Modern private houses are most often built taking into account the fact that even at the design stage they provide for the installation of a heated floor as the main or additional source of heating. In any case, the advantage of houses with heated floors is obvious - they are more comfortable and warm. It is important to understand that the underfloor heating system must first be calculated - this is especially true for the water system. The heated floor design allows you to foresee the power of the system, correctly arrange all the components, and calculate the amount of material. When developing a project, you will need to take into account many nuances: the area of the room and the estimated heat loss in it, the type of pipes, the material of the finishing coating and the method of installing the system itself, as well as much more, without which high-quality installation is impossible.

A properly designed underfloor heating project guarantees the durability and high-quality operation of the heating system

Where to begin

Among the variety of technologies for installing heated floors (electric, infrared and others), the water system is especially popular. It is durable and reliable, but without preliminary correct calculation there is a possibility of increased costs during installation and a decrease in the operational properties of the system.

Water heated floor

A water heating system project can be developed as one of the items in the design documentation for a house. You can also order it separately or do it yourself. Some companies specializing in the installation of water heated floors independently carry out a preliminary design of the system.

The project will be required even if you install a water heated floor yourself. This will allow you to purchase material and shaped elements in the required quantity, and perform the installation itself in a short time, without being distracted by calculations and alterations.

Layout and connection diagram in a private house

To draw up a project, you will need to have and record the following data:

- Floor plan of the building.

- Material of external walls and windows and doors.

- Desired indoor temperature.

- Information about where risers and outlets are located inside the building.

- Furniture arrangement plan.

Knowing the listed nuances of the room, they first perform a thermal calculation, and then begin to draw up an installation diagram.

Now there are several types of “warm floors” on the construction market. They differ in the type of coolant and operating efficiency. How to choose a heated floor? We'll tell you in our article.

Preparatory work and calculation of materials

Such a responsible job as installing a heated floor with your own hands should begin with the preparation of materials and planning. Strictly speaking, an accurate calculation can only be made by specialists who have information about the level of heat leakage in a given room. But for individual needs, approximate calculations are often used that satisfy the requirements.

First you need to draw a plan for the placement of pipes. The clearest and most visual diagram will be a diagram drawn on paper in a checkered pattern, the warm floor on which can be calculated based on the square footage of the room. Each cell will correspond to a pitch - the distance between the pipes.

For temperate climate zone:

- If the house and windows are well insulated, the distance between adjacent turns of the pipe can be 15-20 cm;

- If the walls are not insulated, 10-15 cm.

- In spacious rooms, where some of the walls are cold and some are warm, a variable step is taken: near the cold walls the distance between adjacent turns of pipes is small, and as you approach the warm walls, it increases.

What flooring is suitable for heated floors?

A big mistake is made by those who plan to lay parquet or thick wooden flooring on a warm floor. Wood is a poor conductor of heat and will prevent the room from heating up. The efficiency of such heating may be even lower than that of radiator heating, and heating costs may be too high.

The ideal covering for a heated floor is stone, ceramic or porcelain tiles. Once heated, it will keep warm perfectly, and this is the best option for the kitchen or bathroom. Children love to play in rooms where the floor is warm, and walking barefoot there is more pleasant than on wooden parquet.

A slightly worse flooring option, but more suitable for a guest room or bedroom, is linoleum and laminate. These materials transmit heat well and will not reduce the efficiency of water heating. In this case, the laminate should be chosen with a minimum thickness, and linoleum should be chosen without an insulating backing.

Important!

When heated, many synthetic materials can emit harmful fumes. Therefore, floor coverings with chemical components must have a manufacturer’s mark indicating the possibility of their use in residential premises on heated floors.

Base for heated floors

If we are talking about a house with concrete floors, then the most affordable and generally accepted option is a water-heated concrete screed. The same method is used for the first (ground) floors of private cottages, if the base of the floor is on a sand cushion, which is located directly on the ground.

In houses with wooden floors, this option is not applicable. Wooden floor beams simply will not withstand the enormous weight of a concrete screed, no matter how thin it is. In this case, a lightweight version of heated floors is used, which will be discussed in a separate section.

Installing a heated floor with your own hands begins with preparing the base. The base for creating a warm floor must be flat, without protrusions and depressions. The maximum permissible difference is 5 mm. If the depth of surface defects reaches 1-2 cm, then you will have to pour and level a thin layer of granite screenings (fine crushed stone) with a grain size of up to 5 mm. You will have to lay a film over the leveling layer and walk on wooden boards when laying the thermal insulation. Otherwise, the leveling layer itself will become a source of unevenness.

Documentation

Before you begin installing the system, you must have a plan for the heating system and a list of necessary materials and equipment.

Warm floor plan

The plan structure includes the following data:

- About the location of heating devices.

- A diagram showing the location of the pipes, the distance between them, their diameter and the length of each straight section.

- Information about the required power of each radiator and their locations.

- Thermal calculation of a water heated floor system.

Features of connecting the electrical system

Electric underfloor heating is more often used as inter-seasonal heating and is used when central heating is not yet turned on. Its main advantages include:

- Simplicity and speed of installation;

- No need for “wet” processes;

- Relatively low cost;

- Slight rise in floor level.

Unfortunately, there are also disadvantages:

- Electromagnetic radiation - according to manufacturers, it is within normal limits, but additional shielding will not hurt;

- High cost of operation - electricity is much more expensive than other types of fuel;

- Load on indoor wiring.

What cables can I use?

The main heating element of such a system is a special cable, which is laid on the floor like a snake and attached to the mounting tape. The connection diagram depends on which cable you chose:

- Single-core resistive is the cheapest and simplest type of cable in design. It is a heating core through which current passes. In this case, most of the electricity is converted into heat. The main feature of this type of cable is the need to connect both ends to the mains, which is not always convenient.

- Self-regulating cable - here it is not the current-carrying conductors that are heated, but special polymer couplings. This cable can rightfully be called the most convenient to use, but also the most expensive.

- Two-core resistive - in addition to the heating core, this cable also contains a conductive one. This will allow you to connect it to the network at only one end, and somewhat reduces the level of the magnetic field.

Please note that laying resistive cables on areas of the floor that will be filled with furniture is strictly prohibited. This will inevitably lead to overheating of the system and failure.

Single-core resistive, two-core resistive and self-regulating cables for underfloor heating (from top to bottom)

Connecting sensors and thermostats

The distance between turns is determined based on the required specific heating power and cable power. After laying the cable, we install the floor temperature sensor, having previously protected it with a corrugated tube.

In order to prevent solution from entering the tube with the sensor, carefully use either an end coupling or carefully insulate the end with available materials

The sensor is installed in the middle between the turns of the cable at a distance of 0.5 m to a meter from the wall. We place a vertical piece of wire connecting the sensor to the thermostat in the groove.

The first voltage supply to the underfloor heating cables should be made only after the concrete has completely dried - no earlier than after 28 days.

As a rule, the method of connecting the thermostat is described in detail in the instructions for it. If you are afraid that you will not be able to cope with the task yourself, invite a specialist. It won't cost much

We hope that with the help of this material you figured out how to connect everything correctly yourself. If you still have any questions, we suggest you look at our other articles, or, if you don’t want to do everything yourself, seek help from highly qualified specialists.

Materials

During the design process of a water heated floor system, a list of materials is drawn up. Conventionally, they can be divided into components of the system itself and raw materials for creating the screed.

The main elements in a heating system with an additional heat source in the form of a heated floor

The components of a warm water floor are:

- A thermal boiler that heats the coolant in the absence of a central heating system.

- A pump built into the boiler or separately located for pumping water into the system.

- Pipes for the movement of coolant.

- A collector is installed to distribute water through the pipes.

- The manifold is placed in a special cabinet, and you will also need to purchase splitters for distributing cold and hot, valves, fittings, and balls. It will also be necessary to provide for emergency drainage of water and removal of air from the pipes.

Pipe fastening methods

The list of materials depends on the method of installation of the system - wet (in a screed) or dry (using mats with bosses , for example).

The principle of connecting a heated floor

In the first case, a reflective layer and reinforced mesh are laid over the rough screed and the pipes are fixed. After this, a finishing screed is poured onto which the finishing floor covering will subsequently be laid.

Pipe laying can be done using mats with bosses and thermal plates that effectively reflect heat

In the second case, the pipes are fixed in a given position using special mats with bosses and thermoplates with a groove where the pipe is laid. This method is relevant for rooms with old or weak floors.

How to choose pipe length

One circuit (loop) can have a certain maximum length depending on the diameter of the pipe used. With a pipe diameter of 16 mm, the maximum circuit length is from 70 to 90 m; with a diameter of 17 mm, the circuit length varies from 90 to 100 m; if the pipe diameter is 20 mm, then one circuit can have a length of up to 120 m.

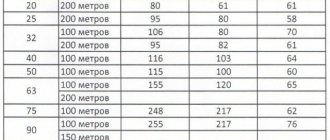

Calculation of the number of pipes taking into account the main criteria

The dependence of the loop length on the diameter is due to the fact that pipes of different diameters have different hydraulic resistance and thermal load. Less hydraulic resistance is observed in pipes with a larger diameter.

Calculation depending on the laying step

Note! In a small room, it is enough to mount one circuit that does not exceed the maximum permissible length values. But if the room is large, then it is better to install two circuits rather than exceed the recommended optimal pipe length.

It is also worth considering that in fact, when installing the system, it is necessary to use pipes of the diameter for which the calculation was made in the project. You can make calculations for pipes of different diameters and choose the appropriate option at this stage, and not later, choosing the appropriate material experimentally.

Calculation of contour lengths for various rooms

When laying several contours, it is necessary that their lengths coincide as much as possible. The length of the circuit is the length of the entire pipe, that is, it starts from the collector. It is clear that during the work it is not always possible to achieve the same length of the contours, but it is necessary to strive to ensure that the difference between the lengths does not exceed 10 m.

Recommendations from experts

The method of laying contours of the same length is influenced by the area of the room. Where it is smaller, when laying pipes between turns, a smaller step is provided. Alternatively, to heat a small room with minimal heat loss (hallway, bathroom), you can use the return pipe of an adjacent loop.

How to choose a pipe laying step

The distance between adjacent turns of pipes (pitch) is 15-30 cm. In this range, the values are multiples of 5, i.e. 15, 20, 25,30. For large rooms, such as gyms, the pitch can be 30 - 45 cm. Near a large window or external wall, the laying pitch is 10 cm. These areas are called edge zones.

Laying pipes in the edge zone (near the window)

The choice of pipe laying step is influenced by various factors: thermal load, purpose of the room, contour length, finished floor material and other nuances. Due to this:

- For edge zones, the optimal number of rows is 6, laying step: 10 -15 cm.

- For central zones: 20 – 30 cm.

- For bathrooms, the step is 10 - 15 cm, but you should be prepared for the fact that due to the need to bypass plumbing equipment, the step may not be the same.

- If the finishing coating has high thermal conductivity (tile or marble tiles, porcelain stoneware), then the distance between the turns is 20 cm.

Calculations of basic parameters for contours of different lengths

Note! In practice, it is not always possible to adhere to these recommendations. According to experienced craftsmen, the most optimal option is a step in the edge zone - 10 cm, in the center - 15 cm. These are the values at which the system will work.

How to choose pipe diameter

For residential premises, the area of which starts from 50 m², the best option would be pipes with a diameter of 16 mm. The height of the tie from the top point of the tube is 5 cm.

Pipe diameter characteristics

It is this diameter that makes it possible to comply with the conditions for laying pipes with a pitch of 15 - 20 cm. This applies even to houses with good thermal insulation, where the pipe laying pitch should not exceed 15 cm. For private houses, the specified parameters are optimal in terms of ease of installation, cost of materials and volume of coolant.

Performance properties of pipes for heated floors

Pipes with a diameter of 18 mm, due to their larger volume, lead to unnecessary costs, including related materials (fittings, etc.).

The advantages of pipes specially designed for underfloor heating are obvious

Accordingly, pipes with a diameter of 20 mm will require even more energy to heat the coolant. In addition, laying with a snake in increments of 15 cm is not realistic, due to the impossibility of bending a pipe of such diameter to the required radius. As a result, the laying step will be larger, there will be less heat in the room, and this with significantly increased coolant costs. Pipes of this diameter are used in public premises with a thick screed.

Properties affecting installation quality

Pipe material

Different pipe materials directly affect the correct operation of the system.

Table 1. Types of material

| Type of material | Positive traits | Flaws |

Copper | 1. The material conducts heat well. 2. Copper is highly resistant to corrosion. 3. The material has a long service life 4. Copper has a unique plasticity that allows pipes to be bent along a fairly small radius 5. The walls are characterized by high mechanical strength and high resistance to temperature changes. 6. An external polymer coating protects copper from negative external influences. | 1. Laying copper pipes requires skill in working with such material. 2. The need to use special equipment. 3. High cost of material. |

Stainless steel (corrugated pipes) | 1. Excellent flexibility. 2. Resistance to kink. 3. High mechanical resistance. 4. High resistance to temperature changes. 5. A wide range of high quality connecting elements that allow joining pipes in a long circuit. | High price. |

Polypropylene | 1. Easy installation. 2. Low cost. 3. Suitable for supplying coolant from the boiler to the collector. | 1. Low plasticity. 2. Short length. 3. When forming a contour, there are many welds, which are potential leakage points. 4. Low thermal conductivity. 5. High level of thermal expansion. |

| Cross-linked polyethylene | 1. High strength of the material 2. Hermetic connection of circuits. 3. Possibility of creating a contour of any length. | Large bending radius. |

Types of pipes

Thermostat for water heated floors

The floor is a connection of pipes connected to the collector. Correct data measurements are the basis for calculating the operating power of thermal equipment. To calculate the distance between pipes and the length required for installation, it is worth familiarizing yourself with the main types of structures and their features. To install a warm water floor, pipes made of the following materials are used:

- Cross-linked polyethylene. This material is difficult to install and has a fairly high cost. However, it also has a lot of advantages, for example, it has memory properties, does not corrode, and is resistant to temperature changes.

- Copper. One of the most durable materials, characterized by high strength and corrosion resistance. The downside is that copper is quite expensive and such pipes are difficult to install.

- Metal-plastic. The advantages of the material lie in its efficiency, strength and safety from an environmental point of view.

- Polypropylene. Polypropylene pipes are characterized by their low cost and high technological characteristics, including low thermal conductivity.

To calculate the required number of pipes, it is necessary to take into account the installation features that will make operation as efficient as possible:

- the average diameter of the pipe is 16 mm, and the thickness of the screed is 6 cm;

- the average laying step in a contour spiral is 10–15 cm;

- the length of the pipe in the heating circuit should not exceed 100 meters, and it should be taken into account that the pipe must exit and enter the collector without breaks;

- the distance between the pipe and the wall should remain between 8 and 25 cm;

- the total length of the circuit should be 100 meters with a total area of 20 m2;

- between the lengths of the turns it is necessary to maintain a difference not exceeding 15 meters;

- the minimum permissible pressure inside the collector is 20 kPa;

- the shorter the pipeline, the less the need to install a powerful pump, since the level of pressure drop is reduced;

- the coolant temperature at the inlet should not differ from the outlet temperature by more than 5 degrees.

The length of the laying step also depends on the individual parameters of the room and weather conditions in a particular region. In addition, the laying step is directly related to the calculation of the contours.

What else will need to be taken into account in the process of designing a heated floor?

In the process of developing a project for a heated floor system, it is recommended to make a schematic drawing indicating the laying of pipes, main dimensions, distances and indentations, and furniture placement.

Collector group

You should also select the final coating material. To do this, you can read our article . In it we will consider the most suitable finishing coatings.

At the design stage, the type of coolant is determined: in 70% of cases water is used, since it is the most accessible and cheapest substance. Its only drawback is its reaction to temperature changes, which result in a change in the physical properties of water.

Floor pie with pipes in screed

Antifreeze based on ethylene glycol or propylene glycol with special additives that reduce the chemical and physical activity of liquids is often used as a coolant for underfloor heating. In any case, the type of coolant must be taken into account at the design stage, since its properties form the basis for hydraulic calculations.

Antifreeze as a coolant

You will also need to take into account the following nuances:

- One circuit is installed per room.

- To place the collector, choose the center of the house. If this is not possible, then to regulate the uniformity of coolant flow through circuits of different lengths, flow meters are used, which are installed on the collector.

- The number of circuits connected to one collector depends on their length. So, with a circuit length of 90 m or more, no more than 9 circuits can be connected to one collector, and with a circuit length of 60 - 80 m - up to 11 loops.

- If there are several collectors, each has its own pump.

- When choosing a mixing unit (mixing module), it is important to take into account the length of the circuit pipe.

- A more accurate calculation would be based not only on data on heat loss in the room, but also on information on heat influx from household equipment and equipment, from the ceiling, if a heated floor is also installed on the upper floor. This is relevant when calculating for a multi-storey building, which is built from the upper floors to the lower ones.

- For the first and ground floors, the insulation thickness is taken to be at least 5 cm, for higher floors - at least 3 cm. Insulation on the second floor is used to eliminate heat loss through the concrete base.

- If the pressure loss in the circuit exceeds 15 kPa, and the optimal value is 13 kPa, it is necessary to change the coolant flow towards a decrease. You can lay several smaller contours in the room.

- The minimum permissible coolant flow rate in one loop is 28-30 l/hour. If this value is higher, then the loops are combined. Low coolant flow leads to the fact that it cools down without passing the entire length of the circuit, which indicates the inoperability of the system. To fix the minimum value of coolant flow in each loop, use a flow meter (control valve) installed on the manifold.

Connecting pipes to the collector

Main characteristics and indicators

Before making the necessary calculations, we should understand what exactly we will be calculating. There are not so many types of such underfloor heating devices, however, to calculate each one you will need completely different data and indicators. A liquid heated floor consists of heating pipes, various devices (including heating ones) and fittings. It is installed directly into the floor covering. The room is heated by the heat generated by the pipes as the coolant moves through the pipes. The coolant can be water, antifreeze and ethylene glycol. Warm floors are the key to coziness and comfort.

Calculation example

Calculation methods

Calculation of a warm water floor can be done in several ways. First of all, we are talking about installing a pipe for a heated floor directly into the screed. This will distribute the available heat evenly over the entire surface. The second option is to use flooring. This type of installation is called polystyrene installation technology, in which the pipes are mounted on the surface of the underlay used. There are special grooves on it, and it consists of dense plastic. Special plates made of aluminum act as heat reflectors. This installation method is used when we are talking about a low and small-sized room, where it makes sense to save every centimeter.

It is necessary to take into account the diameter of the pipes

Another option is used for heating wooden structures and houses. To do this, the underfloor heating pipes are laid on logs or a sheathing created for them. It is not recommended to use the electric floor heating calculator on your own, because we are talking about the safety of the device and the family. To do this, you should take the help of specialists who are not the first to deal with such manipulations. Electrical structures consist of a cable, rods and film, which are mounted in the gap between the finishing layer and the base layer. Heating is carried out by convection. Despite numerous advantages, its operation is not considered one of the most affordable, although it is very convenient to use.

Pipe flow table

The role of a water floor as a main or additional source of heat

A warm floor in a room as a heating system can perform an additional or primary function. As an additional system, underfloor heating affects the comfort of the flooring surface. In this case, the main source of heat is traditional heating radiators. To maintain the coolant temperature, the thermostatic regulation principle is used.

Combined heating system

Controlling the heating level of the coolant allows you to compensate for heat losses in the room and protect it from temperature changes outside, when the water floor is the main source of heat. The warmer it is outside, the lower the coolant temperature should be and vice versa.

In fact, a heated floor is a low-temperature type of heating system and, theoretically, the required coolant temperature can be obtained by setting the boiler to minimum heating. However, a conventional boiler set to a low temperature range is characterized by a sharp decrease in efficiency and from the economic side such a system becomes unprofitable.

Mixing unit

In this regard, there are other ways. For example, the use of a modern heat generator that supplies coolant heated to +30 - 50 degrees. When such a boiler is equipped with a circulation pump, each circuit has a coolant of the same temperature, due to which the most economically efficient process of heating a house with a “warm floor” system is carried out.

Three way mixing valve

If the boiler is not equipped with a low-temperature operation function, then a three-way mixing valve can be used, and the required temperature can be obtained by equipping the mixing unit with a thermostat.

Note! When installing a combined floor covering, for example, wood and ceramic tiles, a separate circuit is laid under each material, since each material differs in thermal conductivity. The water in the circuits will have different temperatures to create uniform heating of the room with such a floor.

It is also worth considering that some types of finishing materials are not suitable for water floors and can be installed in tandem with film or cable electric heating systems.

Infrared film for heated floors

What should be taken into account when calculating

The first and main factors will be the size of the room and its temperature characteristics. Without assessing actual heat losses, it will be impossible to perform an accurate calculation. Therefore, you should definitely take into account the following features:

- the material from which the walls are built;

- number, size of windows and type of glazing;

- temperature outside;

- the presence or absence of heating on the floor below.

Also, the required system power will depend on the finish. After all, different materials (for example, tiles and wood) have different heat conductivity, and the temperature of the floor surface should remain around 30 degrees.

Warm floor in a wooden house

Only by taking into account all these factors and making adjustments for each of them can a high-quality calculation of a warm water floor be made. Only specialists can make accurate calculations and draw up a detailed project. But to have an initial idea of the amount of material and scope of work, you can use the online warm water floor calculator located below. Plus, it wouldn’t hurt to familiarize yourself with the general logic of calculation and installation of such a system.

Warm water floor calculator

| Supply temperature, oC. | |

| Return temperature, oC. | |

| Pipe pitch, m. | 0.050.10.150.20.250.30.35 |

| Pipe | Pex-Al-Pex 16×2 (Metal-plastic)Pex-Al-Pex 16×2.25 (Metal-plastic)Pex-Al-Pex 20×2 (Metal-plastic)Pex-Al-Pex 20×2.25 (Metal-plastic)Pex 14×2 (Crosslinked) polyethylene)Pex 16×2 (Cross-linked polyethylene)Pex 16×2.2 (Cross-linked polyethylene)Pex 18×2 (Cross-linked polyethylene)Pex 18×2.5 (Cross-linked polyethylene)Pex 20×2 (Cross-linked polyethylene)PP-R 20×3.4 (Polypropylene) )PP-R 25×4.2 (Polypropylene)Cu 10×1 (Copper)Cu 12×1 (Copper)Cu 15×1 (Copper)Cu 18×1 (Copper)Cu 22×1 (Copper) |

| Flooring | TilesLaminate on a backingParquet on plywoodCarpet |

| Thickness of the screed above the pipe, m. | |

| Specific thermal power, W/m2 | |

| Floor surface temperature (average), oC | |

| Specific coolant flow, (l/h)/m2 |

What affects the operation of a warm water floor?

How to ensure that a warm floor really is warm and creates a comfortable temperature for the floor covering. Often, due to the large length of the circuit, a high value of hydraulic resistance is observed.

For correct operation of the system in a house with several floors, a separate low-power pump is installed on each level or one high-power pump is connected to the collector.

Pump group

When choosing a pump, take into account the calculated data, coolant volume and pressure. However, it is worth remembering that to determine the level of hydraulic resistance, it is not enough to know the length of the pipe. You will need to take into account the diameter of the pipes, valves, splitters, laying pattern and main bends. More accurate calculations are obtained by using a special computer program into which the main indicators are entered.

As an alternative, it is possible to use standard equipment that has already known technical characteristics. By maneuvering its parameters, the hydraulics of the system are adjusted to the characteristics of the pump.

Manifold with installed pump

Factors taken into account

First, a few words about what warm floors are. This is a system located under the floor covering, consisting of pipes connected through the boiler to the water supply. The hot coolant, spreading through the pipes, evenly heats the entire room.

The advantage of such floors is that heat flows rising from the floor warm the air and make the temperature in the room as comfortable as possible. After this, the cooled air drops to the level of the radiators, heats up again and continues to circulate around the room. In addition, when your feet are constantly in contact with a heat source, it is almost impossible to freeze, even wearing the lightest clothes.

The calculation always begins with determining the type of heating system. A warm floor can be used as an additional heat source, or it can act as a contour of a combined system. In the second case, a completely different approach is required, since it is necessary to take into account the type of pipe layout, the number of heating sources and much more. The main difference between these systems is the power of operation.

Before you start laying the floor, you should consider:

- Weather data, that is, average temperature indicators of the place of residence.

- Detailed floor plan. The materials from which the building was constructed, the type of glazing of the apartment, the dimensions of window and door openings, floor and area are taken into account.

- Volume of heat loss. To calculate this parameter, it is necessary to calculate the presence of heat sources, the average temperature in the room, the thickness of the floor, the type of floor covering and the presence of insulation.

In addition, it is worth taking into account the presence of carpet and the type of furniture in the room. It is also important to remember that before you start insulating the floor, you need to work on sealing the walls and windows

Basically, heat loss occurs precisely because of thin walls and poorly installed double-glazed windows. Taking these factors into account will significantly reduce the cost of installing a heated floor.

When calculating power, the necessary parameters of the heating circuit are determined in parallel, that is, the number of pipes, their length, as well as the features of coolant circulation. The result of a competent calculation will be a finished installation scheme and the exact cost of construction work in an apartment or private house.

Heat distribution: features

Since the area of the rooms in the house varies, the circuits also have different lengths, so it is necessary to ensure the same hydraulic pressure in all areas of the system. It should be taken into account that the pump is a constant value.

Distribution of heat from different sources

Supplying the same volume of water to circuits of each length leads to the fact that the coolant in the longer one cools down faster and at the outlet its temperature will differ from the coolant with a shorter profile. As a result, the floor surface will warm up unevenly - somewhere there will be overheating, and somewhere, on the contrary, the coating will be cold.

The advantage of using heated floors

Due to the high hydraulic resistance, the coolant may not flow into a long circuit at all, since it will move into shorter circuits with less resistance. To prevent this from happening, the system is equipped with a distribution manifold, which allows maintaining a balance of supply and uniform heating of the coolant in each loop.

Using qualified assistance to draft a project

Many people underestimate such things due to lack of funds/desire/experience/time. Professionals offer each client:

- creating a plan taking into account all needs;

- implementation of invested resources by 100%;

- consideration of all prices, from small expenses to the total estimate;

- implementation of a turnkey underfloor heating project;

- quality results supported by experience/knowledge/scientific data/proven methods;

- guarantee of effective heating if all instructions are followed.

We recommend: What characteristics does Caleo underfloor heating have?

All this seems unreal until you have to fully face it. But at the time of reading this article, a person has already appreciated some of the benefits of such information. In large cities, trusting unverified companies is very dangerous.

Which is why it’s better to play it safe once again to achieve your plans. Especially if it is your own comfort and safety.

- Related Posts

- What characteristics does a two-core heated floor have?

- How to assemble a Valtec manifold for underfloor heating?

- Features of Korean heated floors

- How to properly install a heated floor?

- Which plasticizer to choose for heated floors?

- What are the advantages of Gulfstream underfloor heating?

How to calculate the number of pipes

At the design stage, after all the calculations have been made, you can understand how many pipes in linear meters may be required. This will allow you to estimate the cost of the material.

Main stages of installation

So, with a room area of 12 m², the air temperature should correspond to + 20 degrees. The width of the edge sections along the walls with furniture should be 30 cm. If one wall has a length of 6 m, and the other two are 2 m, then the working area of the system can be calculated using the following formula: 12 – 0.3*(6+2+2) = 9 m².

Note! The laying pitch and diameter of the pipes depend on the level of heat loss. The smaller they are, the larger or smaller the pitch of the pipes.

When determining heat loss in a room, the glazing area, the characteristics of the insulation used in the enclosing structures, and the height of the room are taken into account. The resulting value varies from 20 to 300 W/m² depending on the thermal efficiency of the structures and double-glazed windows used, the thickness of the walls and the number of openings.

Warm floors are a serious cost item during renovation, so it is important to accurately calculate how much and what materials will be needed. To ease your labor costs, we have prepared special instructions telling you how to calculate a heated floor - water or electric. Online calculators included. And in the article “What is needed for a heated floor?” you will find a complete list of everything that may be needed during installation.

Number of circuits

The table shows the optimal values for the length and number of circuits for each pumping and mixing unit.

| Name | Maximum circuits, pcs. | Maximum length of each circuit, m | Pipe, mm |

| Pump with a flow rate of 40 l/min. and pressure 6 m (parallel connection diagram) | 8 | 65 | 16 |

| 5 | 80 | 16 | |

| Pump with a flow rate of 40 l/min. and pressure 6 m (series connection diagram) | 12 | 65 | 16 |

| 8 | 80 | 16 |

Popular pipe laying schemes and their features

The main layouts for laying pipes with coolant include “snake” and “spiral”, and other installation options based on them are also often used, for example, “snake” without edge zones.

Common installation methods

“Snake” is a convenient option that can be easily installed in a small room, however, heating of the pipes in this case occurs unevenly. Therefore, pipes are laid along the wall, characterized by large heat losses, which are located closer to the collector (at the beginning) and are better heated.

The pipe laying step according to this scheme should not be more than 30 cm, otherwise the floor covering will have an uneven temperature - heat will be felt above the pipes, and cold between them. The distance between the outer pipes is 20 cm or less.

“Snake” and “spiral” are the optimal ways to form a contour

Note! To ensure that when laying pipes according to the “snake” pattern, the heating of the floor surface is uniform, a second (reverse) snake is laid.

The “spiral” scheme is distinguished by a laying method in which the supply and return pipes are placed parallel to each other. Due to this, the issue of uneven heating of the floor is resolved, and the temperature above both pipes is approximately equal.

Laying options

The spiral type of installation is most relevant for large rooms, with the distance between pipes being 20 cm.

We make calculations

How to install a mixing unit for a heated floor with your own hands

To calculate the number or footage of pipes required, you must first select a suitable installation scheme. The most common are “snake” and “spiral”.

Laying schemes

The first option can have two varieties. In the first case, the pipe is laid in a snake.

Note! “Snake” allows you to save a little on pipes, but the heating of the room will be uneven. First, the floor will heat up on one side, and gradually the heat will move further

In addition, the water will cool down as it moves through the pipes. This means that on one side the floor will always be a little cooler.

Snake

A more effective styling is a double spiral. In this case, the pipes are laid in pairs, the one through which hot water flows, and the one through which the cooled coolant will be discharged. This method allows you to heat the floor throughout the room to the same temperature.

Note! When laying pipes using a “spiral” system, heating of the room will occur from its edges to the middle. This method is considered the most effective.

Spiral

Whatever method is chosen, in order to correctly calculate the footage of the required pipes, you need to draw a diagram. The future system is drawn on paper to scale. The contours of the room and the lines along which the pipes will be laid in the future are drawn. In this case, you need to take into account the location of large furniture elements; it is not recommended to lay heated floors under them. It is also worth considering that pipes must be laid with a distance of at least 20 cm from the walls.

For correct calculation, you need to know one more parameter - the distance between the pipes or the pitch. This parameter will depend on the diameter and thermal conductivity of the pipes, as well as on the temperature of the supplied coolant. The first two indicators can be found in the store where the pipes will be purchased. The second indicator will depend on the boiler used. Also, the choice of step is determined by the required temperature in the room. If you need it to be much warmer, then the step is taken smaller, and vice versa.

Calculation

When making calculations, we must not forget that the length of one circuit should not exceed 60–70 meters. Otherwise, the efficiency of the system will be significantly reduced.

Note! If the area of the room is quite large, and the pipe footage will be more than 70 meters, then it is necessary to create additional circuits (one or two, depending on the area). It is better that they are the same length.

Combined styling

Having made the correct drawing of the future system (taking into account the distance from the walls and the future arrangement of large furniture elements), you can accurately calculate the required number of pipes. But it’s always worth taking with a reserve. With any work, small shortcomings and flaws are inevitable. It is better to make a ten percent reserve than to then run around the shops looking for a suitable pipe.

Installation of heated floors: features

One of the design stages includes the creation of an installation diagram, which will subsequently need to be followed when performing work directly on site.

Floor pie with pipes inside the screed - optimal thickness

The installation diagram should reflect the following points:

- Plan for dividing the base surface into several sections. This stage cannot be ignored when pouring screed over a large area, since thermal expansion in this case leads to its destruction. Dividing into separate sections allows you to form expansion joints between them. In this case, one area should not exceed 40 m², and premises of L and U-shaped configurations are divided into sections regardless of their area.

The principle of laying on mats

- The installation diagram must contain a reference to the presence of expansion joints, which are filled with damper tape, elements made of extruded polystyrene foam or polyethylene foam. Inside the seam, the pipes are placed in a casing, for example a corrugation.

- The project indicates the way in which the pipes will be laid - this will allow you to purchase the necessary material in a certain quantity. They also reflect the method of screed construction - wet, semi-dry or dry.

- The temperature of the pipes is calculated - this will help determine the finishing flooring material, the manufacturer of which indicates the compatibility of the material with the “warm floor” system and its permissible heating. So, parquet can be heated up to 25 degrees - no more.

The principle of laying in a screed

Prices for heated floors Caleo

heated floors Caleo

Video - 5 key rules for installing water heated floors

Determination of room heat loss

If heat loss exceeds the specified value, then you will need to choose a different heating system, or supplement the heated floors by installing radiators. Perhaps the house should be further insulated.

The resulting heat loss is divided by the area of the heated premises. This is the preliminary calculated power of water heated floors per square meter. The final calculation is performed in a special computer program.

If our heating system using floors of the specified design consisted only of it, then the calculations could be considered complete. But it is necessary to take into account the section from the collector to the boiler, taking into account, at the same time, the hydraulic resistance of the section.

Basic parameters for TP design

The location of heating elements that influence the specific power of a heated floor per 1 m2 is designed based on the thermophysical characteristics of the structure. In this rather complex process, many different factors must be taken into account, including:

- regional thermal standards - minimum outside air temperature in the coldest period of the year;

- the average temperature in each room and their location;

- features of building structures - material and thickness of walls, floors and ceilings or interfloor ceilings;

- the number and type of windows, their total area, heat loss coefficient, which largely depends on the type of double-glazed windows installed;

- positioning of the building relative to the cardinal directions;

- the height of the premises, as well as a number of others.

The proposed list of parameters that influence the calculation of heated floors is far from complete - an experienced heating engineer will indicate a dozen more important thermophysical characteristics.

However, the primary task of such a design is to select such a thermal performance of the TP that is guaranteed to be able to compensate for all the energy losses of the heated building. We must also not forget that it is recommended to increase the calculated theoretical power by 10-15% so that the thermal installation does not operate at the limit of its capabilities.

Regardless of whether the calculation of heated floors is carried out with your own hands or by specialized specialists, in all cases they are based on the requirements of GOST R 55656-2013 “Energy characteristics of buildings. Calculation of energy use for space heating." Below is a simplified method for independently designing a small apartment floor heating installation.

Reliable design from a “warm company”

If you need a heated floor, contact us. We will professionally design the system:

- We will conduct a pre-project inspection of the house.

- We will collect all the necessary data (about materials and construction technologies, layout of premises, location of the boiler plant).

- We will select a suitable location for the manifold cabinet.

- We will develop a heated floor design and coordinate it with you.

- Let's calculate the estimate.

In addition to individual design, “Teplaya Kompaniya” also carries out installation of heated floors. As practice shows, such an integrated approach reduces the costs of creating and operating a heating system. To find out the exact price of a heated floor project for your home, call us or fill out an application.

Pros and cons of heated floors in a cottage

Evaluation characteristics are used only when comparing alternative solutions. Warm floors have only one real competitor - radiator heating:

| Radiators | Water heated floor | |

| Project cost | Cheaper by 20-40% both in equipment and in labor. | The price increase starts from the design stage. But this is a one-time expense! |

| Heat distribution and room heating | Heating of rooms is local, and convection currents are responsible for a comfortable temperature throughout the room. | An absolute advantage. The very principle of the underfloor heating system declares that the room is heated over the entire area at once. |

| Life time | Manufacturers provide a 50-year guarantee on high-quality radiators. But even cast iron radiators from the 60s continue to work. | The equipment warranty is 50 years. But water-based heated floors entered the Russian market about 25 years ago, so experimental testing is yet to come. |

| Availability of repairs | No difficulties even with a minimal set of tools. | An extremely time-consuming and difficult task even for professionals. |

| Inertia - adjustment | The radiators themselves react almost instantly to changes in coolant temperature, but this does not affect the heating of the entire room. When the heat supply is turned off, the radiators will cool down first. | The system responds much more slowly; noticeable changes may take up to 1.5-2 hours. But the heating will be felt immediately throughout the entire area of the room. |

| Economical | The situation is quite nasty. If two absolutely identical houses lose the same amount of heat, then to compensate they need to receive the same amount of heat from the heating system. With a typical solution, energy bills will be approximately the same. But water heated floors have the opportunity to realize the inherent potential of the system! | |

| The coolant temperature reaches 95-97˚C. The efficiency of the hot water boiler is ≈85%. | The maximum coolant temperature does not exceed 60˚C. This allows the system to be equipped with a condensing low-temperature boiler. Its efficiency can exceed 100%. | |

| Aesthetics | Even the most modern radiators will be in plain sight, which limits the designer's creative ideas. | Ideal, because the water heated floor system is not visible at all. |

| Comfort | Only next to the heating radiator. | Comfort of stay is noted by 100% of users. |

The tabular data is reliable provided that the heating systems of the cottage were installed by professional builders and on identical sites.