The issue of roof insulation is relevant for all home owners, regardless of whether the under-roof space is used as a living space, or whether it serves only for technical purposes.

Thanks to high-quality insulation, you can achieve a significant reduction in heat losses, which will have a positive effect on the overall comfort in the house.

In the segment of construction and finishing materials under consideration, there is a fairly large selection of options, among which polyurethane foam (PPU) has taken its place.

Thanks to a good combination of performance characteristics, such roof insulation will serve properly for a long time. However, before choosing polyurethane foam as insulation, you should consider its features and specific application.

Description of foam insulation

Polyurethane foam used for insulating surfaces is a product of the chemical interaction of polyol and isocyanate, which, as a result of the reaction that occurs during mixing, form one of the types of gas-filled plastics.

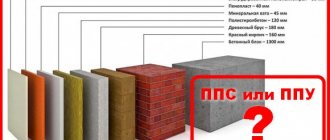

In terms of structure and some characteristics, polyurethane foam can be compared with the well-known polystyrene foam . Due to its porous structure, such insulation performs well in a variety of practical conditions of use, but requires the use of special equipment and high-quality components.

The key difference between the material in question and other analogues on the market is that polyurethane foam is brought into a “working” state directly at the site of insulation. The work is carried out in most cases by spraying onto the surface, which expands the variability of use.

Depending on the need and the chosen method of insulating the under-roof space, polyurethane foam can be applied to the walls or the inner surface of the roof slopes, while forming a uniform coating.

pros

Among the advantages of using PPU, the following should be highlighted:

Before spraying polyurethane foam, no special preparation of insulated surfaces is required.

Due to the peculiarities of the application of the material, it is enough to simply clean the beams and walls from mechanical contaminants.If we are talking about metal surfaces, then it is better to treat them with a primer, which will form a rough structure and improve the adhesion of materials.

- The use of polyurethane foam does not require the use of specialized fastening systems, which simplifies and speeds up the work.

- The specificity of applying foam insulation material allows it to be used regardless of the specifics of architectural and engineering solutions when designing a roofing system. This point is especially relevant when it comes to complex rafter systems of domed and multi-section roofs.

- The polyurethane foam coating has a uniform structure without seams and with equal thickness along the entire perimeter. The absence of seams means increased efficiency of insulation, in the absence of cold bridges. Combined with the extremely low thermal conductivity of the material, this makes polyurethane foam one of the best options in its segment.

- PUF is inert to a wide range of negative environmental factors, which especially concerns the effects of water and temperature changes. If the necessary technological standards are observed at the application stage, the material is able to maintain its characteristics both in direct contact with water and in the temperature range -160°C - +150°C.

As advantages of using polyurethane foam, one can also note the environmental safety of the material, non-flammability, as well as high resistance to fungi and mold.

Limitations for the use of polyurethane foam

Insulation based on polyurethane foam is not recommended in the following cases:

- the house is inhabited by people who are hypersensitive to chemicals;

- near the place where chimneys pass through the roof or ceiling;

- for insulating external walls without applying a light-protective coating.

The use of polyurethane foam for roof insulation is not recommended if people with chemical sensitivities live in the house

Minuses

Among the disadvantages, the following factors stand out:

- The closed pore structure and uniformity of the coating retain heat well, but also do not allow air to pass through, which requires the creation of an effective ventilation system, the condition of which will need to be carefully monitored. Lack of breathability negatively affects the microclimate in the room and can cause pockets of dampness, peeling wallpaper and other problems.

- You can use polyurethane foam insulation only if its surface is not exposed to direct sunlight, since otherwise the material quickly loses its performance characteristics, even to the point of losing its mechanical integrity.

- To apply polyurethane foam coating, it is necessary to use specialized equipment, despite the fact that the work must be carried out in compliance with strict technological standards. There are also high requirements for the quality of the mixture components, which negatively affects the prevalence of the service as a whole.

Another feature of the material is its fairly high price compared to analogues.

Price per square meter

When considering the cost of insulating the roof of a house with polyurethane foam, it should be taken into account that preliminary calculations may be difficult due to the variability inherent in the very idea of application.

The fact is that polyurethane foam can be applied in layers of different thicknesses in the range of 30-150mm, which leads to a difference in price per m2 of coating.

Another limiting factor is the possibility of using components of different quality, which will also affect the price of insulation.

To apply a layer of polyurethane foam you will need a powerful compressor, the purchase of which for roof insulation purposes is hardly reasonable. This means the need to rent such equipment, or contact a specialized company. Prices for such services may vary depending on the region.

On average, prices for roof insulation start from 700 rubles. per square meter excluding the cost of material.

Selection criteria for roof insulation

When choosing a material for thermal insulation of floors or roofs, the following factors should be taken into account:

- roof area;

- the material of the underlying surface on which the working solution will be applied;

- composition of the working solution, it is better to avoid components harmful to health;

- reputation of the manufacturer;

- price.

When choosing foam for roof insulation, you need to take into account the roof area

. In addition to the purchase price, during the analysis you will need to take into account the cost of materials and labor costs for preparatory and additional work: surface preparation, vapor barrier, fire protection, etc.

Types and characteristics

There are three main types of polyurethane foam, each of which can be used as roof insulation. They differ both in the method of application and in structure, as well as in important performance characteristics.

- Hard polyurethane foam - after application it forms a layer that is quite resistant to external influences, which was the basis for the name as a whole. In most cases, the definition of “polyurethane foam insulation” refers to the use of this particular type of material.

- Semi-rigid polyurethane foam is supplied to the consumer market in the form of a one-component composition and is used for local insulation of gaps or small surfaces. In everyday life, such insulation is known as “spray foam” and differs from the analogue described above in its lower density and low resistance to external factors due to its open-cell structure.

- Liquid polyurethane foam has found its application in the formation of thermal protection for flat roofs and has the lowest density among analogues.

Due to the best-in-class characteristics and the highest frequency of use, the first option - rigid polyurethane foam - will be examined in detail below.

- Density, kg/m3 – 20 – 80 depending on the variety.

- Vapor permeability, mg/(m*h*Pa) - 0.02-0.05.

- Water absorption,% - 1.0-3.0.

- Compressive strength, kgf/cm2 - 1.53-10.19.

- Bending strength, kgf/cm2 - 3.3-19.37.

Also an important characteristic is the thermal conductivity coefficient of the material , which is 0.022-0.035 W/(m×°K), which is a good indicator among materials similar in scope.

Rigid polyurethane foam is suitable for roof insulation, regardless of the type of rafter system, the nature of the surface being treated, and can act as an additional layer of waterproofing.

This makes it the most suitable material among its closest analogues for most cases.

Cost of work

| The name of the manipulations performed. | Price per 1 cubic meter/rub. | Price per 1 square meter/rub. | Spray/plate thickness |

| Spraying penoizol | 36 kg – 450; 53 kg - 800; 36 kg - 900; 53 kg – 1550; 36 kg – 1500; 53 kg – 2600; | 0 0 0 | 3 6 10 |

| Purchased foam sheets | 0 0 0 | 1200 1800 2300 | 10 15 20 |

| Pouring during construction | 1500 | 0 | 0 |

| Pouring into prepared cavities | 1500 | 0 | 0 |

| Filling with cavity drilling service | 1700 | 0 | 0 |

*

Calculation of the number of polyurethane foam

When making initial calculations of the required amount of insulation, you should take into account a number of variable factors that will differ at each site. Here you can note surface unevenness, material of manufacture, presence/absence of seams, as well as temperature during work.

In addition, to obtain average indicators of the required amount of spray foam insulation, the free foaming coefficient, which is indicated by the component manufacturer, should be taken into account.

The formula for calculating the required amount of polyurethane foam looks like this:

(Free Foam Density) x (Coating Thickness) x (Surface Area) x 0.01 x 1.3 . Here 1.3 is an amendment for an increase in material consumption depending on the actual conditions of use of the composition.

Read more about calculating the amount of material for roof insulation here.

How to insulate the roof of a house from the inside: technology

Detailed instructions for insulating a roof from the inside can be found here.

As for applying polyurethane foam to surfaces, this procedure is not very difficult - the material is simply sprayed onto the prepared surfaces using a special gun.

The work is carried out in several stages, where the first layer acts as additional leveling and sealing, the second is the “body” of the insulation, and the third layer is used to level the outer surface. Spraying is done from the bottom up, each subsequent layer is applied only after the previous one has hardened.

In the case of using liquid polyurethane foam as insulation, the material is applied by pouring. To do this, the surfaces to be finished must be insulated, if possible, and the presence of large gaps must be eliminated, especially if it is planned to insulate the roof of a private house in this way. PPU is poured in layers, after the previous layer has hardened , until the required insulation thickness is achieved.

Stages of roof insulation with polyurethane foam

When applying the coating, you must follow the technology and sequence of work

Necessary tools and protective measures

To work you will need:

- reusable and or disposable spraying installation;

- mounting knife for cutting rolled and sheet materials and removing frozen excess foam;

- measuring tool for marking surfaces;

- painter's protective overalls with a hood and elasticated arms;

- tight shoes;

- safety glasses or face shield;

- respirator;

- gloves.

Preparatory work

During preparation, it is necessary to clean the surface to be treated from debris, dirt and remnants of old coatings.

Next, install the sheathing and metal profiles or wooden slats. Their thickness should match the planned thickness of the applied foam layer. In the future, the finishing trim will be attached to this frame.

The working solution is thoroughly mixed to the consistency required in the instructions.

Spraying material onto the base

The first layer of foam is applied to the prepared base. It is necessary to achieve a continuous application, closing gaps and filling uneven areas.

Spraying is done from top to bottom. If necessary, after the first layer has hardened, apply the second and subsequent layers. Each time you need to let the previous layer dry and set.

Excess insulation is cut off with a mounting knife flush with the installed sheathing.

If you plan to cover the insulation with a layer of plaster, a polymer or metal reinforcing mesh is mounted on the sheathing.

Application of fire retardant composition

Polyurethane foam is highly flammable and releases toxic substances when heated and burned. Therefore, the insulation layer is coated with a fire retardant compound. The composition must be selected specifically recommended for use together with polyurethane foam. It would be wise to choose it from the same manufacturer as the main material. The layer is applied with a sprayer or roller so that the coating is continuous and the entire insulation is protected.

Reviews

As for reviews from real users of insulation using polyurethane foam, they note the high speed of work, the efficiency of insulation and the possibility of use on a wide range of surfaces. Disadvantages include the relatively high cost of insulation and the possibility of wooden surfaces becoming damp with insufficient ventilation.

Here people discuss the possibility of applying polyurethane foam to the roof themselves, the cost of the work, as well as the advantages and disadvantages of the technology:

- car72.ru

- forums.drom.ru

Application of open cell foam

It must be remembered that if the attic will be used as a living space (and not a dry storage area for things), then the ceiling on the inside will need to be finished with a slope (for example, with plasterboard).

Most often, metal hangers are screwed to the rafters, to which, after applying foam plastic, a standard mesh of steel profiles will be attached, and plasterboard to it.

- When using open-cell foam, there is usually no need to install a vapor barrier film on the room side.

- However, it is necessary to ensure that water vapor can penetrate from outside.

- Consequently, it can come into contact with a highly vapor-permeable roofing film (the so-called membrane), but it is better to leave a ventilation gap between the foam and the formwork made without gaps from boards or wooden panels, and especially covered with bitumen paper.

Contrary to popular belief, wood has a very high resistance to diffusion. Contact of the foam with the formwork will prevent water vapor from escaping.