is in position

“OFF” (see paragraph 5) the boiler does not work (OFF appears on the display), but the electrical circuit of the boiler remains

under voltage and the “frost protection” function remains active (paragraph 9).

7. BOILER TURN OFF

8. Converting the boiler to another type of gas

The boiler can operate on both natural and liquefied gas. Converting the boiler to another type of gas can only be done

qualified specialist.

attention

Turn off the power supply to the boiler using the bipolar switch.

important:

Check the pressure gauge regularly to ensure the pressure is between 0.7 and 1.5 bar when the system is cold

heating. If the pressure exceeds, open the drain valve. If the pressure is below normal, open the fill valve

(Fig. 2).

We recommend opening the tap very slowly to make it easier to bleed out the air.

6. FILLING THE SYSTEM

The boiler is equipped with a differential hydraulic pressure switch, which turns off the boiler in case of

pump blocking or lack of water.

Fig.2

note:

If the pressure drops frequently, have your boiler checked by a qualified professional.

24 F - 24

1.24 F - 1.24 - 1.14 F - 1.14

A - Drain valve

B - Filling valve for heating system

C - Cold water inlet to the DHW system - It is necessary to install a shut-off valve to fill the system

0812_1801/CG_2010

B

A

A

C

Which UPS is suitable for this boiler?

For normal operation of the boiler, a UPS power of 120-130 W is required. This is more than is necessary for installations with an open burner, since it is necessary to provide power to the fan (air pressure switch).

The choice of a specific device is made based on availability in the store and price, the capabilities of the owner and other criteria.

It is recommended to purchase a model with a small safety margin, since over time the UPS parameters slightly reduce their values.