When arranging a heating system, it is necessary to take into account many factors, among which correctly installed radiators play an important role. Installation of heating devices is impossible without the use of special fasteners, in particular, radiator brackets. They will help securely fix the radiators, which in this case will last for a long time without requiring repairs or special maintenance. We present all the necessary fasteners for installation on various base surfaces of radiators made of cast iron, aluminum and bimetal.

Connection to pipelines

The final step when installing heating radiators in an apartment with your own hands is connecting to the pipeline system. It can be carried out by the side or bottom, depending on how provided by the manufacturer of the heating device.

In turn, the lateral connection of the radiator to the pipes can be carried out in several options:

Of course, the connection diagram and all other nuances regarding how to install a heating radiator in an apartment must be carefully thought out in advance, before installation work begins. If everything was done correctly, then the result of such work is a comfortable temperature microclimate in the home, allowing you to survive the harsh and cold winter season without any problems.

https://youtube.com/watch?v=3BaaUUG4JZE

Kinds

It is possible to select the following options for floor brackets for radiators:

- Fixed with plastic cover.

- Adjustable, which will also be equipped with a plastic cover.

- Combined models.

- Special ones with a width of 80-100 mm.

Holders for cast iron radiators

The heaviest batteries are cast iron, so the fasteners for them are the most durable and massive. Such a fastening element must withstand not only the weight of the heating device, but also the coolant circulating in it. Since the gaps of the pipes in cast iron batteries are large, a lot of coolant circulates in them, which increases the already considerable weight of the radiator.

To mount cast iron batteries on the wall, separate pins or the same elements mounted on a strip are used. As a rule, such fastening devices are of considerable thickness and are labeled as “reinforced”. The bracket itself may or may not be painted. The standard color scheme for such holders is white, but when installing a designer battery, the bracket can be repainted in the desired shade.

In addition to special brackets, cast iron batteries can be hung on regular hooks. Such elements are sold together with dowels. There is a thread on one side of this hook.

Installation is carried out as follows:

- a hole is drilled in the wall in the right place;

- a dowel is driven into it;

- A hook is screwed into this dowel using a threaded thread on one side.

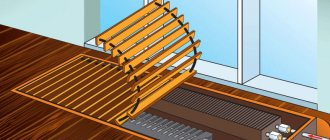

There is also a special bracket for a floor heating radiator. Such stands can be adjusted in height or have specified standard dimensions. Floor fasteners may differ in the upper arcs, which are responsible for fixing the section on the rack. Thus, there are arcs in the form of a chain consisting of moving links, as well as elements made of steel wire. These stands for heating radiators come complete with clamping bolts.

Areas of use

In what cases each type of fastener is used is not difficult to figure out.

- Wall mounts are traditionally used for mounting heating devices on solid walls.

- In rooms with light partitions (slag and aerated concrete, plasterboard, plywood, etc.), floor installation is preferred.

However, the scope of application of floor fasteners is not limited to this.

It applies:

- In rooms with panoramic windows. Heating devices of small height form a thermal curtain that prevents windows from fogging up without blocking the view through them.

- In rooms where the entire wall area is occupied by hanging furniture, plumbing fixtures and other equipment. The floor battery can be placed not only near the wall, but also in the center of the room.

However: such an installation implies a hidden installation of the lines to the radiator. It is performed in a screed or under a subfloor.

- In rooms with a certain style. For example, a floor-mounted cast iron radiator will fit perfectly into the design of a room designed in retro or loft styles.

A cast iron battery on racks will organically fit into the loft style.

How to hang a battery

Installing batteries is considered one of the stages of creating a heating system in a house. Here you need to take into account a lot: the dimensions, the number of heating devices, as well as the design of the mounting of the heating batteries, and so on. To avoid forgetting anything, follow these simple recommendations.

- — heating devices with plugs;

- — spider fasteners;

- — adapters;

- — gaskets;

- - Mayevsky valve or air vent, and also an installation kit;

- — taps with a round hole;

- - metal-plastic or plastic pipes (if necessary).

Before purchasing heating radiators, first of all, calculate how many elbows you will need for any of the rooms. Calculate based on one knee for every two square meters. m. area. It turns out that if the room area is 12 m2, six bends will be required to supply it with heat. When you think about the metal for your batteries, remember that in most cases aluminum batteries are installed in personal homes, and in residential areas - bimetallic ones. Cast iron batteries are gradually being phased out. The battery should be hung with a gap of at least 2.5 cm from the wall surface, otherwise its heat transfer will be low. It is also not recommended to place batteries close enough to the floor surface. Step back 8-10 centimeters from the floor so as not to disturb the heat exchange. And it will be easier to clean under the heating device. If you place the battery under a windowsill, you don’t need to place it too close to it. First of all, mark the places for attaching the spider fasteners: one at the bottom and two at the top. Spider fasteners will be attached to the wall using dowels or by recessing them into the wall and then sealing them with cement mortar. Check the verticality of the fastening using a level. Unevenly hung heating appliances look bad, and heating technology is also disrupted. After installing the spider fasteners, hang the battery on them so that the bottom edges of the water collectors rest on the hook of the support. Next you need to combine the battery with the pipes that lead to the heating system. They are equipped with a thermostatic valve and valve. First of all, insert the Mayevsky tap into the top plug of the heating device from the side opposite to the connection. If you still want to paint newly installed heating devices, remember that they cannot be coated with silver paint or any other iron paint. And you need to be careful not to accidentally paint over the hole in the Mayevsky tap.

how to hang a cast iron battery in 2018

List of tools and materials required to install the radiator mount

Heating radiator installation diagram.

In order to mount the battery to the wall, you must use the following parts and tools:

- dowels;

- brackets;

- Mayevsky crane;

- traffic jams;

- stub;

- horizontal level;

- hammer drill

For concrete or brick walls, you can use brackets, since the strength of the walls will allow them to be drilled for fastening dowels.

Some of the plugs supplied with the radiator are pass-through - they allow the installation of return and supply pipes to them. So, one of these plugs must be plugged, and the Mayevsky tap must be installed in the second.

To fasten steel or bimetallic pipes of a single-pipe heating system, tees with sizes ranging from 25 to 32 millimeters should be used.

Each radiator must be equipped with two tees. In order to properly attach the radiator to the wall, you should also use radiator taps. The use of polypropylene or steel taps is allowed. The material for taps must be selected depending on the coolant. There should be two taps per device.

In order to hang the battery on a wall made of chipboard or plasterboard, you should use special brackets.

https://youtube.com/watch?v=s0y73jaY3Ow

Standardized distances and number of brackets

Most heating radiators are mounted on the wall under the window opening in the room to create a thermal curtain, because the most heat is lost through the glazing of the window.

When installing a radiator under a window, it is important to observe the following standardized distances:

- the device is mounted so that there is at least 8-12 cm from the floor to its bottom edge;

- there should be at least 3-5 cm from the back vertical surface of the battery to the wall;

- There should be a free distance of at least 6-10 cm to the window sill.

It is equally important to correctly calculate the number of fasteners and determine the location of their installation. The total number of brackets required to install one battery depends on the length of the heater

If the total number of sections does not exceed 8-10 pieces, then to mount the battery you will only need two holders at the top and one hook at the bottom.

If the total number of sections exceeds 10, then three brackets need to be installed on top, and two holders should be placed at the bottom. With the subsequent addition of 5-7 sections to cast iron heating devices and 10 sections to aluminum or bimetallic radiators, the total number of fasteners is increased by two (one holder on top and one on bottom).

Calculation of the required number of fasteners

The minimum number of radiator mounts cannot be less than two on top. A device suspended on one bracket will inevitably create tension at the connection points with the pipes of the heating system, which will lead to an emergency. The minimum required set is two fasteners on top and one on the bottom . When installed on a wall, the lower element is more necessary to maintain the vertical position of the radiator.

The total number of brackets can be determined by the standard: 1 bracket per 1 m2 of battery area. But there are recommendations from SNiP 3.05.01-85. For cast iron batteries (there were no others then) for 6-8 sections, the minimum set of fastenings is: 2 at the top and 1 at the bottom. Next, 1 bracket is added for every 5-7 sections. Floor racks are selected in the same way, first 6-8 cast iron sections are installed on 2 supports, then 1 more piece is added every 5-7 elements.

As for light batteries, the minimum set is used for the first 10 sections, then 1 mount is added every 10 radiator elements.

How to choose steel heating radiators wisely

Is it worth it to install radiators yourself?

Many experts do not recommend installing a radiator in a city apartment yourself unless you have good skills in this matter. We are inclined to agree with this opinion for a number of reasons:

- Installing a radiator requires some time, even for experts. If you don't have experience, it will take much longer. And during the period of work it is necessary to turn off the heating throughout the riser. Although, of course, you can postpone everything to the summer, when there is no coolant in the system.

- In addition to time, as we have already said, experience is required. Connecting radiators to a heating system is a very important matter. If you undertighten or overtighten any of the connections a little, and after some time it may lose its tightness. You will flood not only yourself, but also your neighbors with hot water.

- Proper mounting of the battery to the wall is also very important. We will talk about this further.

In fairness, it should be noted that all of the above also applies to performing work in your own home. But in this case, all the damage will concern only you, so the degree of responsibility is still somewhat less.

Features of radiator installation instructions

You should first mark on the wall the place where the radiators will be hung. So, initially, using a pencil, a place for the brackets is outlined. In the future, when installing steel radiators, it should be taken into account that the brackets should be located at the joints between.

After the markings have been applied to the wall, holes of the appropriate diameter should be drilled in the wall. The size of the hole must correspond to the diameter of the dowel supplied with the radiator. After this, a dowel should be inserted into the hole, into which the bracket will later be screwed.

Diagram of the dependence of radiator power on the installation method.

must be carried out in accordance with certain requirements. The threaded part should be unscrewed from the tap and a winder should be wound onto the free thread. In this case, the winding can be a special paste that is resistant to high temperatures. This paste can provide high-quality tightness of threaded connections. Together with the paste, it is allowed to use tow with paint or fum tape.

When using tow, paint should be applied to the threaded area of the part and spread evenly over the entire area of the thread. Along the thread, you should wind the tow itself.

On the part with the tow, the next step is to install the union nut from the tap, which will then need to be screwed into the battery plug. The nut must be tightened tightly using a wrench. The Mayevsky key and plug are installed in the same way.

At the location of the radiator plugs, you can use standard or special gaskets instead of windings, but in this case the degree of tightness of steel heating devices will be lower.

The installation of battery cells must take into account that half of the plugs are equipped with a right-hand thread, and the other half - with a left-hand thread.

The union nut located in the radiator valve does not require additional winding, since it is equipped with a special ring seal. This seal can be chamfered and form a tight connection.

After the plugs are screwed in, the radiator valves should be installed. After the first part of the work - the installation of steel heating radiators - is completed, the final part of the work should begin. Branch pipes should be soldered to the tee on one side and to the radiator valve on the other.

When installing the taps, it is necessary to pay special attention to their length - it is necessary that a certain section of this tube goes into the inner diameter of the part with which the connection is made. When soldering branch pipes, the direction of the tee and the radiator valve must coincide; for this, you can first make marks with a pencil

It is advisable to carry out marking work on a flat, flat surface.

After the installation of the radiator taps is completed, specialists hang the batteries on the brackets and check their horizontal position using a level.

Similarly, all other radiators in the heating system are installed. After installation is completed, the radiators should be connected to each other using pipelines and, ultimately, to the boiler.

Features and Installation device

As you can see, depending on the type of bracket, its design may change, but three main elements are still worth highlighting:

Structure

| Designation in the figure | Item name |

| A | Universal rack designed for batteries up to 90 cm high |

| B | Decorative plastic cover for stand pipe |

| IN | Decorative plastic cover for the heel of the stand |

Installation

As we have already noted, installing a floor-mounted battery mounting system is not difficult and the owner is fully capable of doing it himself. We will look at the progress of work using the example of installation of the adjustable “Standard” model for radiators with a height of 500-600 mm:

| Designation in the figure | description and name of the installation operation element |

| 1 | We mount the sole to the floor, securing it securely |

| 2 | We shorten the plastic holder to the required size in accordance with the dimensions of the heating battery |

| 3 | Screws adjust the required height |

| 4 | Installing the radiator itself without a cover |

| 5 | We fix the structure using the bottom bolt |

| 6 | Put the radiator cap back in place |

But installing the “Plus” bracket for batteries with a height of 200-400 mm has its own nuances, which we will also get acquainted with:

| Designation in the figure | description and name of the installation operation element |

| 1 | We mount the sole to the floor, securing it securely |

| 2 | We fix the upper part of the fastener at a height suitable in relation to the lower part |

| 3 | We mount plastic holders, on which we then install the radiator itself with the cover removed in advance |

| 4 | Using a screw rod, we clamp the washer between the convection plates, securely fixing the structure |

| 5 | Put the cover in place |

Separately, it is worth considering the installation of the sole to the floor.

Other than that, the process is completely simple:

- We place the product in the place where it will be fixed, and use a pencil to mark future holes through the holes, after which we remove the sole to the side.

- Then, if the floor is cement, then we take a hammer drill with a Pobedit drill and drill holes for the dowels.

- We insert plastic dowels into the holes.

- We put the sole in place and screw it with self-tapping screws. If the floor is wood, then fixation with self-tapping screws is carried out immediately.

Types of fasteners

When choosing fasteners for radiators, you need to focus on the convector model. The brackets allow you to qualitatively fix the heating element in the required place. To mount heating radiators, wall holders are best suited. Floor fastenings are used as additional ones, less often as main ones. Such brackets will be needed when the niche is not suitable for installing a battery or design ideas require such an implementation.

Wall

Convectors installed under the window prevent cold air leaking through the glazing from entering the room. Before attaching the radiator to the wall, you should make sure that the fasteners are suitable for installation and include the following parts:

- anchor clamps of different lengths;

- holders that can be adjusted in height, thereby helping to hide various surface defects. For example, adjustable steel fasteners facilitate faster installation of cast iron heating radiators to the wall. The mount allows you to change the position of the battery horizontally and vertically, and correct possible gaps with the wall;

- holders with rubberized surfaces for better insulation of extraneous noise;

- corner fasteners used in installing small, lightweight batteries.

Hooks

For steel heating radiators, a metal corner mount is suitable. One part of it is attached to the wall, the other is equipped with hooks for further fixation of the heating element. To fix cast iron batteries, use hooks supplied with dowels. As a rule, the clamp is recessed into the wall by approximately 100–150 mm.

If you are installing cast iron appliances with a large number of sections, then hooks alone will not do. It is worth strengthening the structure with floor fastenings.

Brackets

Attaching cast iron radiators to the wall is the most labor-intensive process due to their large mass. Despite this, they are perfectly held using special brackets or bent pins. High quality indicators are achieved through the use of a reinforced metal alloy, indicated in price lists as “reinforced”. You need to take into account that fasteners for heating radiators to the wall require a certain size, because sections with different depths must be equally distant from the wall at a distance of at least 30 mm. Therefore, the bracket must be larger than the heating element by the length of the recommended indentation.

Floor-standing

Installing heating elements on the floor has a number of positive aspects:

- happens quickly;

- you can fix any convector, from the lightest to the heaviest;

- the design will be more stable and reliable.

There are no special differences between wall and floor fixation. You just need to know that when installing on a wooden floor, it is still better to use an additional wall bracket.

If you use a floor mount for aluminum radiators, the battery can be installed even next to a wall made of aerated concrete and similar materials.

The stand for mounting the radiator is designed in the form of a metal leg. It is manufactured in two versions - regular or with a mechanism that allows you to adjust the height. The arches on top are made differently, which are designed to fix the sections in the stop. Some are made in the form of a solid steel wire, others in the form of a chain with moving links.

Classification of heating batteries

To understand what heating devices are, you need to study their classification. Types of radiators are distinguished depending on the material of manufacture:

- cast iron;

- steel;

- aluminum;

- bimetallic.

Each type has its own advantages over other models. Therefore, it is difficult to say that any of them is definitely better.

Cast iron models

Batteries made of cast iron are massive, have the ability to retain heat for a longer time, and are not susceptible to corrosion. A definite plus is resistance to large pressure surges. Cast iron radiators are the most suitable option for apartment buildings. The service life is at least 50 years, sometimes longer. Instead of regular models, you can install ones decorated with patterns.

It is worth considering that due to the large mass, it is necessary to select a reinforced mount for cast iron heating radiators.

Steel radiators

A steel battery is a steel casing, inside of which there are plates and pipes made of the same metal. Structures are divided into panel and tubular. A well-thought-out structure allows air to actively circulate, so the room quickly warms up. But the device cools down quickly after the heating supply is stopped, which can be considered a significant drawback. Due to its low weight, mounting the radiator to the wall is not particularly difficult. Compared to cast iron representatives, steel appliances consume one third less coolant, which makes them very economical.

Aluminum radiators

The complex design of the convector allows for efficient circulation of air masses. The thermostat quickly responds to commands, which allows you to change the room temperature in a short time. Depending on the production method, structures are divided into injection molding and extrusion. The first ones are of better quality, but expensive. The latter are cheaper, but cannot be repaired. They are relatively lightweight, which greatly simplifies the installation process. These batteries look attractive, but are not very easy to clean.

Bimetallic radiators

An improved version of aluminum batteries is bimetallic. The system is reinforced with steel elements, which make them resistant to higher pressures. Convectors quickly warm up and begin to give off heat. They weigh a little, making them easy to install. The surface is easy to clean from various contaminants, unlike cast iron models. These devices are more resistant to corrosion. But bimetallic heat exchangers are more demanding on the quality of incoming water.

Rules for mounting the holder

The ideal placement of the heating device is considered to be in the center of the window opening. For efficient heating of the room, the holders are mounted at a certain distance:

- about 100-150 mm from the floor;

- 40-50 mm from the wall;

- at least 90-120 mm to the window sill.

Most often, radiators are placed under windows

For successful marking, it is necessary to determine the middle of the window opening and mark this place with a level. Further calculations depend on the wiring:

- in the case of lower wiring, a horizontal line parallel to the floor surface is marked;

- with a lateral connection, the calculation is carried out based on the position of the upper supply pipe - the horizontal is marked parallel to the axis of the supply pipe.

The distance between the points of the holder is transferred to the marked horizontal lines; for greater accuracy, you can attach the bracket directly to the mounting surface. Upon completion of installation work, the reliability of the system is checked by light pressure from top to bottom. There are three main types of radiator connections:

- lateral one-sided - the most common option. The supply pipe is connected to the upper pipe, which discharges, respectively, to the lower one;

- lower. Used if the heating system is hidden in the floor;

- diagonal. The best option for long radiators. The supply pipe is connected to the upper pipe on one side, and the outlet pipe is connected to the lower pipe on the other side.

Fixed type bracket

Marking fastening points and calculating the number of fastenings

A water heating radiator passively heats the air, radiating heat into the interior of the room and organizing the movement of thermal air upward, receiving a cooled flow from below. For its normal operation, choosing a location where there are no obstacles to performing functions is the main task. Specific recommendations for the location of the heater and corresponding fastenings are given in the technical documentation for the device, but they are based on the following standards SNiP 3.05.01-85:

- the central axis of the radiator should not deviate from the central vertical axis of the window by more than 20 mm;

- the width of the heating radiator should be within 50-75% of the window width;

- the distance from the floor to the radiator is at least 60 mm;

- the gap between the radiator and the wall is in the range of 25-50 mm. Closer to 50 mm is better;

- the distance between the battery and the window sill is at least 50 mm.

Recommendations for placing heating radiators under classic windows.

Some tips:

- The batteries need to be placed further from the entrance, in a niche under the window, then it will not fog up.

- If it is impossible to comply with the standards in a tight niche under the window, you need to make decorative holes or slits in the window sill board.

- It is necessary to maintain a slope of 4-5 mm in the supply pipe to the heating device so that air pockets do not form in the radiator.

Stages of work

If you decide to do the battery installation work yourself, you need to know what steps the process involves.

The instructions for carrying out such work divide it into:

- Preparation of materials and equipment.

- Location calculation.

- Installation of brackets.

- Production of the actual installation.

- Soldering or sealing the joint.

- System check.

Preparatory stage

These operations are not recommended to be performed in winter, especially in severe frosts - this is unsafe. Even if you decide to do all the work yourself, you will still have to call a plumber from the housing office to disconnect your apartment from the common riser. In preparation for installing the system, you will need to purchase or find the following tools and additional materials, such as:

- Keys.

- Tow.

- Valves.

- Sgony.

- Couplings.

- Adapters.

- Brackets.

- Bushings.

- Nipples.

- Corners.

If you still choose, for example, cast iron batteries, you will probably have to purchase Mayevsky taps and install them yourself. In bimetallic and aluminum sections they are already built-in. This device allows you to bleed excess air from the system and maintain its functionality, preventing airing.

Features of radiator installation instructions

You should first mark on the wall the place where the radiators will be hung. So, initially, using a pencil, a place for the brackets is outlined. In the future, when installing steel radiators, it should be taken into account that the brackets should be located at the joints between the radiator sections.

After the markings have been applied to the wall, holes of the appropriate diameter should be drilled in the wall. The size of the hole must correspond to the diameter of the dowel supplied with the radiator. After this, a dowel should be inserted into the hole, into which the bracket will later be screwed.

Diagram of the dependence of radiator power on the installation method.

The installation of bimetallic radiators must be carried out in accordance with certain requirements. The threaded part should be unscrewed from the tap and a winder should be wound onto the free thread. In this case, the winding can be a special paste that is resistant to high temperatures. This paste can provide high-quality tightness of threaded connections. Together with the paste, it is allowed to use tow with paint or fum tape.

When using tow, paint should be applied to the threaded area of the part and spread evenly over the entire area of the thread. Along the thread, you should wind the tow itself.

On the part with the tow, the next step is to install the union nut from the tap, which will then need to be screwed into the battery plug. The nut must be tightened tightly using a wrench. The Mayevsky key and plug are installed in the same way.

At the location of the radiator plugs, you can use standard or special gaskets instead of windings, but in this case the degree of tightness of steel heating devices will be lower.

The installation of battery cells must take into account that half of the plugs are equipped with a right-hand thread, and the other half - with a left-hand thread.

The union nut located in the radiator valve does not require additional winding, since it is equipped with a special ring seal. This seal can be chamfered and form a tight connection.

After the plugs are screwed in, the radiator valves should be installed. After the first part of the work - the installation of steel heating radiators - is completed, the final part of the work should begin. Branch pipes should be soldered to the tee on one side and to the radiator valve on the other.

When installing the taps, it is necessary to pay special attention to their length - it is necessary that a certain section of this tube goes into the inner diameter of the part with which the connection is made. When soldering branch pipes, the direction of the tee and the radiator valve must coincide; for this, you can first make marks with a pencil

It is advisable to carry out marking work on a flat, flat surface.

After the installation of the radiator taps is completed, specialists hang the batteries on the brackets and check their horizontal position using a level.

Similarly, all other radiators in the heating system are installed. After installation is completed, the radiators should be connected to each other using pipelines and, ultimately, to the boiler.

How to hang a heating radiator on brackets

Almost any radiator is hung on brackets as follows:

- Holes are drilled in previously marked places, dowels are driven into them and brackets are screwed in (when screwing pin brackets, the depth of screwing is determined by the requirements for the gap between the radiator and the wall). The hooks should hit the junctions of the sections.

- The lower brackets are fixed in the same way.

- After installing the battery on the brackets, pressing checks the reliability of the installation and the accuracy of the level.

- If floor supports are used, adjust them in height and secure them.

The algorithm for installing any radiators is the same: high-quality markings, installing brackets, hanging batteries, checking the level, fixing them in place, connecting the pipeline, control and monitoring systems. The nuances of the specific model of heating device and the fasteners used are reflected in the accompanying documentation, but the general construction work is the same.

Heating radiators

Procedure for installing the radiator to the wall

Radiator mounting dimensions diagram.

You should first assemble the battery (do not completely remove it from the original packaging). To do this, you need to screw the radiator plugs into the plug using gaskets.

After this, shut-off valves and the Mayevsky valve are installed. On the radiator you need to mark the areas where the brackets will be installed. Next, the brackets are fixed to the wall using dowels so that their hooks are located exactly between the sections of the battery.

Now you need to establish the degree of horizontality of the heating device using a horizontal building level. If necessary, adjust the level of the radiator using brackets.

In accordance with the diagram, you need to connect the batteries to the heating system. If you install the radiator at a level less than 7 cm from the floor, heat transfer will be significantly reduced and difficulties may arise with cleaning the room.

When this occurs, the shut-off and control valves should be opened smoothly and carefully to prevent water hammer from occurring. After installing the radiator, you need to draw up a report on its commissioning.