In what cases is it compiled?

The act is required when:

- Commissioning of new equipment. The certificate will confirm that each element is in its place, the installation was carried out responsibly, and the system is working.

- The heating season is approaching. After a summer break in work, the pipes could fail. After checking their capacity, a report is drawn up.

- Already carried out repair work.

- The occurrence of contained emergency situations on the pipeline. In this way, specialists identify the amount of work required and the weak points of the existing heating network.

For the uninterrupted operation of the heating system, preventative control checks and reliable information about the quality functioning of the system upon startup are necessary.

Second point

The entire second paragraph of the boiler room inspection report is devoted to the attached technical documentation. The inspector determines whether the equipment installed in the boiler room corresponds to the parameters specified in the papers. And if this is so, then does all this correspond to the requirements for the premises?

The following information should also be included:

- Boiler developers, technical specifications for its development. Mandatory - what power was installed for a specific type of equipment.

- Which organization issuing the technical specifications reviewed the project, under what number and when was the conclusion of the conformity assessment body issued?

- Fuel mode.

- Who performed the installation work, with the obligatory license number and the date of completion of the work.

- Which commissioning organization was responsible for the installed equipment subsequently.

- Number and date of permission to admit electrical installations that are present in the premises at the time of inspection.

- Numbers and dates of acceptance certificates for metering devices.

- Permission to operate all boilers stated in the documentation.

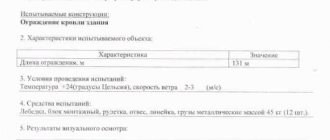

The essence and types of crimping

Nowadays heating is most often carried out by a “water circuit” system. At the same time, heated water circulates through the works, imparting its thermal energy to the premises. Leaks are unacceptable; the pipeline must be completely sealed for normal operation. Pressure testing specifically creates a larger volume in the pipe than normal.

When this is done using air, it is called pneumatic pressing.

When using water, then hydropressing. The latter method is considered safer and therefore more popular. For this reason, an example of hydropressing is provided as a form.

When testing, it is recommended not to exceed the pressure inside the pipe more than 15 MPa. If we are talking about raising pressure with water, then there are limitations. The maximum possible pressure should not exceed the normal operating pressure by more than 30%.

First point

The first paragraph with all its subparagraphs describes the boiler room equipment. Here the data is organized in the form of tables. The first table is devoted to the characteristics of the boiler. It includes:

- Boiler power. This refers to the maximum possible value.

- Load that is connected to the boiler. With it, the equipment must successfully perform its functions.

- What fuel is used? Several types may be listed here, indicating which fuel is the main fuel and which is the backup. For example, the main one is gas. And the backup is electricity. This state of affairs is only possible if the boiler room has several boilers running on different fuels, or one common for both types.

- What coolant is used: water or steam.

- Type of HVO.

- Diaerator type (if available).

- How many cubic meters does BAGV occupy?

- Type and variety of heaters.

- The volume of the fuel oil tank (if available) is measured in cubic meters.

- Data on the presence or absence of additional, in addition to the boiler, equipment or technical additions to the boiler itself.

The first table is immediately followed by a second with additional description including:

- Line number. Each boiler located in the room is described in its own line.

- Boiler type.

- The manufacturer of each product.

- Serial number of the equipment being studied.

- Coolant. It can be water or steam.

- Power.

- Steam pressure at the time of inspection.

- The temperature of water or steam required for normal operation.

- The efficiency of the boiler operation when the main fuel is connected.

- The same data when operating on reserve fuel. Everything is indicated as a percentage.

Also in the first paragraph, the coolant that is supplied to heat-consuming installations and heating networks is discussed in detail. The pressure, temperature graph and flow of water or steam are considered in the form of a table. It also indicates how much is returned to the heating system in the form of condensate.

Components of the heating system pressure test report

At the top left is information about the organization that carried out the inspection. Ideally, there should be a signature for approval by the chief power engineer of the heating supply organization.

The top right should contain subscriber information. That is, about who is the client and consumer of heating services. This could be a partnership of residents of a particular house, any organization that occupies the building, the owner of a private house, etc.

It is important to provide names and other information accurately and in detail. In this case, an address is required.

The main part of the act states:

- City.

- The date of signing the act (and the pressure test itself).

- Heat supply organization: its form of ownership, name, full name of the representative.

- Which of the subscriber's representatives accepted the heating system after the test: full name, position.

- To what indicators the pressure in the system was raised is indicated in kgf/cm2.

- To what indicators did it drop after 10 minutes following the shutdown (the units of measurement here are also kgf/cm2, it is also permissible to measure it in mPa if accurate data on this matter is available).

- Whether the system passed or failed the test (the person completing the form needs to highlight the correct option).

The final part consists of the signatures and seals (if any) of the representatives:

- Subscriber.

- Heat supply organization.

- Service organization.

In general, the act of pressure testing the heating system is a convenient primary document, for filling out which the heat supply organization is responsible.

chemical flushing of the boiler _______, inventory number _______,

____ year of manufacture, located in the boiler room _____________________

We, the undersigned: 1 Repairman____________________, 2. Chemical engineer _________________________, have drawn up this ACT stating that during the period from _______ to _______ in the boiler room _________ a chemical flush of the boiler ________________________________ was carried out in the following volume. 1. Installation and hydropressure testing of the flushing circuit, testing the performance of the flushing equipment on water. Duration __ hours. 2. Acid flushing of the boiler. Sulfuric acid concentration __%. The concentration of methenamine inhibitor is __%. The temperature of the washing solution is __ OS. Air stirring - every __ hours. Washing duration is __ hours. 3. Water flushing of the boiler. Filling the boiler and emptying it – __ times. Duration __ hours. 4. Alkaline-phosphate boiler flushing, acid neutralization, passivation of steel surfaces. Alkali concentration __%. Phosphate concentration __%. The temperature of the washing solution is __ OS. Air stirring - every __ hours. Duration __ hours. 5. Water flushing of the boiler. __multiple water exchange has been carried out. Duration __ hours. 6. Chemical control of washing water at the end of washing: — transparency – __; — pH – __; — sludge (visually) –__; - hardness - __.

As-built documentation

Download other construction acts.

Acts on the construction of gas and oil networks:

1 Acceptance certificate for the completed construction of a gas distribution system facility, form,

1a Certificate of acceptance of a gas distribution network facility completed by construction, example,

2 Acceptance certificate for construction and installation work of the gas pipeline, form,

3 Act of laying out the gas pipeline route, example,

4 Pipeline purge report, form,

5 Gas pipeline purge report, example

,

6 Visual and measuring inspection report (VII) of welded joints, form,

7 Act of visual and measuring control of VIC, example,

8 Certificate for scanning vertical mounting joints of the tank wall, form (VSN 311-89), example,

9 Certificate of transfer of the oil pipeline section by the customer to the work contractor for major repairs, form,

10 Acts of transfer of operation of technical devices (GRPSh, etc.), form, .

11 Acts of transfer of operation of locking devices, form,

12 Technical device testing report, form,

13 Certificate of acceptance and transfer of executive documentation of ITD, example,

14 Certificate of acceptance of laid and ballasted pipeline, example,

15 Certificate of acceptance into operation of a completed overhaul of a gas pipeline, example,

16 Certificate for backfilling, deboning of a laid pipeline, example,

17 Act on monitoring the continuity of the insulating coating of a pipeline, example,

18 Report on the results of testing products for compliance with technical specifications. documentation, example,

19 Report on the results of inspection of IKP products, example,

20 Report on the results of product inspection, complete visual inspection, example,

21 Incoming quality control act, example,

22 Act on the actual quality and ballasting capacity of products, example,

23 Report on preliminary testing of the pipeline, example,

24 Certificate of pneumatic testing of the pipeline for strength, example,

25 Pneumatic test report for a gas pipeline, example

,

26 Certificate for cleaning the cavity and calibrating the gas pipeline, example,

27 Preliminary test report for a gas pipeline valve unit, example,

28 VIC certificate of welds, example

,

29 Report on the results of incoming inspection of materials and equipment - Bobyshka, example

30 Certificate of inspection of the technical condition of the PP MNPP, form,

Acts on the construction of a water supply and sewerage network:

1 Act on conducting a hydraulic test of a pressure pipeline for strength and tightness, form,

2 Report on conducting pneumatic testing of the pressure pipeline for strength and tightness, form,

3 Certificate of washing and disinfection of the household pipeline. drinking water supply, form,

4 Act on the flushing and disinfection of pipelines of KhGSV, form,

5 Certificate of flushing (blow-down) of pipelines, form,

6 Pipeline flushing report, example

,

7 Washing act, example

,

8 Certificate of hydrostatic or manometric leak testing of pipelines, form,

9 Hydrostatic or manometric leak test report, example

,

9a Act on conducting hydrostatic and pressure testing for strength and tightness, example,

10 Test report for the internal sewerage system and drains for spillage, form,

11 Test report for the internal sewerage and drainage system, example

,

11a Act on testing sewerage and drainage systems, example,

12 Test report for internal fire water supply for water loss, form,

13 Certificate of individual testing of equipment (pumps, water heaters, etc.), form,

14 Certificate of individual testing of equipment (pumping station), example

,

15 Certificate of acceptance of the system and releases of internal sewerage, example,

16 Act on conducting a hydraulic test of a pressure pipeline for strength and tightness, form,

17 Certificate of acceptance hydraulic testing of the pressure pipeline for strength and tightness, form,

17a Certificate of acceptance hydraulic testing of a pressure pipeline for strength and tightness, example,

18 Certificate of acceptance hydraulic testing of a free-flow pipeline for tightness, example,

19 SK Act on conducting an acceptance hydraulic test of a gravity pipeline for tightness, example 2,

20 NVK Act on conducting an acceptance hydraulic test of a sewer well for tightness, example,

21 Certificate of completion of work on installation of pumping station and pumping unit, example

,

22 Certificate of work performed on installation of insulation of storm sewer pipelines, example

,

23 Inspection report for storm sewer structures, form

24 Act on the readiness of on-site and (or) in-house networks and equipment, form,

25 Act on connection (technological connection) to the central water supply system, form,

26 Act on delimitation of balance sheet ownership, form,

Acts on the construction of a heat supply network:

1 Certificate of acceptance into operation of the heating network, form,

2 Certificate of acceptance for operation of the heating pipeline, form,

3 Certificate for flushing the heating network, form,

3a Certificate of flushing (blowing) of heating system pipelines, example,

4 Certificate of visual and measuring inspection of heating network pipes, form,

5 Hydraulic test report of the heat consumption system, form,

6 Report on hydraulic testing of the heating network pipeline during technical examination, form,

7 Certificate for inspection of the heating pipeline when opening the gasket, form,

8 Act on the layout of the heating network route, form,

9 Certificate of readiness of the gas boiler house for operation, form,

10 Certificate of readiness of the coal boiler house for operation, form,

11 Certificate of readiness of heating systems and heating networks of the subscriber, form,

12 Certificate of readiness of the heating point for operation in winter conditions, form,

13 Act on conducting a trial fire in houses, form,

14 Report on testing the water heating network for the maximum temperature of the coolant, form,

15 Certificate of stretching of compensators, form,

16 Act on stretching compensators, form,

17 Certificate of thermal testing of a central heating system for effect, example,

Acts on electrical installation work:

1 Incoming inspection report (on the results of checking materials, equipment, etc.), example.

2 Certificate of readiness of the construction part for electrical installation work, form,

3 Certificate of readiness of the construction part of the premises for electrical installation work, example,

4 Certificate of inspection of the lighting network for the functioning and correct installation of installed machines, form,

5 Certificate of checking the lighting network for operation and correct installation of installed machines, example,

6 Certificate of checking the lighting network for correct ignition of internal lighting, example,

7 Certificate of technical readiness for electrical installation work, form,

8 Certificate of technical readiness for electrical installation work, example 1,

9 Certificate of technical readiness for electrical installation work, example 2

+

,

10 Certificate of technical readiness for electrical installation work, example 3,

11 Certificate of technical readiness for electrical installation work, example 4,

12 Certificate of technical readiness for electrical installation work, example 5

+

,

13 Certificate of approval of the electrical installation for operation, form,

14 Certificate of acceptance of a trench for cable installation, example

,

15 Certificate for electrical installation work during the construction of electrochemical protection devices (VSN012-88), form

16 Certificate of acceptance of electrical equipment for installation (VSN012-88), form

17 Certificate of acceptance of the transfer of electrical equipment for installation, example

+

,

18 Act of laying out underground grounding axes from a strip, example

+

,

19 Certificate of checking the reliability of fastening lamps, example,

20 Act of acceptance of the transfer of executive documentation, example,

21 Certificate of delivery of equipment, example,

22 Certificate of delivery of apartment meters, example,

23 Act for temporary connection of power to an existing transformer substation, RTP, example,

24 Visual inspection report of electrical equipment, example

+

,

25 Report on checking the insulation resistance of electrical circuits of power electrical equipment, example

+

,

26 Certificate of checking the resistance of grounding circuits, example

,

27 Act on the technical condition of the electrical equipment of the facility, example,

28 Certificate of acceptance of construction and installation work for tread protection, form,

29 Certificate of acceptance for installation of a power transformer, form,

30 Act of laying out a trench for laying a power cable, example

,

31 Certificate of acceptance of trenches, channels, tunnels, blocks for installation (laying) of cables, example

,

32 Certificate of external inspection of drum and cable, example

,

33 Acceptance certificate for laying cables in a trench before backfilling, example

,

34 Certificate of technical supervision of cable laying, example

,

35 Report on identified equipment defects, example

,

36 Act on laying a 0.4 kV cable line, example,

37 Start-up act in the 0.4 kV switchboard, example,

38 Certificate of inspection of cable ducts in trenches and channels before closing, example,

Painting certificates:

1 Certificate of inspection and quality control of the preparation of metal structures for anti-corrosion protection work, form 1, example,

2 Certificate of inspection and quality control of the preparation of metal structures for anti-corrosion protection work, form 2, example,

3 Certificate of acceptance of anti-corrosion preparation of automatic transmission of metal structures, form 3, example,

You may be interested in: “Does the lack of executive documentation exempt you from payment for work performed?”

Acts on ventilation and air conditioning:

1 Certificate of commissioning of ventilation and air conditioning systems, example,

2 Certificate of completion of commissioning of ventilation systems, example,

3 Certificate of individual testing of ventilation system equipment, example,

4 Certificate of acceptance and commissioning of ventilation systems, example,

5 Act of the working commission on acceptance of equipment after comprehensive testing, example,

6 Test report for drainage pipeline systems, example,

7 Acceptance certificate for air conditioning systems, example,

8 Certificate of hydrostatic test or manometric leak test, example,

9 Certificate of individual testing of air conditioning system equipment, example,

10 Certificate of completion of commissioning of the air conditioning system, example,

11 Act of flushing the fan coil cooling system, example,

Acts on fire alarms, emergency fire alarm systems and fire alarm systems, sprinkler systems:

1 Fire alarm inspection report, form,

2 Security and fire alarm inspection report, form,

3 Certificate of transfer of equipment, products and materials for installation (according to the form of the State Statistics Committee of the Russian Federation), form,

4 Certificate of readiness of buildings and structures for installation work, form,

5 Certificate of completion of installation work, form,

6 Certificate of completion of installation work of the alarm system, example,

7 Certificate of measurement of insulation resistance of electrical wiring, form,

8 Certificate of completion of commissioning work, form,

9 Certificate of completion of commissioning and commissioning works of the APS and SOUE systems, example,

10 Thermal test report of the heating system for effect, example,

11 Certificate of inspection of instruments and automation equipment, form,

12 Certificate of acceptance into operation of automation equipment, form,

13 Certificate of acceptance of technical means of emergency fire alarm system and SOUE into operation (Certificate of acceptance of alarm systems), example,

14 Certificate of technical readiness of the fire alarm system, example,

15 Report of hydrostatic or manometric leak test - fire sprinkler system), example,

16 Certificate of acceptance of APT technical equipment into operation - automatic fire alarm system APS, example,

17 Act of flushing the fire sprinkler system, example,

18 Certificate of acceptance of technical signaling equipment into operation, form,

Acts on the construction of a communication network, SCS, ACS:

1 Certificate of individual testing of SCS equipment, example,

2 Certificate of acceptance of SCS technical equipment into operation, example,

3 Certificate of technical readiness of SCS systems, example,

4 Certificate of cable tightness at the installed reinforcement section (form 18 MVLKS), form,

5 Certificate of individual testing of ACS equipment, example,

6 Acceptance certificate for ACS systems, example,

Elevator installation certificates:

1 Certificate of complete technical inspection of the elevator (from an accredited testing laboratory), form,

2 Certificate of acceptance of the elevator into operation (PUBEL form), form,

3 Certificate of readiness of the elevator for commissioning, form,

4 Certificate of transfer of the elevator for inspection, form,

5 Certificate of inspection of metal structures, welded joints, elevator components using non-destructive testing methods, form,

6 Inspection report for an elevator that has completed its standard service life, form,

7 Inspection report of the construction part of the elevator installation for installation, form,

Acts on road works:

1 Certificate of sampling of materials for road markings, form,

2 Certificate of laboratory testing of material for road markings, form,

3 Act of operational quality control of road marking devices, form,

Acts on the construction of a base station:

1 Acceptance certificate for completed work on constructing a container fencing, example,

2 Acceptance certificate for installation and grounding of metal structures of the feeder route, example,

3 Certificate of acceptance of work on laying, cutting, grounding the HF feeder, installation and sealing of HF connectors, example,

4 Certificate of acceptance of work on the power supply system, example,

5 Acceptance certificate for completed work on the climate system, example,

6 Certificate of technical acceptance of base station technological equipment, example,

Acts on roofing works:

1 Roof acceptance certificate, form,

2 Certificate of acceptance of roof transfer, example,

3 Certificate of measurement/measurement of the roof, example,

4 Roof inspection report, example,

Acts applied on the Russian Railways:

1 Cable box installation certificate, form,

2 Damage report at a traction substation, form,

3 Report on damage to the contact network, form,

4 Report on damage to power supply devices of signaling systems and other non-traction consumers, form,

5 Act on violation of the normal operation of special self-propelled rolling stock of the JSPS, form,

Acts on general construction works:

1 Certificate of sealing of entry and exit points of utility lines, form,

2 Certificate for sealing technological holes, form,

3 Report on conducting a hydraulic test of a free-flow pipeline for leaks, form,

4 Act on laying out the axes of a building on the ground, form,

5 Act of laying out the axes of a capital construction project on the ground, form,

6 Act of laying out the axes of a capital construction project on the ground, example 1,

7 Act of laying out the axes of a capital construction project on the ground, example 2

+

,

8 Act of laying out the axes of a building, example

+

,

9 Report on the results of testing the gravel-sand mixture technical. documentation, example

,

10 Report on the results of checking the fittings for compliance with technical specifications. documentation, example

,

11 Test report for fittings for glass pipelines, form,

12 Certificate for degreasing fittings, connectors and pipes, form,

13 Report on the results of testing bitumen-polymer mastic for compliance with technical specifications. documentation, example

,

14 Cable duct inspection report, example,

15 Certificate of inspection of cable ducts in trenches before closing

,

16 Certificate of inspection of cable ducts in trenches and channels before closing,

17 Certificate of inspection of pipe piles before immersion, example,

18 Dynamic load test report for piles, form,

19 Pile field acceptance certificate, example,

20 Interim acceptance certificate for critical structures, example

,

21 Test report for structures, buildings and structures, form,

22 Act of cleaning the cavity of the whips when performing welding and installation work, example,

23 Act on securing the route, site (VSN012-88), form

24 Certificate for welding of the warranty joint, platform (VSN012-88), form

25 Certificate for welding a technological hole (VSN012-88), form

26 Certificate of acceptance of the crane unit, unit for receiving and starting up cleaning devices for adjustment and backfilling (VSN012-88), form

27 Act on bank protection and bottom protection works (VSN012-88), form

28 Certificate for the execution of earthworks (at the facilities of JSC Russian Railways), form,

29 Act on the production of control samples of concrete, form,

30 Act on the production of control samples of building masonry mixture, example,

31 Test report for fasteners, example,

32 Certificate for installation and testing of a drilling machine, example,

33 Corrosion inspection report of an underground structure, form,

34 Certificate of readiness for concreting in sliding formwork, form,

35 Act on verification of the implementation of measures to ensure uninterrupted high-quality construction of objects in the autumn-winter period, form,

36 Inspection report of a building located near the designed pile foundations, form,

37 Facility inspection report for major repairs, form,

38 Premises inspection report, form,

39 Certificate of inspection of dead-end stops, form,

40 Certificate of inspection of dead-end stops of load-lifting cranes, form,

41 Act of general autumn inspection of the building (on readiness for winter), form,

42 General spring inspection report of buildings, form,

43 Certificate of determination of the strength of concrete of reinforced concrete structures, form,

44 Act of inspection of green spaces, example,

Other acceptance and transfer certificates:

1 Acceptance certificate for transfer of equipment for installation, form,

2 Certificate of acceptance of transfer of equipment, example,

3 Act of acceptance of the transfer of an object for work, example

4 Certificate of acceptance into operation, example

5 Certificate of acceptance of trenches for cable installation, example

,

6 Act of the working commission on acceptance of work performed at the site, example,

7 Act of the state acceptance commission on acceptance of the object, form,

8 Certificate of acceptance and transfer of executive documentation of ITD, example,

9 Equipment acceptance certificate after checking construction readiness, example

,

10 Act of transfer of temporary operational and sanitary maintenance of an object, example,

11 Certificate of acceptance of laid and ballasted pipeline (VSN012-88), form

12 Interim acceptance certificate for connection areas of compressor stations, oil pumping stations, receiving and starting units for treatment devices, gas flow measurement and reduction units (VSN012-88), form

13 Interim acceptance certificate for the passage of a pipeline through a road or railway (VSN012-88), form

14 Interim acceptance certificate for the pipeline crossing a water barrier (VSN012-88), form

15 Certificate of acceptance of the finished trench for laying (VSN012-88), form

16 Certificate of acceptance of completed work, form,

17 Acceptance certificate for completed work, form,

18 Certificate of acceptance of trenches, channels, tunnels and blocks for installation of cables, form 14A (word), example,

19 Lightning protection acceptance certificate, form,

20 Lightning protection acceptance certificate, form IGASN No. 44/99 (word), example,

21 Act of the commission on acceptance of work performed to preserve a cultural heritage site, form,

22 Certificate of acceptance for operation of electrical protective installations, form,

23 Certificate of acceptance of work on current repairs of linear structures, form,

24 Certificate of acceptance into operation by the working commission of a completed construction of a separate building, built-in or attached premises included in the facility, form,

25 Certificate of acceptance of a completed construction facility, form,

26 Act of the working commission on the acceptance into operation of a completed building, structure, premises, form,

27 Report of the working commission on acceptance of equipment after individual testing, form,

28 Equipment acceptance certificate, form,

29 Act of the working commission on acceptance of equipment after comprehensive testing, form,

30 Certificate of acceptance into operation by the working commission of elements of a residential building completed with major repairs, form,

31 Act on acceptance into operation by the working commission of parts of a residential building completed with major repairs, form,

32 Certificate of acceptance of completed works on improvement of public territory, example,

Other inspection reports:

1 Certificate of verification of technological properties of electrodes, form, download rar.

2 Certificate of quality control of the applied protective coating, example,

3 Certificate for checking the laying of the pipeline at the crossing of a water barrier (VSN012-88), form

4 Report on the results of testing products for compliance with technical documentation (VSN012-88), form

5 Report on the results of product inspection, example of filling

6 Instrumental verification report (word), example,

7 Emergency oil pipeline inspection report, example,

8 Certificate of checking the quality of foundation soils in an open pit, example,

9 Certificate of geodetic inspection of the bridge in plan, form,

10 Report of a comprehensive inspection of a highway section, form,

11 Certificate of control check of the carrying capacity of the ice crossing, form,

12 Certificate of control check of topographic and geodetic works, form,

13 Certificate of inspection by external inspection and measurement of the dimensions of seams of welded joints, form,

14 Certificate for checking the welding technological properties of electrodes, form,

Other incoming control acts:

1 Incoming quality control report, form,

2 Certificate of incoming quality control, example,

3 Incoming inspection report example - pierced mineral mats M100,

4 Certificate of incoming inspection of a batch of pipes made of polymer materials, form,

Other certificates of compliance:

1 Certificate of compliance of the parameters of the constructed (reconstructed, repaired) capital construction facility with the design documentation, including the requirements for equipping the capital construction facility with metering devices for the energy resources used, form,

2 Certificate of compliance of the constructed (reconstructed) capital construction facility with the requirements of technical regulations, form,

3 Certificate of compliance of the constructed or reconstructed capital construction facility with the requirements of technical specifications, form,

Other test certificates:

1 Report of hydraulic, pneumatic, combined strength test, leak test (VSN012-88), form

2 Hydrostatic test report for boilers, form,

3 Hydrostatic leak test report, form,

4 Certificate for preliminary testing of the pipeline and sections of categories B and 1 (VSN012-88), form

5 Individual equipment testing report, form,

6 Certificate of testing of pipe lines for strength and density, form,

General acts:

1 Certificate of completion of installation and commissioning work, example

2 Act of organization and implementation of emergency response and investigation of the causes of the accident, form,

3 Certificate for backfilling, deboning of a laid pipeline, example,

4 Act on monitoring the continuity of the insulating coating of a pipeline, example,

5 VIC certificate of welds, example,

6 Act on monitoring the continuity of the insulating coating of a buried pipeline (VSN012-88), form

7 Certificate of assessment of the quality of insulation of underground pipeline sections completed by construction, using the cathodic polarization method (VSN012-88), form

8 Certificate for cleaning the pipeline cavity (VSN012-88), form

9 Certificate for laying a protective casing when crossing a pipeline through a road or railway (VSN012-88), form

10 Certificate for geodetic preparation of the route, site (VSN012-88), form

11 Certificate for backfilling of the laid pipeline (VSN012-88), form

12 Certificate of approval for construction and installation work on the territory of an enterprise, residential area, form

13 Report on industrial accident, form

14 Report on an accident at work, form,

15 Act on the posting of material assets, example,

16 Act of downtime (on suspension of work), example,

17 Certificate of visual and measuring control of welded joints, example,

18 Pipeline inspection and rejection report, example

,

19 Act on suspension of construction, form KS-17, form,

20 Certificate of quality of soil strengthening, example,

21 Act of anchoring the load-bearing, bracing, traction rope in the coupling, form,

22 Rope installation certificate, form,

23 Certificate of commissioning of a completed construction of a utility infrastructure facility, form,

24 Act of weighing counterweights, form,

25 Act of visual inspection of an object damaged as a result of an emergency, form,

26 Act of selection of land plot, form,

27 Certificate of defects during construction and installation work, construction and installation work, form,

28 Certificate of release from major repairs, form,

29 Certificate for the release of the car from repair, form,

30 Certificate of guaranteed welded connection, form,

31 Act on substandard and incomplete products, form,

32 Certificate of shortage (surplus) detected upon acceptance of products at the recipient’s warehouse, form,

33 Certificate for flushing (purging) of the pipeline, form,

34 Certificate of delivery for major repairs, form,

35 Act on write-off of low-value and wear-and-tear items, form,

36 Certificate of external inspection of equipment upon arrival at the warehouse, form,

37 Certificate of adjustment of instruments and automation equipment, form,

38 Certificate of completion of work on installation of automation systems, form,

39 Act on assigning a car to the driver (drivers), form,

40 Act on the implementation of a quality management system for the operation of construction machines, form,

41 Report on identified defects in technical signaling equipment, form,

42 Report on identified equipment defects, form,

43 Act of the working commission on the readiness of the completed construction of the building, form,

44 Act on the replacement of engineering equipment that has not served its service life, form,

45 Certificate of recertification of flaw detectorist, form,

46 Report on the results of the analysis of the state of production, form,

47 Certificate of conformity of materials used, form,

48 Certificate of compliance of completed off-site and on-site preparatory work with labor safety requirements and readiness of the facility for the start of construction, form,

49 Certificate of completion of off-site and on-site preparatory work and readiness of the facility, form,

50 Report on the cost of repair work performed, form,

You can order the preparation of ID, acts, journals and other things in the section: “Order ID”

Return to the section: “Acts, protocol diagrams, etc.”

See the composition of the executive in the section: “Composition of the executive”

Download acts, protocols and more in the section: “Acts and other”

Download useful books, GOSTs, SNIPs in the section: “GOSTs and books“

Third point

The entire third paragraph is devoted to operational documentation. Operation involves listing the employees who will use the equipment and their knowledge (with reference to testing knowledge of PTE and PTB).

Important points in this regard are the qualifications and the total number of persons approved for operation.

Also, the third paragraph describes operational and technical documentation, if available. The journals that are desirable for keeping are listed separately, with a note about their presence or absence and an assessment of their maintenance.

At the end, as a conclusion, it is concluded whether the existing equipment meets the declared specification or not. These data are recorded separately for main and additional equipment.

PREPARATION WORK

2.1. The manufacture of pipeline components and parts from steel pipes should be carried out in accordance with technical specifications and standards. Manufacturing tolerances should not exceed the values specified in table. 1.

Document year: 2019

Type of document: Act

Download formats: DOC, PDF

Test reports are drawn up in the form of document forms in which the results of testing the performance of mechanisms and equipment are recorded.

In today's article, we will consider in detail the testing of pipeline systems, sewerage systems, stairs and stepladders, roof fencing and fire tests.

Examples of drafting acts can be downloaded for free at the end of the article.