During the beginning and end of the summer season - namely early spring and late autumn - the temperature outside is hardly above zero. That’s why it’s cold in the country house. This problem is easy to fix - you just need to take care of heating your home. How exactly to do this? Summer residents often use heaters , but these devices require a lot of electricity to operate. Moreover, air heaters do not provide a favorable microclimate in the house; they do not dry out the premises after winter.

Heating a dacha with heated floors

The best option can be considered a warm floor in the country. But which heating system should you choose? Is it necessary to prepare a country house for installation? How exactly is underfloor heating installed? You will find answers to all these questions below.

Main or additional heat sources for a country house

Electric floor heating can be performed specifically on a dilapidated floor: on ceramic tiles or parquet.

In this case, it is most ergonomic to use heating mats. They make it possible to easily improve thermal comfort in a room that is already in use, without raising the floor level significantly and creating additional load on the ceiling.

When planning the installation of electric underfloor heating in a dilapidated building, you should not forget that as the main source of heat it can only be justified in buildings with good thermal insulation. If the total heat loss through the outer walls, floor and roof is enormous, in other words, exceeds thermal standards, underfloor heating alone will not be enough to heat the room to the required temperature.

In this case, electric underfloor heating can only serve as an addition to a second type of heating, for example a system with radiators. Here we are not talking about reducing electricity consumption but about floor temperature. It cannot be larger than the defined values. Otherwise, the floor must provide no more than pleasant warmth, neutral from a physiological point of view.

It is generally accepted that in rooms such as the living room or kitchen, the floor temperature should be a maximum of 29°C, and in the bathroom - 34°C. In areas under the windows, along the outer walls, the floor temperature can be as high as 35°C. But this is often not enough to compensate for heat losses at home and ensure a comfortable temperature in the room during frosts reaching -15-20°C (calculated temperature taken depending on the region of the state).

Electric heating mats

What electric mats can be used for heating? Any, corresponding power. When you use electric infrared heating mats for heating, you have two components at once - direct heating and heating of objects with infrared radiation.

You can heat a small country house or cottage with high-power electric mats. However, when heating a large house this way, you will have two issues that you will need to resolve:

- How will you heat the rooms on the second floor without overheating the rooms on the first floor? After all, electric mats placed in the ceilings of the second floor will also heat the rooms on the first floor.

- Preparation of second floor floors. Infrequently, small private houses and summer cottages are built with reinforced concrete floors; more often, floors with wooden joists are used.

Well, the issue with electricity consumption, which will be discussed below, is the disadvantage of this type of heating.

Methods for insulating a wooden floor

SNiP 02.23.2003 clearly defines the standard values of heat transfer resistance and requirements for thermal engineering calculations, which should be used to guide the choice of insulation thickness. Many inexperienced self-taught builders mistakenly believe that the thicker the insulation, the better. If the insulation is too thin, the house will be cold; if it is too thick, you will be wasting your money.

That is why it is important to choose the right layer thickness depending on the thermal insulation material and the material from which the walls are made. The climatic conditions of the area in which the house is located also play an important role.

All these nuances are described in detail and taken into account in SNiP.

Without going into the intricacies of thermal engineering laws, experts advise building floors over a cold basement with insulation 12 cm thick for the middle zone, 20 cm for the northern regions, and insulating the interfloor floors with an 8-centimeter layer.

It is much more convenient to insulate wooden floors in a house than walls or ceilings, if only because their design involves the use of joists and a subfloor. You can pour expanded clay, shavings into the space between the joists, lay the slabs neatly and tightly, or blow everything out with foam. Thus, insulation with any material occurs according to the general principle - it is placed between the joists and covered with a finished floor (in some cases, additional hydro- or vapor barrier is required).

Insulation of floors with low underground

In houses with a limited subfloor size, it is impossible to place thermal insulation material as usual - between the joists. To do this, you will have to dismantle the entire flooring, so if this is your case, get ready for labor-intensive work.

Sequentially perform the work:

This method describes how to insulate a floor in a country house if construction has already been completed, but it is best to take care of thermal insulation at the time of designing the house.

Insulation of floors above a high cellar

The nature of the actions in this case is no different from the previous one, except that you do not need to increase the height of the logs, dismantle the finished floor covering and the stages of work should be performed in the opposite order. The only caveat is that for insulation in this way you cannot use bulk materials - expanded clay or sawdust.

Progress:

Everyone decides for themselves how to insulate the floor, but it must be done in any case. A warm floor in a dacha will keep you warm in the winter and give you coolness in the summer, reduce heating and electricity costs, and become the key to the health and comfort of the residents.

Waterproofing layer

The first encounter with cold temperatures occurs in the basement - the place where the foundation meets the subfloor. This is where it’s worth waterproofing and insulating if you don’t want to later deal with the consequences of floods and dampness. The waterproofing procedure involves laying an impregnating layer or roll film. You can use special mixtures to fill the floor, which will reliably protect against moisture, this is very convenient. Roll coating is only suitable for perfectly smooth walls without cracks; moreover, they must be dry, so it is better to carry out the work in the hot season.

The floor in the country house is most often concrete, because this material is the most durable and comfortable, so it will become your basis. Before carrying out any kind of work, it must be cleaned of dirt and dried. Mold stains or other growths must be removed. If the room goes underground, waterproofing must be done along the perimeter of the walls, since water will rise along their entire height, especially during the period of melting snow.

General principles for arranging wooden floors

If you are planning to install floors made of natural materials in your country house, plan the work for the end of spring

This is important because during this period the tree will absorb less moisture. If the assembly of floors in a cottage or house cannot be postponed until the recommended time and the work needs to be done in the summer, choose a dry, hot period, without heavy rains and dew.

Regardless of the method used to install floors, it is extremely important to pay maximum attention to the quality of the lumber. Wood must be treated with special agents against rotting, moisture, insects, as well as a fire retardant composition

Real heating with electric floors

The most reasonable option for heating a house with an electric floor is to use a cable electric floor. In this option, you have the opportunity to supply much more electrical power to the heating device and, accordingly, receive greater thermal output.

Naturally, all equipment and controllers in this option must be used with a higher maximum power.

Installation of heated floors

The easiest way to install a heated floor yourself is thermal film, the installation of which does not require much time and effort. During the work you will need the following:

- heat reflecting material;

- thermostat;

- electrical power cable;

- electrical tape (mounting tape);

- rivets and pliers;

- mounting grid (if you plan to make a screed).

Scheme of a warm water floor.

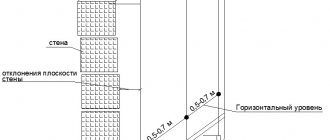

Thermal film is placed at a distance of 50-70 cm from the walls around the perimeter. A very important point: you cannot place furniture on it and do not install a plinth on top of it. The thermal film strips are fixed with clamps parallel to each other and insulated with tape. It is not necessary to make a screed; you can immediately lay the covering. However, if you plan to lay a soft covering, for example, carpet or linoleum, then it is worth giving the base additional rigidity by laying sheets of plywood or MDF.

Cable heating systems require additional dexterity and certain skills when installing. For installation you will need the following materials:

- thermal insulation, which can be solid foam with a density of at least 20 kg/m, polyurethane or hard mineral wool;

- polyethylene film;

- metal mesh for fastening the heating cable, it ensures insulation of the cable from the surface of the thermal insulation;

- cable ties or soft binding wire to secure the cable to the metal mesh;

- mounting tape (used instead of metal mesh);

- heating cables;

- thermostat.

Before you begin installing a heated floor, you need to develop a project and prepare the base; it must be level and clean. A layer of thermal insulation, plastic film and metal mesh must be laid out on the prepared surface. Be sure to follow this sequence.

According to the heated floor design, the heating cable is attached to a metal mesh. You can secure it using cable ties or soft binding wire. you can also use a special mounting tape if the thermal insulation will be filled with a special solution (for fastening the heating cable).

Once you have completed installing the cable, you can move on to the next step - installing the temperature sensor. Then the entire surface is filled with sand-concrete mortar, the thickness of which must be at least 50 mm. You can also use a self-leveling (self-leveling) solution. In any case, the cable must be completely “sunk” in the solution from start to finish. After the screed has completely dried, you can begin laying the final coating.

Installing water heating is technically more complex. In the process of installing a water heated floor, the following stages can be distinguished:

- Development of a project, which involves dividing the area of the premises into sections whose area does not exceed 40 sq.m.

- Laying insulating material on the prepared surface (necessary to avoid heat loss).

- Installation of reinforcing mesh and laying of pipe contours.

- Pressure testing of the heating system.

- Pouring concrete.

- Final finishing.

If you doubt your own abilities, it is better to seek help from professionals. This way you will save money and avoid disappointment.

Installation of underfloor heating system cable

The cable is laid on a layer of thermal insulation (expanded polystyrene or mineral wool), covered with moisture-proof insulation (film) and a narrow layer of cement paste. The film protects the thermal insulation from the penetration of liquid from the solution. If the cable is laid in wet areas (in the bathroom or kitchen), moisture-proof insulation must be placed under the top layer of the floor.

The thickness of the thermal insulation layer depends on the base and the type of premises underneath:

- a narrow layer (3-5 cm) is laid in floors above heated rooms;

- a thicker layer (7-10 cm) - in floors above basements or unheated rooms;

- The thickest layer of insulation (more than 10 cm) is needed for floors on the ground, floors with open space under the floor, floors above a bay window or loggia.

In addition, the design of the floor is important: the higher the thermal insulation properties of the flooring material, the thicker the layer of thermal insulation needs to be laid. Heating cables are fixed to a tape or mounting grid at the required intervals, and then covered with a layer of cement mortar with the addition of a plasticizer or a layer of gypsum or cement screed.

Attention! In underfloor heating systems installed in wooden floors on joists, heating cables are laid brightly on thermal insulation and mortar

are not covered. An air gap of 3-5 cm is left between the heating wooden covering and the body elements.

Insulation of floor coverings for panel heating

When choosing a heating method for the floor, you need to consider that it should be:

- not heavy;

- retains heat well;

- resistant to moisture;

- environmentally friendly.

If you decide to insulate the floor of your dacha, then you need to decide on the material. Current options today are polystyrene foam or mineral wool. But it is worth considering that the first material can serve as housing for rodents, and the second is capable of absorbing moisture, which will negatively affect the tree. Wood concrete, expanded clay, and glass wool will be a good alternative to the materials listed above.

Warm floor on a concrete base

For the liquid floor line and for the cable sections, it is necessary to provide a fastening system. The best option is reinforced mesh. It is necessary if the system is subsequently covered with screed or tile adhesive.

The floor line to the mesh is reinforced with tapes with reverse teeth. Staples, a stapler, and mounting tapes with locks are used as fastening elements.

- The ends of the liquid line are connected to the distribution comb. Pipes lead from it to the heat exchanger, which is located in the firebox. The cable is connected to the thermostat.

- No fastenings are needed for cable and carbon mats. They are produced in rolls. The rolls are rolled out over a heated area. If it is necessary to rotate the cable mat, then the mesh is cut. The conductor remains intact. The system can be rotated at any angle. To rotate the carbon mats, the connecting wire is cut. The integrity of the rods is not violated.

- The thermal film is cut along the dotted lines, forming sheets of a certain length. The distance between the sheets should be 1 cm. Secure the tape to the base with tape.

- Mats and sheets of thermal film are connected in a parallel way.

- A temperature sensor is placed on the surface of the electric floor. A niche is being created for him.

- Connect the electrical wires from the “warm floor” and the temperature sensor to the regulator.

System selection

There is electricity at the summer cottage. Water is often supplied only on certain days of the week; houses are usually not connected to the gas mains. Liquid heating is installed only if the room has a stove that runs on solid fuel.

It is advisable to install water heating in a two-story house or in a cottage with a large heating area.

If the summer house does not require heating units, then electric heating elements are used as heating:

- cable section; a conductor is laid on the floor; It is recommended to cover it with a 5 cm screed or tile adhesive; for normal heating it is enough to cover 70% of the active area; Cables are not laid under furniture and household appliances; the circuit is mounted with a double “snail” or double “snake”; in this case, the cold circuit is located between the hot turns of the cable; heating is effective over the entire floor surface;

- cable mats; the system is easier to install than sections; the conductor is secured to the mesh with a snake; heating may be uneven; the further away from the power source, the cooler the cable will be;

- carbon rods; the rods are assembled into mats; installation is not difficult; cover the mats with screed or tile adhesive;

- carbon thermal film; the system is installed on any surface; laminate is immediately laid on it; for linoleum you will need to form a covering from plasterboard; the film can be covered with fiberboard or clapboard, but to cover it it is necessary to install logs and make lathing; It is not recommended to violate the integrity of carbon elements;

- electric liquid heating; a pipeline is laid on the base; it contains a heating cable; pipes are filled with propylene glycol; the coolant does not circulate through the main line; it heats up due to the cable, transfers heat to the floor; the conductor is connected to the network.

We recommend: How do we fix pipes for heated floors?

For a country house that does not have a liquid or solid fuel stove, it is recommended to install electric heating systems. They consume less energy than air heaters.

Heating can be turned off if the country house is not in use. It will take 48 hours to achieve normal thermal conditions in the premises, so it is recommended to turn on the system long before arriving at the site.

If there are frequent power outages in the area, then the optimal heating system will be a liquid circuit from the furnace. A “warm floor” in a country house is installed without a circulation pump. Pipes are brought to the floor main at an angle.

For the return pipe, the slope is made towards the boiler. The coolant circulates due to gravity. The stove is chosen to burn for a long time so that the coolant does not heat up to a high temperature.

Water-type warm floor

The design of this system is simple: heat comes from water, which passes through pipes located in the screed. This system includes:

- pipes;

- thermal insulation;

- fastening materials,

- components for making expansion joints,

- manifold with fittings for connecting pipes to the heating system.

This system uses metal-plastic and polyethylene pipes. They should be laid in the same way as an electrical cable - with a snake. The distance between the turns should be no more than 30 centimeters. Installation of water heated floors is much more difficult than electric ones. The step-by-step instructions are as follows:

- The beginning of the installation of this system will be the installation of a manifold and a unit in the form of a block, which will combine a pump and a mixer. It is the unit that will ensure that the temperature you select is maintained. The block is responsible for distributing water among the turns. This entire structure is attached to the manifold cabinet.

- The next step is to prepare the floor, it is worth clearing it of debris and checking the evenness of the surface.

- Thermal insulation tape is laid around the perimeter.

- Then it is worth laying a vapor barrier to protect the system from moisture from below.

- Next, for quick installation of pipes, the floors are lined with polystyrene foam boards. The slabs are laid overlapping; for this they have special grooves.

- When laying pipes according to the diagram, be sure to maintain the distance between turns. A spring conductor is used to fix the bend.

- When the design of the circuits is completed, the ends of the pipes must be connected to the distribution manifolds, and servos are installed. They make it possible to regulate the operation of the entire structure using a room thermostat.

- Before starting the system, it will need to be checked for leaks, only after that you can make a concrete screed. The floor can be put into operation no earlier than after 28 days.

To summarize, I would like to note that electric-type underfloor heating is better suited for summer cottages. If you want to make a water-type structure, you must be prepared for the fact that at the end of the summer season you will have to drain the water from the pipes. Another advantage of an electric floor is that it is more economical compared to others. Now you know what a heated floor is and which option is best for your suburban area. You can safely begin installing it, and let your home be warm.

Variety of heating systems

The heating system is responsible for creating a warm, favorable microclimate in the house. In a private home, this could be radiators or heated floors. The disadvantage of the battery is its small surface area of the device. Due to the increase in temperature, the speed of air movement increases. In addition, dust often accumulates in batteries.

But a warm floor has a large heat transfer area, which allows you to heat large volumes of air faster. The most common type of heated floor is considered to be a water floor, which is powered by a gas boiler : it heats the water, it goes through pipes and becomes a source of heat for the floor.

The entire variety of types of heated floors is divided according to the following criteria:

- according to the operating principle: infrared or convective;

- by type of boiler: it can operate on solid or diesel fuel, gas or electricity;

- by coolant: they are air, water, electricity.

Choosing the required heating system is a complex and responsible matter that should be entrusted to professionals. They can take into account all the advantages and disadvantages of heating types and the conditions of a particular home. The heating system is selected at the design stage . After all, one of the factors influencing the choice is the material from which the building is constructed. This is also important to consider.

Heating mat

Fiberglass heating mats, which are equipped with a heating cable system, are also popular among consumers. The advantage of such products is their ease of installation, because their installation does not require such a labor-intensive procedure as additional pouring of concrete. The system is fixed in a layer of adhesive composition designed to fix the tiles. Thanks to this, the final layer of screed does not exceed three centimeters.

Heating mat

The devices are sold in rolls, which makes installation of the system easier. The technical characteristics of such products are exactly the same as in the case of prefabricated heating cable systems.

Types of heated floors and their features

There are several heating options:

- water;

- electric;

- infrared.

Water heated floors are a simple and effective solution. To install it, heating elements are placed in the concrete screed. As a rule, polyethylene and metal-plastic pipes (less often copper) are used. Hot water flows through them.

Unfortunately, this type of underfloor heating cannot be used in apartment buildings, as this disrupts the overall heat supply system. Of course, if you wish, you can try to get permission and coordinate the project with utility services. Water heated floors are an excellent solution for a private home; they do not require approvals, are safe, durable and economically attractive. However, it requires maintenance (filter replacement, etc.)

Electric heated floors are installed in a similar way, only the main element is a shielded heating cable with temperature sensors. There are different options here: heating cable, film material and special heating rods, depending on whether you are ready to raise the floor level. The heating cable is laid under a screed 5 cm high. When using a thin heated floor, namely mats, a screed is not required.

Diagram of a riser for a heated floor system.

You can use single-core or double-core heating sections, which are suitable for heating a wide variety of premises (residential, office and industrial). Using a thermostat, you can control the climate by setting the optimal temperature. In addition, you can monitor your energy consumption. Electric heated floors are more expensive than water ones.

Infrared heated floors (ITP) are very popular. A significant difference of this type is the use of infrared radiation with a length of 5-20 microns. This option is economical in terms of energy consumption.

Types of products powered by electricity

Electric heating can be:

- modern type heating cables, which can have different power levels and have different lengths;

- mesh mats consisting of fiberglass and equipped with heating elements;

- film products with wires.

Each type of heating has its own operational and technical features, as well as the specifics of the installation installation.

Heating cable systems are equipped with temperature regulators. The cable itself consists of a special alloy that has a high electrical resistance.

As an addition to the system, a metal mesh and a layer of insulation are attached.

Despite the fact that the device looks like the most ordinary electrical cable, unlike standard products, heating occurs during the passage of current. It converts electrical energy into thermal energy.

Cabling

On the market you can find products with one or two cores. The main difference between these devices is the type of connection. Twin-core structures are attached at one end, single-core structures are connected from both sides. Two-core products, which are suitable even for rooms with an unusual layout, are popular among consumers.

The heating cables are installed in a concrete screed, the minimum layer thickness of which is 5 cm.

This heating method is convection, which imposes certain restrictions on the installation of the finishing floor covering.

Such exceptions include:

- parquet;

- laminate;

- linoleum;

- other types of carpet materials.

These coating options require careful handling. But if you don’t take any risks at all, then it is best to use ceramic tile products, since when heated, ceramics and concrete screed retain heat for a long time. The result is significant savings in electrical energy spent on heating the room. For a comfortable atmosphere, it is enough to warm the floors well, after which you will only need to maintain the required temperature level.

Features of installing products with your own hands

If you are undertaking the installation of an electric floor system in a country house or country house with your own hands, then first you must carefully study the installation instructions, which are attached to the products and contain all the necessary information regarding installation, features of operational use and general safety.

Film placement diagram

A list of several rules will help avoid such problems:

- Be sure to calculate the area that needs heating and choose the system rationally.

- You cannot lay the cable under pieces of furniture that do not have high legs, and the infrared film must be placed only in an open space free of furniture.

- The base must be thoroughly leveled and dried.

- Under no circumstances should you shorten or lengthen the cable, cut it or perform other manipulations.

- Turning on the system is allowed only after the screed layer has completely hardened and dried. This usually takes from 28 days to a month, at least.

If you plan to use tile products as flooring, then it is best to choose a cable-based device, since this option is the most budget-friendly and suitable for this case.

Range of film products

First of all, you should prepare a place to place the temperature regulator, form a groove where the electrical wiring and temperature sensor tubes will be hidden. The output of the mounting ends will also be located in this area.

After this, the base is leveled, cleaned of dust and debris and covered with a layer of primer. Then the heat-insulating material is laid, and the corresponding sections of the mounting tape are glued according to the laying diagram.

Material cutting

Key points that should not be forgotten:

It is necessary to check the electrical resistance in the network. The cable should be taut during installation, but without much effort. It is necessary to take into account the minimum permissible bend. On straight sections you need to use special couplings. Do not allow the cable turns to intersect or touch.

Next, the temperature regulator is installed and connected to the electrical network. When installing a temperature sensor, a corrugated tube is used, which, for ease of repair work, should be placed between the turns of the cable.

After all connections are made, the system is checked for damage, resistance measurements are taken on the sections and the sensor and checked against the numbers in the documents. When the screed is completely dry, the device can be turned on.

Installation of mats

Making a system from heating mats is a less labor-intensive process than laying cables.

First, the mats must be laid out on the floor for estimation. They are laid with the wires down. After this, carefully cut the mesh fibers in the right place, taking care not to damage the cable.

Then you need to lay out the pieces of the mat so that they cover the entire free surface in the room. Mats with one-sided power supply are more ergonomic to install. Recently they have become cheap on the domestic market.

Mats with power connections on both sides are more difficult to lay so that the ends of the cables reach the junction box together.

Once fastening and installation are complete, the mats are covered with a thin layer of plastic mortar and a new floor covering is laid on it. In bathrooms and all other wet areas, under the floor covering, for example, under tiles, it is necessary to additionally install moisture-proof insulation.

If the coating is thin, the floor level will rise by only 1-2 cm.

Attention! Heating cables should not be laid above expansion gaps because they are easily damaged in such places. As a result, this may lead to a heating system failure

If the heating element is damaged, safety will be ensured by a differential involuntary switch, which will turn off the electricity supply, preventing electrical breakdown.

How to insulate a floor in a country house without dismantling the old floor, step by step from above

The beam structure of the base is considered more reliable and optimal. The strip foundation also allows for the installation of thermal insulation along the joists. Warming takes place in stages:

- Installation begins with laying the skull blocks or boards. They are attached to the floor beams. A subfloor made of plywood sheets or second-grade boards is mounted on these supports. To use less building material and provide ventilation for thermal insulation, the boards are attached with a gap. A waterproofing layer is attached to the rough coating, which simultaneously protects against drafts and acts as a vapor barrier.

- Then the heat-insulating material is attached in 1-2 layers. With double flooring, the insulation is placed so that the joints of the first layer are covered with the second layer. To protect against vapor formation, a vapor barrier layer is laid on top of the thermal insulation.

- A slatted counter-lattice is mounted to the joists. It presses the vapor barrier and provides a technological gap (2-3 cm). Sometimes, to protect against rodents, reinforced fine mesh is placed under the waterproofing layer on the subfloor.

On a note!

If the rough base is laid without lyes, penoplex acts as thermal insulation. The underlay of the waterproofing layer can be dispensed with.

Advantages and disadvantages

Before installing a heated floor, it is necessary to evaluate all the pros and cons of this design. The benefits include:

comfort and safety; efficiency (compared to other methods of heating a room, power consumption is lower); aesthetics; hygiene (especially important for the bathroom); easy to install and requires no maintenance (electric heating); Suitable for all types of floors (i.e. can be installed under carpet, marble, wood, etc.). Heated floor temperature control diagram

Scheme for adjusting the temperature of a warm floor.

First of all, the materials used for final finishing must be safe so that during the heating process no harmful substances are released that can harm people.

If you decide to install a heated floor, then you should not use a coating that will interfere with heating. For example, a coating with double insulation will not work.

Operating conditions are directly related to the materials used. If you have chosen parquet, then you must take into account that the temperature should not exceed 24 degrees, and the power should not exceed 130 W/sq.m. Many experts do not advise laying parquet and cork on a heated floor. Parquet is too capricious a material, and cork has low thermal conductivity.

Flaws:

- financial costs associated with installation;

- the floor heating system emits an electromagnetic field, but it is minimal and safe for the inhabitants of the house (electric heating);

- maintenance required (water heating).

Pros and cons of using water floors

Water heated floor technology in a private home has the following advantages:

- economical consumption of electricity: installing a water heated floor in a private house can significantly reduce heating costs;

- uniform heating of all rooms;

- eliminating the risk of burns;

- the possibility of using such a heating system as the only one in the entire house;

- no electromagnetic field is created;

- the air in the rooms is not dried;

- the ability to regulate the microclimate if each room has its own heating circuit;

- its maintenance is inexpensive;

- any technology can be used to cover the floor: heating the surface will not damage it and will not lead to the release of toxic substances;

- creates a comfortable stay for all residents. Warm floors are especially pleasant for young children, who spend most of their time sitting on its surface.

With water heating it is much easier to remodel.

To be fair, the disadvantages of water heated floors should also be outlined:

- installation is quite complex and is a lengthy process. For example, a concrete screed takes at least a month to dry;

- sometimes leaks occur; to eliminate them, complete dismantling of the coating is necessary;

- there is a risk of a decrease in pressure in the heating system;

- you need to install mixers to regulate the temperature;

- it is impossible to install it on the landings of a country house;

- the price of water heated floors in a private house is much higher than that of an electric system.

Two structures could serve as support for the lag

- Special support beams that were placed in nests arranged in the stone foundation of the house or rested on the lower crown (if the house was wooden).

- Brick columns, which were installed in the underground space and could serve as both a base for support beams and a support directly for the logs.

Nowadays, when there is a wide choice of building materials, including concrete, a concrete slab or pad is often used as the base of the ground floor.

And, if the slab is mounted directly on the foundation, then the cushion is poured inside it and distributes the load directly onto the soil located inside the foundation contour.

Floor installation without screed

Basically, the issue of installing heated floors on prefabricated wooden foundations arises in individual households. In the apartments, all floors are concrete, and such technology may only be necessary if you do not want to remove the old wooden flooring or parquet during renovation. And in houses, even if the floors of the first floor are arranged in the form of a concrete screed on the ground, the vast majority of interfloor floors - even in brick houses - are constructed from beams.

Even if the beams are steel, the top layer of the floor will be wooden

The floors of the first floor are also often made on beams

Laying heating elements between joists

Option for installing a heated floor on top of the ceiling

- This design is a multilayer sandwich, the top of which is the subfloor of the above room. If the house is just being built, heating elements can be placed inside this pie; if it is already in use, floor heating can be organized without removing the sheet flooring.

- The layering of the structure can be different and depends both on the structure of the floor as a whole and on the type of floor covering that is supposed to be laid at the finish. And note, this does not necessarily have to be a board, carpet or some decorative chipboards. It may well be ceramics, which, with proper preparation of the base, fits perfectly on wood.

- With the same success, heating elements can be installed under any coating, and the choice of one or another installation technology depends on their type. You can, for example, provide a traditional wet screed, on which it is very convenient to install not only ceramic, but also quartz vinyl tiles. And it’s not so much about convenience as it is about the better ability of the solution layer to accumulate and transfer heat.

Heated ceramic floors can also be installed in a wooden house

Note! However, today there are alternative ways to improve the heat transfer of prefabricated wood floors. For example, for laying water pipes or cables, metal plates were invented that warm up to the temperature of the coolant and give off heat well.

Heat distribution plates

The plates have recesses, thanks to which the heating elements do not protrude to the surface and do not interfere with the laying of the finished floor. Only a thin membrane is laid between them, which helps remove steam from the internal space. This is if the coating itself is vapor permeable. You can also pour a screed on top of the plates, only in this case the layer between them must be waterproof.

Heat distribution plates

Are there any advantages to not having a monolithic screed?

If there is a concrete monolith floor in the cake, the principle of the heating effect is more or less clear to everyone. Heating elements - be it pipes with hot water, molded electrical cables or rolled mats and films - transfer thermal energy to nearby material.

Monolithic heating system

- If it is a stone, which is a concrete screed, then it heats up perfectly and gradually transfers heat to the overlying layer. If it is tiles made of natural or artificial stone (ceramics also belongs to this category), the tandem turns out to be simply ideal, since their properties are approximately the same.

- But when the heat source is shrouded not in a material that transfers heat, but insulating it, the efficiency of heating the premises is significantly reduced. Hence the need arose to use metal strips that could accumulate and transmit instead of structural material.

- However, in some situations, the absence of a screed is even preferable. For example, if there is a cellar under the first floor, into which heat should not flow. Or in old houses, where after many years of use the floor beams may lose some of their original strength, and it is undesirable to load them with a rather massive layer of concrete.

water heated floor

It is very easy to install heating elements in this design

On a note! Let us give one more, very significant argument in favor of a prefabricated heated floor, which does not have a screed. Such a floor can be used immediately after installation, whereas when pouring concrete, you must first wait the required 28 days to gain strength (you can walk, but you cannot apply heat). Moreover, even without a screed, you can lay any covering, including tiles, at the finish.

Methods for dry assembly of heated floors

The most common method of installing layers of insulated flooring is the laying option. In this case, pipes or other heating elements are laid either between the joists or on top of the rough boards.

Between the joists

In the first case, a special structured substrate is laid between the lags, into the recesses of which it is very convenient to install pipes.

Water pipes between joists

It is best to take the substrate with a reflective top layer, but you can also use regular foil insulation. Simply, thanks to the recesses in the special substrate, you don’t have to figure out how to fix the pipes in the desired position.

But if necessary, you can always come up with something, as the photo below convinces us of. Here, transverse strips were installed between the logs, to which the heating elements were fixed with metal clamps. Finally, all this is sewn up with sheet material, on top of which a decorative covering is already mounted.

If you don’t have a special substrate, you can do it like this...

On rough surface

In the case of laying pipes or cables on top of a subfloor or an old plank floor in the latter, it is necessary to mill grooves into which the metal plates that we have already mentioned above must be inserted. The only problem is that the tool needed for this is unlikely to be at hand, and not everyone can handle it. And hiring a specialist for this work will cost about 65 rubles/m2.

Option with milling of rough flooring

To avoid milling, you can use the method shown in the example below. Here, in order to install galvanized plates, boards were mounted on a wooden base. They were chosen to be of such a thickness and installed at a pitch that would allow the protrusion in the plate to fit perfectly into the gap.

Option - plates between boards

It is doubtful that this method provides any savings, because you have to pay for milling and boards one way or another. If it is not possible to lay heating elements between the beams - you do not want to dismantle the old floor, or the small height of the ceiling does not allow installing another tier of logs, it is much more convenient and cheaper to use heating films rather than pipes. True, due to the cost of the coolant, such a floor may turn out to be more expensive in operation.

Manufacturer's recommendations

You don’t even need to make a screed on top of them - just cover the system with a protective film and lay the laminate. But under the rolled materials you will have to arrange an intermediate hard layer in the form of plywood or other sheet materials. But this is a double-edged sword.

self-leveling floor

On a note! Such a layer will become an additional obstacle to heat - reflective elements will not help much either. For greater heating efficiency, a mortar screed is still better. In the case of film, it can be made very thin, from a self-leveling floor or a self-made mortar without large filler, which adds increased weight to ordinary concrete. Just keep in mind that the filler mixture must contain additives that make the monolith immune to elevated temperatures.

It is best to fill such a structure with a screed

There is no uniform technology for assembling heated floors on wooden bases. Here everything needs to be decided based on the specific situation, and there are quite a lot of options. You can come up with your own way of arranging layers, only in this case you need to correctly compare the abilities of a particular material to perceive and transfer heat.

Let's talk about the finishing coat

Before laying down the finishing coating, you should decide what kind of material you need. After all, each room has its own load and humidity level. In addition, when planning the installation of floors in a dacha, you need to take into account that in winter the room will not be heated.

Concrete covering

A concrete floor for a summer house can theoretically also be installed independently. If you make it perfectly smooth and paint it, it will have a fairly good appearance. This coating is strong and durable; you will need to refresh the paint every few years and the floor will be like new.

But no matter how hard you try, concrete is concrete, it will be cold, if you cover it with a carpet or bedding, the cold will still be felt. Even in the summer, doctors do not recommend walking barefoot on concrete.

This option may be suitable for a summer kitchen, garage or outbuildings. In residential premises, a concrete screed is used as the basis for the final coating.

We use natural wood

The installation of natural wood floors in a dacha is a classic. People have been laying them for hundreds of years. The price of such a coating will be average, but wood is a natural material and requires careful processing and care. In particular, good waterproofing of the wooden floor in the country house must be provided. Otherwise, the tree can quickly deteriorate.

This coating is also convenient because with a good base and well-equipped waterproofing, you will not need powerful insulation. The covering is covered with a tongue-and-groove board with a thickness of at least 40 mm, which itself is quite warm.

When deciding how to paint wooden floors in a country house, experts advise paying attention to acrylic varnishes and paints. In the old days, the floor was traditionally painted with oil paint, of course it is practical and durable, but with such a coating the wood does not breathe and the whole meaning of naturalness is lost

A classic wooden floor is installed exclusively on joists, because it requires constant ventilation from below. DIY installation instructions are quite simple. Initially, waterproofing is laid, wooden logs are mounted on it, onto which a tongue-and-groove floorboard is already nailed. Insulation is laid between the joists.

Laminate

Laminate coating appeared about 20 - 30 years ago, and currently it is one of the most popular. The appearance of the laminate can be anything, the range of colors here is one of the widest. As a rule, it emits natural wood.

The advantages include a low degree of abrasion, ease of installation and durability. If we talk about the disadvantages, then this coating requires a perfectly flat, waterproofed base. The price of expensive types is steep, but budget options are afraid of moisture and cannot withstand heavy loads.

Linoleum

This material can deservedly be called the king of floors not only in the country, but also in most other residential or office premises. It can be thin or dense. Smooth and corrugated surfaces with varying degrees of stability are available. Linoleum behaves well in a humid environment and is not afraid of temperature changes, plus laying linoleum does not require high professionalism.

Linoleum has few disadvantages. In fact, experts consider the most sensitive area to be the ability to push through the material. Linoleum is afraid of sharp heels and heavy furniture. Plus, its installation requires a perfectly flat surface.

Wood is a material valued for its environmental friendliness, aesthetics and durability, and therefore it is not surprising that dacha owners choose wood as a construction resource for constructing floors. Coverings made of natural materials are laid not only in the country - in small summer houses, a wooden floor can be laid in a brick cottage or a foam concrete structure. How to lay a wooden floor in a country house and whether it can be done with your own hands - we’ll figure it out together.

Conditions for installing a water floor

It is recommended to include the installation of an additional heating circuit in the project even before the start of construction - this makes calculations easier.

In a finished new house or building where the radiator system has been in operation for a long time, installing a water floor is also possible, but under certain conditions.

The benefits of water heating have long been appreciated by residents of Europe and Russia: it effectively heats rooms, saves expensive energy, creates the most comfortable environment in bedrooms, bathrooms and children's rooms

If the desire to insulate the floor arose after the construction of the house, you should determine whether the building is suitable for this. One of the main conditions is pre-made thermal insulation of the house, since heat losses above 100 W/m² will make the installation of the floor useless.

Pay attention to the height of the ceilings: the installation “pie” with pipes takes about 15 cm, or even more, from the total height of the room. After implementation of the system, the dimensions of doorways must be maintained, with a height of 210 cm or more.

Special requirements apply to the foundation. It should be strong, smooth, clean. An unstable base will lead to unevenness, and these will lead to deformation of pipes with coolant

If the house is new, then before starting installation it is necessary to completely complete construction - erect walls and ceilings, install windows, and plaster.

Heating on a wooden floor

When working with wood flooring, you should always remember that the heating elements are located below the floor surface. There are several installation methods:

- the pipeline or cable sections are routed between the lags on the surface of the gypsum plasterboard; to pass the elements through the logs, holes are made; they install corrugated tubes or insulation for pipes;

- if the floor is made of boards, then a contour is drawn on the surface; For this purpose, a wall chaser is used; foil material is placed in the grooves;

- make the contour from plywood or lining; distance between workpieces 50 mm; metal thermal distribution plates are installed in the resulting niches; reflective material is placed in them;

- Thermal film is installed on a wooden floor without preliminary preparation;

- instead of concrete screed, wooden sheathing or sheets of plasterboard are used; the cladding is laid on a clean dry screed; laminate, linoleum; I'll have to give up the tiles.

When installing underfloor heating in a country house, it is necessary to provide an optimal source of energy. If possible, use a liquid line. The pipeline is filled with antifreeze. It doesn't freeze. Additionally, a circuit for DHW is output. Electric heating is provided if there are no power outages.

Autonomous heating with your own hands.

Economical battery boiler for heated floors Heading Do-it-yourself autonomous heating. Economical battery boiler for heated floors Heading Warm floors under laminate in 1 hour EASY and SIMPLE Heading Warm floors. 10 mistakes you should NOT MAKE

Rules for preparing a country house

Regardless of the presence or absence of heating, it is advisable to insulate the country house in any case. Moreover, it is necessary to insulate not only the floor, walls, but also the roof. Thanks to this, the house will remain warm in winter and cool in summer.

- The rough foundation must be prepared for installation of a heated floor. If the floor is not insulated, it must be opened and covered with crushed stone and expanded clay in a layer of about 30 cm.

- Next, membrane waterproofing is laid and insulation is laid (thickness - 20 cm).

- A 5 cm cement screed is poured.

- A special moisture-repellent impregnation is applied over the screed.

- It is also important to place damper tape around the perimeter of the floor on the walls.

- The underfloor heating cable must be laid on a previously laid reflective screen.

- Next, the heated floor is installed directly.

- At the end, a screed . If the heated floor is liquid, then it is 80 mm thick, and if it is mats or cable, then it is 50 mm. As for IR film, it does not require a screed.

Warm floor on a concrete base

Note! Wooden floors are laid over lathing between the joists. Preparation is carried out in the same way as described above, but instead of screed, the heating elements are covered with cement-fiber boards or plasterboard.

Heating on a wooden floor

The system is mounted on a foil backing, and a wooden sheathing is made on top. Infrared film can be laid directly on a wooden floor.

Prices for heated floors REHAU

Warm floors REHAU