Gas boilers are among the most economical and easy to operate. That is why they are installed everywhere where there is a centralized gas supply. Connecting a gas boiler to a gas pipeline must be carried out by certified specialists from specialized organizations. But its connection to the heating and hot water supply system - piping - can be done independently. The piping methods may differ slightly depending on the type of equipment: single or double circuit, floor or wall. We'll talk about typical schemes in this article.

Single-circuit boiler

Almost all modern models of gas heating boilers have the same design of incoming and outgoing pipes used to connect gas, heating and water supply. The pipes are located as follows:

- For gas - in the center;

- For the heating system - coolant supply on the far left, return on the far right;

The sequence of actions for connecting a gas boiler to the heating system is as follows:

- Shut-off valves. Ball valves are installed on both the supply and return pipes. They are needed to quickly disconnect the heating system from the boiler if repairs are necessary. The tap can be connected to the pipe directly or through plug-in connections: a union nut or an American one. All professional installers recommend using additional connections that greatly facilitate the process of connecting and disconnecting the boiler to the system. The American version is more expensive, however, it justifies itself by providing a more reliable connection that does not leak even with frequent use.

- Coarse filter. Water, which is most often used as a coolant, circulates through the heating system and washes dirt out of it. Solid insoluble particles can settle in the heat exchanger, significantly reducing its efficiency. To avoid this, a coarse filter—a “mud filter”—is installed on the return pipe. It is mounted directly after the ball valve connected to the boiler, and is also separated from the rest of the heating system by a second valve. This is done so that the filter can be cleaned without disconnecting it from the pipes and without draining the coolant from the system.

Coarse filter

IMPORTANT! It is permissible to install the filter only in a horizontal position with the storage compartment facing down.

- Fill and drain tap . A conventional ball valve, which is installed at the very bottom of the heating system on the return line. It serves to drain and supply coolant to the system. If necessary, a flexible hose is connected to this tap, which, depending on the function, is discharged either into the sewer system for draining, or is connected to the water supply system for filling. Also, the coolant can be supplied from a conventional container through pumping equipment. This is convenient if antifreeze is used as a coolant. In modern wall-mounted gas boilers, the connection diagram includes a built-in feed tap.

- Expansion tank - a container that compensates for the increase in coolant volume during thermal expansion of the liquid. Many modern models of gas boilers have an expansion tank as standard. However, when connecting such a boiler, it is necessary to check the maximum permissible volume of coolant for which such a tank is designed. As a rule, it does not exceed 70-100 liters of coolant in the system. This is enough to heat a small one-room apartment. In all other cases, it is necessary to install an external compensator. The tank cuts into the main return line and is separated from it by a ball valve.

Closed type expansion tank device

- Security group . Many models of gas boilers are equipped with their own safety devices. However, for volumetric heating systems that are intensively operated in various modes, it is recommended to install separate safety groups consisting of the following devices:

- Pressure gauge - shows the current coolant pressure in the heating system pipelines. For apartments this figure is no more than 1.5 atm. For large private cottages it can reach up to 2 atm;

- Safety valve - resets excess coolant from the system when the permissible pressure rises critically. Sometimes used for manual removal of air from pipelines;

- Mayevsky valve (automatic air vent). The main function is automatic removal of air from the heating system.

The safety group is installed at the highest point of the heating system on the coolant supply pipeline. The recommended distance from the boiler is no more than 1.5 m.

Recommendations for arranging the circuit

Let's take a closer look at the application of this heating scheme for a 2-story house.

On the ground floor: kitchen, dining room, toilet, bathroom. On the second: three bedrooms. We use a primary and secondary ring system. It is advisable to design the boiler room in the basement of the house. We decide on the boiler power: a heat generator with a capacity of 25 kW is suitable for such a house. Selects the type of boiler: pellet or pyrolysis, it doesn’t matter whether both will work. Here the fuel decides which fuel is best to buy, and we install that unit.

We install the system sequentially:

- install a heat generator;

- We mount a closed primary ring nearby;

- we cut the main circulation pump into the primary ring;

- We connect the fuel unit to the primary ring with pipes from the boiler and to it, the distance between the connected pipes is no more than 300 mm;

- we install pipes for heating underfloor heating on the 2nd floor for 3 rooms: three entrances and three exits;

- we cut in consumers on the first floor - everything is also parallel;

- connect the expansion tank;

- install a faucet to fill the system with water;

- For each heating circuit we install its own pump on the return pipeline;

- all secondary circuit pumps must be connected to temperature sensors, which will regulate the supply of coolant individually to each branch, and, if necessary, turn off the pump.

The use of a primary-secondary system will allow:

- create the necessary microclimate in the house at minimal cost and maximum use of equipment;

- use the heating system most efficiently;

- avoid the passage of water through idle units (that is, increase the efficiency of the system as a whole);

- quickly and easily carry out repair work on system elements.

Double-circuit boiler

The connection diagram for a double-circuit gas boiler to the heat supply system of a private house is carried out in the same way as a single-circuit one. The difference lies in the presence of additional pipes for the domestic hot water system. They are installed on gas heating boilers as follows:

- On the right, between the gas pipe and the return pipe, there is a connection pipe to the cold water supply system;

- On the left, between the gas pipe and the supply, there is a pipe for supplying hot water to the local hot water system.

Just like a heating system, DHW pipes are separated from the boiler by ball valves at separate connections. Connection of cold and hot water supply is carried out without any restrictions. As an additional element, a special filter is used on the cold water supply pipe. It is recommended for use in old systems with centralized water supply with a large amount of solid insoluble particles in the flow. They can settle on the walls of the secondary circuit heat exchanger, reducing heating efficiency.

Electrical connection

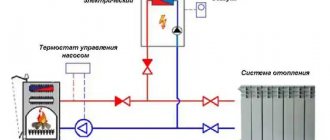

Connecting a gas boiler to electricity

There are two ways to connect a gas boiler to the network:

- Plug into the socket.

- Cable with three cores.

The choice is determined by the equipment model. But you always need to work through local protection. Connect to the panel. And don't forget to ground. It would be great if there were stabilizers or backup sources if the plugs suddenly went out.

The circuit breaker must be located next to the equipment. In any case, there must be a local outlet. And she must eat through a machine.

Building a ground connection on a gas pipeline or battery is prohibited! According to gas service standards, the resistance does not exceed 10 ohms.

Floor

When piping a floor-standing gas boiler, the following rules must be observed:

- The equipment must be located in a separate room with good ventilation: a window, a ventilation vent, etc. The area of the room must be at least 4 m2, and the free volume must be at least 8 m3. At the same time, the recommended ceiling height is 2.5 m;

- Ventilation should provide fresh air. For this purpose, a permanent ventilation duct is equipped, the area of which is calculated at 8 cm2 per 1 kW of boiler power;

- Combustible materials cannot be used as decorative finishing. It is prohibited to install suspended ceilings or false floors, as well as other decorative niches where combustion products or gas may accumulate;

- No gas appliances, including gas meters, should be installed in the immediate vicinity of the boiler;

- The boiler itself must be installed on a pallet made of fireproof materials: concrete or brick.

Requirements for boiler rooms

SNiP 2.04.08.87 provides the following standards for the placement of boiler equipment:

- It is not allowed to install more than two boilers (water heaters) in one room.

- If it is necessary to locate a boiler room outside a residential building, the decision is made by an architectural design organization or gas operating service. The requirements for these premises are similar to those for residential buildings.

- Installation of water heating boilers is permissible in kitchens and other non-residential premises with the exception of bathrooms.

- It is prohibited to place any gas-consuming equipment in basements, with the exception of individual housing, if these premises are illuminated by natural light and the fuel is natural gas.

- Hanging gas boilers should be placed on walls with a non-combustible coating or insulated with sheet steel over a 3 mm asbestos sheet.

- The insulating coating must extend beyond the overall dimensions of the unit by 100 mm.

- When placing heating equipment on the floor, the gap to the wall is taken to be 100 mm.

- If heating equipment is placed in the kitchen together with a gas stove, its volume is taken 6 cubic meters more than the norms for gas-consuming stoves.

- When placing a heating unit with a chimney, the ceiling height in the room must be at least 2 meters with a total volume of 7.5 m3. If two boilers are installed in a private house, the volume of the room should not be less than 13.5 m3.

- The boiler room must be equipped with a standard sized ventilation duct facing the street.

- At the bottom of the wall partition or door leaf there should be an opening (grid) with a total area of 0.02 m2.

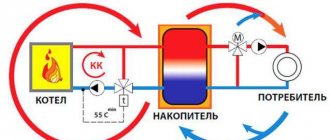

Gas boiler and boiler

A single-circuit gas boiler can also be a source of heating for the DHW system. For this purpose, special equipment is used - an indirect heating boiler, which is included in the connection diagram. It is a container inside which there is a pipeline connected to the heating system.

The connection is made as follows:

- Shut-off valves are installed at the inlet and outlet groups of the boiler so that, if necessary, the device can be excluded from the general heating system.

- The boiler is connected using three-way thermostatic valves. With their help, the coolant leaving the boiler is divided into two streams: into the indirect heating boiler and into the heating system.

- The adjustment is carried out automatically. After the temperature in the boiler drops below critical, the coolant flow is transferred to the pipeline running through the indirect heating tank. After leaving it, the pipe is connected to the heating system.

Unit installation features

There are no difficulties at all with a floor-standing boiler. The main thing is to strictly follow the instructions and take into account the features specified by the manufacturer. If the boiler is wall-mounted, then installation is carried out using special brackets (they are usually included in the kit). Installation is best done by two people. This will prevent damage to the equipment during the installation process, and will also speed up the installation process without loss of quality.

The most difficult thing in installing a gas boiler is choosing a location. What is important here is not only ease of use, but compliance with all standards for gas equipment. Basic rules for installing a gas boiler:

- the room for its installation must be ventilated and have good ventilation (ideally, forced ventilation should be installed, or the installed equipment should be equipped with a turbine);

- there should not be any devices nearby;

- the wiring in the room must be in full working order;

- Installation of equipment in damp or flooded areas is not allowed.

A wall-mounted gas boiler should be located at a height of 80 cm from the floor or more and at a distance of 50 cm from the nearest walls. This allows for maximum operational safety.

conclusions

Of course, there is no single instruction for all cases that would describe in detail how to heat a two-story house from a boiler step by step. But there is an action plan that is common to everyone (and not just the owners of two-story mansions). It includes 3 main parts:

- Preparatory. She is the most responsible, and therefore takes a lot of time, but the result justifies this investment.

- Technical. Partially it is still carried out by external specialists.

- The final one. This includes installation and configuration of additional devices, test run of the system, monitoring of operation, etc.

If you go through each stage without errors, the heating in the house will work without failure for at least 20 years (as practice shows). Subject to annual maintenance of the equipment, of course.

What it is?

An autonomous heating system involves a complete rejection of central heating.

That is, it will be necessary to dismantle the radiators and pipes related to this system. The basis of individual heating in this case will be gas or electric boilers. And to them, in turn, new pipes and batteries should be attached. The principle of operation of boilers is quite simple - they heat water and send it to circulate through the created system, thereby heating the premises in the required mode.