With the onset of cold weather, there is a need to heat the premises. It is not always possible to provide central or autonomous heating to premises such as a garage, barn, paddock, or greenhouse. The reasons may be different: lack of funds due to the high cost of connecting such systems or lack of technical capabilities.

If you make a gas heater with your own hands, it will effectively heat utility rooms. Now on the market you can choose and buy many different models of gas heaters at different prices and with different characteristics. However, the price includes a steep seller's markup.

We will tell you how to assemble an almost free homemade product from available materials. Here you will find a detailed description of homemade devices and instructions on how to make them. To help do-it-yourselfers, we offer assembly guides and valuable advice.

Model on diesel fuel

A diesel gun-style garage heater is also quite economical.

During operation, exhaust gases are transported to the heat exchanger. This design makes it possible to maximize the safety of the installation due to indirect heating. After entering the purifier, the purified air mixture is supplied outside, which heats the room. The use of this kind of guns requires a sufficient supply of fresh air, as they burn oxygen. The features of a diesel garage heater include the following:

Built-in flame control system. The presence of automation to turn off equipment at critical temperatures. Built-in thermostat. High mobility, which is important for a small building.

Why do you need a heat exchanger?

There are many types of gas tent stoves. And their common disadvantage is that some of them do not remove combustion products to the outside. This is quite dangerous; there is a risk of poisoning from combustion products. Also, moisture formed during the combustion process gets into the tent space - moist heat is not an optimal environment for long-term stay of people.

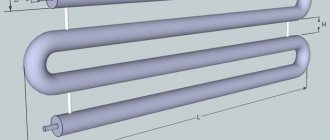

A heat exchanger for a winter tent is an excellent solution that provides safer heating using gas burners. The principle of their operation is simple:

- The burner located under the heat exchanger heats the structure;

- Air is drawn through the exchanger tubes, heating up and entering the winter tent;

- Combustion products are discharged through the chimney to the outside of the tent.

The power source is a battery; low-noise computer coolers or other types of fans are used as a fan.

In its design, the device resembles a small fire-tube heat exchanger used in solid fuel heating boilers. The heat from the burner passes through it, and air is driven through the tubes. At the output we get dry heat, which is quite comfortable and warms people.

Which heating option to choose

Which version of the thermal unit to choose depends, first of all, on the degree of fuel availability. It could be:

Heating using a gas boiler. It can be installed if there is access to the gas main. But to install the supply to the garage, you will have to use the services of gas service specialists, having previously received permission to carry out such work. The installation of gas heating also requires the presence of supply and exhaust ventilation in the garage. A popular solution is to use a gas cylinder with a heat gun.

Heating with solid fuel stoves. Usually these are heating units with open fireboxes, made by hand from scrap materials. Such heat sources can be very effective and work on peat, coal, wood waste, pellets and many other combustible materials

When using such stoves, special attention should be paid to a high-quality chimney and good ventilation. The disadvantages of stove heating include the relatively short burn time of fuel and the need to constantly load it into the firebox. This circumstance can be partially offset by the use of long-burning pyrolysis furnaces, in which one load of fuel can burn for up to 12 hours or more

The advantages may include quick heating of the room. Solid fuel stoves are also used in water heating systems for garages. But in this case, antifreeze must be used as a coolant so that there is no need for constant intervention in the heating operation. When using open hearth stoves, do not store flammable liquids, such as gasoline, in the garage

This circumstance can be partially offset by the use of long-burning pyrolysis furnaces, in which one load of fuel can burn for up to 12 hours or more. The advantages may include quick heating of the room. Solid fuel stoves are also used in water heating systems for garages. But in this case, antifreeze must be used as a coolant so that there is no need for constant intervention in the heating operation. When using open hearth stoves, do not store flammable liquids, such as gasoline, in the garage.

Thermal units using liquid fuel. They can run on kerosene, diesel fuel, waste oil and other flammable liquids. At the same time, which is an undoubted advantage, one filling of the tank with fuel can be enough to ensure operation for several days. The types and designs of such stoves are very diverse and often individual, since they are made by hand.

Electric boilers. Also very diverse designs, intended both for heating with heating elements and for heating the coolant in liquid heating systems. Induction boilers stand apart, which are not subject to any control body. The advantage of such heaters is the ability to fully automate the process and operate in a continuous mode without outside control. The disadvantages include the relatively high cost of electricity. If the user is able to ignore this circumstance, it is difficult to offer a better choice.

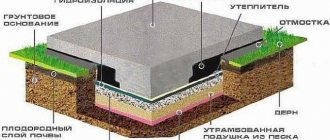

Using solar energy. There is no need for complex equipment for this. It is enough to build a pipe grid along the outside walls of the garage. Heat is obtained by heating the liquid circulating through the pipes and accumulates in the heating system of the internal circuit. Even under unfavorable weather conditions, such a system can provide 20–50% of the required thermal energy. The rest can be supplemented with a different type of heating unit included in the same system, for example, an induction boiler. This seems complicated only at first glance. Having considered each task separately, you can understand its feasibility in a short time with your own hands.

In a garage, one of the best solutions seems to be a heated floor with any heating element, including water, electric or infrared.

Heating with liquid fuel

Do-it-yourself budget heating of a garage can be done using liquid heating units, including homemade ones. In our reviews, we have already described exhaust furnaces that provide cheap, and in some cases, free heat. For example, if you are changing engine oil, then over the spring and summer you can collect several barrels of finished fuel. A properly assembled oil stove will generate a large amount of heat and will delight you with even combustion without soot and soot.

Pyrolysis-type furnaces consisting of several parts, as shown in the figure, give good results. A fire is lit in the oil container, as a result of which oil vapors and pyrolysis products begin to form. They are burned in a vertical pipe with holes, producing a large amount of heat. By regulating the access of oxygen, you can adjust the intensity of combustion.

When using any stove, it is better to allocate a separate corner for it. You also need to think about a reliable foundation and lining the adjacent walls with non-combustible materials.

Using a stove with a plasma bowl to heat your garage, you can achieve maximum heat transfer and minimum fuel consumption. The oil here breaks down into its constituent parts in a hot bowl, after which it burns to form a bluish-white flame, similar to plasma. Of course, there is no trace of plasma here, since it is formed at much higher temperatures. These furnaces are characterized as the most productive.

Pros and cons of diesel heaters

Like any device, a heater that runs on diesel fuel also has its pros and cons.

Advantages:

Compact size; Autonomy; Cost-effective – from a financial point of view, purchasing diesel fuel is much cheaper than purchasing electricity; Mobility – you can take it with you or move it to the most convenient place; Large range of heaters.

In addition to all of the above, modern models have additional functionality, are as economical as possible, and can be controlled remotely.

Flaws:

- High cost of the unit;

- High noise level during operation;

- Combustion products that can be released when heating a room.

Radiator preparation: inspection, adjustment

To make a radiator, you will need two sections of a cast iron battery assembled together. One side of them should be muffled. The lower plug with the fitting must be unscrewed in order to inspect and improve the tightness of the connection.

PHOTO: YouTube.com The cast iron plug with fitting must be unscrewed from the radiator

The long thread on the plug fitting is not needed, so it can be trimmed a little and then carefully chamfered. Otherwise, screwing the nut onto the thread will be problematic.

PHOTO: YouTube.comThe thread is shortened and carefully processed

Next, a sealant (FUM tape) is wound onto the threads of the plug, and the element is screwed into place. The plug is pulled out using a gas wrench. This requires a lot of force - everything must be extremely tight.

PHOTO: YouTube.com For tightness, FUM tape is wound onto the threads

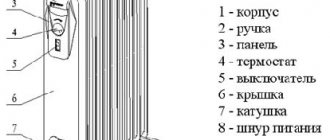

Oil device

A homemade oil heater is a fairly functional and safe device. It has high efficiency and is therefore suitable for those rooms where various household appliances are repaired.

Its design consists of a sealed housing, inside of which there is oil and heating elements.

Before making a heater with your own hands, you need to prepare the following materials:

- Sealed container. You can use an aluminum or metal battery or a car radiator as it.

- Technical or transformer oil.

- Heating element 4 pcs.

- Electric motor with a power of 2-2.5 kW. Instead, you can use a pump with the same power.

- Switch.

- Set of drills.

- Corners or profile pipe with dimensions 40x40 mm.

- Two tubes. Must withstand temperatures of 100-150 °C.

You will have to work with a drill and a welding machine.

Algorithm for manufacturing an oil heater

Frame welding. Before this, draw a diagram of the frame. To do this, you should start from the size of the selected container and the height at which the case should be placed. The frame can be made in the form of two rectangles. The width of the rectangle should be greater than the depth of the selected container, and the length should be greater than the height of the container. The main part will be inserted into rectangles. These parts of the frame should be at the ends of the container. Each rectangle must have two legs. It is advisable to connect them with one corner, which will run along the body.

At the beginning of frame manufacturing, the corners or profile pipe are cut into pieces of the required length. Next, weld the rectangles and weld the legs to them. The longitudinal angle can be fixed with bolts. Thanks to this, the frame can be disassembled and hidden in a convenient place until the start of the next winter season.

- Cutting 7 holes in the selected container. 4 of them must be such that a heating element can fit in one hole. They can be located in the corners of the radiator. 2 holes are needed for the pump. They are made at the bottom of the radiator. Another hole is needed to fill the oil. It needs to be done at the highest point of the radiator. You can use a grinder or welding to cut holes. The best option is autogen.

- Making a mount for fixing the pump. To do this, metal plates with holes cut in them for bolts are welded to the container. These plates should be located close to the pump holes.

- Fixing the pump and connecting it to the radiator. To connect it you need to use two tubes. They can be welded to the radiator and connected through shut-off valves to the pump. You can weld fittings to the holes intended for the pump and attach tubes to them.

- Mounting heating elements. They are secured using bolted connections. The easiest way to mount those heating elements is the base of which has a thread and is a kind of large bolt. In this case, a fitting with internal thread is welded to the holes in the radiator. A nut may also work. A heating element is screwed into it.

- A fitting with an external thread is placed and welded onto the oil filling hole. There will be a lid on it. It can be made from a pipe. To do this, an internal thread is cut at one end. It should be the same as the thread on the fitting. The pipe must have a larger diameter than the fitting. A metal square plug is welded to the second end.

- Check the tightness of all holes. To do this, create a lot of pressure in the middle of the oil heater.

- Heating elements are connected. To do this, use the parallel connection method.

- Connect the voltage regulator and cable with plug.

- Place the housing on the frame and ground it.

- Pour oil.

Economical heating with electric batteries

The oil heater is now ready and can be used. Over time, it may fail and require repair. Repair comes down to replacing heating elements or pumps. Sometimes it may be necessary to improve the tightness of connections. This type of repair is not very difficult.

- https://trubexpert.ru/heating/kak-sdelat-samodelnyj-obogrevatel-dlya-garazha/

- https://ventcondition.ru/obogrevatel-radiatora-avtomobilya-svoimi-rukami/

- https://oventilyacii.ru/otoplenie/kak-sdelat-obogrevatel-iz-chugunnoj-batarei-svoimi-rukami.html

- https://sovet-ingenera.com/otoplenie/radiator-obogrev/samodelnyj-obogrevatel-dlya-garazha.html

- https://poluchi-teplo.ru/radiatoryi/drugie-rad/izgotavlivaem-svoy-obogrevatel.html

Making a tabletop fan heater

This type of device is a heater and fan rolled into one. If desired, it can be used as an improvised air conditioner.

A heater placed in the body of the device will provide heat in cold weather, and a computer cooler placed there will create a pleasant breeze in the hot months

This type of heater is convenient because it allows you to regulate the heating temperature and the rotation speed of the cooler.

Selection of required materials

To create a fan heater you will need the following materials:

- rheostat;

- switch;

- power connector;

- electrical wire;

- LED Strip Light;

- 12 Volt computer cooler;

- three-amp 12-volt power supply;

To fix the heating element, you will also need two ten-centimeter rods of copper wiring with a cross-section of 1.5 sq. mm.

The body of the device will be made of wooden blanks 9 mm thick, and the supporting legs will be made of sticks of the same material with a diameter of 12 mm

The tools you need to prepare are:

- jigsaw;

- hammer drill or drill;

- soldering iron;

- hole saw;

- glue for woodworking;

- “moment” or superglue;

To clean wooden workpieces, removing burrs along the edges, you will also need fine-grained sandpaper.

Assembly of body parts

The future heater will have the shape of a cube. Therefore, to make it, it is necessary to cut out the following from wooden boards 9 mm thick:

- two square blanks measuring 12x12 cm;

- 3 pieces measuring 10.2x10.2 cm;

- two rectangular blanks 12x10.2 cm;

- four small rectangles measuring 1x1.5 cm.

To make the legs of the structure, a wooden stick D12 mm is sawed off into 2 pieces, each 3 cm long.

To ensure that the generated heat freely goes beyond the heater, holes with a diameter of 8-10 mm are drilled in square blanks

To simplify your task, make paper patterns, the dimensions of which correspond to the dimensions of the blanks 12x12 cm. Marking the location of the holes is applied directly to the patterns. They are applied to each side and drilled through.

In a workpiece 10.2x10.2 cm, maintaining a distance of 2.5 cm from the edge, make a hole D7 mm. On the second similar workpiece, two similar holes are made, maintaining a distance of 2.5 cm between them. On the third workpiece, 10.2x10.2 cm, a through hole of D9 cm is made in the center.

In each of the four rectangular blanks measuring 1x1.5 mm, holes D5 mm are made.

On the long side of a rectangle measuring 12x10.2 cm, moving 1.2 cm from the edge, make two holes D12 mm, maintaining a distance of 7 cm between them.

To assemble the structure, square blanks 10.2x10.2 centimeters are glued to the side edges of a 10.2x12 cm rectangle

A square blank with a 9 cm drilled hole is installed inside the body. After this, the last rectangular part is attached, closing the body of the structure. At the final stage, the legs are glued.

Installation of heating elements

A spring stretched between two copper rods will act as a heating element. To determine whether the spring is suitable, you need to connect it to a 12-volt power source and take measurements using a multimeter.

So, to create a warm flow, it is enough if the multimeter readings are 2.5 Amperes. With these parameters, with a power supply of 12 Volts, about 30 Watts of heat will be generated.

The selected spring is soldered to copper rods, the ends of which are fixed to blanks measuring 1x1.5 cm. The assembled structure is glued to the corners of the body. The bare “tails” of the electrical cable are soldered to the ends of the rods. After this, a bar equipped with holes is attached.

To connect the cooler, solder the ends of the LED strip to the blue and red braided wires, and then pull them out through a hole with a diameter of 5 mm

Having fixed the cooler inside the case, the same manipulations are performed with the rheostat, switch and power connector.

If all structural elements are connected correctly, then when the rheostat is turned on, a blue light will light up on the LED strip. When the switch is turned on, the LED strip will acquire a red tint, which will create a violet color against the background of the main blue. After this, the heater spring will begin to heat up.

The main condition for the device to work is for the spring to work only when the cooler is on; otherwise it will simply burn out

The assembled structure from the outside can only be sanded and treated with wood wax, or varnished in 2-3 layers. Thanks to its presentable appearance, such a heater can be safely used not only for heating a garage, but also when arranging living rooms.

Advantages and disadvantages of IR

Garage IR heater equipment, technical indicators and features of use have specific advantages and disadvantages.

Advantages:

- connecting equipment does not require large financial investments;

- the basic package consists of the necessary parts for installation;

- simple connection of an electric emitter;

- installation of gas equipment may require obtaining the necessary permit;

- the possibility of separate zones of the room, rather than the entire garage;

- modern models are protected against overheating of the surface and fire in the event of a fall.

Minuses:

- the power of household appliances is much reduced in order to obtain favorable heating conditions;

- the high cost of the device and the large number of Chinese counterfeits that fill the climate system market.

The IR heating system has no analogues. Compared to a standard heating radiator, they allow you to get instant heating even in a cold building. High efficiency and almost no significant disadvantages explain the popularity of infrared emitters.

Features of heating a greenhouse with an infrared heater

Fire safety requirements for a garage heating system

Before starting the installation of heating equipment, you will have to draw up a detailed diagram - this will allow you to identify vulnerable areas, including:

- wooden surfaces next to which the equipment will be located. They are covered with galvanized sheet metal;

- the location where the chimney pipe passes through a hole in the ceiling or wall;

- fuel storage areas. Flammable substances are located as far as possible from the heating device and always above the level of the floor covering.

The main thing is to ensure safety

The future locations of fire extinguishers and other fire protection equipment must be marked. If the system is planned to use flammable fuel, it would be useful to place a box with asbestos fabric near the boiler - it will help localize the fire in the event of an emergency.

But in such a box there are plenty of problems even without heating

No. 4. Electric garage heating

Electric heating is the easiest to organize, but you have to pay dearly for such convenience.

Advantages:

- simplicity and high speed of arrangement. All you have to do is buy a heater and plug it into a power outlet;

- large selection of heating devices;

- absence of combustion products, so a chimney is not needed;

- high level of security;

- high heating rate;

- ease of temperature adjustment.

There are also disadvantages:

- long-term heating with electricity will cost a pretty penny;

- not suitable for regions with power outages;

- rapid cooling of the room after turning off the heating;

- low durability of equipment.

Most often, the following electric heaters are used to heat a garage:

- Heat guns are a more powerful analogue of a household fan heater. Cold air passes through the heating element, heats up and is blown into the room using a fan. You can place a heat gun anywhere, it is mobile and allows you to adjust the degree of heating. There are very powerful models that must be connected to a 380 V network. The gun can raise dust into the air, this is especially noticeable in small garages, so you will have to keep the room clean;

- A fan heater is inferior in terms of power to a heat gun, costs the least, and dries the air. They, like guns, are characterized by fairly high noise levels. Ceramic fan heaters are more durable, economical and comfortable to use than their spiral counterparts;

- A convector is a heating element in a housing with holes. The room is heated due to heat transfer from the housing and the release of warm air through the openings. Many models are equipped with wheels for easier movement. The convector heats the room more slowly than a heat gun, but after switching off the housing takes a long time to cool down. Another disadvantage is the higher price;

- An oil heater is more complex than a convector. Here the heating element first heats the oil, then the oil heats the body, and the body already heats the air. The room takes a long time to heat up, so this is not the best option for a garage;

- IR heaters heat surfaces and objects, which then heat the air. The person feels warm immediately. The sun warms the planet using the same principle. Such devices consume a minimum of electricity, but during operation they heat up significantly - be careful if the garage is small. It's best not to point the beams at the car;

- inverter split systems are a fairly economical way to generate heat, but the equipment itself is very expensive. The system can operate at temperatures not lower than -20C.

Electric heaters are suitable for temporarily heating a garage: you plan to do some work, turn on the heater, do everything and turn it off. It won’t hurt your wallet, and you won’t have to bother with kindling and a chimney. If the garage is a workshop where you spend time regularly, then this heating method is not for you.

Are you here

A gas convector for heating a garage is the most economical heating method compared to electrical appliances. For one reason or another, it is not always possible to heat a garage with electrical appliances (insufficient electricity, interruptions, high cost). Yes, initially the cost of a gas convector is higher than the cost of electric heaters, but its payback (due to the difference in the cost of gas in relation to electricity) is only one month. The clean operation of the device consists in the intake of air and the removal of combustion products from the street through a coaxial pipe; only the heat exchanger is in direct contact with the room. The only main disadvantage of a gas convector in comparison with electrical appliances is the complexity of its installation and the installation of a coaxial pipe.

Advantages of gas convectors

Durability, cast iron heat exchanger, service life more than 20 years. A wide range of models, divided by power, from 2 to 10 kW, is easy and convenient to select for any area. The device is easy to use, does not take up much space, and is silent. In order to calculate your benefit, simply compare the cost of gas and electricity.

Electric garage heating

The easiest way to heat a garage with electricity is to use a suitable heater, either purchased or homemade. If you don’t have the money to buy factory equipment, you can make it yourself. The simplest heating device is a goat heater, the most affordable, but also the most ineffective. It is done easily and simply - take some kind of non-flammable dielectric, and wrap a nichrome wire around it. Next, connect the electrical cable to the product and plug it into the outlet.

Among all the options for heating a garage, this option is considered the most dangerous - electricity is generally not a joke. Bare nichrome wire is used here, there is no insulation of any kind. Users may be burned or receive electric shock, and there is a risk of fire. It is prohibited to leave such heating unattended. And in general, you should not use such makeshift and extremely dangerous heaters.

Electric heating of the garage can be organized using factory heating devices:

Before you start choosing the type of heating, you should take care of at least minimal thermal insulation of the garage. Otherwise, the heat will simply go outside.

- Heat guns - they are extremely safe and provide quick heat injection into the garage. It only takes a few minutes to warm up the entire volume, after which the room will become warm. Minus – increased noise level;

- Infrared heaters are a modern solution that pleases with high efficiency. Infrared heating of the garage does not dry out the air and is not harmful to health. Simple IR heaters are used here, which heat not the air itself, but the surrounding objects, as a result of which they begin to emit heat;

- Electric convectors are a great way to heat a garage in winter and not have to worry about installing or manufacturing complex equipment;

- Electric boilers - in this case, classic water heating using an electric boiler is organized in the garage. A boiler for a garage is selected according to its area and heat losses, focusing on the formula 1 kW of heat per 10 sq. m. area.

Heating of the garage can also be organized using a homemade boiler - for this you will need an electric heating element of suitable power, which must be built into a metal pipe of one diameter or another. Next, bends are welded to the pipe, to which a water heating system with batteries is connected. By the way, these same batteries (heating registers) can be made independently using pipes with a diameter of 100 mm.

OCD

Model using IR silicate glass

Since IR silicate glass is used, products of different brands experience sharp changes in thermal conductivity and transparency. For this reason, make and test one emitter. Based on the test results, it may be necessary to vary the diameter of the material.

The following arithmetic principles should be taken into account for quartz installations.

Material parameters

0.5 mm: power – 350 W, current – 1.6 A.

0.6 mm – 420 W and 1.9 A.

0.7 mm: 500 W and 2.27 A.

0.8 mm: 530 W and 2.4 A.

0.9 mm: 570 W and 2.6 A.

Thin wires have a solid radiating surface. When using thick versions, exceed the IR power that glass can transmit.

Testing

The finished product is placed vertically on a non-flammable surface. Supported with a heat-resistant object. A current of 3 A is supplied to the product. A digital tester is used to monitor the current.

We need to check the behavior of the glass. If it quickly heats up and cracks within half an hour, it is not suitable.

After 1.5 hours, the radiation power is checked. Place your palms parallel to the radiating planes. The distance from them is 15-17 cm. You need to hold it for at least 3A min. Then you will feel a soft warmth for 5-10 minutes. If your palms immediately get burned, you need to reduce the diameter of the wire. If after 20 minutes there is not even slight heat, thicker material is needed.

How to make cheap and quick garage heating with your own hands

We will give several options for garage heaters that you can make yourself:

The simplest of them is a potbelly stove, which is usually heated with wood. This can be a stove of any configuration, made from any ready-made container. For example, from a 200-liter barrel, which is cut in half crosswise. The oven is made from half. Although you can place the barrel horizontally without cutting it. The main thing is to make a pipe for the chimney, a firebox into which a partition made from a grate welded from fittings is inserted, and a door to close the combustion chamber. As practice shows, making such a heating device in three to four hours is not a problem.

Wood stove from a two hundred liter barrel

A good option related to electricity. But this is a water heating system. To do this, you need to weld a heating register from several pipes. The more pipes in the structure, the larger their diameter, the higher the heat transfer of the device. An ordinary household boiler with a power of 1-1.5 kW is welded into the lower pipe from the end. And a vertically installed small open-type expansion tank is welded into the upper pipe from the end. Water or antifreeze will be poured into the system through it. The last one is better. The register is filled with coolant, the boiler is plugged into the socket. Literally in half an hour the heating device will already be hot and will begin to heat the garage.

Water heating in the form of a register with a boiler as a heating element

Another option with air heating elements. To do this, you will have to use a potbelly stove with a water circuit. Only instead of a full-fledged heating system, a regular radiator from a car is used along with a fan. The radiator is hung on the wall so that the fan fits behind it. The latter is connected to the mains supply through a step-down transformer. The radiator is connected to the coil with hoses or plastic pipes. The connection should be made as follows: the upper pipes of the coil and radiator are connected by one hose - this is the coolant supply circuit, the lower ones form the return circuit. The effectiveness of this method of heating a garage lies in the fact that assembly requires a small boiler that can quickly heat the coolant. The fan effectively removes heat, lowering the water temperature to the maximum. That is, the ring system operates according to all thermal laws. By the way, you can replace the potbelly stove with a boiler.

Car radiator as a source of thermal energy

We recommend watching a video that shows one of the DIY garage heating options.

Watch this video on YouTube

How the gun works

Insert the lighter into the hole, turn on the gas, light it, take out the lighter, turn on the fan. Combustion products exit into the ashtray of a wood-burning stove made from an empty gas cylinder. Then everything is removed through a chimney to the outside. Warm air enters through the side pipe on the heat exchanger. Household gas cylinders of 50 liters are used. The gas supply is adjusted by a regulator, which is installed after the standard reducer. Approximate gas consumption is 15 liters for the autumn-winter period. The room temperature is 18 °C. The gas gun is convenient, useful and mobile.

An important principle for good heating of a garage with a homemade heater is compliance with fire safety rules:

- prevent ignition or explosion of the device;

- heating parts of the device should not emit harmful substances and burn oxygen;

- ability to quickly heat the room;

- the device should be compact and take up little space;

- the cost of the product should not exceed factory analogues;

- You need to know that the permissible temperature in the garage in winter is about 5 degrees.

It is recommended to equip the created installations with thermostats (bimetallic, electronic) to maintain a comfortable temperature.

Application of gas heaters for heating a garage:

- To improve heat transfer, the burner body is lengthened. A metal disk is attached to the end of the burner; 8 holes with a diameter of 10 mm are drilled into it.

- The gas supply tube is extended with a suitable diameter.

- To increase heat transfer, metal plates are inserted crosswise from one end of the extension cord.

- A clamp is attached to the other end of the burner extension, and then the heat exchanger will be mounted.

- The burner is assembled.

- To allow the heated air to exit, a hole is cut out in the heat exchanger body and a piece of pipe with a diameter of 80 mm is welded.

- A ring is welded to the front end of the heat exchanger that matches the diameter of the burner.

- A fan switch is attached to the other end of the heat exchanger.

- A fan is installed from the car heater.

- For ignition, a hole is drilled on the side.

- A household gas lighter is used.

- A stationary household gas cylinder of 50 liters is used.

Gas supply regulator. To secure it to the heat exchanger body, a clamp is mounted on the burner side. In order to improve heat transfer, two strips of steel 2 mm thick are welded crosswise on the opposite side. To manufacture the heat exchanger, a thin-walled steel pipe of 180 mm is used. The front end is plugged and a hole with a diameter of 80 mm is cut in it for the passage of the burner extension.

The burner with extension is inserted and secured to the clamp with two self-tapping screws. A hole is also made in the side of the heat exchanger pipe and a piece of pipe with a diameter of 80 mm is welded to allow hot air to escape. A fan from a car heater with a power of 12 V is installed on the heat exchanger pipe; it is allowed to use any one with a suitable diameter, with a power of 220 V. A hole is drilled to ignite the gun, and the structure is placed on a stand.

Gas garage heating

It would be very practical and very economical to use gas for heating a garage space. Special heat generators work together with them. In this case, you can use methane, butane or propane, classic natural gas.

To assemble a gas heating garage with your own hands, you should take into account several significant features of the work:

- The gas cylinder must be installed in a special, reliably insulated cabinet

- Even if the room is small, you will have to try and set aside a protected corner for installing the required equipment

- If the garage will not be heated often, you should consider other options.

One of the advantages of gas heating is the availability of equipment on the market and the cost of the coolant, which is one of the cheapest types of fuel.

A little about fire safety

When arranging garage heating with your own hands, you will definitely have to take into account a very important requirement - follow all safety rules. Any equipment is a fire hazard and can cause serious consequences.

The most important requirement is reliable protection of all nearby surfaces. This is especially important when passing through a wall or roof of a chimney pipe.

To eliminate its contact with building structures, it is recommended to make a special sleeve based on mineral wool. Wooden or plasterboard areas will have to be fenced with a metal shield. All gaps are compensated with asbestos cord.

Other tips to consider:

- If heating boilers are used, it is necessary to close the damper to regulate draft only in cases where the fuel has completely burned out and smoldered

- Do not keep flammable substances in the garage, especially if they are located near heating equipment

- Be sure to place a fire extinguisher or other fire extinguishing equipment in the room.

- If the heating system operates constantly or the garage is located in close proximity to the house, it is recommended to equip a fire alarm

- You should not dry any things on heating devices, especially various rags that could come into contact with flammable liquids.

- Storage of gas cylinders is permitted only above the level of the floor surface

- It is not recommended to leave the heating on at night

Connecting electric heaters

It is necessary to think through heating with electric heaters most carefully and competently. If their power is too high, the wiring and the meter are not able to cope with the load, you will have to opt for weaker equipment. You can install new wiring, but such a garage conversion will be too expensive.

Let's look at some features of connecting electric heaters in a garage:

- The minimum recommended wire cross-section is 2.0 mm, with preference given to copper

- It is not advisable to use a portable cable to connect electric heaters. If necessary, its length should not exceed 5 m

- Single-phase electrical wiring can withstand the connection of an electric heater with a power of up to 2.5 kW. Parallel connection of 2 or more devices will cause the voltage to drop to 170 V, which can be very dangerous

Let's sum it up

Arrangement of a heating system for a medium-sized garage intended for one car starts from a modest 5-6 thousand rubles and can reach a couple of tens. Each owner must evaluate the options considered based on needs and wishes.

To reduce the cost of operating equipment, part of the money should be spent on insulating the walls and ceiling in the room. Work should be carried out outside, otherwise the insulating material may cause a fire.

It is necessary to ensure that there are no holes or cracks through which precious heat will leak out. Roof insulation is best done using expanded clay, while taking care of reliable waterproofing. For walls, foam plastic up to 10 mm thick or non-flammable mineral wool is used.

Calculation of gas consumption from cylinders and operating time of a gas convector

How long will a gas heater last on one cylinder? This question worries many suburban residents. Let's look at the consumption of Pavel V.

The gas convector has 3 power modes - from 1 to 2.3 kW. A 50-liter cylinder is filled with about 42 liters of gas, because... the container is filled to approximately 85% of its full volume. One liter of gas contains 0.545 kg of fuel (if the summer mixture is 50% propane and 50% butane) and 0.517 kg of fuel (if the winter mixture is 90% propane and 10% butane).

This means that in a 50-liter cylinder, on average , (depending on the type of gas - “summer” or “winter”) 22 kg of fuel . The convector consumes:

- In the first power mode - 100 g of fuel per hour.

- In the second power mode - 200 g of fuel per hour.

- In the third power mode - 300 g of fuel per hour.

In total, the convector will work:

- 1st mode – 220 hours.

- 2nd mode – 110 hours.

- 3rd mode – 73 hours.

Knowing the amount of fuel (in kg) in cylinders of different displacements and the fuel consumption of the heat generator at different power modes, you can estimate the operating time of the gas convector and the cost of this type of backup heating.

To determine the volume of remaining gas, it is necessary to weigh the cylinder with the mixture, subtract the weight of the container from its mass and calculate the remaining fuel depending on its density (0.545 kg/l or 0.517 kg/l).

Method thirteen, well, this is really for extreme sports enthusiasts

If you often find yourself in situations where you have to fight the cold in the car (for example, you are a traveler), then you can take a regular wood stove with you on the road. If you don't believe me, look:

A real oven in the car

So how? Did you believe it? You can stock up on firewood or brushwood for free, for example, if your forced stop occurred in the forest or next to an old and dilapidated building with a lot of boards.

If your car stalls in winter, don’t despair. Armed with any of the heaters listed above and having studied all the tips described, you will not freeze and survive in harsh weather conditions. Even if you find yourself in a car at night, face to face with a cold and harsh winter, you can create all the conditions in the cabin that are similar to the comfort of home. So, don't worry, motorists!

The best prices and conditions for the purchase of new cars

It has long been known that a comfortable temperature for a driver is the range from +21...23 degrees Celsius. Low temperatures negatively affect concentration and alertness while driving, causing irritability. And safety is affected by driving with limited visibility due to icy windows.

If you have at least once had to get to your car in a parking lot in severe frosts or simply get into an icy car interior after leaving a warm home, then you know firsthand that this feeling is not a pleasant one. And how I would like to warm up at this moment. You can, of course, run around the car or leave the snow while the interior warms up, but there are also less radical methods. As always, there is a solution, and it has long been known among motorists - an autonomous interior heater, which will happily provide comfort.

Review of popular models of garage stoves

There are a variety of options for garage stoves on the markets. They differ in the heating principle and design solutions. Some models deserve special attention:

- The Bullerian stove is made to run on solid fuel. The design has a convection mechanism for high-quality heating of air masses that move through the pipes;

- a durable option is the Stavr stove. It is made of cast iron, a similar material can withstand high temperatures;

- Termafor stoves have convection pipes in their design, which are placed in the combustion chamber. Such models are designed for both standard and pyrolysis combustion;

- The Alaska stove has a stylish design and good heat output. The design is equipped with a hob;

- A cheap alternative to Buleryan is the model of the domestic manufacturer Breneran. It can operate on wood and waste from the manufacturer.

| Image | Model | Construction type | Price, rub |

| "Delta" D-81G | Heat gun | 3930 | |

| Ballu BHDN-80 | Diesel indirect heating device | 55900 | |

| ELITECH TP 3G | Ceramic gas panel | 2960 | |

| Resanta | Gas heat gun | 6700 | |

| Breneran AOT – 06/00 | Wood stove | 10500 |

Some stove models are assembled independently

Autonomous heating systems

Let us dwell in more detail on the advantages and disadvantages of different methods of autonomous garage heating, which have their own characteristics and nuances that can cause many problems if they are not taken into account at the design stage.

Gas

The main advantage of a gas heating system is economic benefit. In terms of cost, gas is the cheapest fuel, outperforming both electricity and diesel fuel. In addition, the gas generator has a fairly high efficiency of 90%.

However, it must be remembered that gas is a dangerous explosive. Under no circumstances should you install a gas heating system in a garage with your own hands. It is necessary to invite a qualified specialist who can independently install and run the system, guaranteeing its complete safety during further operation.

Scheme of gas heating in the garage

In addition, dubious homemade parts are prohibited - only high-quality industrial equipment should be used. There is no need to be afraid to play it safe once again - after all, we are talking not only about the safety of your property, but also about your life.

Despite all the above advantages, it will be impossible to organize a gas system in the garage if there is no main gas supply nearby.

Electricity

Electricity is the most accessible source of energy to be converted into heat. The methods of using it for heating a garage are varied - these include heating devices, a heat gun, and an electric boiler. If you wish, you can assemble your own structure with your own hands or buy a ready-made one.

The availability of electricity and a large selection of devices operating on it are the main advantages of this option, which is why this type of heating is so popular.

Electric heating circuit

However, there are also disadvantages.

- Electricity costs will be higher than, for example, gas or coal;

- Cheap electrical appliances are not very reliable and often break down.

- Electrical wiring must be made of thick cable.

Firewood and coal

If independence from centralized sources of gas and electricity supply is critical for you (for example, there are interruptions in one or the other), old proven means can come to the rescue - solid fuel, such as firewood or coal.

This option is very economical - you can easily assemble a simple stove with your own hands. But in operation, such a stove requires special attention and care; it must be cleaned regularly, monitor its operation and remember that there should be no explosive substances in the garage. In addition, the garage must be equipped with a good ventilation system.

Working off

Used engine oil can serve as fuel for heating your garage - it just needs to be cleaned and processed in a special heating unit. This option is suitable if you want to assemble such a device with your own hands - it is simple and allows you to use waste raw materials cost-effectively.

Important! Due to the fact that used oil is heterogeneous, one can expect that such a device will soon wear out and break down quite often.

Summarizing the above, we can summarize: choosing an autonomous heating system is a choice of balance between the cost of fuel, the cost of equipment and the complexity of operation. Electric heating for a garage is quite expensive, but it is perhaps the easiest to organize; gas is cheap, but installing the equipment will require significant material costs.

However, homemade heating devices using solid fuel (wood, coal) cannot be discounted - sometimes, in the absence of other energy sources, they may be the only way out.

Subtleties of choice

Now it’s time to find out how to choose an outdoor electric heater for your dacha with your own hands. This process will not take much time, even if you do not have specific knowledge. If you choose the right device, then you can raise the temperature to 25 degrees. If necessary, you can also choose a model that has an interesting design.

If you take into account all the points when choosing, then you can get a reliable device:

- Device power. During manufacturing, the manufacturer must indicate how much area the device can heat. Before purchasing it, you must correctly calculate the dimensions of your terrace. If you are planning to choose a heater for your dacha, then its power should be 2 kW.

- Automation. Many models may have a special motion sensor. This will make your life much easier. You just need to enter the room and the device will automatically start heating.

- Availability of power regulator. Thanks to this addition, you can independently set the correct heating mode.

- Material of manufacture. The housing must be made of plastic or stainless steel. This will allow you to get a truly reliable device.

- Design. This criterion is considered quite important. Today there can be a wide range of different models, which can have a variety of designs and, accordingly, installation methods. Only you decide which device to choose. Typically, many summer residents choose the floor installation option.

- Cord length. Before purchasing a heater, you should choose a unit that has a long cord. It is best not to use an extension cord while connecting this device.

- Availability of special rollers. Typically, heaters are heavy and therefore it is better to use special rollers to move them.

- Fall protection. If the heater falls or deviates from its axis, then the device will automatically turn off the power.

- Remote control. Now many manufacturers have begun to produce devices that can be controlled by remote control. Thanks to this, you can greatly simplify the management process.

- When choosing, you need to take your choice of company seriously. Recently, the leading position has been occupied by Enders.