The advantages of heated floors (abbreviated as TP) over conventional radiators are well known. Therefore, many owners of apartments and private houses want to install underfloor heating circuits and supply coolant from the existing radiator system.

A number of difficulties arise here - you need to install and correctly connect the water heated floor from the heating system so that the water temperature in the loops remains within 55-60 °C. But the first task is to make sure that it is technically possible to lay the TP “pie” and connect to existing highways at the lowest cost.

Features of two-pipe circuit wiring

The two-pipe system comes in several varieties.

They have a different connection diagram for heating radiators in a private house, and a different vector of coolant movement. In small private houses, the following types of two-pipe heating systems are used:

- dead end;

- passing;

- collector (radial).

Brief characteristics of two-pipe systems

Collector is the most expensive heating distribution scheme for a private house due to the need to lay pipes to each battery, and their installation is hidden.

Open "gravity" two-pipe system

For successful operation of the “gravity” system, a slope of 3-5 mm/m is ensured during installation. Due to gravity, any type of heating system can operate if the necessary conditions are created - the slope of the coolant supply lines for natural circulation. It must be taken into account that the “gravity” system can only work with an open expansion tank.

Closed two-pipe system

And in order to install the heating of a two-story private house with your own hands, the wiring diagrams must contain the required number of liquid supply branches. One branch of the collector should power the batteries on the upper floor, the second branch should power the batteries on the lower floor. The water that has given up its heat returns to the boiler through the “return”. A closed system must have a circulation pump to create pressure.

Radiator connection

Powering a heated floor from a radiator operating both from central heating and from an autonomous boiler (how to choose, power calculation, boiler connection diagrams) is the easiest way. The connection can be made by directly connecting the ends of the circuit to the battery supply and return pipes; we suggest that you familiarize yourself with the various connection diagrams.

How to connect a section of a heated floor to a radiator branch.

Proper operation of the device, with this method of connecting a heated floor, can be achieved:

- if the common boiler has the automatic ability to maintain the temperature in the system;

- if the size of the heated room is maximum 10 m2;

- with a powerful pump to ensure fluid circulation;

- if each radiator is equipped with a separate collector.

This connection of a heated floor in a private house is not considered the best option, since:

- The movement of water is carried out along an easier path, that is, along the main line and batteries. But through the loops of the heated floor, the rate of fluid circulation will be much lower, this will lead to a decrease in temperature.

- If you increase the temperature in the system, the floor surface will overheat.

An alternative solution in this situation is to install a thermostatic valve.

Heating system elements

In country houses it is better to use water heating. This method is considered traditional. Heat is supplied to the house using a coolant, which can be heated by various energy carriers.

Such a system includes the following components:

- heating system devices;

- heat source;

- pipeline network.

If you do not have the time and opportunity to handle heating yourself, then contact the GWDE Engineering Company. Specialists in the installation of engineering systems will perform their work efficiently and will provide a guarantee for up to 7 years.

Full work is impossible without such equipment as:

- expansion tank;

- buffer capacity;

- circulation pump;

- distribution manifold;

- automation devices;

- hydraulic separator;

- heating boiler.

It is important that for a water heating system a mandatory piece of equipment is an expansion tank. Everything else is installed if required.

Heat distribution: features

Since the area of the rooms in the house varies, the circuits also have different lengths, so it is necessary to ensure the same hydraulic pressure in all areas of the system. It should be taken into account that the pump is a constant value.

Distribution of heat from different sources

Supplying the same volume of water to circuits of each length leads to the fact that the coolant in the longer one cools down faster and at the outlet its temperature will differ from the coolant with a shorter profile. As a result, the floor surface will warm up unevenly - somewhere there will be overheating, and somewhere, on the contrary, the coating will be cold.

The advantage of using heated floors

Due to the high hydraulic resistance, the coolant may not flow into a long circuit at all, since it will move into shorter circuits with less resistance. To prevent this from happening, the system is equipped with a distribution manifold, which allows maintaining a balance of supply and uniform heating of the coolant in each loop.

Heating with electricity

It's no secret that not all communication and engineering networks reach suburban villages. But one network is present always and everywhere. This is a power line. True, in most cases one can argue about the quality of supply, but electricity is available everywhere.

Therefore, heating the house using electric current is the best option. In this case, you can use heating devices such as:

- Oil radiators

- Electric convectors

- Heat fans

- Infrared emitters

- Electric boilers for water heating

The first four options are the simplest. All you need to connect them is an outlet. Such devices can be installed in any room and anywhere. Simplicity, convenience and safety are what characterize them. And the only negative is the receipts that you will receive for the electricity consumed. The numbers in them will be rather large.

But with a heating boiler that runs on electricity, there are more problems:

- Firstly, you will have to install the entire heating system, which includes pipes, heating radiators, shut-off valves and all kinds of devices for monitoring and regulating the temperature.

- Secondly, this is the boiler itself. It's not cheap, plus its wiring and connection. So you can’t do without financial expenses.

There is one more point that is worth paying special attention to. The supply of electricity largely depends on the quality of the laid lines and the power of the transformer. And power outages in most cases are associated with these two factors

And power outages in most cases are associated with these two factors.

The first is fraught with broken lines in winter. And if there is not enough transformer power for all consumers, the boiler will operate inefficiently. What can you do? Option one is to install a combination boiler that runs, for example, on both electricity and wood. You can choose another combination of different types of fuel.

Preparing to install a steam system

To properly make steam heating, you need to start by preparing the project. Its development is a complex task, which is best solved by specialists. There are many things that need to be taken into account in the finished project.

First of all, the thermal loads on each of the premises and on the building as a whole are calculated. The steam source is selected, and the mechanism and degree of automation of the system are determined.

In addition, the steam consumption must be determined, based on this, the equipment and the scheme for its use are selected. Once the project is ready, you can begin drawing up an installation plan.

To complete it, you will need a building plan on which the equipment locations are marked. They usually start with the boiler. Its location is determined. If the system has natural circulation, the boiler should be below the level of the batteries.

In this case, it is usually lowered into the basement or basement floor, so the condensation can drain to the device on its own. Then the layout of the entire heating system is applied to the house plan. Moreover, all necessary equipment is noted.

Experts advise performing this operation directly “on the spot”, being in the room where the equipment will be located. This is the only way to notice and take into account all the ledges and obstacles that you have to go around.

Before starting installation, be sure to make a plan diagram of the future system, which marks all the equipment and mounting locations for radiators

All transitions and angles must be marked on the diagram. After it is completed, you can proceed to calculating the amount of material required for its implementation. Once again, it is worth paying attention to the importance of choosing the right equipment.

The steam system is potentially hazardous, so you should not skimp on materials and equipment. Everything must be of high quality and certified, otherwise serious problems cannot be avoided.

How to connect to the boiler

An economical option, if you have any own boiler (gas, steam, running on liquid or solid fuel) in a private house, is to use a circuit for connecting a water heated floor directly to it. This is very convenient, since the floor will work regardless of the heating in the room, even in summer if necessary.

All necessary fittings are connected to the boiler. A circulation pump is connected; there are modules where it is already mounted inside the container. From the tank, water goes to the collector unit, where it is distributed along the contours of the floor. Having passed through the loops, the liquid returns to the thermogenerator through the return pipe.

The advantage of this method is the ability to adjust the boiler to the heating level of the coolant required for heated floors.

The main features that you need to pay attention to when installing such a structure:

- When using a gas device, it is recommended to connect a condensing boiler - this will achieve the highest efficiency of the system and extend the life of the heat exchanger.

- When using a solid fuel boiler, a buffer tank will be required. Without it, it is difficult to adjust the heating level of such devices.

But for this, a heat exchanger must be installed above the firebox, to which the floor pipes are connected. It will also be necessary to install a pump to circulate the liquid, and a mixing unit to dilute the water to the desired heating level.

What is a combined (combined) heating system

In general, heating is called combined in two cases. The first is when two home heating systems are combined - radiator and underfloor heating. The second is the use of two boilers that are connected in parallel. And they can work in turns or simultaneously. Depends on the connection method.

To ensure that it is always warm, two boilers are installed

But two boilers in one heating system are more often called redundant or guaranteed heating. In most cases, a combined system refers to the use of heated floors together with radiators. Moreover, the heated floor is water, which is connected to one system with radiators. This introduces its own adjustments and features into the scheme. So it is precisely this system that will be discussed further.

What is combined heating?

Today there are two types of water heating - the familiar radiator and water heated floor. Moreover, most often, both systems are connected to the same heat source. The heat source usually means heating boilers. So a combined heating system is usually installed in private homes. Here you can do everything (or almost everything) you want.

Typically, combined heating means radiators and heated floors in one system.

In apartments with centralized heating, it is almost impossible to install water heated floors. This system has too much hydraulic resistance and will simply stop circulation in the riser (if connected to it). No warmth for you or your neighbors. And if it doesn’t stop, then the outlet from the heated floor will be absolutely cold water, which will definitely not suit your neighbors.

But there are exceptions - these are new houses that have risers for connecting batteries (high-temperature riser) and heated floors (low-temperature). In this case, each system is connected to its own branch. If you really want to, there is a way to connect a water floor in the apartment - install a boiler to ensure the operation of this system. The solution is expensive, but at least it can be implemented somehow.

What does combined heating provide?

Why make a combined heating system? After all, even radiator heating is not cheap to make, and if you install two different systems, the costs will almost double. There are reasons. Why do they make heated floors? Because it feels more comfortable to be in rooms with heated floors. Why then radiators? Firstly, they heat up and cool down faster. Warm floor - pipes embedded in concrete. While the concrete warms up, it will be cold. It is for this period that radiators are required. They will quickly heat the air.

In a cottage they often try to install heated floors on the ground floor and place radiators higher

The second reason why they prefer to make a combined heating system is that there are not many coated ones that work effectively when laid on a heated floor. Only tiles, stone or porcelain stoneware are ideal. But we don’t use this type of coating in living rooms, and others (although there are compatible types) do not transfer heat very effectively. So, to be warm and comfortable, you need both radiators and pipes in the floor.

Which heating is better: warm water floor or radiators

Which is better: warm water floor or radiators?

In most cases, the choice of heating system is between water heated floors or radiators. In order to decide, it is enough to compare both options according to several key characteristics, which will allow you to evaluate all the possibilities, pros and cons of the technologies.

Economical

This is one of the most important issues, which in the future will determine the amount of annual/monthly heating costs. If we compare both options for the distribution of hot air flows in the room, it turns out that the greatest heat from the battery remains next to it. Heating from the heated floor occurs throughout the entire area of the room.

Batteries are always installed under a window to avoid intense condensation. But this same decision causes intense heat loss to occur in the same zone. In addition, if the walls are insufficiently insulated due to the high temperature difference, the situation is aggravated.

Also, the efficiency of using a heated floor is increased due to the fact that during its operation the concrete slab is heated, which becomes a powerful source of heat, and the radiator can only act on the nearby air. As a result, savings when using heated floors average up to 30%.

Which is cheaper: water heated floors or radiators?

In this case, much depends on the area of the premises and the installed equipment. But due to the large amount of work involved in installing concrete screeds, hidden laying of pipelines, and the need to attract specialized specialists to perform such tasks, the cost of equipment and its installation when using a radiator system will be lower.

Inertia

The rate at which the room heats up when the heating is turned on is an important issue that largely determines the degree of comfort in using the system. In this case, deciding whether a warm water floor or radiators is better will not be easy. The peculiarity of the first option is that, for objective reasons, it will take longer to heat up a concrete slab than a radiator exposed to air. But at the same time, cooling when the heating is turned off using a heated floor will occur much more slowly. In this regard, the decision about whether this is a plus or a minus of water heated floors can only be made by the user himself.

Maintainability

The main problem in this case becomes the issue of accessibility of installed equipment and pipelines. For water heated floors, this is a minus, but at the same time, provided that the equipment is properly selected and the system is correctly designed and installed, the service life of hidden heating without the need for repairs will be equal to the service life of the pipes. That is, on average, you won’t have to open the screed for about 50 years. Equipment based on radiators is always open to access, but at the same time it requires repairs much more often.

There are many arguments in favor of each option, but the optimal solution in most cases is to use a combined system using both technologies. At the same time, all the pros and cons of warm water floors and radiators will be taken into account and used so that in the end the project will only benefit from their joint use.

Warm floor as the only CO - arguments against

1. Where there are wardrobes, sofas, beds and armchairs on a warm floor, it does not heat the air in the room, but the furniture. When calculating, it makes sense to calculate not the total area, but the area not occupied by furniture.

2. Greater inertia of the heated floor. The screed takes a long time to cool down, but also takes a long time to heat up. You won't be able to turn on the heating for an hour or two.

3. The underfloor heating system may not cope with heating rooms with an area of more than 25 square meters, especially with large windows and other translucent structures.

4. TP is categorically not suitable for heating the vestibule.

AleroFORUMHOUSE Member

The vestibule is always a risky area for COs. Not everyone may have this room in the area of main walls; of all the options for heating it, you need to choose the safest one and exclude defrosting. If the outer walls or floor are frozen, condensation will not “fall out”, but frost will happen easily. It is almost impossible to prevent the flow of warm air from the living space into a cold vestibule.

5. It may not be comfortable.

vladimirtmb43FORUMHOUSE Member

Floor surface temperature +27 - +28 degrees. It’s comfortable for my feet, but +26 in the room is hot for me. If you do less so that the air is +24, your legs are already uncomfortable and cool.

6. Due to the high inertia of heated floors, it is impossible to configure the automation based on the internal temperature - only using the external sensor.

Which pipes are suitable for combined heating

It is very convenient to install the water circuit for underfloor heating using cross-linked polyethylene pipes. Due to the flexibility of the material, products can be laid in rooms with complex configurations, and not just in a straight line. Installation of such pipes in a screed is allowed. Products are delivered to places of sale in coils, so it is not difficult to deliver them to the place of work.

As for connecting radiators, polypropylene pipes are suitable for these purposes. They are quite cheap and easy to work with. To install them, you will need to prepare a chamfer, nozzles, a socket welding machine and a shaver if the pipes are reinforced. In addition, for the installation of radiators, locking elements are also needed.

Single-pipe wiring and connection to it

When there is only one pipe in the system through which the coolant flows, it is called single-pipe or “Leningrad”. Previously, all houses were connected in this manner, but now more efficient working schemes have been developed.

Single-pipe wiring

The Leningradka is characterized by trouble-free operation and high reliability. Its main drawback is the temperature drop as the coolant moves. The first radiators are much hotter than the last ones. The temperature may not be sufficient for rooms far from the boiler. If you connect a heated floor circuit to such wiring, the temperature will drop even more, plus the hydraulic resistance will increase, which will require the installation of an additional pump.

Coil of pipes for heated floors

To more or less balance such a system, you will need to meet the following requirements.

- To prevent the temperature on the radiators from dropping, the connection must be made on the return section of the line, after all the batteries.

- For this you need to use a DN pipe

- Such a connection is allowed only to a circuit with no more than 5 radiators.

- To maintain the floor temperature at the same level, you need to include a three-way mixing valve in the system.

- This valve is designed in such a way that it constantly mixes hot water into the cooled water, keeping the temperature at the same level.

- Together with it, a pump must be included in the circuit for forced circulation. Due to it, water will move even when the valve is completely closed.

Three-way valve for mixing coolant

No matter how you cast magic, the result will always be somewhat negative if you don’t initially do everything as it should be. This system is also rarely used, since its operation cannot be called stable. A running pump creates some pressure inside the circuit to force the coolant to flow in the desired direction. When the valve opens, this pressure is transferred to the radiators, creating additional hydraulic resistance. This causes the radiators to become unbalanced and changes water flow.

When heating operates in this mode, accidents often occur. Therefore, before connecting, think about whether it might be cheaper to run the route normally from the boiler, through the mixing unit.

Installation procedure

A one-pipe system is assembled as follows:

- In the utility room, the boiler is installed on the floor or hung on the wall. Using gas equipment, the most reliable and efficient single-pipe heating system for a two-story house can be installed. The connection diagram in this case will be standard and will allow you to carry out all the work, if desired, even independently.

- Heating radiators are hung on the walls.

- At the next stage, the “supply” and “return” risers are installed on the second floor. They are located in close proximity to the boiler. At the bottom, the outline of the first floor is connected to the risers, and at the top – to the second.

- Next, the connection to the battery lines is made. A shut-off valve (on the bypass supply section) and a Mayevsky valve should be installed on each radiator.

- An expansion tank is mounted in the immediate vicinity of the boiler on the “return” pipe.

- Also, on the “return” pipe near the boiler, a circulation pump is connected to a bypass with three taps. A special filter is installed in front of it on the bypass.

At the final stage, the system is pressure tested in order to identify equipment malfunctions and leaks.

As you can see, a single-pipe heating system for a two-story house, the design of which is as simple as possible, can be a very convenient and practical equipment

However, if you want to use such a simple design, at the first stage it is important to make all the necessary calculations with maximum accuracy

When thinking about installing heating, we first determine what type of fuel will be used

But at the same time, it is extremely important to decide how independent the planned heating will be. So, a heating system without a pump will be truly autonomous, which does not require electricity to operate. To operate effectively, all you need is a heat source and properly positioned piping

To operate effectively, all you need is a heat source and properly positioned piping.

A heating circuit is a set of elements designed to heat a home by transferring heat to air. The most common type of heating is a system that uses boilers or boilers connected to a water supply as a heating source. Water passing through the heater reaches a certain temperature, and then is sent to the heating circuit.

In systems with a coolant that uses water, circulation can be organized in two ways:

Boilers are used as a heat source for heating water. Their principle of operation is based on the conversion of a specific type of energy into heat and its subsequent transfer to a coolant. Depending on the type of heating source, boiler equipment can be gas, solid fuel, electric or fuel oil.

Depending on the type of connection of circuit elements, the heating system can be single-pipe or two-pipe. If all the circuit devices are connected in series relative to each other, that is, the coolant passes through all the elements in order and returns to the boiler, then such a system is called a single-pipe system. Its significant drawback is uneven heating. This is due to the fact that each element loses some amount of heat, so the difference in boiler temperatures can be significant.

A two-pipe type system involves parallel connection of radiators to the riser. The disadvantages of such a connection include the complexity of the design and twice the material consumption compared to a single-pipe system. But the construction of a heating circuit for large multi-storey premises can only be done with such a connection.

A system with gravity circulation is sensitive to errors made during heating installation.

How to calculate the number of pipes

At the design stage, after all the calculations have been made, you can understand how many pipes in linear meters may be required. This will allow you to estimate the cost of the material.

Main stages of installation

So, with a room area of 12 m², the air temperature should correspond to + 20 degrees. The width of the edge sections along the walls with furniture should be 30 cm. If one wall has a length of 6 m, and the other two are 2 m, then the working area of the system can be calculated using the following formula: 12 – 0.3*(6+2+2) = 9 m².

Note! The laying pitch and diameter of the pipes depend on the level of heat loss. The smaller they are, the larger or smaller the pitch of the pipes.

When determining heat loss in a room, the glazing area, the characteristics of the insulation used in the enclosing structures, and the height of the room are taken into account. The resulting value varies from 20 to 300 W/m² depending on the thermal efficiency of the structures and double-glazed windows used, the thickness of the walls and the number of openings.

Warm floors are a serious cost item during renovation, so it is important to accurately calculate how much and what materials will be needed. To ease your labor costs, we have prepared special instructions telling you how to calculate a heated floor - water or electric. Online calculators included. And in the article “What is needed for a heated floor?” you will find a complete list of everything that may be needed during installation.

Advantages and disadvantages of underfloor heating from existing heating

Installing a water heated floor according to this scheme has several advantages:

- optimal and uniform heating of the entire floor surface, which is achieved by introducing additional control devices into the design;

- creating a comfortable indoor environment. All the heat is concentrated from below, and the cold air is located near the ceiling. This scheme is considered more comfortable for any person;

- for the construction of all elements, a material is used that is not susceptible to corrosion and destruction over a long period of time, subject to all installation rules;

- when installing a warm water floor, the movement of air masses in the room is reduced, which reduces the amount of dust. This has a positive effect on the body of people who suffer from allergies;

- using one source for floor and conventional heating, you can significantly save on installation and the number of additional units for their normal functioning;

The disadvantage of this design scheme is the impossibility of its use in multi-storey buildings with centralized heating. Some difficulties may also arise during the installation of all elements. But if you take into account all the recommendations, this is not so difficult.

How to fit a “pie” into a room with low thresholds

Almost all homeowners who decide to install underfloor heating in a habitable house or city apartment face this problem. The essence of the issue: the height of the thresholds of entrance or interior doors is not enough to install a full-fledged “pie” of warm water floors with screed (see drawing below).

Let us analyze the composition of a monolithic heating circuit located on an interfloor or basement floor:

- Waterproofing - bitumen coating, more often - polyethylene film.

- Insulation – extruded polystyrene foam with a minimum thickness of 30 mm or polystyrene foam 5 cm.

- Damper tape around the perimeter of the room.

- A heating pipe (usually metal-plastic or cross-linked polyethylene with a diameter of 16 x 2 mm), laid in a snail or snake pattern.

- Cement-sand screed 8.5 cm thick.

- Floor covering (sometimes a vapor barrier layer is placed underneath it). The thickness depends on the material, laminate and linoleum will take up to 1 cm, ceramic tiles with an adhesive mixture will take about 20 mm.

The traditional surface heating scheme is made without reinforcement

An important nuance. If a monolithic heated floor is installed above the ground, the thickness of the insulation increases to at least 100 mm of polystyrene foam or 60 mm of extruded foam. The density of both materials is 35 kg/m³.

In total, the total height of the “pie” with a laminate coating will be 85 + 30 + 10 = 125 mm. No normal owner envisages such high thresholds. How to solve the problem and implement underfloor heating in a similar situation:

- Dismantle the existing screed to the very foundation - the ground or floor slab. This is what multifoil looks like - a durable material with closed air chambers

- Instead of a heat-insulating polystyrene layer, use multifoil up to 1 cm thick.

- Reduce the power of the tie to 60 mm. The structure will have to be reinforced with masonry or road mesh with dimensions of 150 x 150 x 4 and 100 x 100 x 5 mm, respectively.

- Use flooring systems - “dry” heated floors installed in wooden houses without screed. The total thickness of the “pie” is 6-10 cm.

- Heat the flooring with electric carbon film instead of a water pipe system.

Reference. The only room in the apartment where the thresholds remain high is the balcony and loggia. There is no need to reinvent the wheel; usually the monolith fits freely along with thermal insulation.

Overlay surface heating system, laid using a dry method.

Some home-grown craftsmen do not lay insulation at all or reduce the thickness of the screed to 4 cm. In the first case, half of the generated heat will go into the basement, the ground or to the neighbors below; in the second, the monolith expanding from heating will soon crack.

An expert will tell you in more detail and clearly in the video how best to make a heated floor in an apartment building:

Criteria for choosing a boiler for autonomous heating of a private house

When choosing the type of boiler for heating, there are no alternatives only if gas is supplied to the house; it is the cheapest type of fuel and, in comparison with other sources (electricity is not considered), has a number of operational advantages - it does not require space for storing reserves, highlight There are fewer combustion products released into the environment and does not pollute the chimney system as intensively.

The main parameters that people pay attention to when choosing a boiler are:

- Unit power: directly related to the area of heated premises and temperature conditions, which are usually chosen based on building codes and GOSTs.

- Number of circuits: if the house does not have hot water supply, it is more practical to choose a dual-circuit model that can heat water.

- Location: usually the unit is installed downstairs in the basement on the floor; there are also hanging options for small houses.

- Material of manufacture of the unit and heat exchanger: cast iron, stainless steel, copper.

- Type of combustion chamber according to the method of supplying air to the firebox: open or closed.

- Availability of automatic control and monitoring systems, possibility of programming operating modes.

- The ability of the boiler to work with alternative fuels: relevant for liquid fuel modifications.

Rice. 14 Design of the Rinnai gas boiler

When choosing a boiler, the following tips may be useful:

- If there is no hot water supply in the house, it is rational and cheaper to choose a double-circuit boiler model than to install a separate single-circuit unit and a gas water heater, an electric boiler.

- When using electricity, the night tariff is much cheaper than the day tariff, in this case you can save on the cost of electricity. To do this, at night they warm up the entire house, with the exception of the bedrooms, and during the day they turn off the boiler for a long time or operate it in the minimum heating mode.

- For reliable operation of all boilers controlled by automation powered from the mains, you should purchase an electric generator with automatic switching on in case of power failure - this will allow the boiler equipment to continue operating in case of emergency situations on the power line.

Rice. 15 Construction of a Kolton solid fuel boiler

Tips for use

It is worth saying that a warm water floor is an inert heating system. Therefore, it is possible to feel temperature changes in the room only after several hours after adjustment.

Experts recommend during operation:

- Maintain a temperature level of the floor surface in living rooms of 25 - 30 degrees. In the corridor, bathroom and along external walls, heating up to 35 degrees is allowed.

- Add fiberglass or other filler to the solution - this will reduce the degree of shrinkage of the concrete screed. The dosage can be found on the packaging.

- Replenish the system with liquid in a timely manner and monitor the heating temperature.

- Choose pipes for underfloor heating of the same diameter as the heating system (supply and return).

- When using a two-pipe scheme, make the length of the floor loop no more than 50 meters.

For your information! Warm floors require virtually no additional maintenance.

The temperature regime of the heating circuit is often regulated manually. Although it is possible to install an automatic adjustment device, equipped with a controller with a program that controls the servo drive and pump. Such a device is capable of creating a comfortable microclimate according to specified parameters independently.

When deciding whether to connect a heated floor to a radiator with your own hands, experts recommend making a careful calculation. In addition, when choosing a scheme, you need to take into account its features, as well as all the recommendations that are outlined in this article, and then you will be able to install a properly heated floor in an apartment using a radiator.

Laying schemes for water heated floors

The uniformity of surface heating depends on the correctly selected layout scheme. “Snake” is used when the same intensity of heating of the floor covering is not needed. For example, in a living room it is not necessary to heat the space under cabinet furniture or wardrobes.

The “snail” scheme allows you to arrange pipes with coolant for uniform heating.

The combined method makes it possible to warm up the corners of the outer walls of the room.

Snake

The “snake” layout begins along the perimeter of the entire room, then the loop is bent 180 degrees and laid from wall to wall in zigzags. In this case, the surface is heated unevenly; there are areas with more and less intense heating.

The second “snake” method implies that pipes with hot and cooled water are placed side by side. As a result, uniform heating of the entire surface occurs.

The “Snake” scheme has the following features:

- The maximum bend of the loop reaches 180

- the circuit laid in this way operates from a not very powerful circulation pump

- actively used in the bathroom and toilets

- installed in rooms with a linear slope, laying from the mixing unit towards the slope

Snail

The pipes are laid along the walls, then at the farthest wall the loop turns back. It is laid in a spiral, moving towards the center of the room. The advantage of this method is the uniform heating of the entire surface, even near the outer walls, which makes it possible to reduce the boiler power while maintaining the coolant output.

Features of the “Snail” installation scheme:

- pipe bend is 31-90

- used for heating large areas, where heating occurs due to several water circuits

- do not use in rooms with a linear slope, because there is a high probability of frequent formation of air jams

Combined layout scheme

With a combined scheme, part of the room is heated with a water circuit laid in a “snail” way, and the second half is heated using a “snake” scheme. Or two living rooms in the house can be heated according to the “snail” scheme, and several turns of the “snake” can be laid in the bathroom and shower room. How to draw up a floor laying plan according to plan?

When drawing up a floor installation plan, consider the following:

- decide in which rooms the “warm floor” system will be installed and where the radiators will remain

- boiler power

- room sizes in m2

- number of heated floors

- base material (wood, concrete, polystyrene)

- arrangement of furniture in rooms

- surface inclination angle

Also, when calculating, you should pay attention to some nuances:

- the length of the circuit (total length of the coolant pipe) should not exceed 80 m, otherwise circulation will be disrupted

- the difference between the length of the contours in different rooms should be no more than 15 m

- the minimum contour area should be 15 m2

- the amount of material depends on the laying step

| Loop distance/cm | Material consumption/linear meter |

| 10 | 10 |

| 15 | 6,7 |

| 20 | 5 |

| 25 | 4 |

| 30 | 3,4 |

That. the amount of material is calculated by the formula:

linear meter of pipe (taking into account the distance between loops) x room area

The plan of a house or room is transferred to graph paper or a special program is used.

Materials

During the design process of a water heated floor system, a list of materials is drawn up. Conventionally, they can be divided into components of the system itself and raw materials for creating the screed.

The main elements in a heating system with an additional heat source in the form of a heated floor

The components of a warm water floor are:

- A thermal boiler that heats the coolant in the absence of a central heating system.

- A pump built into the boiler or separately located for pumping water into the system.

- Pipes for the movement of coolant.

- A collector is installed to distribute water through the pipes.

- The manifold is placed in a special cabinet, and you will also need to purchase splitters for distributing cold and hot, valves, fittings, and balls. It will also be necessary to provide for emergency drainage of water and removal of air from the pipes.

Pipe fastening methods

The list of materials depends on the method of installation of the system - wet (in a screed) or dry (using mats with bosses , for example).

The principle of connecting a heated floor

In the first case, a reflective layer and reinforced mesh are laid over the rough screed and the pipes are fixed. After this, a finishing screed is poured onto which the finishing floor covering will subsequently be laid.

Pipe laying can be done using mats with bosses and thermal plates that effectively reflect heat

In the second case, the pipes are fixed in a given position using special mats with bosses and thermoplates with a groove where the pipe is laid. This method is relevant for rooms with old or weak floors.

How to choose pipe length

One circuit (loop) can have a certain maximum length depending on the diameter of the pipe used. With a pipe diameter of 16 mm, the maximum circuit length is from 70 to 90 m; with a diameter of 17 mm, the circuit length varies from 90 to 100 m; if the pipe diameter is 20 mm, then one circuit can have a length of up to 120 m.

Calculation of the number of pipes taking into account the main criteria

The dependence of the loop length on the diameter is due to the fact that pipes of different diameters have different hydraulic resistance and thermal load. Less hydraulic resistance is observed in pipes with a larger diameter.

Calculation depending on the laying step

Note! In a small room, it is enough to mount one circuit that does not exceed the maximum permissible length values. But if the room is large, then it is better to install two circuits rather than exceed the recommended optimal pipe length.

It is also worth considering that in fact, when installing the system, it is necessary to use pipes of the diameter for which the calculation was made in the project. You can make calculations for pipes of different diameters and choose the appropriate option at this stage, and not later, choosing the appropriate material experimentally.

Calculation of contour lengths for various rooms

When laying several contours, it is necessary that their lengths coincide as much as possible. The length of the circuit is the length of the entire pipe, that is, it starts from the collector. It is clear that during the work it is not always possible to achieve the same length of the contours, but it is necessary to strive to ensure that the difference between the lengths does not exceed 10 m.

Recommendations from experts

The method of laying contours of the same length is influenced by the area of the room. Where it is smaller, when laying pipes between turns, a smaller step is provided. Alternatively, to heat a small room with minimal heat loss (hallway, bathroom), you can use the return pipe of an adjacent loop.

How to choose a pipe laying step

The distance between adjacent turns of pipes (pitch) is 15-30 cm. In this range, the values are multiples of 5, i.e. 15, 20, 25,30. For large rooms, such as gyms, the pitch can be 30 - 45 cm. Near a large window or external wall, the laying pitch is 10 cm. These areas are called edge zones.

Laying pipes in the edge zone (near the window)

The choice of pipe laying step is influenced by various factors: thermal load, purpose of the room, contour length, finished floor material and other nuances. Due to this:

- For edge zones, the optimal number of rows is 6, laying step: 10 -15 cm.

- For central zones: 20 – 30 cm.

- For bathrooms, the step is 10 - 15 cm, but you should be prepared for the fact that due to the need to bypass plumbing equipment, the step may not be the same.

- If the finishing coating has high thermal conductivity (tile or marble tiles, porcelain stoneware), then the distance between the turns is 20 cm.

Calculations of basic parameters for contours of different lengths

Note! In practice, it is not always possible to adhere to these recommendations. According to experienced craftsmen, the most optimal option is a step in the edge zone - 10 cm, in the center - 15 cm. These are the values at which the system will work.

How to choose pipe diameter

For residential premises, the area of which starts from 50 m², the best option would be pipes with a diameter of 16 mm. The height of the tie from the top point of the tube is 5 cm.

Pipe diameter characteristics

It is this diameter that makes it possible to comply with the conditions for laying pipes with a pitch of 15 - 20 cm. This applies even to houses with good thermal insulation, where the pipe laying pitch should not exceed 15 cm. For private houses, the specified parameters are optimal in terms of ease of installation, cost of materials and volume of coolant.

Performance properties of pipes for heated floors

Pipes with a diameter of 18 mm, due to their larger volume, lead to unnecessary costs, including related materials (fittings, etc.).

The advantages of pipes specially designed for underfloor heating are obvious

Accordingly, pipes with a diameter of 20 mm will require even more energy to heat the coolant. In addition, laying with a snake in increments of 15 cm is not realistic, due to the impossibility of bending a pipe of such diameter to the required radius. As a result, the laying step will be larger, there will be less heat in the room, and this with significantly increased coolant costs. Pipes of this diameter are used in public premises with a thick screed.

Properties affecting installation quality

Pipe material

Different pipe materials directly affect the correct operation of the system.

Table 1. Types of material

| Type of material | Positive traits | Flaws |

Copper | 1. The material conducts heat well. 2. Copper is highly resistant to corrosion. 3. The material has a long service life 4. Copper has a unique plasticity that allows pipes to be bent along a fairly small radius 5. The walls are characterized by high mechanical strength and high resistance to temperature changes. 6. An external polymer coating protects copper from negative external influences. | 1. Laying copper pipes requires skill in working with such material. 2. The need to use special equipment. 3. High cost of material. |

| Stainless steel (corrugated pipes) | 1. Excellent flexibility. 2. Resistance to kink. 3. High mechanical resistance. 4. High resistance to temperature changes. 5. A wide range of high quality connecting elements that allow joining pipes in a long circuit. | High price. |

Polypropylene | 1. Easy installation. 2. Low cost. 3. Suitable for supplying coolant from the boiler to the collector. | 1. Low plasticity. 2. Short length. 3. When forming a contour, there are many welds, which are potential leakage points. 4. Low thermal conductivity. 5. High level of thermal expansion. |

| Cross-linked polyethylene | 1. High strength of the material 2. Hermetic connection of circuits. 3. Possibility of creating a contour of any length. | Large bending radius. |

Types of radiators

If we consider radiators, they are available in three types:

- Aluminum is the most common model. The entire battery body is made of aluminum, which makes it lightweight and increases heat dissipation. The only negative is not high strength.

- Bimetallic - have an aluminum body with a steel or copper core. The presence of such an insert gives the product strength; it can withstand high pressure and temperature changes.

- Cast iron is a classic, they are still popular today, although they have an impressive weight and are quite inert. They have a long heating time, but they hold and release heat well.

In addition, radiators are divided into gravity and forced. The essence of the gravity system is to heat the water in the boiler, after which, according to the laws of physics, it rises up the riser and falls when it cools.

There are one and two pipes. In forced-action batteries, the presence of a pump is implied, which promotes the movement of liquid in the pipes.

Recommendations for installing heated floors

Let us immediately make a reservation that the technology for installing water floors for heating differs in the following cases:

- work is carried out from the ground level, from the soil layer;

- installation occurs from the basement floor or rough concrete screed;

- water floor in an apartment or on the 2nd-3rd floor of a private house.

The differences will be highlighted during the review of work technology. When the device starts from the ground, it should be compacted and a rough concrete screed should be completed according to all the rules. Ideally, the screed should gain strength within three weeks, but since during installation the loads will be significantly lower than the calculated ones, you can wait 3-5 days, after which you need to make a waterproofing layer on top. The result should be a smooth surface without drops or other rough irregularities.

Next, the installation of water heating in a private house or apartment will be described using the technology of the AQUATHERM company, which is one of the leaders in the market of underfloor heating systems. The general diagram of the “pie” is presented below.

Water heating device inside the floor

First, the walls are covered with an elastic damper strip along the entire perimeter; it allows future heating plates to expand within 5 mm in each direction. Thermal insulation is laid on top of the waterproofing film, usually high-density polystyrene foam. With increased fire safety requirements for floors, slabs made of basalt fiber should be used as a thermal insulation material.

If water heating is being installed in a private house on the ground floor, then the thickness of the insulation layer is taken according to calculation, but not less than 50 mm. In the case when work is carried out in an apartment above the first floor or on the upper floors of a cottage, the thickness can be reduced to 20-40 mm, since the temperature difference between apartments is small.

It is recommended to lay a special polyethylene film with markings on top of the heat-insulating layer; it is more convenient to lay out and install pipes along it. The material is rolled out with an overlap of 80 mm, after which the joints are taped.

If subsequently increased static or dynamic loads on the floors are expected in the room (heavy furniture, equipment, etc.), then it is recommended to lay meshes of reinforcement with a diameter of 5 mm on top of the insulation, and attach the pipes to them with plastic clamps.

Metal-plastic or other pipes for heated floors are attached to the insulation with special plastic brackets, the layout is carried out in calculated increments according to a pre-agreed scheme, of which there are several to choose from.

Pipe layout options

At the same time, the bending radii of the pipes must be observed so as not to damage their structure; for each type of pipeline, this data will be provided by the sales representative.

The AQUATHERM company offers for its systems not metal-plastic materials, but pipes made of polyethylene and polybutylene with a diameter of 14, 16, 17 and 20 mm with a minimum bending radius of 80 mm.

From the home boiler installation, the coolant is supplied to a rod distributor assembled complete with a circulation pump. This mixing unit ensures the required temperature and movement of the coolant in all heating elements; it is used to distribute heated floors throughout the rooms. If necessary, the distributor can regulate the indoor climate based on signals from room thermostats; in the simplest version, it maintains the temperature in the supply pipe using a clamp-on sensor.

Important! It is prohibited to connect the central water heating of apartments to the floor heating distributor. This will unbalance the entire riser and as a result everyone will be cold. Connection is only possible to an individual boiler.

After securely fastening the pipes and checking them for tightness (pressure testing), the installation of heated floors continues with the installation of a sand-cement screed, the thickness of which is within 100 mm, the layer of mortar above the top of the pipe is provided with a thickness of 50-55 mm. The screed is kept until it hardens, and during setting, false seams are created in it (between the contours of one room) and deformation seams (at the joints of slabs in different rooms). Lastly, the coating is laid, after which only commissioning and balancing of the system remains.

A little background

The very idea of insulating floors, as well as walls, by laying hot water pipelines inside them is by no means new. Back in Soviet times, experimental projects of panel houses were created and implemented, in which hot water circulated inside the floor slabs and walls, thereby providing apartment heating without radiators. It was believed that the absence of batteries saves useful space in rooms and does not spoil their aesthetic appeal.

Connecting a heated floor to a heating system

It is quite natural that such buildings have not stood the test of time, due to the almost zero maintainability of heating systems and extremely low economic feasibility. Indeed, most of the heat was not spent on heating the interior, but went to heat the structural elements of buildings and the surrounding atmosphere.

Channels made of iron corroded very quickly due to constant contact with water under pressure and at high temperature.

This publication is devoted to a description of floor heating systems combined with heating communications, as well as consideration of the nuances of installing heated floors.

Positive experience of heating a house using only underfloor heating

On the largest construction portal in Russia, FORUMHOUSE, you can find many reviews about the successful heating of a house only with heated floors. Thus, a portal participant from Tomsk with the nickname TTJ believes that discussions on this topic should be taken into account in the past - of course, a warm floor can heat a house.

TTJFORUMHOUSE Member

The banner should be hung here, in large letters on the floor of the screen: “WARM FLOOR IS ENOUGH FOR THE EYES WITH A CORRECTLY BUILT HOUSE!”

Our Canadian participant with the nickname Roracotta has a house of 300 square meters. There are no radiators - only heated floors.

RoracottaFORUMHOUSE Member

I have a system that heats hot water, temporarily disconnecting from the heating. A very rational option. The water is heated for a maximum of 30 minutes. During this time the house will never have time to cool down. But everything needs to be calculated. Heating is the most important and main system in the house. You can't do it at random here.

Our participant with the nickname vlkam has a heated bathroom: 3 external walls, one and a half bricks, without insulation and even with tiles on the walls.

vlkamFORUMHOUSE Member

Heating with only underfloor heating at -30 degrees was sufficient.

Special radiator models

In apartment buildings, heating wiring is often made in such a way that only side or bottom connection of heating radiators is possible. Changes to the project can only be made in agreement with the commission, and this is a long and tedious task. But many manufacturers of radiator batteries anticipate this problem and produce systems with diagonally routed collectors:

- For lateral connection of radiators, a flow extraction extension is used. This is a bracket with a tube installed, which is screwed into the lower or upper inlet. Due to the bracket, the coolant is taken in or released in the far corner of the radiator and the flow passes through the entire battery diagonally.

- For the bottom connection of radiators, insulation of the outer section is most often used. To do this, a plug is installed at the factory at the junction of the lower manifold of the last and penultimate sections. It blocks the direct flow of the coolant, turning the entire remaining battery into a radiator with a diagonal connection.

Such upgrades can be made with already installed batteries. Brackets with flow extensions can be easily found at plumbing supply stores. An experienced plumber will be required for installation, as it will be necessary to disconnect the radiators from the network, disassemble the approach or outlet pipeline and seal the assembly.

There are similar solutions for covering the end section. Most often this is a coupling that twists at the exit point and has a remote plug. It closes the hole between the penultimate and last sections of the radiator and redirects the main coolant flow along a bypass path.

And finally, some useful tips:

- do not make branches that are too long, especially to other floors. The coolant must reach the radiator;

- When placing the collector in a room, do not place it at the end. The length of the branches to the radiators should be approximately the same. Otherwise, the temperature of the coolant in different radiators may differ markedly;

- When installing pipes in the floor or ceiling, lead them to the radiators entirely, without breaking the connections. Otherwise, if one day such a pipe leaks, it will be a very big problem.

As you can see, there is nothing complicated in the connection diagrams for heating radiators of typical heating systems. Anyone with a general secondary education can understand them in order to design and install their own system. Of course, when creating heating systems, it is necessary to take into account many nuances, but this is a topic for another discussion.

Simplified connection option

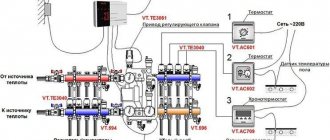

Here is our proposed solution for a mixed home heating system with radiators and heated floors. The first picture is a version of the mixing unit with a three-way valve, the second is with a two-way valve. Both options are equally functional, however the second option may be more suitable for a larger area of underfloor heating, it all depends on the characteristics of the mixing valves.

With 3-way mixing valve

With 2-way mixing valve

The pictures show:

- heat source (wall-mounted gas or electric boiler) with a built-in pump, expansion tank, safety valve, etc.;

- bypass valve for the radiator circuit;

- mixing valve for underfloor heating (three-way or two-way);

- circulation pump for water heated floors;

- bypass valve for underfloor heating circuit;

- safety thermostat;

- balancing valve on a mixture for a two-way mixing valve.

Using the built-in pump

In this scheme, it is proposed to use a boiler pump, which is built into almost any household wall-mounted boiler of good power (up to 35 kW) to circulate the coolant in the radiator circuit. It would be unreasonable not to use its potential and further complicate and increase the cost of the heating system.

Expert opinion

Sergey Permyakov

Heating systems engineer

Circulation pumps built into wall-mounted boilers provide a pressure at the boiler outlet of about 20 - 25 kPa at coolant flow rates of 1000 - 1500 l/h. For example, for a Baxi Luna 3 Comfort 24 kW boiler, the coolant flow will be 1100 l/h with a pressure drop at the boiler outlet pipes of 25 kPa. Such a supply with a temperature difference ΔT=20°K can provide a heating power of 24 kW. This means that if the radiator circuit has a hydraulic resistance of no more than 25 kPa, then the pump built into the boiler will be enough to transfer the full power of the boiler (24 kW) to the radiator circuit.

In order to take advantage of the potential of the boiler pump, and even ensure circulation through the heated floors in a separate circuit, they must be properly linked to each other. This is achieved in our scheme by organizing the so-called. ring circuit .

The boiler room circuit contains two independent coolant circulation rings: 1. boiler circuit (boiler-radiators-boiler); 2. TP circuit.

These two rings have one region C-D in common with each other. Structurally, it consists of two closely spaced tees with outlets to the heated floor circuit. The close location of the tee branches (at a distance of no more than 100 - 200 mm from each other) guarantees low hydraulic resistance of this section C-D, and therefore little influence of the circuits on each other. This is a kind of analogue of a hydraulic needle, only without the functions of a sludge trap and air separator.

The function of a sludge trap will be performed by an oblique mud filter with a mesh, which must be installed in the heating system, and there are air vents in the boiler itself (automatic), radiators and on the underfloor heating manifold.

Operating principle of the ring circuit

The water heated in the boiler enters the radiator circuit supply (point A). Due to the pressure difference between the supply and return pipes of the boiler, the coolant passes through the radiators and returns to the boiler along the path: boiler supply-A-radiators-B-C-D-boiler return.

A bypass valve 2 is installed between points A and B, which we set to a pressure drop of 20 - 25 kPa. This means that as long as all or most of the radiators are open, the main coolant flow goes through the radiators themselves, and not through bypass valve 2. When part of the radiators is closed, excess coolant begins to pass through bypass valve 2. When the radiators are completely blocked (mode " only underfloor heating"), the entire flow passes through valve 2.

Expert opinion

Sergey Permyakov

Heating systems engineer

Thus, a constant coolant flow is maintained in the boiler circuit. This, firstly, has a positive effect on the operation of the boiler heat exchanger itself, and secondly, the full flow of coolant is also always maintained in the CD ring section, from which we can remove heat for the needs of the heated floor.

When the circulation pump of the underfloor heating circuit 4 is turned on, the pressure difference it creates forces part of the coolant from point C to flow into the three-way mixing valve and, accordingly, at point D to return cooled from the underfloor heating circuit to the return of the boiler ring. Regardless of the speed at which pump 4 operates, how open valve 3 is, or how many underfloor heating loops are running at the moment, the amount of water entering tee C is equal to the amount of water leaving tee D into the boiler. Those. the amount of coolant passing through the boiler ring is constant.

When the boiler pump is turned off (the boiler stops when the required temperature is reached), parasitic circulation does not occur through the boiler heat exchanger. The coolant circulates around the ring of the heated floor circuit and only in the CD section of the boiler ring.

When the heated floor pump 4 is turned off and the boiler pump is turned on (the “radiators only” mode), the pressure drop in the CD section is not enough to cause parasitic circulation in the heated floor circuit. Check valves become unnecessary.

Bypass valve 5 in the heated floor circuit ensures minimal coolant circulation when the heated floor loops are closed. It can be omitted if the pump is frequency-controlled or if room-by-room automation for heated floors with a circulation pump control module is used.

Safety thermostat 6 is installed on the supply pipe of the heated floor circuit and if the temperature in the circuit exceeds 50°C, it turns off pump 4.

In a circuit with a two-way thermostatic valve, valve 7 is necessary to balance the degree of mixing of the coolant in the underfloor heating circuit. Its position is adjusted during commissioning of the heating system.

Eventually:

- It is possible to dispense with a hydraulic needle, an additional circulation pump for the radiator circuit and their piping elements without compromising the functionality of the heating system; only correct calculation is required;

- The controllability of the heating system is simplified and the operating costs for electricity for the third pump are reduced (savings of about 20 - 40 kWh per month).

Heating with solid fuel boiler

Combined heating with a solid fuel boiler is a closed gravity system with a heat storage device. Both one-pipe and two-pipe wiring are allowed. To increase efficiency, it is worth installing chokes on each of the heating devices.

During operation of a solid fuel boiler, a large amount of heat is generated. It is better not to interfere with this process, but to redirect the excess heat to the heat generator. Then the fuel will be consumed efficiently, and the system will not quickly cool down after the fuel burns out in the boiler.

When the coolant in the main circuit begins to cool, hotter water from the heat generator will be supplied to the system. If the electricity goes out, the water supply from the heat storage tank stops and the bypass opens.

One of the best options for solid fuel boilers will be a unit with a pyrolysis type of combustion. The fuel in it is burned in two stages, which releases more heat and less carbon monoxide. Almost only carbon dioxide and steam remain at the boiler outlet.

Each consumer makes the final choice of a heating boiler, radiators, pipes for connecting them and for heated floors, as well as the wiring diagram, taking into account many factors. Among them are not only the costs of arranging the system, purchasing fuel and the principle of operation, but also personal preferences. If necessary, all work on system design can be ordered from professionals.

Installation of a system with a gas boiler

The main difficulty is organizing the wiring along two circuits with different coolant temperatures. The most rational options are a serial connection or a hydraulic arrow. Serial connection is more economical, and the hydraulic arrow is practical, because its use will ensure optimal operation of the condensing boiler. The heating circuit will receive coolant at a lower temperature than the radiators.

The temperature of the heating devices is regulated automatically; as they cool down, circulation pumps should start in each circuit. To stop the operation of one of the circuits, just turn off the pump. To minimize the inertia of the system, choose pipes with a small internal cross-section, optimally 20 mm.

Gas heating equipment is installed in separate rooms. The ceiling height in the boiler room must be at least 2 m, and the volume of the room must be at least 7.5 cubic meters. It is imperative to take care of ventilation

A detailed description of the connection diagram for combined heating with heated floors and radiators is in the video below:

Wiring of a solid fuel heating boiler, diagram

It should be noted that the piping diagram of a solid fuel boiler includes several elements and devices that must be used. so that the heating system operates for a long time.

The wiring diagram for a solid fuel boiler is the necessary devices and elements that together form a single heating system. This heating system includes:

- Boiler.

- Circulation pump.

- Expansion tank.

- Emergency power system.

- Co-mixing system.

- Buffer capacity.

- Emergency circuit

- Corrosion protection system.

- Pressure gauge, drain cock, special valve. It's all collected in one block

- Thermal valve.

- Float valve.

Three-way valve circuit

Connecting a heated floor to the heating system in a private house is often done using a three-way valve. To build such a structure you need to have:

- heating radiators, with a coolant heating level of up to 70 - 80 degrees;

- heated floor contours with water heated to 40 C.

The main task is how to cool the water coming from the radiator to the desired degree. This problem can be solved by using a three-way thermostatic piston. It is installed on the supply pipe, and after it a circulation pump is mounted. In the process, hot water is mixed with cooled water, which comes from the return pipe of the heated floor, until the desired temperature level is obtained.

However, such a combined heating design has one drawback - the inability to regulate the flow of waste coolant. This will lead to periodic supply of either excessively hot or cold water to the circuit. This deficiency affects the performance of the floor.

Differences can be partially compensated using a concrete screed. But it is difficult to calculate the optimal thickness of the concrete layer.

It is impossible not to mention the advantages of this method:

- ease of installation;

- reasonable cost of equipment.

This option is justified for a small private house. In addition, the use of a three-way valve allows you to assemble this structure yourself.

Choosing between electric and water heated floors

During operation, water and electric heated floors work with almost the same heat output, unless gross violations were committed during their installation. However, significant differences between these two systems lie in the cost of their installation and further operation.

During installation, you will have to spend much more money on a water heated floor than on laying an electrical circuit. However, the price of electricity is such that you will have to pay a lot for its use and constantly during the heating season.

In this regard, many consumers make the choice in favor of a water floor. It is best to choose to install a water-heated floor and radiators from one condensing-type boiler.

If we are talking about an apartment in a multi-storey building, then there may be problems connecting radiators and heated floors to one collector. But the total cost of installing the water circuit and its further operation will depend on the complexity of the system.

As for the electric floor, in an apartment, on the floor you can lay infrared film, carbon heating mats or two-core cables. The choice in this case depends entirely on the desires and financial capabilities of the apartment owner. The advantage of electric floors is their ease of installation.

A few words about choosing radiators

The most “fashionable” radiators are bimetallic and aluminum. They have good heat transfer, look good, and the bimetal will last for many years. Steel is inferior to aluminum and bimetal in all respects, but good old cast iron is a completely acceptable option. When choosing, you should focus not only on heat transfer rates, but also on the resistance of materials to corrosion and durability.

The easiest way is to choose radiators for a private house with autonomous heating. The owner can control the quality of the coolant himself, and there are no powerful water hammers in the system. You can choose any type of radiator for your home. Cast iron is cheaper and more durable, but more difficult to install and less economical. Aluminum will cost more and last less, but appliances made from it are thermally efficient and very beautiful.

If you are planning a combined system in a house or apartment with central heating, then the choice is small - either bimetal or cast iron. Heating devices made from these materials adequately cope with water hammer and the effects of chemically active coolant.

If funds allow, it is better to opt for bimetallic models. The best European brands are Sira, Global Style, Radena, Regulus-system. Radiators of these brands are adapted for the CIS market. Among Russian manufacturers, Rifar has no competition. All models are assembled from high-quality materials using Western technologies. The Rifar Monolit model is especially popular, its characteristics are not inferior to the best “Italians”, but much cheaper.

Thanks to the successful combination of materials, bimetallic models are durable, resistant to all types of influences and effective. When you turn on the heating, they almost immediately begin to give off heat, because... The coolant volume is small and the body warms up almost instantly. “Bonus” - stylish appearance

Conclusion

Each house is too individual to promise anything without calculations. It is possible to heat a house with underfloor heating, but this issue needs to be discussed at the stage of the architectural project.

Combine bedrooms with a dressing room, increase the area of the rooms due to corridors and moving doors. Conceptually, you need to think through each room separately.

A house without a project is just “savings”.

If you find a company that easily answers this question, I advise you to doubt the competence of these people. The issue is complex and requires a thoughtful approach.

If you don’t have time to experiment with the heating system, or don’t have extra money for constant improvements, I recommend calculating the heat loss of the building, or better yet, designing a heating system and heated floors.

You can order a project from me in the “Services” . Based on calculations, we will be able to select the right radiators, pipes and find out the exact cost of equipment and installation work. We will be able to understand which rooms can be heated with underfloor heating and what architectural modifications are needed for this.

Preliminary project cost calculator

Thanks for reading! For the design of engineering systems, please call or email [email protected]

You might be interested in:

How to choose a design company? Guide for the Customer What is included in the design cost? 10 reasons to work with us

Comments

- Leonid:

06/01/2020 at 17:23In practice, 3 houses are fully heated with underfloor heating, everyone is happy. You have too many pros and cons.

Answer

- Goltsov Alexey:

02.06.2020 at 15:57

Leonid, Good afternoon. Thank you for your attention. An excellent phrase: “In practice, 3 houses are completely heated with underfloor heating.”

1) What do you mean heated? At what temperature? At -10°C - is it “heated”? and at -25°C? Professionals don't talk like that. According to the standards, “houses are heated” at -25°C for 5 days for Moscow. This temperature has not been seen for a long time. I suspect that you are misleading me.

2) What does completely mean? — My sofa is near the window, the guests are sitting with their backs to the window. In the morning they complain - “the back is blown.” Is it complete or not complete? or is the guest to blame? or is the owner a fool? And the Code of Rules SP 60.13330.2016 - are we violating because we come up with our own rules? Is that how it works?

3) The house will be warmed up with warm floors from 12 degrees to 23 for 11 hours. This is a minus that outweighs all the pluses.

Answer

- Alexander:

01/18/2021 at 10:06

I will be very surprised if my post gets approval)) But the author must be able to admit his mistakes.

Answer

- Goltsov Alexey:

01/18/2021 at 14:38

Alexander, Good afternoon. There is no need to treat people as idiots. I really won't post your messages with an advertising link.

You are involved in heat pumps. Radiators don't work with a heat pump, so you're left with underfloor heating. Your income and the well-being of you and your family depend on it.

For my readers: - Alexander wrote that heated floors are 20-30% cheaper than radiators. — Local overheating zones are not dangerous. I didn’t specify what exactly is not scary. — Stained glass windows and heated floors are combined within reasonable limits. He did not specify where reasonable limits begin and end. — Sent the video to my resource

Answer

- Ulvi:

04/25/2021 at 21:00

I don’t even know what to say, but I was working in such an office, sitting all day in a huge room of 150 square meters, even more, and there was only a warm floor. It was very hot, even stuffy in winter. But in our street the maximum temperature is -2

Answer

- Goltsov Alexey:

04/26/2021 at 13:23

Ulvi, the floor area of an office space is much larger than the area of the external walls and windows; if you have a single room of 150 m2, then underfloor heating is possible. My article about underfloor heating for private homes.

Answer

- Robert:

13.12.2021 at 17:36

Alexey, hello! Being a civil engineer, I generally share your professional approach to the issues of heating private houses and, in particular, the possibility of using heated floors as an addition to the main heating with radiators for most of our climatic conditions. I would like to add the following (you are talking about this, I want to strengthen it): floors made of any other materials, taking into account their components (with the exception of stone and ceramic tiles), will smell of “chemistry”, no matter what environmental certificates are presented. I intend to order you a project or a fundamental solution to complex heating issues (radiators + heated floors). I would like to get your opinion on the composition of the plank floor structure with joists on a reinforced concrete screed on the ground. In this case, how to organize additional floor heating solely for comfort. Ekaterinburg Sincerely, Robert

Answer

- Goltsov Alexey:

01/10/2022 at 18:29

Good afternoon, Robert. I will write a separate article about floor pies on joists, on the ground, etc. There's simply not enough time for this. There are standard pies for these occasions. For example, Vladimir Sukhorukov “heat-water” popularly talks about them. I know Vladimir personally. Everyone should be good only in their professional role. He is a good installer (not a designer). Watch his video on the channel.

Answer

Advantages of radiators

1. Installed under the windows . Windows are a source of rapid heat loss. The temperature outside changes all the time, which leads either to an increase in the cold flow from the window or to its decrease. The radiator smoothes out these flows.

2. No requirements for premises. Over the years, you can replace tiles with parquet, lay carpets, install monolithic furniture and not depend on the requirements for heated floors.

3. No overheating areas that are uncomfortable to walk on.

4. No odors from furniture or carpets. Warm floors heat up the furniture. There is a smell coming from the furniture.

Analysis of misconceptions