Here you will learn:

- Features of using the device

- Error codes for the gas water heater "Oasis"

- Main causes of malfunction and their elimination

- How to prevent breakdown of the Oasis geyser

Before you start troubleshooting the Oasis geyser and choosing a way to eliminate them, you must clearly understand what type of device it is, know the device, and the principle of its operation.

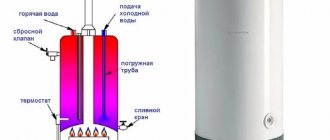

The layout of the Oasis gas water column components is typical for most models of Chinese-made flow columns

The diagram above shows the design of a typical gas water heater, which is also typical for Oasis columns. Let's look further at how the most common type of brand's flow-through chimney model with automatic ignition works.

When the tap is opened, water is supplied through the inlet pipe into the water-gas unit, which turns on the ignition and gas supply. As soon as it ignites, a signal is sent from the flame sensor to the electronic unit to stop sparking.

Next, the water passes through a coil rigidly fixed to a heat exchanger, which is heated by burning gas. The coil transfers heat to the flowing water coming out.

When the tap closes, the water-gas unit turns off the gas supply. The combustion stops and the column goes into standby mode for the water tap to open.

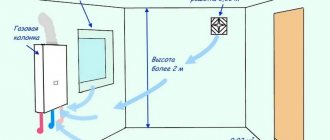

An important condition for the normal and safe operation of the column is the removal of combustion products through the ventilation chimney. If the hood is missing or insufficient, the draft sensor is triggered and the column is turned off.

An overheating sensor is responsible for timely shutdown of the column when the maximum temperature is reached. It is an important element of the column, providing protection against overheating

Maintaining the required temperature regime is an equally important condition for fire safety and long service life of the column. Overheating negatively affects the condition of all elements, primarily the heat exchanger, which leads to their premature failure.

Other faults

Also, malfunctions of the water heater can be caused by the following reasons:

Ignition system failure

In speakers without an igniter (electronic ignition), the spark is generated by the batteries; perhaps they have run out.

The battery capacity is not always enough for a year, as the manufacturer promises. In other models, a spark is produced by a piezoelectric element triggered by a turbine installed in the water supply.

If the water pressure is weak, such an ignition device will not work.

When buying a column, you need to pay attention to the minimum water pressure that it requires for normal operation. In columns with an igniter, the latter can become clogged: its flame becomes weak, sometimes yellow (this is how the lack of air in the gas-air mixture manifests itself). As a result, it either cannot ignite the main burner at all, or does this after a large volume of gas has entered, as a result of which the column ignites with a characteristic bang

After cleaning the igniter the situation returns to normal.

As a result, it either cannot ignite the main burner at all, or does this after a large volume of gas has entered, as a result of which the column ignites with a characteristic bang. After cleaning the igniter the situation returns to normal.

In columns with an igniter, the latter can become clogged: its flame becomes weak, sometimes yellow (this is how the lack of air in the gas-air mixture manifests itself). As a result, it either cannot ignite the main burner at all, or does this after a large volume of gas has entered, as a result of which the column ignites with a characteristic bang. After cleaning the igniter the situation returns to normal.

The membrane of the water unit has exhausted its resource

This element, made of a polymer material, must have sufficient elasticity, but over time it loses it, becoming rigid, and may even crack. It can also become overgrown with lime deposits.

Accordingly, the column will stop turning on, even if the user opens the tap completely.

The membrane must be inspected and if its condition is truly unsatisfactory, it must be replaced.

Control module board burnt out

This often happens with imported speakers, which are very sensitive to the quality of the power supply. They should be connected through a stabilizer.

It is also useful to know that smart speakers with electronics should not be turned off at night.

Mixing flows

Unregulated heating modes, when hot water comes out at a temperature of more than 55 C, it requires cooling. In this case, the user opens the cold water tap in the mixer, which leads to a drop in pressure in the water supply. In cases of low-mode systems, this can lead to a complete stop of the column.

This temperature of heated water also causes intensive processes of scale formation in the internal heating surfaces of the water heater, due to the presence of hardness salts in the water - Ca and Na, which reduce the flow rate and overheating of the finned tubes until fistulas form and water leaks into the inside of the column.

Additional Information! In order to prevent these types of temperature violations, it is necessary to set the maximum heating temperature with the regulator to no higher than 50 C.

Water unit malfunction

Most often, geyser repairs are made due to a faulty water block. Its work is that, under the influence of liquid pressure, the membrane located inside it, arching, transmits movement to the rod, and it then moves the pusher of the gas unit. As a result, the spring valve opens and the electrical power supply to the control module is turned on. Therefore, if the water unit is faulty, the device will not start.

A broken water block can be determined by external signs.

.

If you notice even one sign, the unit will need to be removed and repaired. The water unit can only be removed together with the gas module, since they are a single structure. You can do this in the following way:

- after you have made sure that the gas valve on the pipe is in the closed state, you can disconnect the supply hose (a);

- similarly, when the water supply is turned off, the nut on the water block pipe (b) is unscrewed;

- then, using a wrench, you need to unscrew the nut that connects the water block to the heat exchanger (c);

- disconnect the terminal block (d) on the conductors connecting the solenoid valve to the control module;

- wires (d) going to the switch are disconnected in the same way;

- using a screwdriver, you need to unscrew the 2 screws (e) attaching the pipe to the water-gas unit, through which fuel is supplied to the burner manifold;

- After unscrewing the fasteners, the entire assembly can be easily removed from the device.

Repairing a Neva 3208 gas water heater due to a faulty “frog” is similar and intuitive, although the internal appearance of the unit is slightly different. The Neva 4511 gas water heater can be disassembled in the same way, and repairing it yourself is quite feasible.

a Chinese gas water heater repaired?

, the size of the water node is always surprising. It is quite small in size, and to disassemble the “frog” you only need to unscrew 4 screws.

Radiator leak

Heat exchangers made of copper and copper-containing alloys have the greatest risk of leakage. The reason is that manufacturers often use alloys in which the percentage of copper is lower and lower.

During operation, as a result of corrosion and mechanical damage, small holes begin to appear, violating the tightness of the radiator. These are the so-called “fistulas”. In these places, the heat exchanger begins to let water through.

By the way, even a high-quality copper heat exchanger is not protected from rapid destruction.

Corrosion occurs under the influence of stray currents that arise in the water supply when the dispenser is not properly grounded or when other operating rules for gas-using equipment are violated.

Elimination: you can replace the heat exchanger with a new one, but this will cost a third of the price of the column. Often this is not justified; it is much easier to solder it without disassembling the entire column and removing the radiator.

Before you start soldering, you need to drain all the water from the radiator, otherwise heating the pipeline will be problematic.

To do this, you need to turn off the water supply to the column, disconnect the incoming pipe from the pipe, place a container under it, and open the hot water tap.

When the water has drained, it is necessary to blow through to remove residues. You can use a vacuum cleaner or compressor. If such devices are not at hand, you can blow through with your mouth.

To do this, you need to select a rubber hose of suitable diameter and fit it tightly onto the coil, strengthen the connection by crimping.

Soldering can be done in two ways: with a gas torch or a soldering iron.

Gas burner:

- For soldering you will need a torch with a gas cartridge, a sponge, flux paste containing tin and copper, and solder.

- Start by heating the leaking tube to evaporate any remaining water. Clean the soldering area with a sponge. Apply flux paste. Heat again until the flux color changes from gray to silver.

- To prevent flux residues from leading to corrosion, it is necessary to remove them with a damp cloth.

Soldering iron:

Prepare a powerful soldering iron of 100 W or more, POS-50, POS-61 or other solder with a melting point of at least 200 degrees.

Flux: rosin or solder fat, you can also use aspirin tablets. Using a hair dryer makes warming up much easier.

The soldering area must be cleaned with a zero polish until all traces of corrosion are removed from the metal surface. Then degrease it with alcohol or solvent.

Heat the soldering area well with a soldering iron. Additional heating with a hair dryer gives excellent results. Tin the soldering iron tip with a piece of solder.

Apply a small amount of flux to the soldering area and immediately tin the metal surface with a soldering iron. Try to maintain the fluidity of the solder by adding flux from time to time. Bring the solder thickness to 1-3 mm.

With good heating, a thin layer of solder is enough to reliably eliminate a leak and prevent destruction of the pipeline at the soldering site.

Elimination of traction disorders

To test traction, try using an ordinary match. Bring it to the chimney and determine if there is a draft, then the flame will deviate towards the chimney.

If there is no draft, the gas water heater will not light and users will not receive hot water. Many dispensers are equipped with draft sensors, and if they show insufficient draft, ignition will be impossible. Situations are possible when the flame lights up and immediately goes out - this is due to the fact that the combustion products simply have nowhere to go, they remain in the combustion chamber, and the flame goes out due to lack of oxygen. Lack of draft will require an inspection of the flue gas collector and the chimney itself. If there are blockages here, they can interfere with the normal passage of combustion products. The column perceives this as a lack of traction and does not allow the gas to ignite (or the gas goes out immediately after turning on). Unfortunately, you will be able to independently check only the part of the chimney that is visible before entering the wall - further work must be carried out by specialists. If the house is private, you can try to figure out the chimney yourself.

What if the equipment is still noisy?

If, after these manipulations, the gas water heater still ignites with a bang when you turn on the water, then it is better to stop further independent research. In such situations, you will have to seek help from qualified specialists.

They will carry out competent diagnostics of the equipment, will be able to clearly determine what is causing the cotton and, based on the data obtained, will be able to provide you with options for solving the problem.

In certain cases, independent repair is impossible, then cooperation with qualified specialists will be a rational solution.

Eliminating other column faults

Most often, you may encounter a situation where the column does not initially ignite a flame. First you need to determine what exactly led to this. After all, the problem may not be in the heat exchanger at all, but, for example, in dead batteries. Therefore, it is impossible to do without diagnostics. Moreover, some breakdowns can be fixed by yourself, and in some cases you will have to call a specialist from the gas service.

External inspection of the water heater

Competent diagnostics will allow you to quickly carry out repairs on your own.

It is not recommended to carry out independent repairs if the geyser is under warranty. The service department can remove the device from warranty service.

There are a number of basic steps that should be performed before you go to examine the inside of a water heating device:

- Replacing the battery and cleaning the power contacts.

- Checking the chimney draft and the presence of pressure in the cold water supply system.

- Checking the fuse (for turbocharged speakers). You can flip the plug in the switch to change the phase location - this is important for imported models, since they are quite sensitive to this.

- Cleaning the strainer. This is a dirt trap that can be found on the pipe supplying cold water. Often the mesh is a structural component of the water unit.

- Observe the ignition electrodes. To do this, just open the hot water tap, after which sparks should form. If the camera is closed, then you can listen to the body. Characteristic sounds like the clicking of charges should be heard.

The above steps may not always help. Then you have to look inside the speaker, for which you have to remove the housing.

Each geyser repair should begin with checking the batteries and cleaning the contacts if they are oxidized. You also need to inspect and clean the igniter. There are speaker models that have a small window for access to the electrodes, which can be cleaned with a brush

Troubleshooting inside the column

If an external inspection and replacing the batteries did not help, then you can start troubleshooting directly inside the device.

To do this, you need to remove the water heater casing and check the main components one by one. It is better to perform all actions with an assistant. He should be asked to open the hot water, and he himself should monitor the movements of the rod. The responsibility of this element is to act on the pressure plate in order to move it away from the microswitch button.

If the pusher does not perform any movements, then there is a 100% probability that the problem lies in the water block. If this problem occurs, it is necessary to disassemble the unit to clean and change the membrane in it.

Also, the rod can press on the plate, but the button will remain pressed. In this case, it is necessary to check the water regulator for scale. It should be found and cleaned.

If all of the above elements operate in normal mode, the button is pressed, but no sparks are formed, then in this situation the microswitch itself may be the culprit. To make sure of this, you need to disconnect its connectors and clamp the two terminals with a screwdriver. If sparks immediately begin to form in this case, then the switch is faulty and should be replaced.

It is necessary to check by shorting the connector that is connected to the pulse unit. The microswitch plug should not be touched in this case.

The solenoid valve may also fail, causing no gas to flow. To do this, you should check each of the sensors in the circuit by short circuiting one by one. You can also use a multimeter to test.

Standards for installation and connection of the Mora column

The basic requirements are listed in the technical data sheet of the device and the operating manual. Violations made during installation lead to refusal of warranty service for the boiler. Requirements:

- The connection must be carried out by qualified specialists with the appropriate license and work permit. After installation, a report is drawn up (the form is in the device passport) and a stamp is placed indicating that the water heater is put into operation.

- A coarse filter is installed on the supply pipeline; in some cases, at low pressure, a booster pump is connected.

- The column must not be installed in rooms with high humidity (bathroom, toilet), directly above a gas stove or refrigerator.

- The room used for the boiler room must comply with the standards described in SP and SNiP.

Maintenance of Mora Top geysers should be carried out at intervals of at least 1-2 years. Independent or unqualified repairs lead to removal of the water heater from the warranty, which lasts 3 years from the date of commissioning. Repairing a Mora gas water heater with your own hands will inevitably lead to a refusal of free service. If a breakdown occurs after the warranty expires, call a gas technician. It is better not to try to repair the water heater yourself.

Common breakdowns and troubleshooting of the Mora gas water heater:

- The main burner does not turn on - the reason is dead batteries, poor water pressure, lack of sufficient oxygen in the room.

- Presence of a leak - the rubber membrane of the water reducer has broken, corrosion has corroded the heat exchanger (a copper coil is installed on the Mohr column, there will be a green coating in the place of leaks).

For supplying hot water and heating a private home, the most popular equipment is a gas water heater. It is available to almost everyone and does not require large expenses. But it is necessary to choose quality equipment. After all, a comfortable atmosphere in the house and safety depend on this. In this article we will consider all the advantages and disadvantages, as well as the features of the Mohr gas water heater.

Starting the device and adjusting the temperature

To correctly set up hot water in the device, you must:

- Open the hot water mixer fully;

- Using the water switch, select the required temperature value;

- Close the tap.

According to the advice of professionals:

- Wait for the moment when the pressure in the line drops, but the column will still work;

- Turn the water toggle handle to the maximum;

- Turn the gas regulator to the minimum value until the temperature is as desired.

For final preparation, it is worth adjusting the gas supply. To do this, you need to look at the technical data sheet and find out the minimum value for this brand.

The toggle switch is turned to the minimum value.

Turn on the gas supply valve. At the gas water heater, Electrolux and Ariston do this after connecting to the network. The Oasis, Junkers and Bosch gas water heaters are connected when the batteries are installed.

The hot valve is turned on and the device starts working.

How to adjust the water temperature

Turn on the mixer and check the water heating temperature. It must be twenty-five degrees more than the original one. It is worth noting that the water in a gas boiler heats up gradually. The geyser is adjusted using the gas lever.

Professionals do not recommend heating water above fifty-five degrees. This has a bad effect on the device, as scale forms.

Blood pressure problems

Setting up a geyser requires some time. Accordingly, the result will be visible later. After each stage, it is worth pouring out the water and letting it heat up again so that the values are correct. Low pressure in the device may interfere with normal operation.

If you have problems with blood pressure, you should perform the following manipulations:

- Remove the casing from the device;

- Loosen the locking bolt, use a pressure gauge to check;

- Remove the seal from the adjusting screw;

- Turn on the boiler;

- Set the values to maximum, unscrew the hot water supply taps;

- Adjust the desired pressure.

The Bosch gas water heater, namely its pressure in the nozzles, is regulated in the following way:

- Remove the casing;

- Attach a pressure gauge;

- Loosen the locking screw;

- Attach a pressure gauge to check the pressure in the injectors to the nozzle.

Next, the Bosch gas water heater with maximum thermal power is regulated:

- Remove the seal from the screw;

- Turn on the device;

- Hot water taps are turned on;

- The adjusting screw adjusts the pressure in the nozzles;

- Put the seal in place.

There are brands that have a special “Winter-Summer” mode with temperature adjustment. This handle was made at the bottom of the Ariston gas water heater. Adjustment of the Oasis gas water heater is located on the front panel. The peculiarity of the mode is that in winter the power is higher than in summer. The heating power of the liquid in the column is directly related to the temperature of the inlet stream. In winter, the regulator is set to “maximum”, the heating will be at its highest. In summer, the temperature of the inlet flow is higher and is set to the minimum position. This saves resources.

It is easy to remove bad pressure when checking.

To do this, you must perform the following manipulations if the device has already been used:

Pay attention to the rubber membrane. The performance of this part is directly related to the pressure in the line

At the moment the integrity of the membrane is broken, namely when it is exhausted, gas does not flow and the burner does not turn on. The problem is solved by replacing the part. Pay attention to the mesh filter. It is located at the entrance to the water block. The water pressure becomes lower due to debris clogging the part. The problem is solved by cleaning.

Lights up but goes out

Let's consider several moments when the column fades out some time after ignition and what ways there are to solve this problem:

One of the reasons is insufficient draft due to the lack of air movement inside the room where the device is located.

Checking the traction force

This happens when windows and doors are tightly closed. For this reason, the protective relay overheats and the overheating sensor is triggered.

You can eliminate it by opening a window or vent, creating a draft in the room. A gas heater burns a very large amount of oxygen during operation, so it requires a constant supply of fresh air to operate.

The second reason for the column to fade out may be the insufficient time of holding the ignition button. It should be held for at least 20 seconds; if held for less time, the column will go out.

A malfunction of the combustion products exhaust sensor is the next point. To check the sensor, you need to ring it by connecting two terminals. Normally, the resistance should show infinity. If the reading is different, the sensor will have to be replaced.

Strong cold water pressure and low hot water pressure - this situation also often causes the water heater to fade. This happens when you use hot water and open a cold tap. To eliminate this problem, you need to adjust the water supply in such a way that you do not have to open cold water in order to dilute the hot one. In addition, this is incorrect operation of the device and can lead to damage to the heater.

High water pressure can lead to attenuation. This problem is especially typical for the Lux Eco model, which is designed to work with low water pressure. In this case, the strong pressure of the flow bends the membrane of the water unit, the membrane moves the rod in the gas supply. It is necessary to adjust the gas supply or, if possible, adjust the water pressure.

The temperature sensor has activated, protecting the device from overheating.

Column temperature sensor Vector

The heater works for some time after ignition, then goes out again. If you try to turn on the device right away, there will be no result. After some time, about 25 minutes, the burner lights up, but then goes out again. The problem is that the sensor is too sensitive. In this case, only replacing it will help.

Poor contact between thermocouple and solenoid valve.

If the thermocouple is working, you need to clean the contacts and the automation unit.

The design of the igniter itself (device for generating an electric spark). The electrode is mounted in such a way that the spark hits the comb, which is welded to the edge of the gas burner at a distance of about 12 mm from its outlet. Provided that the gas supply is adjusted to low water pressure, the gas leaves the burner in a small volume and at a low speed.

Taking into account the fact that a small reverse draft is almost always formed inside the system, a weak level of gas goes down under the pressure of this draft, not reaching the spark. This situation can be corrected by bending the electrode from the comb to a level at which the spark does not fall on the comb, but through the gas exactly in the center of the burner. After performing such manipulations, the device almost always lights up, ignition is fast, stable and soft.

The formation of holes between the gas exhaust pipe, the connecting pipes of the gas exhaust device and the chimney, between individual sections of the gas exhaust pipe. Determined visually, to eliminate it, it is necessary to seal the gaps with self-adhesive heat-resistant tape or other materials that are resistant to high temperatures.

Scale on the heat exchanger - how to fix it

The need to clean the heat exchanger is usually caused by the following reasons.

- The water takes a long time to heat up.

- Poor water pressure.

- The overheating sensor is triggered and the column turns off.

If the above happens to the column, this means that it is necessary to clean the heat exchanger, since a large amount of scale has formed in it.

Step-by-step instruction

Cleaning the heat exchanger consists of the following steps.

- It is necessary to shut off the water supply to the heater with the valve and dismantle the heat exchanger, disconnecting it from the water pipes. If cleaning is carried out infrequently, it is recommended to use a lubricating spray for dismantling, which makes it easier to unscrew the oxidized nuts. After treating the nuts with a spray, you need to wait 15-20 minutes and start unscrewing them.

- After dismantling the heat exchanger, you can begin cleaning it. To clean scale, you can use a solution prepared at the rate of 100 grams. citric acid per half liter of hot water. Using a watering can, the solution is poured into the heat exchanger and left there for 12 hours.

- Afterwards, you need to drain the solution and rinse the part thoroughly with clean water. It is necessary to thoroughly clean the heat exchanger from any remaining scale, as it can clog the tubes, blocking the flow of water. This can be done using pressurized water or compressed air.

- The final stage at which it is necessary to install the heat exchanger in place in the heater after first changing the sealing washers.

Peculiarities

High consumer demand and popularity of Oasis geysers are due to a number of undeniable advantages of these devices:

- The high safety of using the units is explained by the presence of protective sensors that turn off the device in emergency situations.

- The ability to provide stable heating of the coolant, regardless of pressure drops in the water supply system, makes the operation of the dispensers simple and comfortable.

- The location of the main module away from the hot water pipe increases the safety of the device and protects important structural components from overheating.

- The presence of a mesh filter protects the system of pipes and pipes from clogging and rust accumulation.

- Economical fuel consumption is due to the presence of “Winter-Summer” modes. This allows you to automatically regulate the fuel supply and significantly save on water heating.

- The presence of a heat-resistant alloy in the radiator eliminates the formation of scale on the internal walls of the device.

- High efficiency rates and long service life distinguish Oasis speakers from other devices available in this price category.

- The presence in the product line of turbocharged models capable of forcibly removing gas combustion products. They allow you to use the water heater without installing a chimney and make its operation even safer.

- The modern and aesthetic design allows you to install speakers in kitchens and bathrooms without the risk of spoiling their appearance.

- All Oasis models are equipped with a liquid crystal screen and a control panel, which makes using the device simple and convenient.

Gas smell when turned on

This is a serious and dangerous problem. Shut off the gas supply immediately! Contact your gas company.

The seal is probably worn out. Replacement in the event of a gas leak must be carried out by a specialist. We described above how to disassemble the gas-water unit and get to the oil seal.

Before using the equipment, read the instructions. It is recommended to carry out a preventive inspection of all components of the water heater once a year. Now you know what to do. And if you are confused, turn off the fuel supply and contact the service center.

Oasis geyser device (with diagram)

The internal part of standard hot water gas equipment is presented:

- plate heat exchanger with a water tube;

- gas burners;

- exhaust gas collector;

- piezoelectric element or automatic electric ignition.

The electronics are powered through batteries, from the mains, or using a miniature built-in turbogenerator. The water temperature control in budget models is carried out by a water reducer or so-called frog, and in more complex and modern models - automatically via electronics.

Gas boilers are characterized by the presence of an open or closed combustion chamber, and the difference between models of the first type is represented by the intake of air masses directly from the room.

Exhaust gases are removed naturally through a chimney system, or using forced ventilation and a coaxial chimney.

The components and main components of flow-through gas equipment that require competent maintenance and explain the principle of operation are listed in the diagram.

Modern gas water heating equipment Oasis is equipped with protective automatic gas supply shutoff

Modern water heating equipment is characterized by the presence of protective automation, represented by flame control and a traction sensor, which allows you to shut off the gas supply automatically.

How to connect and configure

Gas water heating equipment is installed in the kitchen or any other non-residential but heated room in accordance with the gasification project and in accordance with the basic requirements of gas supply organizations:

- water heating equipment is connected to a chimney system that has good and stable draft;

- It is prohibited to install equipment above any open flame sources or heating devices;

- before installation, permission from gas service specialists to install equipment must be obtained;

- installation of the unit is carried out by the operating organization of the gas industry or other licensed companies;

- installation is carried out on non-flammable coatings, including brick, concrete and ceramic tiles with mandatory insulation with galvanized sheets and BTK;

- the protective layer of insulation should protrude beyond the body by at least 10 cm along the entire perimeter;

- the column is suspended using brackets attached to the wall, supplied with the gas equipment;

- all shut-off valves in the form of water supply to the gas supply to the unit are located in an easily accessible place;

- a filter system is installed in front of the water heating equipment to purify the water supplied for heating;

- to connect to the water supply, pipes or flexible hoses are used with an internal diameter of 13–14 mm or more.

Below is a standard connection diagram for a gas boiler.

Connected gas equipment must be registered

After installation and until it is put into operation, the water heater must be registered with the gas service.

Popular models for apartments and country houses

A review of efficient Oasis instantaneous water heaters with an affordable price will help you make the best choice for arranging comfortable living in city apartments and the private sector.

| Glass 20VG | TUR 24 | B-12W | |

| Removal of combustion products | chimney | forced ventilation | without chimney |

| dimensions | 340*590*145 | 330*620*185 | 290*370*120 |

| power supply | batteries | circuit | batteries |

| additional functions | RCD, thermostat | thermostat | thermostat |

| antifreeze | There is | ||

| winter – summer function | There is | ||

| price, rub. | 4000 | 9000 | 4000 |

| productivity, l/min | 10 | 12 | 5 |

| automatic ignition | There is | There is | There is |

| display | There is | There is | There is |

| mechanical flame control | There is | There is | There is |

Model “Glass 20VG”

Glass 20VG has a low cost, energy-saving function, an anti-freeze system and sufficient performance to supply hot water to two points. Disadvantage: battery operation and the need for a chimney.

The TUR 24 consumes a little more power, but has forced ventilation, an electrical connection and greater performance, which makes this model more affordable. Installation and connection methods

Installing a gas water heater for the first time or when replacing a faulty one that has failed requires various preparatory operations.

When installing a gas device, the project must be agreed upon and the gas wiring to the installation site of the column must be correctly completed. The document indicates the characteristics of the room, installation location, and type of device. It is better to entrust these works only to specialized organizations licensed for this type of activity. The connection is made in accordance with the instructions and SNiP.

Before connecting, turn off the gas. Using a gas wrench, unscrew the hose nut. It is difficult to damage a flexible connection using a hose, but if the connection was made using metal pipes, it will have to be dismantled by sawing. It is better to replace old hoses.

Then turn off the cold water supply. Begin installing the water heater according to the attached diagram. The distance from the outlet of the exhaust gas column to the chimney must be at least 50 cm, but in rooms with a height of 2.70 m, installation with a height of 25 cm is allowed.

At the next stage, connect the water supply, connecting to the input and output of the column. Modern flexible hoses allow you to avoid leaks by tightening the fixing nuts. When using pipes, it is necessary to eliminate leaks with tow or FUM (tape sealant).

Then connect the gas. It is better to use the services of a specialist.

Mixing cold water in the mixer

Many people, instead of adjusting the degree of heating on the gas water heater itself, mercilessly torment the mixer. If you open the cold water too much, the lit column will simply go out. If at that moment it was not burning, then it will certainly not catch fire. Make it a rule to turn on the hot water supply first, and only then the cold water supply. It’s best to adjust the degree of heating using the appropriate controls.

You also need to remember that intensive mixing of cold water is not welcomed by the developers of geysers - this can lead to their damage.

Specifics

PKO Pipe Coil JSC, which produces Astra gas water heaters, has been around for more than fifty years. Perhaps our grandparents also used his products. True, then this company was called differently.

The Astra column is necessary for working with hot water supply. Only gas is used as fuel.

The design of such a column is very simple and includes several components. The main part – a rectangular body – is fixed to the wall. The front panel contains windows for ignition and combustion control, a power button, and gas supply adjustment knobs. At the bottom there are connecting elements with threads on both sides of the gas supply, cold and hot water, and on top there is a section of the chimney pipe.

All key components are located in the middle of the case and secured to the panel located at the rear. It also includes holes for fastening. The firebox is made of good fire-resistant material that has a long service life. Ease of execution is considered an advantage in the model market and provides the manufacturer with great demand for its own products.

The working principle is as follows: in order for gas to enter the gas block and the ignition wick, you need to turn the ignition burner knob to the left and turn on the device by pressing the button - the burner will methodically turn on. The hot water outlet temperature is set by the position of the control knobs. By turning from the right side to the left, the gas supply increases, thus increasing the water temperature, and from left to right, on the contrary, it decreases.

According to functionality, the components of the column are figuratively divided into water and gas parts. On the market you can choose repair kits and spare parts for any unit separately, as well as the entire unit.

The technical properties of Astra speakers make it very easy to compete with other manufacturers. The main advantage is the power of the device: for certain models it is equal to or even exceeds 20 kW. A large firebox and relatively low gas consumption distinguishes this brand perfectly.

Naturally, each model has its own small details in the characteristics, but general values can be derived. For example, the hot water supply is approximately 10-12 l/min, the outlet water temperature range is 35-60 degrees, the operating pressure range is 0.5-6 bar.

The manufacturer also thought about the safety of its own products. If the burner goes out, the water supply will end.

Each model comes with a passport and instruction manual, which outlines operating rules and non-hazardous work in more detail, and also includes an important diagram of the device.

Now on the market there are a lot of gas-powered speakers with an original color palette. Consumers sometimes make the mistake of giving preference to color over technical specifications. The Astra gas water heater does not strive to distinguish itself due to its appearance, but focuses on its ability to work and has its own range of models.

Model 8910-00.02

has high power - up to 21 kW and an operating capacity of 12 l/min. Dimensions – 700x372x230 mm. The chimney has a diameter of 120 mm. Gas consumption per hour is 2.3 cubic meters. m. Ignition occurs manually.

Open type firebox. It is not difficult to study cravings. The gas pipe for connection has a cross-section of 3?4 inches, the water pipes - 1?2 inches. The weight of the device is 15 kg.

Model 8910-08.02

has slightly low power (up to 18 kW) and productivity (10 l/min). However, fuel consumption is also lower - 2 cubic meters. m/h. The weight of the unit is 14.7 kg. Otherwise, the device is very similar to the previous model. Ignition is also done manually

Model 8910-15

It has one significant difference - this system has electronic ignition of the burner, which is very comfortable. Now there is no need to worry about the availability of matches.

The power of the unit can reach 20 kW, productivity – 10 liters of hot water per minute. Gas consumption is 2 cubic meters. m/h. Speaker weight – 13.9 kg. The diameter of the chimney is 135 mm.

Model 8910-16

It is also equipped with an electronic automatic burner ignition control system. This automatic device is a record holder for power (up to 24 kW). The device heats water at a speed of 12 liters per minute. Gas consumption – 2.3 cubic meters. m/hour. The weight of the device is 14.7 kg.

It should be noted that spare parts for Astra speakers can be easily found at inexpensive prices.

Causes of problems and DIY repairs

The use of geysers, however, like any other equipment, is accompanied by malfunctions, frequent or rare. At the same time, there are some malfunctions that can only be eliminated by specialists who have the necessary knowledge and permission to do so. But there are also some that can be easily eliminated with your own hands, so we will consider them.

Video - sensor malfunction

Video - repair of a Chinese gas water heater

- The most “popular” type of failure is that it simply does not turn on. If it has an electronic ignition, then you can easily solve a similar problem - just check the batteries and, if necessary, replace them with new ones. Often, such troubles overtake the owners a year after purchase, since the batteries last only that long.

- Also, when using a gas water heater, it may happen that the water in it does not warm up or warms up, but not well enough. Often the cause of such problems is the water node, or more precisely, its defect. As a result, the membrane stops responding to changes in pressure in the water supply system. And if this membrane stops stretching under the pressure of water, then, as a result, the gas valve will not open, or it will open, but not completely. To solve this problem, you must know at least in general terms the structure of the geyser, because the defect can be of several types. If salt deposits have accumulated.

- If the system is clogged.

- If cracks have formed, etc.

To fix this problem, you must first disconnect the column from the gas supply, then clean the water unit and check the membrane.

If the internal elements of the device are covered with soot or dirt, this can also lead to failure. To solve this problem, you must remove the outer casing of the device, then clean each of the elements using a vacuum cleaner. The next sign that the gas water heater has stopped working correctly may be that the burner goes out immediately after turning on. This happens because the ventilation duct is clogged. Modern models of geysers are equipped with special sensors for such cases, which will inform the owner if there is no draft. After this, the gas supply should be turned off immediately. Next, the chimney should be checked. To do this, the plug is dismantled and everything that has accumulated there is removed.

Important! You can check the draft of a chimney in the old “old-fashioned” way: bring a lit match to it. If the fire on the match deviates in the direction of the chimney, then everything is fine with it

If this does not happen, then it needs complete cleaning.

It is for this reason that the gas water heater should be inspected annually - this is the only way it will work correctly.

We also recommend that you familiarize yourself with the basic requirements

Typical breakdowns and how to fix them

Repairing a gas water heater is an activity for highly qualified specialists. However, some breakdowns can be fixed with your own hands. Before starting work, you need to close the water and gas supply taps. After this, you need to unscrew the mounting screws and remove the handles and speaker housing.

Here are some examples of when a gas water heater won't light up:

Water heaters with automatic ignition systems may run out of batteries. All you need to do is replace the batteries. For water heaters that have a built-in generator, the piezoelectric element, electrode or power cable may malfunction. It is necessary to clean the contacts of the automatic ignition system, check the electrodes and wires for malfunctions. If all these steps do not help, you need to check and replace the power button and the piezoelectric element. If there is no draft, you need to clean the ventilation; to do this, you should call a specialist. If the pressure is insufficient, you should pay attention to the water supply or heater assembly. All that is needed is cleaning the pipes, washing or replacing filters. If the gas water heater does not turn on, you should check and, if necessary, replace the membrane of the water unit. To do this, remove the water-gas unit and, by unscrewing the screws, separate its water part

Before removing the rubber plate, it is important to remember its location. Then you need to clean the inside of the lid and install a new rubber part on the plate with the stem

It is better to replace the membrane with silicone, which lasts longer. Finally, you can tighten the screws (preferably diagonally). Some gas devices have a knob for adjusting the water flow. If the column does not light up, you need to check how the mechanical switch is located. If the pressure is not large enough and the column does not start, you should set the knob to the leftmost position and switch to the right until the device turns on. You need to adjust the jet at startup.

Water flow problem

Often the column does not light up when the water is turned on due to a decrease in water flow. With such a malfunction in the tap, the stream of water when turned on is observed to be very thin and weak. There is a feeling that the gas water heater is faulty in appearance. This happens with absolutely any brand: Neva, Oasis, Bosch.

A decrease in water flow can occur:

- Abruptly, the loss of performance disappears instantly.

- Gradually, with a noticeable decrease in the performance of the gas water heater;

A sharp loss of performance of a geyser can occur in connection with street work. During this time, the street water supply may be repaired. Accordingly, the overall pressure of cold water everywhere will be sharply reduced. The owner can easily skip this moment and look for the cause in the gas water heater, disassembling it. The reason lies on the surface, but a person gets confused and looks for it in something completely different.

Also, the water pressure in a gas water heater may gradually decrease due to simple contamination of the aerator intended for the mixer. To eliminate the cause of the malfunction related to the aerator in the faucet itself, it is necessary to remove it and clean it.

This is a standard aerator that is installed on the faucet. Try cleaning it

Owners who have a mesh filter at the inlet should also not forget about it and periodically clean it.

Coarse filter. It is installed to supply cold water to the column. Clean it too

The filter flask can also cause a gradual decrease in water pressure in the gas water heater

You should not forget about this and, first of all, if the wick of the gas water heater does not ignite, pay attention to it. If you miss the reason that lies on the surface, there is a risk of investing money in unnecessary diagnostics or repair of the gas water heater.

Repair and diagnostics of the gas water heater are not appropriate in this case.

Two filters for water purification in flasks. They can also get clogged

There is another case associated with a lack of water pressure when the gas water heater is turned on. This happens due to mechanical clogging of the hose. Scale was found in the hose, and it blocked the path of water. The scale could have come from the heat exchanger.

Preparing for replacement

To change the membrane in a gas water heater, first of all, you should shut off the water at the inlet to the water heater or in the entire apartment. After this, the gas valve closes and the hot water tap opens. You should open the tap that is located lowest in the apartment, usually it is in the bathroom. Then all the water from the system will drain and will not interfere with repairs.

To replace the membrane, we will need Phillips and flat-head screwdrivers, 24 and 19 wrenches, a new membrane or a repair kit.

Before removing the casing, remove all the handles from the front side and disconnect the wires from the display, if present. In some speakers, the housing is additionally secured with screws that are located at the bottom and top of the speaker, under the adjustment knobs or decorative trims. The casing is also secured with simple latches.

The chimney duct is clogged

Lack of draft when the Oasis gas water heater does not light up usually appears when there is soot in the smoke ventilation system and heat exchanger, which clogs the fin pipes. This indicator is measured by a sensor and at low values, a protective mechanism is triggered, cutting off the gas to the device.

Under such conditions, the column will not be able to light up. It’s easy to check the draft; to do this, bring a lit candle to the ventilation, and if the fire is pulled towards the channel, then everything is fine; if not, you will need to clean the flues and internal heating surfaces from soot deposits.

Another reason for poor draft may be poor ventilation in the room. Currently, many apartments have plastic windows installed, which, to put it mildly, “are not good for ventilation”; in such rooms the unit only works if the window is open. In order to avoid this type of failure, you will need to install a special supply valve that ensures proper air circulation in the room.