Arrangement of the roof is one of the most important stages in the renovation or construction of a private house. Improper design can cause accumulation of sediment and uneven load distribution, which in turn will lead to damage to the coating and failure of the entire structure. Roof elements laid in violation of the technology will allow moisture to pass through, and the attic space that is not insulated from the inside will allow cold air to pass through. It is not possible to fully exploit and live in such conditions throughout the year. In this article we will tell you how to efficiently insulate a roof from the inside using all possible methods, and also provide practical advice from roofing professionals

Roof insulation is a responsible process

Factors that affect the roof

Any structure that is used as housing must meet certain standards and requirements. Only if they are followed will life in the house be comfortable and peaceful . Every detail is important - the correct laying of the foundation, the construction of walls, the laying of communications and the construction of the roof. The choice of roofing depends on the weight that will put pressure on the supporting structures of the house, the time and cost of installation work. In addition, an equally important step in arranging the roof is its insulation from the inside. It will not only protect the premises from the effects of external cold air masses , but will also act as a good sound insulator.

The roof must withstand freezing temperatures and a layer of snow

In different climatic zones, roofing elements are affected by many factors. The following natural phenomena correspond to our latitudes:

- rain;

- hail;

- excessive ultraviolet radiation from the Sun;

- snow;

- strong gusts of wind;

- icing, etc.

In order to withstand these disasters, the roof structure must be well assembled and covered with sufficiently durable roofing materials.

A typical private house is a structure that usually includes a main floor (one or two) and an attic. If the latter is used for housing, it is built in the form of an attic. It has been proven that with an uninsulated roof, in the cold season, up to 15-20% of the heat from the room is lost through the ceiling. This entails the need to increase heating and, as a result, increased energy bills.

Heat is lost through an uninsulated roof

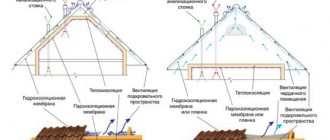

The peculiarity of the space under the roof is not only in its geometric component, but also in the method of distribution of thermal energy. In summer it is hotter here than in other rooms, and in winter, on the contrary, it is colder. To create a comfortable microclimate inside and maintain optimal temperature, experts recommend creating a multi-layer “pie” from various materials. It usually includes a waterproofing layer, vapor barrier and insulation.

Schematic representation of the roofing “pie”

Interesting to know! With large heat losses through the roof, in winter the snow cover on it begins to melt, forming a crust of ice. With minimal, even technologically advanced, holes in the roof, there is a possibility of leakage.

Types of roofs according to insulation method

The roof is insulated not only to eliminate heat loss, reduce high fuel consumption and save on heating. Thermal insulation protects the roof from overheating (and in the summer it will no longer be unbearably hot in the attic), prevents the appearance of ice and icicles, and muffles the noise of rain or wind drumming on the roof. The roof is insulated, even if the house has an uninhabited, cold attic.

According to the method of insulation, the entire variety of roofs is divided into two large groups:

- Warm roof, attic;

- Cold attic.

Warm roofing is an option for residential heated attics with full-fledged living spaces. For high-quality attic insulation, both the composition of the roofing cake and the correct choice of insulation are equally important.

A cold roof is made for an unheated attic: the structure consists of rafters, waterproofing, counter battens and roofing. One of the main advantages of a cold attic is the ability to save on thermal insulation. Cold air in the attic prevents the roof from heating up, and the snow on the roof does not melt, roll down, form ice, or scratch the roofing material. For such roofs, only the ceilings on the attic side are insulated.

Processes taking place under the roof

In order to properly insulate a house and make its roof a full-fledged protective barrier from the cold, it is necessary to choose the material wisely. Usually it is selected based on the nature of the processes occurring in the attic space. The most significant include:

- Moisture exchange is a phenomenon that arises directly from human activity (showering, cooking), breathing, body evaporation, etc. The vapors that appear in the room slowly rise upward, condensing moisture particles that are removed through the roof. When the roof is well insulated, humidity levels remain normal , and excess moisture, along with odors, is removed by properly equipped ventilation.

- Heat exchange is a process that occurs due to the difference in temperature in the living space and outside. If attic floors are not insulated, a significant portion of the heat escapes through the roof. The function of insulation is to resist this and maintain optimal temperature values inside residential premises. Thermal insulation material has a porous structure. This prevents the entry of cold masses and the loss of warm air from the rooms, which in turn eliminates the need to unnecessarily heat them.

Vapors are created in the process of life

A layer of hydro- and vapor barrier prevents the appearance of condensation , which occurs at the point of contact between warm and cold air flows (dew point). Therefore, it is laid together with a layer of insulation, helping the latter to maintain functionality and appearance. Properly organized insulation increases the service life of the structure several times and minimizes the need to carry out annual repair and restoration work.

Is it worth insulating the roof of a house?

Whether you choose to insulate the roof of your house or abstain is up to you, but this type of work implies the following advantages:

- reduction of heat losses by approximately 15%. And if we take into account the regular rise in energy prices, then insulating the roof is a significant saving in energy resources, as well as finances;

- increase in living space. When the roof is insulated, the building acquires additional premises, but only on the condition that it is done accordingly;

- reduction in temperature fluctuations. Temperature indicators have a fairly noticeable effect on any type of roof. For example, let’s take the lower part of the attic, located directly under the roof - the temperature there is close to room temperature. From the outside, the temperature varies depending on weather conditions. Insulating the roof will solve problems associated with large temperature changes, since external air currents will not penetrate inside the house, and warm air will not escape outside.

The roof can be insulated both from the inside and outside of the house

Therefore, there is no need to doubt the need for roof insulation.

When choosing a material for roof insulation, consider not only its temperature characteristics, but also moisture resistance, environmental friendliness, resistance to negative formations, as well as diffusion and capillary humidification.

Is it possible to do without insulation?

A private house is usually equipped with roofs with several slopes, which form an attic on top of the main floors. Often the attic space is converted into living space , creating additional square meters in the house. This is very important for large families. If there is no insulation of the attic or attic, as such, then living in such conditions will be physically uncomfortable and impossible, due to the lack of heat necessary for the human body.

An insulated roof saves heating costs

Any roofing material, be it iron or slate, will not be able to protect the interior space from the cold, as a specially designed heat insulator (mineral wool, polystyrene foam, etc.).

If you ignore the installation of insulation or postpone it for an indefinite period, you can soon get not only heat leakage from the house, but also problems with the rafter system . It will be covered with fungus and will gradually rot, creating the danger of destruction of the entire structure. If you insulate the roof, but incorrectly calculate the thickness of the thermal insulation, then instead of a protective function, you will get an inversely proportional one - a destructive one.

Insulation of a sloping roof

With proper organization of insulation, the temperature difference will not lead to the formation of condensation. If the thickness of the layer does not meet the required standards, then drops of condensate will appear on it in large quantities. The latter contribute to the loss of strength of the rafters and disruption of heat exchange in the rooms as a whole.

Failure to comply with construction and installation standards is fraught with consequences for human safety. When choosing insulation, you need to be guided not only by its physical and chemical characteristics, but also by the possibility of installing it yourself. If you have questions or difficulties in choosing insulation and the method of its installation, it is better to seek help or comprehensive advice from professional roofers.

Poorly designed roof leaks

Errors and recommendations

Visually, errors in roof insulation manifest themselves in the appearance of wet spots on the inner lining , melting snow on certain areas of the slope, or other signs of condensation accumulation. Most often they arise due to violations of the pie laying technology, including:

Excessively tight connection of the insulation to the impermeable waterproofing layer.- Errors in the installation of insulating films and layers (fastening without overlapping or sealing joints, choosing the wrong side, mechanical damage, overhanging or excessive tension, lack of ventilation gaps).

- Wrinkling of insulation when laying from the inside.

- Installation of materials that have accumulated moisture or covering wet surfaces with them, carrying out work under unfavorable conditions.

- Refusal to prepare and process wooden frame elements and sheathing.

Errors in organizing condensate drainage and cake ventilation deserve special mention. Ventilation gaps between layers will not matter if there is no possibility of condensate being discharged outside, an unprotected cornice or insufficient air exchange.

When installing internal insulation, many owners miss this point and leave the overhangs unlined or, conversely, tightly block the eaves or ridge. The last mistake is more common; internal insulation of the roof is often carried out after it has been put into operation, with previously installed and sewn eaves.

Advice. If you doubt your skills, you should discuss the method of draining and weathering condensate with specialists.

Preparing surfaces for insulation

Before carrying out thermal insulation measures, you need to clearly know what kind of structure you will have to work with . Based on its technical characteristics, a work plan is determined. The following factors are taken into account:

- geometry features (angle of inclination, width, length, etc.), shape and number of slopes;

- type of roof covering;

- type of rafter system;

- main building material of the building;

- availability of laid communications;

- the roof extends beyond the main structure.

Preparing roof surfaces

It is worth correctly calculating the necessary materials and the approximate time for their installation. When the process is visually presented, everything is weighed and scheduled, then you can cope with absolutely any task. Whether it’s the roof of a rural house or a huge country villa, the algorithm of actions is similar. To properly insulate a roof, you need to properly prepare it:

- carry out a thorough inspection of the rafters and sheathing - if damaged elements are found, they must be replaced;

- treat wooden parts with varnish or antifungal solution;

- check the integrity of communications laid in the under-roof space.

Communications under the insulation

Once the preliminary stage has been completed, you need to make sure that you have all the materials and tools necessary for insulation. If everything is in order, you can start working.

CONCLUSIONS:

- Roof insulation is necessary to maintain heat in the house.

- The work must be treated especially carefully when planning the installation of an attic.

- Insulation is carried out in three ways: the material is laid between the rafters, on the rafters or under the rafters.

- The material for thermal insulation must meet several basic requirements: be moisture-proof, retain its shape and not emit toxic substances.

- The universal insulation material is URSA.

- Mineral wool and spatula insulation are also very often used.

- When carrying out work, it is necessary to adhere to a certain sequence of actions.

How to properly insulate a roof, watch the video clip.

Selection of tools

If you ask a professional roofer what tools you need to have to insulate the roof, he will probably answer that a knife, a hammer, a clear head and skillful hands. Essentially, this is the case, but there are subtleties and secrets that not everyone wants to divulge.

Roofing tools

The most important detail and, accordingly, the trick is choosing a knife . If you take a regular mounting knife, you will be able to work, but throughout the entire time you will suffer from unevenly cutting off pieces of insulation. Such a construction tool has a blade that is too short and is unable to cut through a thick layer of heat-insulating material. In addition to all this, a standard knife will quickly become dull on polystyrene foam or mineral wool.

If you don’t have a knife, then you can use improvised means for cutting - a hacksaw for wood or a wide kitchen bread cleaver with a lumpy sharpening.

The ideal option would be to purchase a special professional long knife . It is made taking into account the requirements placed on it - made of carbon steel with a length of 35 cm and a comfortable handle made of high-quality plastic.

Professional knife

In addition to a good cutting tool, you will definitely need a hammer, a screwdriver, self-tapping screws of different lengths, a long strong cord, reliable protective clothing, glasses to preserve your vision and a respirator.

It would also be a good idea to listen to the following recommendations:

- the place where thermal insulation materials are to be cut must be well ventilated;

- carefully protect your hands, head area and, especially, the respiratory tract with your eyes - they are most susceptible to damage from flying fibers;

- after work, immediately take a shower, thoroughly washing your hands, face and other areas of the skin;

- before cutting, make sure that the size is correct - the pieces should fit freely between the rafters, without falling out or being squeezed;

- It is advisable to cut mineral wool across the fibers - this minimizes the release of flying particles.

Cutting mineral wool

Material selection criteria

The insulation material must be suitable in all respects

Do not rush to purchase the first thermal insulator you come across, just because it looks thick, is packaged in colorful film and has an attractive price. First of all, the material must clearly meet your requirements and also meet all building codes.

| Characteristic | Explanation |

| Safety of use | Raw materials for roof insulation must be environmentally friendly and completely safe for humans. Its composition should not include toxic chemical compounds released both when heated and at normal temperatures. |

| Minimum thermal conductivity | This is one of the main conditions for products of this type. The insulating material should retain heat inside the house as efficiently as possible and not allow cold masses to pass in from outside. At the same time, it does not deform and can withstand temperature changes well. |

| Moisture resistance | Quality plays a significant role. The insulation should not absorb moisture either from the atmosphere or directly falling on it. If this characteristic is lame and the material absorbs liquid like a sponge, then it will soon lose its properties. |

| Fire safety | There are already a lot of flammable wooden elements in the roof structure. Therefore, the insulation should not support the combustion process. |

| Noise insulation | This is one of the most important characteristics. Sound absorption will contribute to quality sleep and a comfortable time in the house. If the sound insulation properties of the material are not good enough, then even light rain on the metal roof slopes will create a rumble. |

| Durability during operation | The material should not attract insects and rodents, and also be resistant to the development of microorganisms such as mold and fungi. |

| Ease of installation | If you are planning to insulate the roof of a private house with your own hands, then it is important that the raw materials are pliable and convenient for installation work. |

| Economical consumption | A factor that occupies not the last place, especially for those who have a limited budget. |

Types of thermal insulation material

The modern construction market offers a wide selection of insulation materials that can satisfy almost all existing customer needs. The most popular and in demand are the following types of thermal insulation:

Mineral wool

Mineral wool is a universal material that enjoys well-deserved trust among builders. It has excellent thermal conductivity and can be used to insulate not only roofs, but also walls and floors. This heat insulator can be used both inside and outside buildings. It is fireproof and can withstand air temperatures up to +700 degrees. Due to this, it is widely used in the construction of heating mains.

Laying mats with mineral wool

The term “mineral wool” includes such concepts as glass wool, slag wool and stone wool. Insulation comes in different structures and densities. To arrange the thermal insulation of an iron or slate attic, it is better to purchase raw materials with fibers located vertically.

Stone wool

The second name of the product is basalt wool . This is a type of thermal insulation material that is created on the basis of natural mountain raw materials. Stone wool is an expensive material. But its price is justified by its environmental friendliness and fairly long service life .

Basalt wool

The production of basalt products is quite expensive and involves the use of high temperatures (up to 1.5 thousand degrees). Modern methods for creating such products are based on the binding of fine particles using phenol-formaldehyde.

Glass wool

One of the subtypes of mineral wool , which has been used for many years in insulating under roof spaces. As the name implies, it is based on fine-crystalline glass particles, mainly broken glass containers and glass production waste.

Glass wool insulation

Fiberglass has proven itself excellent in insulating broken roofs. Thanks to its high-strength structure, it is noticeably different from its analogues. Glass wool fibers are several times longer than those of ordinary mineral wool.

Interesting! Glass wool is easy to cut, fits perfectly, has a budget price, and is also suitable for external and internal work.

However, despite all its advantages, this material requires a special approach in terms of safety. The finest glass fibers, getting on the skin, cause severe itching and irritation. Therefore, personal protective equipment during installation must be at the maximum level.

Ecowool

An innovative insulation material that has not yet gained as much popularity as mineral wool or polystyrene foam. Its distinctive feature is the release form - sheets or rolls. This heat insulator has a loose base , the connecting link of which is electrostatics. It is applied by spraying.

Ecowool insulation

Ecowool is made from cellulose production waste and is considered an environmentally friendly insulation material. Its main advantage is that it completely fills the required space, including even small holes and cracks. Its thermal conductivity is at the highest level and is comparable to mineral wool.

Cellulose wool

The disadvantage of the heat insulator is its naturalness. in it , and rodents and other insects feel good. To give the combustible material fire-fighting properties, it is treated with fire retardants.

Styrofoam

Everyone is familiar with foamed polymer, which has a low specific gravity and consists of miniature air bubbles. They are the main heat insulator. Polystyrene foam comes in different densities - pressed and unpressed . The one that has a structure reminiscent of a honeycomb and crumbles without effort is the unpressed type. The pressed material is much denser, cuts perfectly and does not crumble into fractions.

Foam insulation

Both types are used as insulation. Foam boards are available in different sizes and are very easily mounted to the rafter system using adhesive mortar or self-tapping screws . Reinforcing plaster is easily applied to the surface of the slabs. To insulate the attic floor, foam blocks 7-10 cm thick are used.

Important! Polystyrene foam is a “non-breathable” heat insulator, and therefore a room insulated with it needs high-quality ventilation.

Extruded polystyrene foam

This building material is also known as penoplex . It was invented in the middle of the 20th century and since then has been actively used as insulation for roofs, floors and walls of residential premises. The process of its production is very similar to the production of polystyrene foam, but differs in the high-temperature processing of raw materials. The produced material has excellent thermal conductivity, high density and strength . Due to the latter advantage, it is even used for thermal insulation of airport runways.

Sheets of extruded polystyrene foam are manufactured with a technological chamfer along the edges. This allows them to be securely fastened without gaps or visible joints.

Application of polystyrene

Penofol

An innovative solution for arranging a warm roof . Thin thermal insulation material is a layer of foam on aluminum foil. The insulation has a unique ability to reflect heat - up to 97%, and does not allow water and air to pass through. The action of such material is functionally similar to a thermos . There are samples on the market with coating thicknesses from 3 mm to 4 cm.

Working with penofol

As a rule, professional roofers combine penofol with other materials, where it plays the role of a waterproofing agent.

Polyurethane foam

Relatively new material, originally from Germany. In modern construction it is used in the form of foam and slabs . The latter are rarely chosen for ceiling insulation, since they are not very convenient to work with, and they are quite expensive. But polyurethane in liquid or foam form is an excellent option for arranging thermal insulation for roofs, walls and floors. With its help, all voids, cracks and gaps can be easily filled. If other materials need to be carefully cut to the required size, then in the case of polyurethane foam, the foam masses themselves fall in the given direction.

Treatment with polyurethane foam

The innovative product is very convenient to use for insulating slate and broken roofs. Also, its undeniable advantage is the uselessness of arranging a layer of hydro and vapor barrier. The material has high safety indicators, as it resists flammability.

Types and characteristics of materials for do-it-yourself insulation

Before insulating a finished roof, you should decide on the material for interior work.

The choice should be made taking into account the following characteristics:

- Density. This indicator directly affects the quality of heat transfer of the material. The lower the density, the higher the porosity. As porosity increases, the thermal conductivity of the material decreases, which means its thermal insulation properties increase.

- Heat transfer. This indicator affects not only the degree of porosity, but also the temperature and humidity level of the material. As these indicators increase, heat transfer also increases.

- Ability to absorb moisture. To prevent the insulation from absorbing and retaining moisture between the fibers, it is treated with special hydrophobic substances. In particular, the presence of such treatment should be clarified when purchasing mineral and glass wool.

- Flammability.

- Ability to withstand low temperatures.

- Chemical resistance.

- Environmentally friendly.

Based on the indicated characteristics, the optimal materials for insulating a metal roof from the inside are the following varieties:

- Mineral and glass wool . You can purchase such materials both in the form of individual slabs and in rolls. In terms of fire resistance, mineral wool is slightly superior to glass wool.

- Polystyrene foam or polystyrene foam . Available in slabs or extruded products. This material is quite flammable and releases toxic substances when burned. Therefore, it requires additional fire protection.

- Polyurethane foam . This material can be presented in the form of panels or liquid compositions. The latter are applied to the roof surface using special equipment, so specialized teams of builders are engaged in such work.

Algorithm for carrying out installation work

In order to insulate the roof from the inside with your own hands as efficiently , you need to carefully prepare - study topical articles and forums, watch training videos, consult with professionals. The work procedure itself can be divided into four stages:

- Arrangement of waterproofing. This step is usually done when covering the roof with roofing material. The waterproofing film is mounted to the rafters with slight sagging. When laying a hydrobarrier, it is important to lay it with the smooth side facing up, then seal the joints with tape. After the film covering is laid, it is fixed with counter-battens, to which the sheathing is nailed.

- Installation of thermal insulation. At this stage, insulation of optimal thickness is selected, cut to the required size and placed between the rafter beams. To keep the insulation in place, it is secured using small slats, rope or fishing line stretched between the rafters. To avoid the appearance of cold bridges, heat-insulating mats are placed with each row offset to the side.

- Installation of vapor barrier. This film material is placed with the smooth side towards the insulation, and the rough side towards the room. It is important to do everything clearly and not confuse the bottom with the top. Laying a vapor barrier is an important step when arranging the “pie”. Its installation is carried out using thin counter-battens or a construction stapler.

- Installation of bars and guide profiles. This stage is necessary for installing facing materials and creating a ventilation gap.

You can do the work yourself

Pitched roof insulation technology

A pitched roof can be insulated in the following ways:

- Installation of insulation between rafters.

- Formation of a continuous layer of insulation on top or under the rafters.

- Combined method.

Insulation between rafters

The easiest way is to install insulation with single-layer ventilation using a superdiffuse membrane. For this method, insulation is purchased, the thickness of which is equal to the depth of the cell:

- First, cut the insulation boards according to the cell sizes, after adding 2 cm on each side. The allowance is necessary to ensure that the slab fits tightly into the cell.

- In this situation, it is assumed that there is no waterproofing film, so it is necessary to secure a superdiffuse membrane. The rafters are covered with a membrane and secured with a stapler to the sheathing under the roofing material. The edges of the membrane along the perimeter of the room are brought out under the roof overhang.

When installing waterproofing, the film passes along all the rafters and tightly envelops them - Then the cut insulation is inserted into the cells. If the slabs have a foil coating on one side, the material is laid with foil inside the room.

If the insulation boards have a foil coating, it should be directed indoors - If the lower vapor barrier is made of a superdiffuse membrane, then it is immediately attached on top of the insulation.

- If regular film is used, you need to create a bottom ventilation gap. To do this, the insulation is lined with a thin strip.

- The internal vapor barrier film is overlapped over these slats. The joints are taped.

- Stuff the lathing for installation of interior finishing.

The superdiffusion membrane is attached closely to the insulation.

If you have an old waterproofing film and you plan to use a film with low vapor permeability (microperforated film) for padding underneath, then the gap between the insulation and the film should be on both sides. To do this, it is necessary that the panel is not completely recessed into the cell, but with a distance of 2–3 cm from the edge. The same gap must be left on the attic side. The thickness of the insulation should be 5 cm less than the depth of the cell. The support for the panel can be padded slats around the perimeter of the cells or pieces of wire stretched over nails:

- A thin strip (2 cm) is placed along the upper edge of the cell, and nails are driven in at a distance of 2 cm from the upper edge of the beam.

- Nylon threads or wire are wound crosswise around the nails. Now, when laying the insulation into the cell, the necessary gap will remain between it and the film.

- Exactly the same operation is performed after installing the mineral wool panels. The threads on the bottom side will prevent the material from sagging or moving in the cell.

To create a ventilated gap, the thickness of the insulation must be less than the depth of the cell between the rafters.

Insulation with foam boards must be done in two layers. This is done in order to cover the gaps at the joints. In this case, the joints of the slabs of the second row should be shifted relative to the joints of the first row.

It is necessary to select the thickness of the foam insulation so that it does not extend beyond the rafters. If the material (or two layers of it) protrudes from the cells, the rafters must be extended with timber.

Video: laying mineral wool between rafters

The disadvantage of insulation between the rafters is the presence of cold bridges around the perimeter of the cells. Therefore, many owners use combined insulation methods, additionally installing a layer on top or under the rafters.

Insulation over rafters

For insulation over rafters, foam boards that have sufficient rigidity are ideal. This material copes well with the load that it will experience under the roofing material, so most often in new buildings a continuous layer of insulation is mounted on top of the rafters from the outside. This is much more convenient than screwing panels from the inside. In addition, you can save interior space. And if you do not combine the laying of slabs with insulation between the rafters, then the open parts of the timber inside the attic will be an original element of the interior.

Foam insulation is not afraid of moisture, so there is no need to waterproof the under-roof space

If extruded slabs are used, then there is no need to put a vapor barrier under the insulation and lay waterproofing on top. The work is carried out according to the following principle:

- Before installation, it is necessary to lay a continuous OSB flooring over the rafters.

- On top of it, insulation boards are attached to the rafters using long self-tapping screws. Self-tapping screws are screwed through the solid flooring. Typically, the foam is laid in two layers, overlapping the joints.

Slab insulation is laid in two layers with offset joints - A block is screwed on top along the rafter line, to which the roof sheathing is attached and which will simultaneously create a gap for ventilation.

Combined insulation technologies

The most common method of combined insulation during repairs is insulation under and between the rafters. This option is the described insulation method with one ventilation duct and an additional continuous layer below.

This technology uses cotton materials:

- First, a superdiffuse film is filled or a stop is made to arrange the ventilation duct using the technology described above.

- Then the insulation is cut and inserted into the cells. It is advisable to use the same type of material, but with different densities. The thermal resistance of the bottom layer should be 80% less than the thermal resistance of the base layer material. A vapor barrier film will be installed between them, and if this condition is not adhered to, condensation will appear on the film.

- To install the second layer of insulation, a transverse beam is installed. The cross-section of the timber is equal to the thickness of the insulation.

Insulation is installed both between the rafters and on top - Then a strip is stuffed to secure the interior finishing material.

A roofing pie with combined insulation consists of two layers of mineral wool and a vapor barrier film between them

This design is the simplest, easiest to implement and cheapest. Installation of an additional layer on top of the rafters is most convenient; it is performed during a deep inspection of the roof with subsequent replacement of the roofing material. For houses in harsh climatic zones, the most effective method of insulation will be a combination of all three methods.

Video: insulating the roof of a cottage with a layer of foam plastic 20 cm thick

The main mistakes when insulating a roof

Actions that can negate all your work and expenses:

- incorrect selection of the thickness of the thermal insulation material can lead to wasting extra money or the lack of the desired result;

- ignoring ventilation will create excess moisture and condensation in the room, which will lead to damage to the coating and rafter system;

- By neglecting the steam and water barrier, you can get a negative result in the form of condensing moisture, which will be absorbed into the heat insulator, violating its properties.

Almost all private households located in most regions of the country roof insulation from the inside Therefore, such events should not be postponed “for later”. It is better to carry out thermal insulation at the construction stage of the building. Properly organized roof insulation is the key to comfortable living in the house and a noticeable reduction in energy costs.

Warm or cold roof – which option to choose?

When building a house, special attention is paid to the attic - the spatial volume under the roof, which is thermally isolated from the main premises. The homeowner has 2 ways to arrange additional space: leave it cold or insulate the roof and adjacent walls. In the latter case, the attic can become a cozy attic, a guest bedroom or a study. Advantages of organizing a warm roof:

- Possibility of effective use of the attic space all year round.

- Increased living comfort.

- Reducing heat loss and heating costs.

For your information!

Insulation of the roofs of private housing constructions began to be done at the end of the 90s of the last century. The refusal to install a thermal barrier in an earlier period is explained by the lack of necessary thermal insulation materials.

In modern construction, a cold attic is often chosen to save money. This design is more affordable for most developers. In addition, the decision to limit yourself to a cold roof may be determined by other factors:

- the difficulty of performing high-tech construction work with your own hands (steam, heat and waterproofing);

- the need to supply communications to the attic (heating, water supply, sewerage);

- installing a staircase that will occupy part of the lower floor.

Despite the difficulties of arranging a warm roof, this will expand the living space in the house, and the property owner will receive compact housing with a good level of energy saving.